Preparation method of wheat whole wheat flour

A production method and technology of whole wheat flour, applied in the directions of food preservation, grain processing, food drying, etc., can solve the problems of difficult mixing and uniform density, and achieve the effect of avoiding excessive crushing, reducing water content, and reducing materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

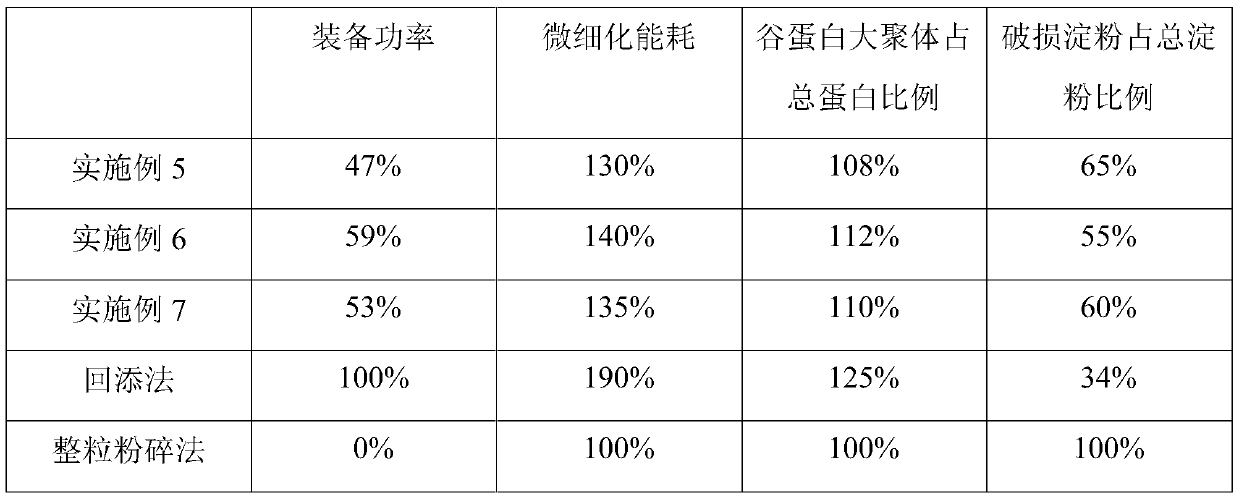

Examples

Embodiment 1

[0045] The present embodiment provides a kind of whole wheat flour preparation method, and the steps comprise:

[0046] 1) Obtaining wheat bran with part of the endosperm, non-flour components of wheat germ and flour by grinding;

[0047] 2) The non-flour components are micronized and mixed with the flour components to obtain whole wheat flour.

Embodiment 2

[0049] The present embodiment provides a kind of whole wheat flour preparation method, and the steps comprise:

[0050] 1) non-flour components and flour are prepared by grinding, the flour components are 53%, and the non-flour components are 47%;

[0051] 2) The non-flour components are micronized and mixed with the flour to obtain whole wheat flour.

Embodiment 3

[0053] The present embodiment provides a kind of whole wheat flour preparation method, and the steps comprise:

[0054] 1) non-flour components and flour are prepared by grinding, the flour components are 67%, and the non-flour components are 33%;

[0055] 2) The non-flour components are micronized and mixed with the flour to obtain whole wheat flour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com