Patents

Literature

31results about How to "Avoid over processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

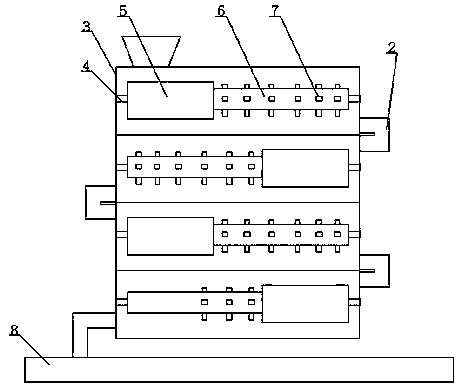

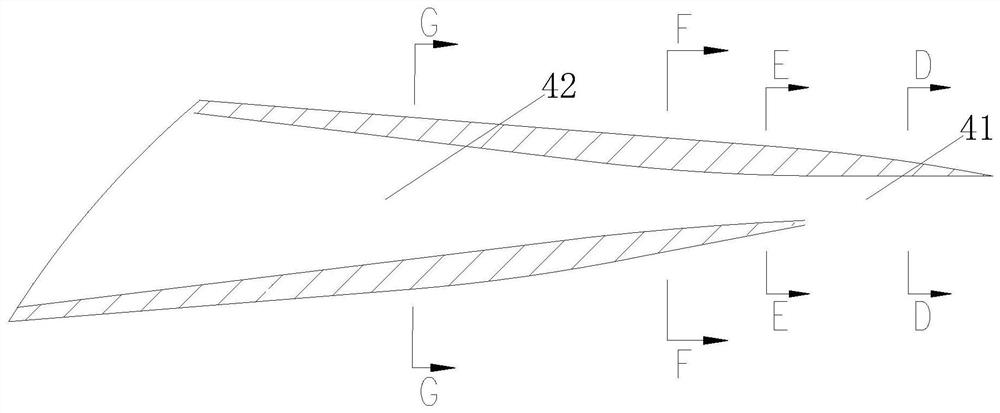

Agricultural smashing machine

ActiveCN105413791ARedistribution lawImprove crushing efficiencyGrain treatmentsPulverizerAgricultural engineering

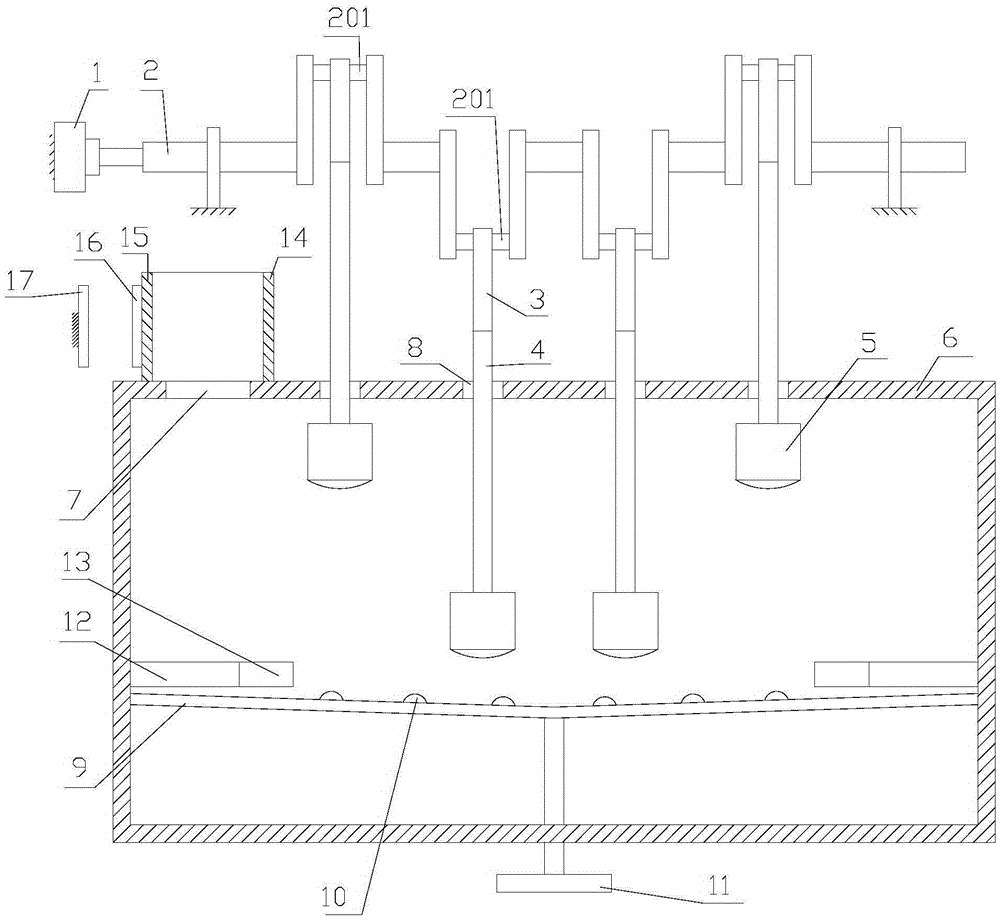

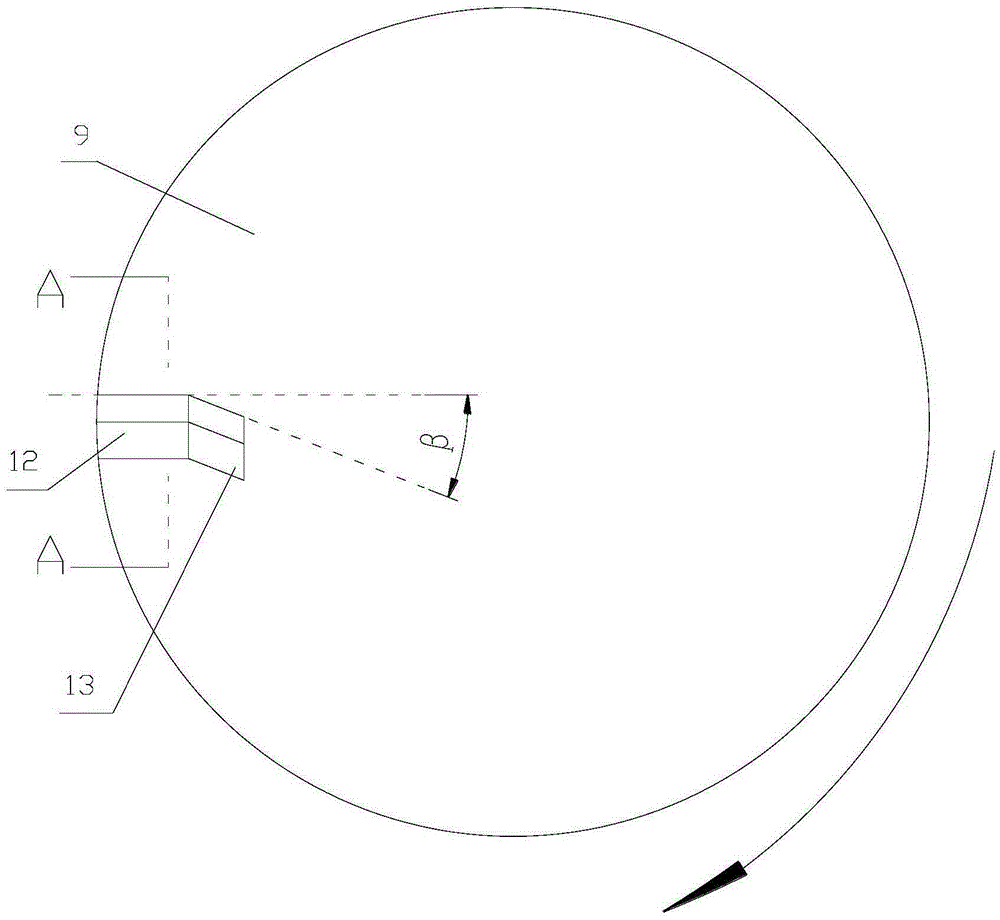

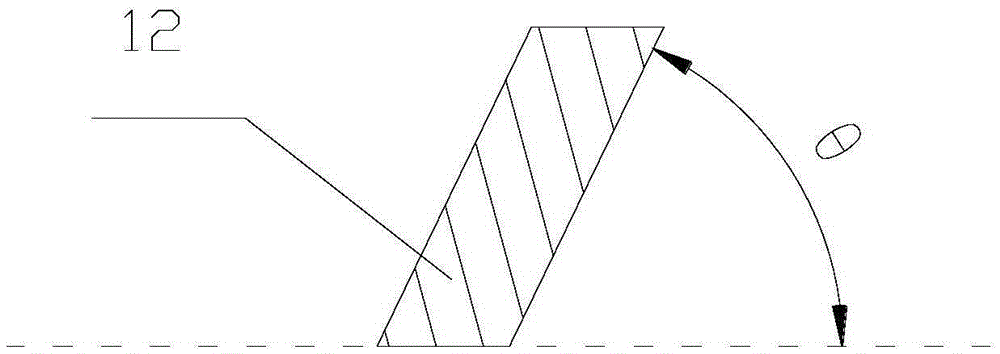

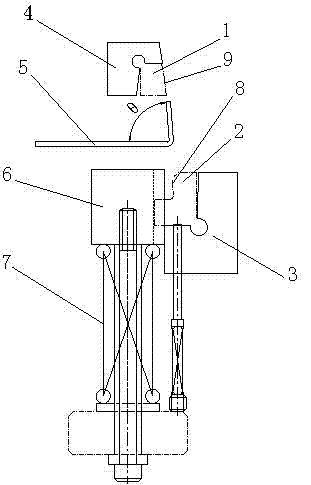

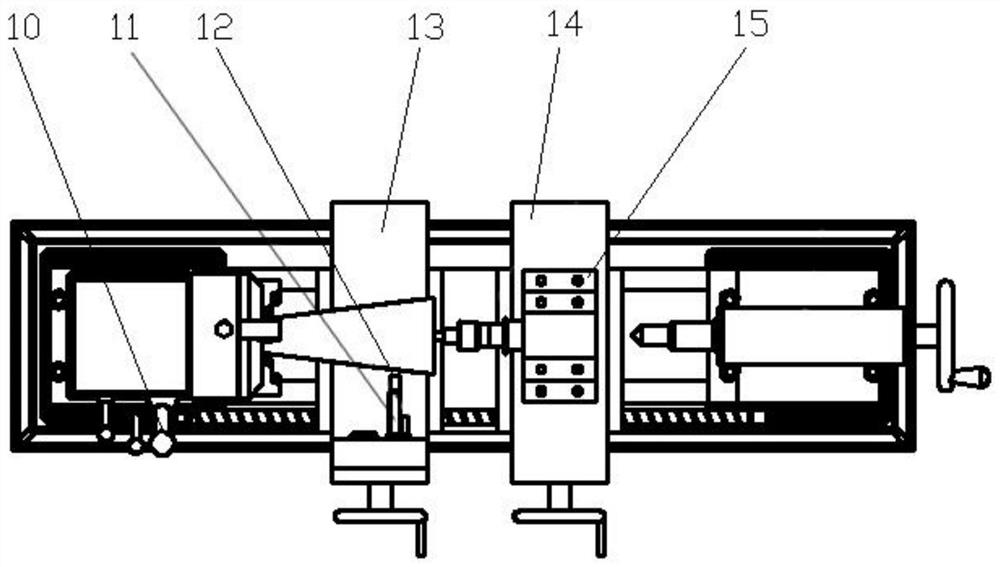

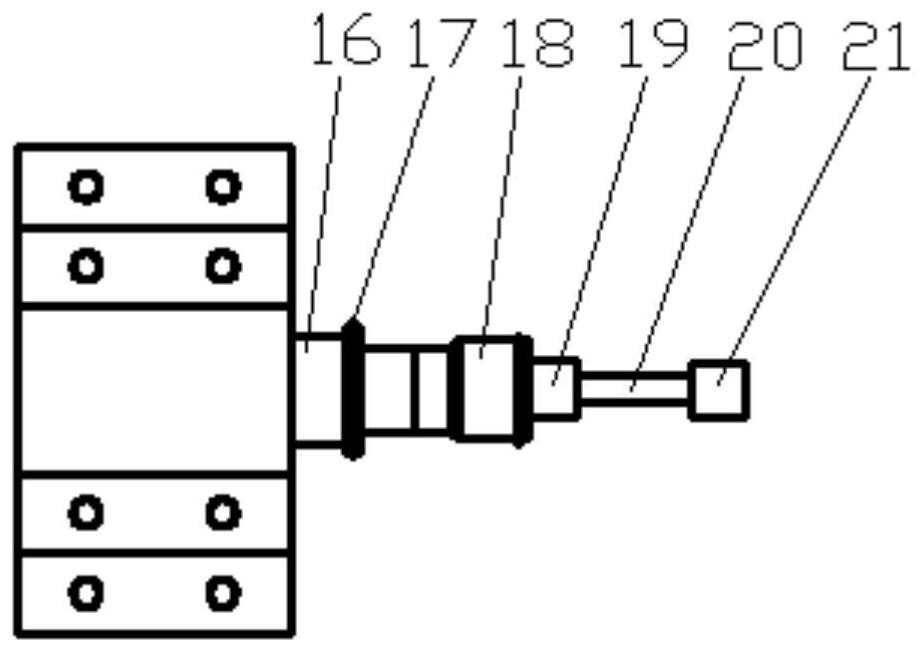

The invention discloses an agricultural smashing machine. The agricultural smashing machine comprises a driving unit, a crankshaft, N connecting pieces, N connecting rods, N striking pieces and a box; the driving unit is connected with the crankshaft in a transmission manner to drive the crankshaft to rotate; the crankshaft is horizontally arranged and comprises N connecting shaft necks; the N connecting pieces are rotationally connected with the N connecting shaft necks respectively; and one ends of the N connecting rods are rotationally connected with the N connecting pieces. The agricultural smashing machine is good in material processing effect and high in material processing efficiency.

Owner:全椒县汊河农机服务专业合作社

Fresh fruit konjak functional food and preparation method thereof

The utility model relates to a function food of the fresh fruit konjak, which can be used as the food extender for the crowd who are losing weight and controlling weight, and a preparation method thereof. The utility model uses the konjak flour and the fresh fruit as the mother stock, and adds a right amount of the function oligose and other prebiotics material; the main preparation steps comprise, choosing the edible parts of the fresh fruit; preparing and pelletizing the material; drying in a low temperature; sterilizing. The utility model appears in a granular form, and the fruit pulp tissue is visible; the utility model can be directly prepared and drunk with water in different temperature, can not only guarantee the effective dose of the konjak flour but also improve the pasty and disagreeable taste which are not good for drink, and also has the natural flavor and the eating quality of the fruit, and still has the health protection effect of adjusting the intestinal flora in the human body and promoting the health of the frame; the utility model fits for the crowd who are overweight, the crowd who have abnormal blood lipid levels and the crowd who are suffering diabetes mellitus, and also fits for the aesthetic ladies of all ages and the persons who are controlling weight for the need of professions, and also is the best function food for the general population.

Owner:刘五一 +4

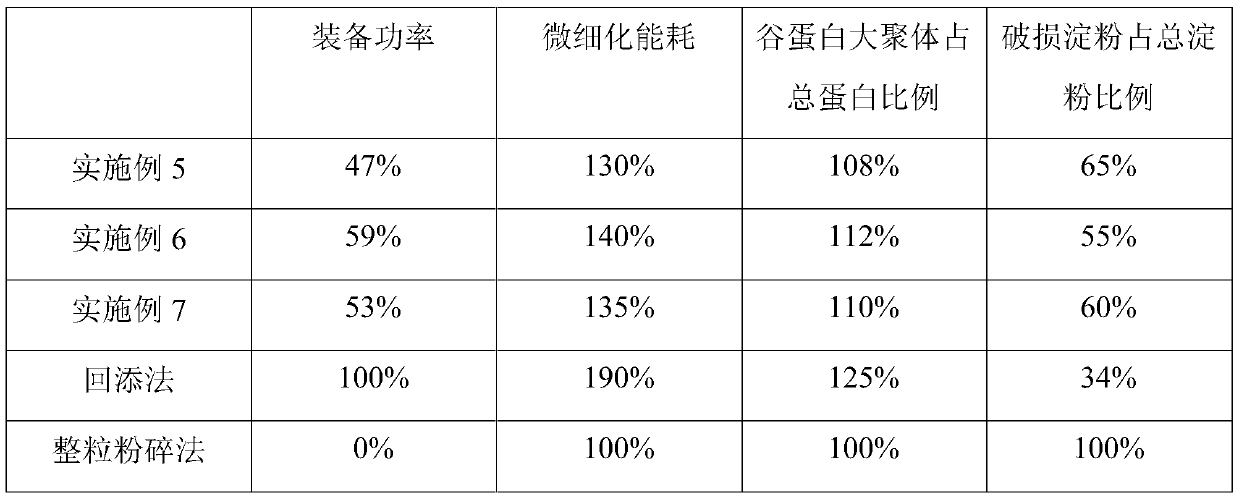

Preparation method of wheat whole wheat flour

InactiveCN110013903AHigh densityImprove crushing efficiencyFood preservationFood dryingWholemeal flourWater content

The invention discloses a preparation method of wheat whole wheat flour. The preparation method of the wheat whole wheat flour comprises the following steps that 1) grinding is performed to obtain non-flour components of wheat bran and wheat germ with part of endosperm and flour; and 2) the non-flour components undergo micronization treatment and then are mixed with the flour components to preparethe whole wheat flour. According to the preparation method, through microwave drying, the water content of the non-flour components is reduced, the enzyme activity of the non-flour components are inactivated and reduced, the easy-to-crush property of the wheat bran is improved, the micronization efficiency and stability of the non-flour components are improved, the micronization energy consumption of the non-flour components is reduced, and the shelf life is prolonged; and meanwhile, through the process that the wheat bran, the wheat germ and the endosperm are properly separated and then micronization is performed, materials needing to be micronized are reduced, the preparation energy consumption of whole wheat flour is further reduced, excessive crushing of the endosperm is avoided, thenatural structure of the protein and the starch is kept, and the basis of the quality of the whole wheat product is laid.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Food supplement with combination of astaxanthin and omega-3

InactiveCN104856055ARich in nutritional valueWide range of functionsFood ingredient functionsFood preparationWhole bodyCholesterol

The present invention discloses a food supplement with combination of astaxanthin and omega-3. The food supplement is characterized in that the components of the food supplement comprise haematococcus pluvialis powder, perilla seed powder, flax seed powder, schizochytrium limacinum powder and coralline algae powder. The combination of astaxanthin and omega-3 is capable of balancing human immune functions efficiently, enhancing the capability of the body against antiviral infection, inhibiting cancer cell proliferation, curing body injuries rapidly and eliminating vivotoxin. Meanwhile, the growth of bodies, especially bodies of children, is promoted and the physical quality get enhanced. The immune system is enhanced, and the blood circulation of the brain and the whole body is improved. The rise of the blood pressure and blood sugar is suppressed, the brain health is promoted, the cell vitality is improved, the serum cholesterol level is lowered, and the risk of tumor incidence is lowed.

Owner:曾晓飞

Nutrition supplementing liquid combining astaxanthin and omega 3

InactiveCN104799298ARich in nutritional valueEnhance immune functionFood preparationDiseaseCancer cell

The invention discloses a nutrition supplementing liquid combining astaxanthin and omega 3. The nutrition supplementing liquid is prepared by the following components: fatty astaxanthin, perilla seed oil, flaxseed oil, schizochytrium limacinum oil and peony seed oil. The nutrition supplementing liquid has the advantages that by combining the astaxanthin and the omega 3, the nutrition value of the single astaxanthin is more complete, and the function of the omega 3 which combines alpha-linolenic using the perilla seed oil, the flaxseed oil and the peony seed oil as the main materials and DHA (docosahexaenoic acid) combination using the schizochytrium limacinum plant as the main material is more broad; the rise of blood pressure and blood glucose is inhibited, the content of serum cholesterol is reduced, the blood environment is improved, the cell vitality is improved, the human immune function is effectively enhanced, the brain health is promoted, the capability of resisting the virus infection is improved, the propagation of cancer cells is blocked, the body injury is quickly restored, the toxicity in the human body is removed, the content of the serum cholesterol is reduced, and the risk of chronic diseases is reduced.

Owner:曾晓飞

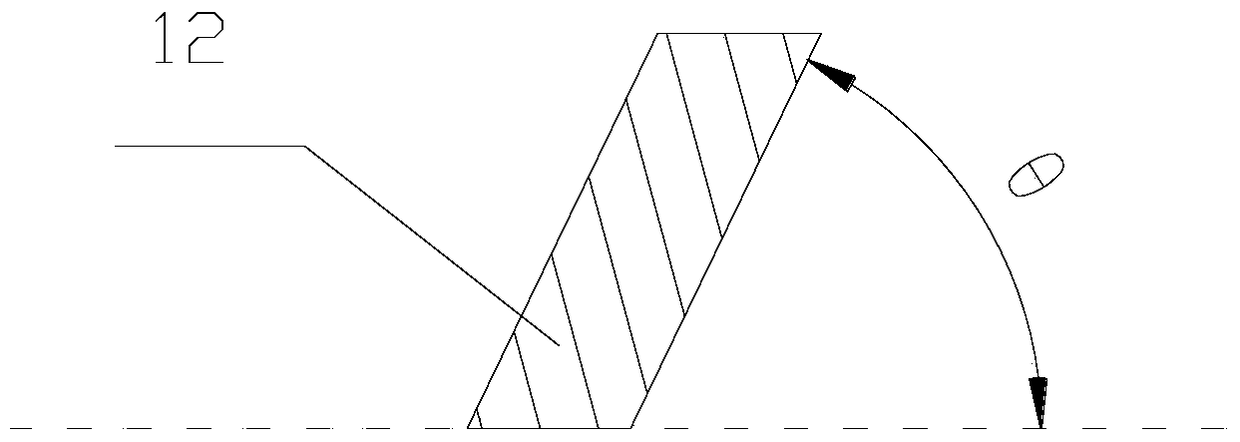

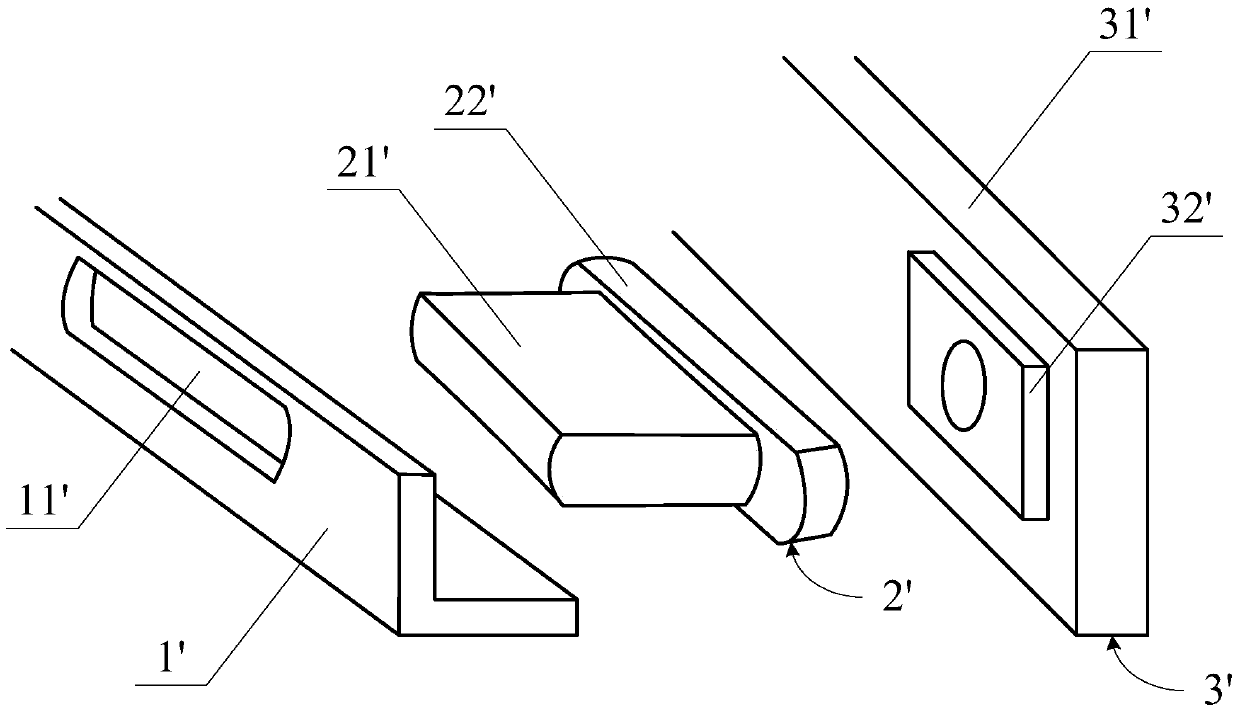

Fast molding mechanism for negative angle of die processing product

The invention discloses a fast molding mechanism for negative angle of a die processing product. The fast molding mechanism for the negative angle of the die processing product is provided with an upper die molding block, a lower die molding block, a lower die molding block rotary swing mechanism, an upper die molding block rotary swing mechanism, a material pressure block and a spring mechanism; the bent molding of a processing part is finished by the downward pressure of the upper die molding block and the lower die molding block, so that the processing part forms a certain negative angle through the swing force of the upper die molding block rotary swing mechanism and the lower die molding block rotary swing mechanism and finishes processing of the product. The angle is fast molded; excessive processing is avoided; the flat and non-deformed surface of the product part is kept, and the production efficiency is high.

Owner:JIANGSU RONGTENG PRECISION COMPONENTS

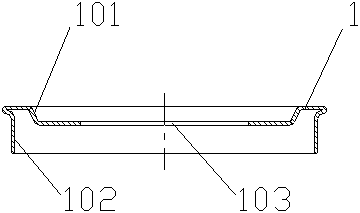

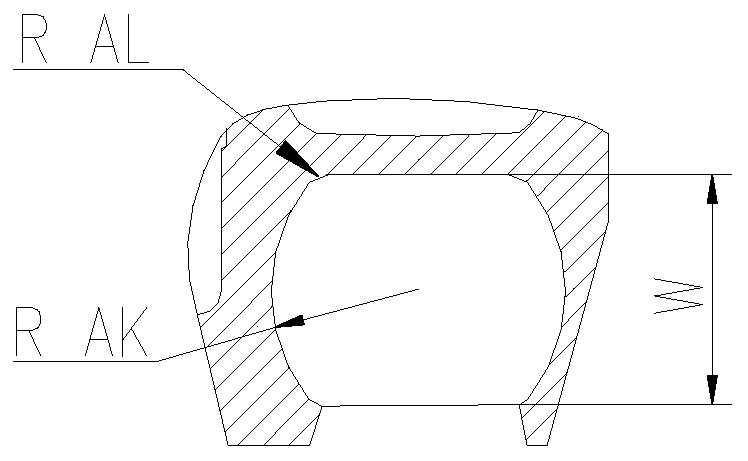

High-necking end cap and machining die thereof

InactiveCN102873226ALarge shrinkagePrecise force controlShaping toolsHollow articlesAdhesiveUltraviolet

The invention discloses a high-necking end cap and a machining die thereof. The high-necking end cap is provided with a first necking, a second necking and a through hole. The machining die of the high-necking end cap is provided with an upper die holder, an upper die plate, an upper pad, a stop plate, springs, a piercing punch, an upper die drawing punch, a stripper plate, a lower die plate, a lower clamping plate, a lower pad, a lower die holder, a lower table, lower die UV(ultraviolet) adhesives and a lower die drawing punch. The necking quantity of the high-necking end cap is large, and the necking diameter can be larger than the necking quantity. The machining die can be used for completing necking at one step, and the situation of completing necking by multiple steps in the prior art is changed. Spring stress is replaced by elastic UV adhesives on the lower die of the machining die, stress in machining of the high-necking end cap is controlled precisely, the necking size is controlled accurately, excessive machining is avoided, defect of cracking is eliminated, quality of products is stable, production efficiency is high and production cost is low.

Owner:昆山铭佳利电子制品有限公司

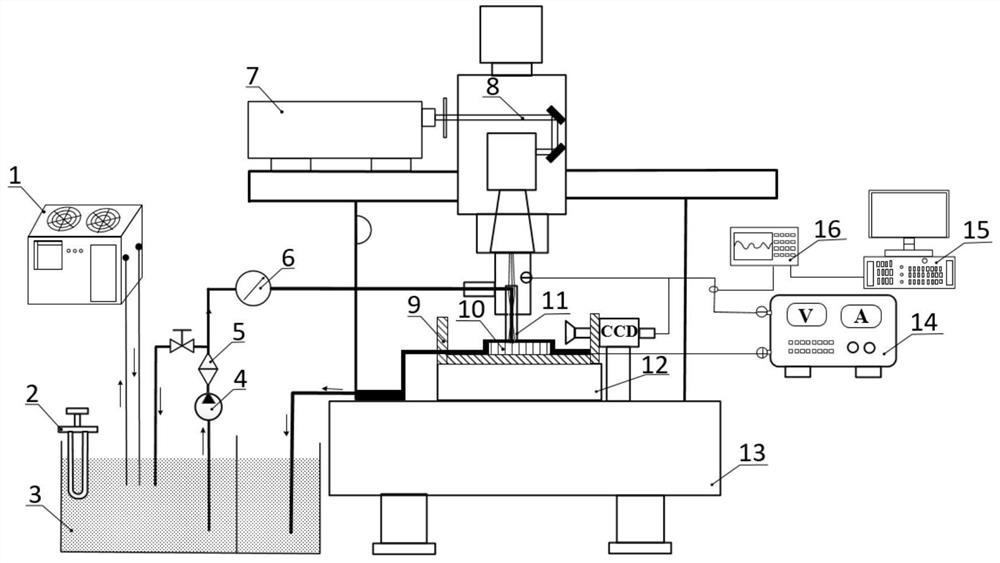

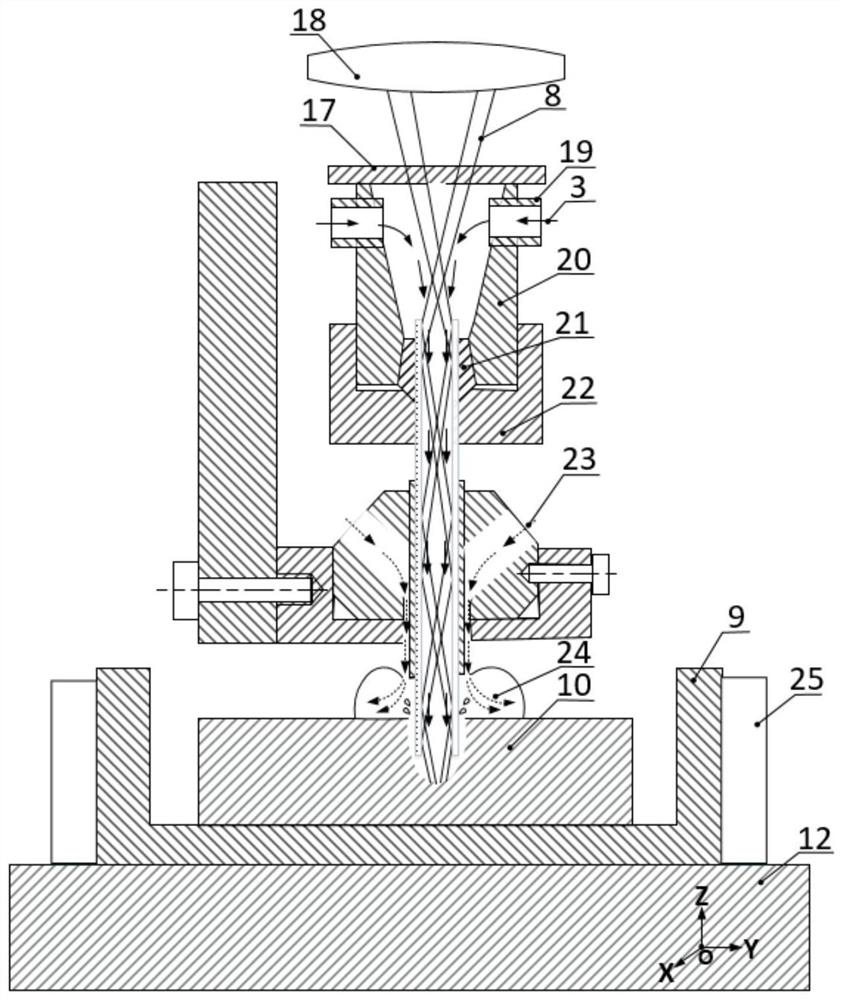

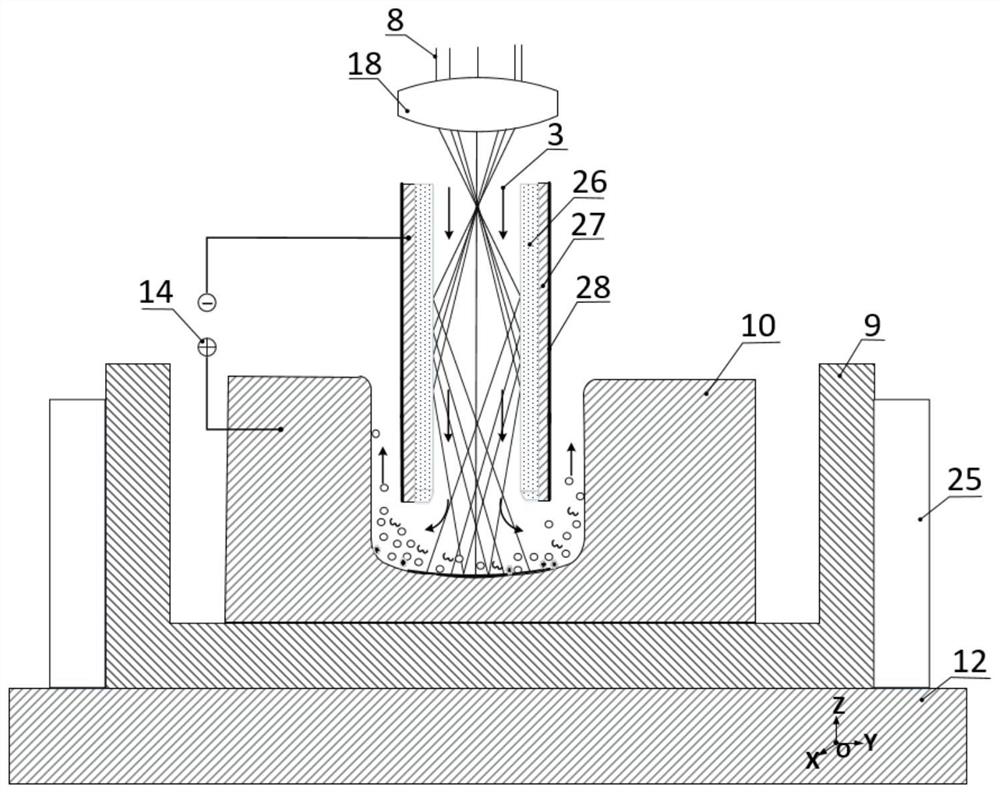

Ultrasonic-assisted laser and electrochemical composite multi-energy field collaborative processing system and method

PendingCN114346339AEfficient removalAvoid shockMaintainance and safety accessoriesElectrical-based auxillary apparatusElectrochemical responseElectrolytic agent

The invention discloses an ultrasonic-assisted laser and electrochemistry composite multi-energy-field collaborative machining system and method, and relates to the field of non-traditional machining. A positive electrode of a pulse power supply is connected with a workpiece, and a negative electrode is connected with a tool electrode; the laser beam is totally reflected by the tool electrode to form a plurality of laser beams which simultaneously act on the surface of the workpiece; meanwhile, the electrolyte flows out through the tool electrode and then acts on a workpiece machining area to generate electrochemical reaction, turbid electrolyte continuous liquid flow after the electrochemical reaction is converted into a gas-liquid mixed state by high-pressure low-temperature gas, and therefore a vaporific gas-liquid mixed area is formed on the periphery of the workpiece machining area; and the turbid electrolyte continuous liquid flow is changed into discontinuous vaporific liquid drops, so that the turbid electrolyte continuous liquid flow flowing out of the machining area is prevented from forming a continuous conductive loop to generate impact and electrocorrosion on the periphery of the workpiece machining area. According to the invention, high-efficiency and high-quality processing of large-depth and low-damage deep small holes can be realized.

Owner:JIANGSU UNIV

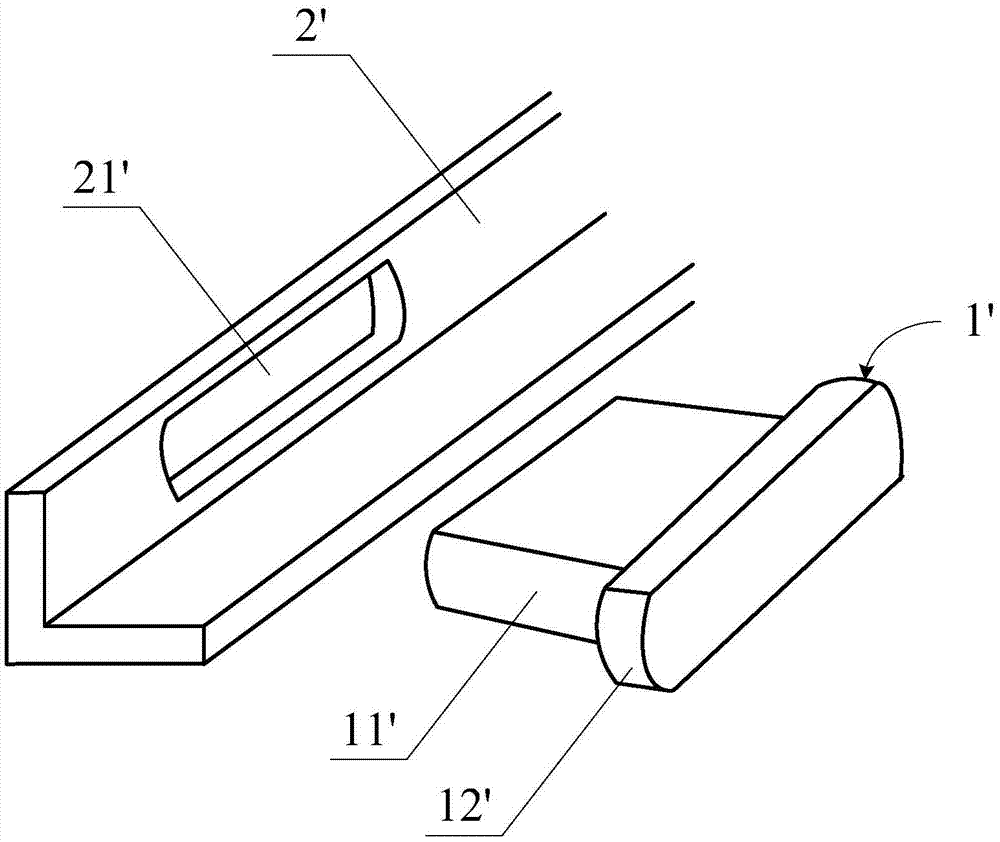

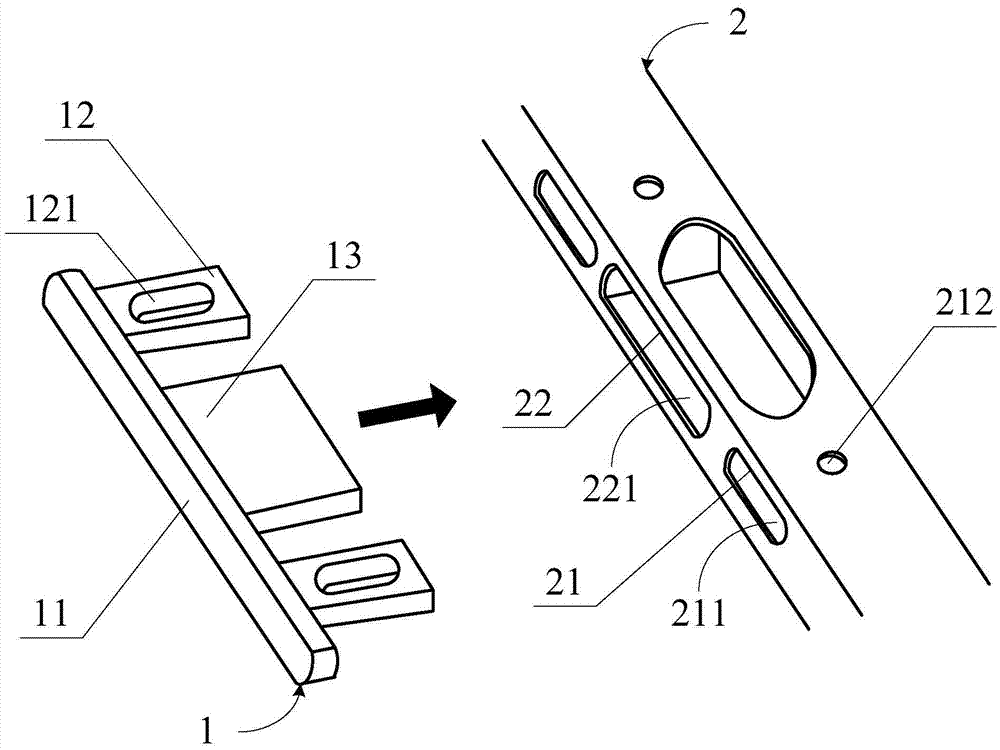

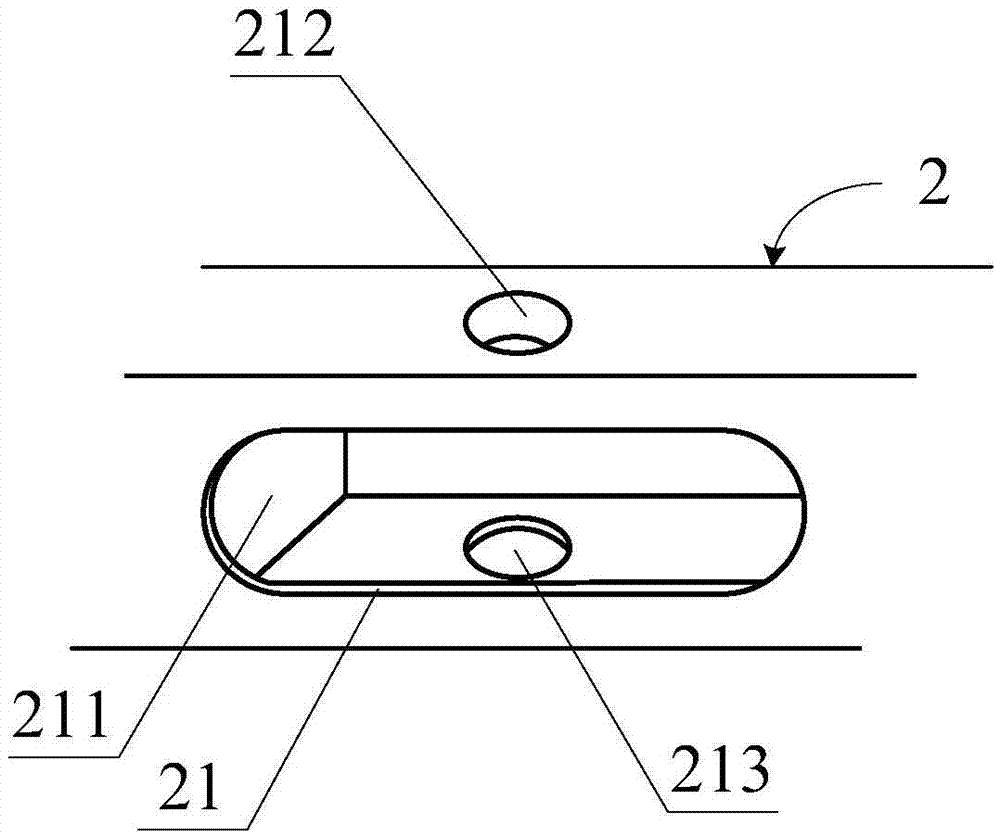

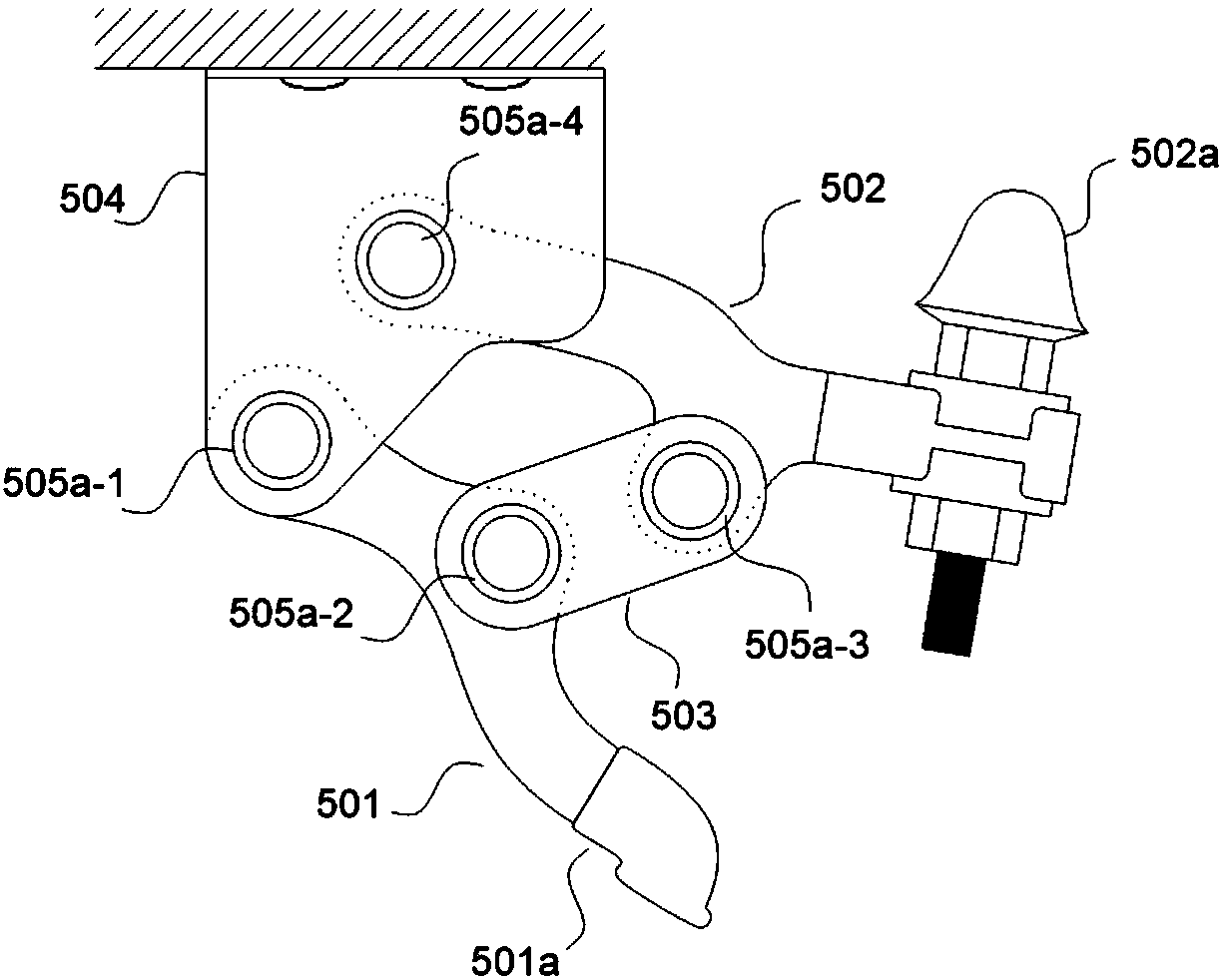

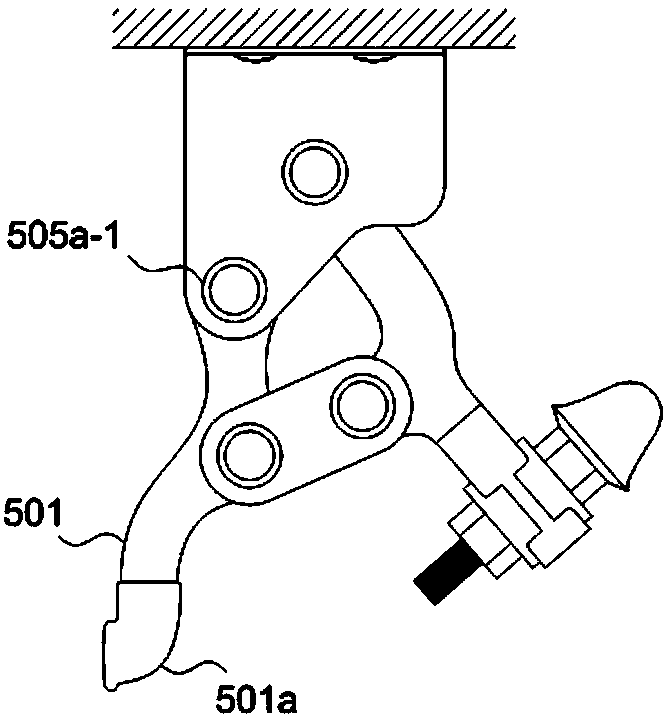

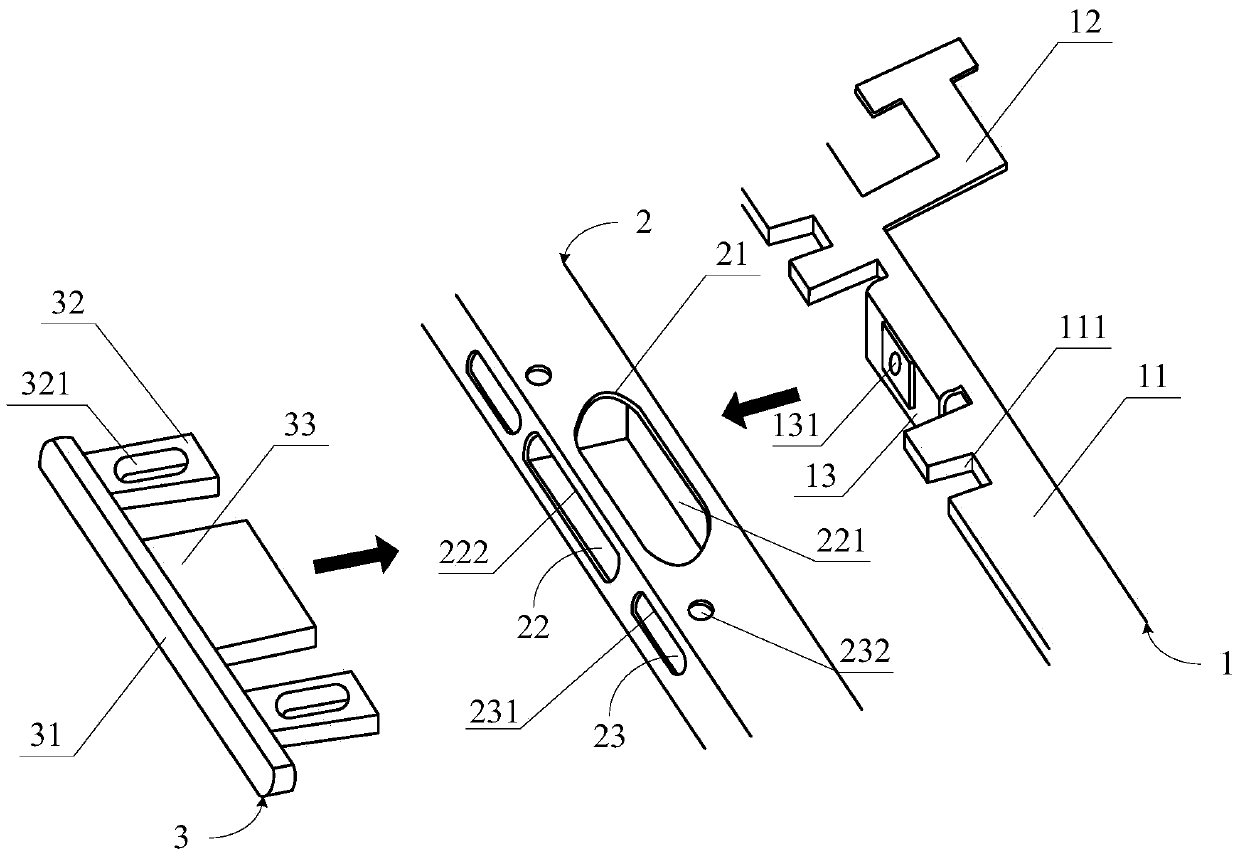

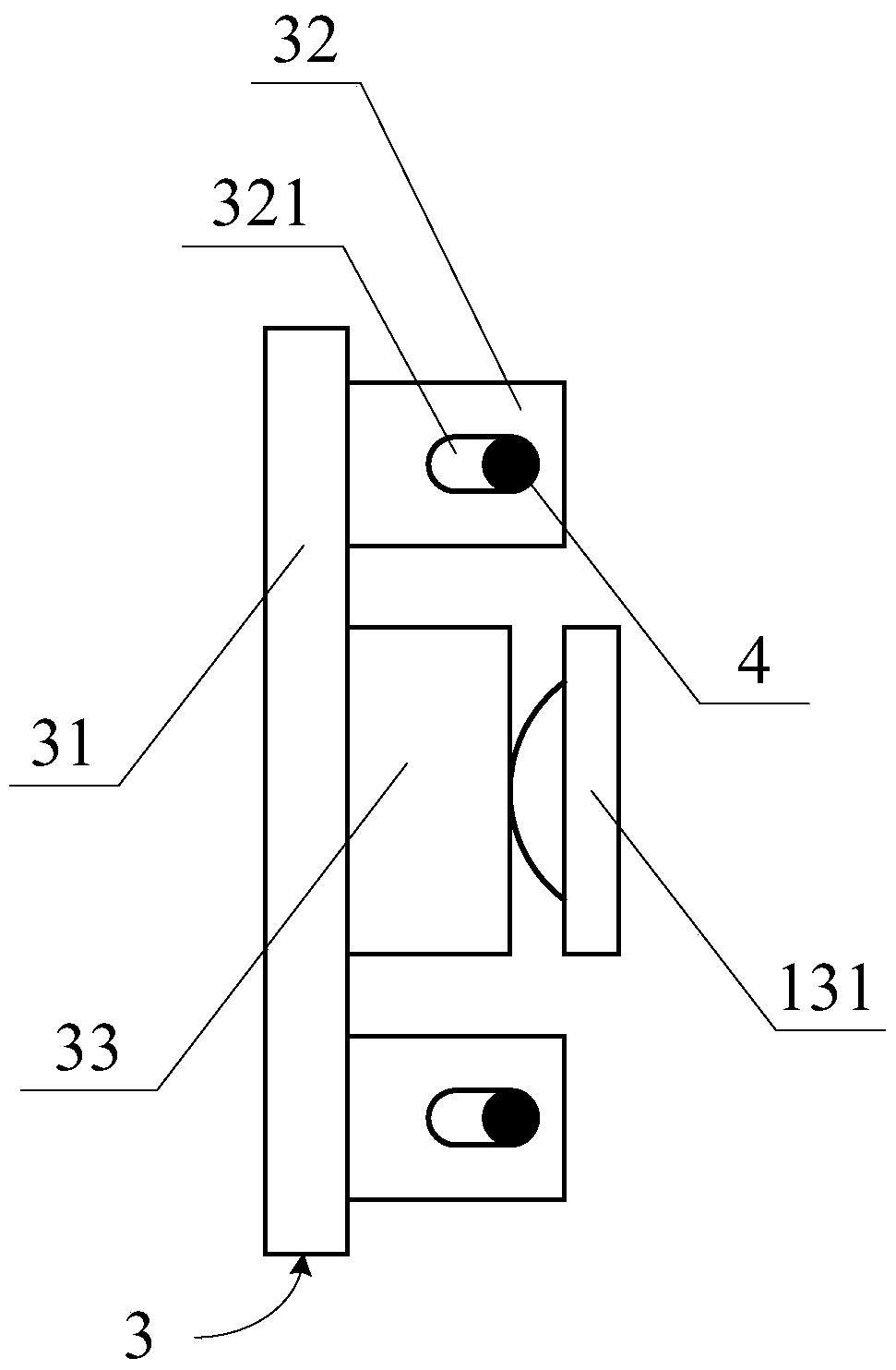

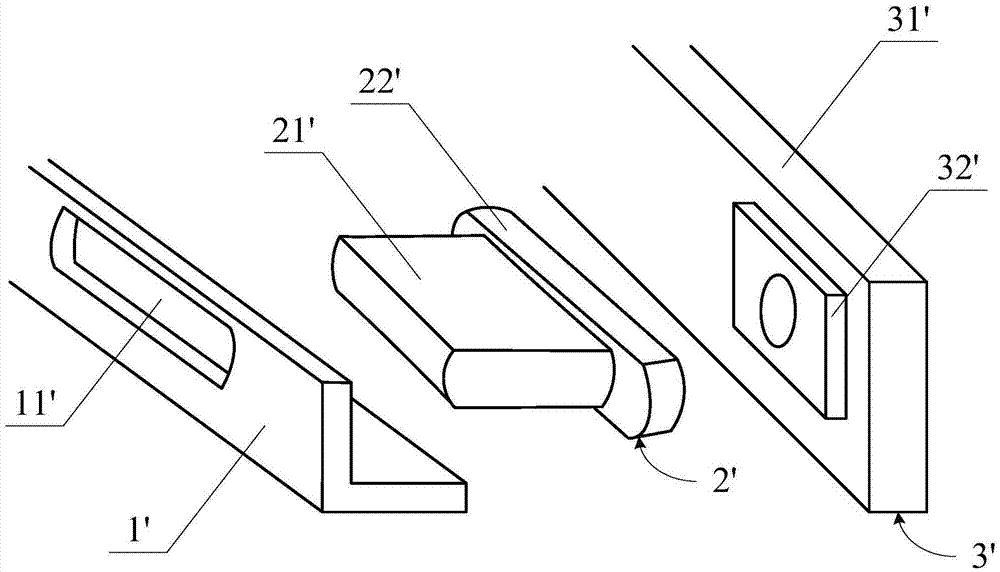

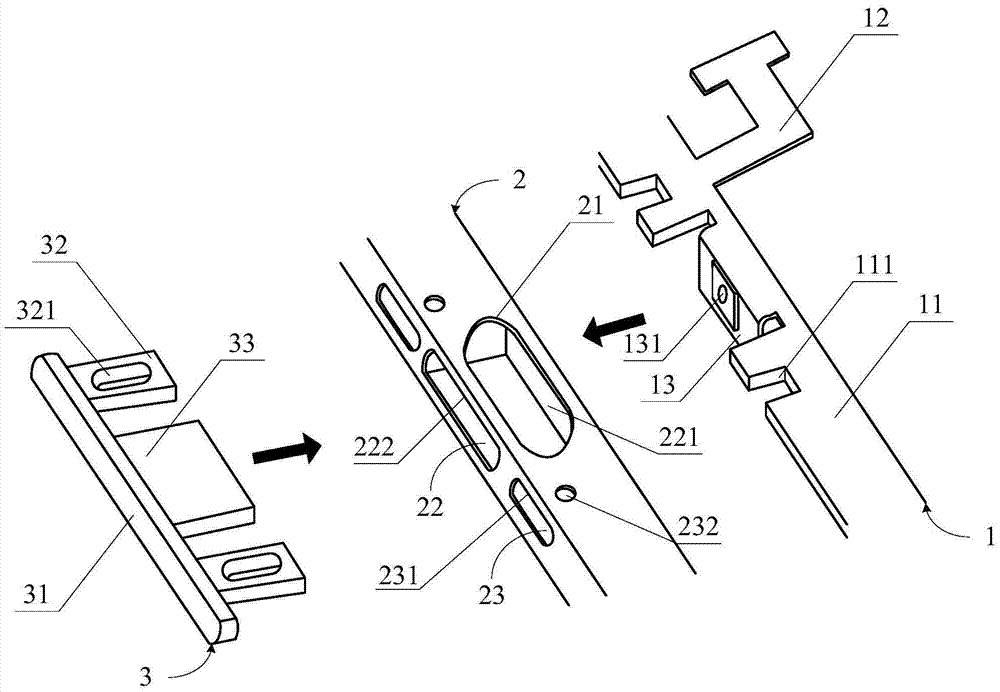

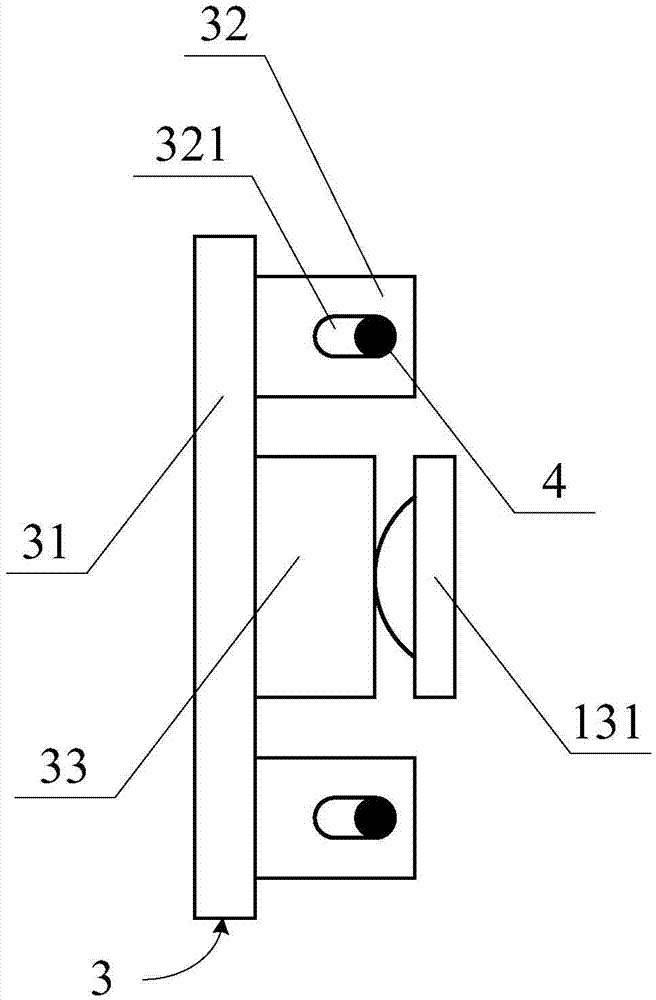

Key structure, shell structure of electronic equipment, and electronic equipment

InactiveCN106920709AReduce space consumptionAvoid over processingCasings with display/control unitsElectric switchesKey pressingEngineering

The invention discloses a key structure, a shell structure of electronic equipment, and the electronic equipment. The key structure can comprise key bodies, wherein each key body forms one or more connecting bumps and one or more pressing bumps in a preset pressing direction separately; one or more through holes are formed in each connecting bump; the connecting bump can enter a connecting cavity which is positioned in a frame and connected with a connecting opening; and each pressing bump can enter a pressing opening in the outer side wall of the frame in the preset pressing direction so as to enter a pressing cavity which is positioned in the frame and connected with the pressing opening, wherein when the connecting bump is positioned in the connecting cavity, the connecting bump can be fixed by a fixing pin which passes though the through hole, and the pressing bump can be matched with a corresponding trigger switch arranged in the pressing cavity in a pressing manner. By virtue of the technical scheme disclosed by the invention, the key structure can be matched with narrow frames of the electronic equipment, and excessive influence to the strength of the frame structure can be avoided.

Owner:XIAOMI INC

Omega III fatty acid-rich nutrient enrichment food taking kappaphycus as main material

ActiveCN104605370AEnhance the comprehensiveness of nutritionAvoid over processingFood ingredientsFood preparationNutrientHuman health

The invention discloses an omega III fatty acid-rich nutrient enrichment food taking kappaphycus as main material. The nutrient enrichment food is mainly prepared from the following raw materials in parts by weight: 50-70 parts of kappaphycus, 5-12 parts of chia seeds, 5-12 parts of flaxseeds, 7-15 parts of wood of shinyleaf yellowhorn, 7-15 parts of sea-buckthorn and 3-7 parts of chitosan oligosaccharide. The nutrition comprehensiveness of the nutritional food can be improved, so that the nutritional food contains rich mineral substances, protein, amino acids, vitamins, calcium, other phytochemicas and trace elements; particularly, the omega III fatty acid is organically combined with ionized calcium, so that the important matters which are rare to the human health can be obtained in the daily dietary process without overly processing natural food, and therefore, the nutrient enrichment food is an enriched food capable of more comprehensively supplementing the nutritive value.

Owner:颐麦科技(北京)有限公司

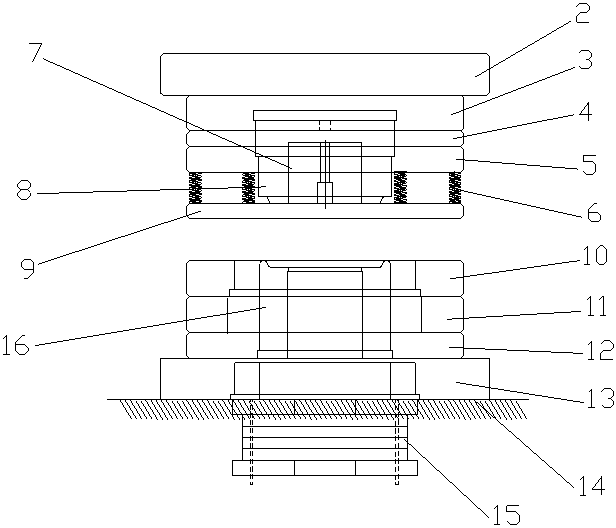

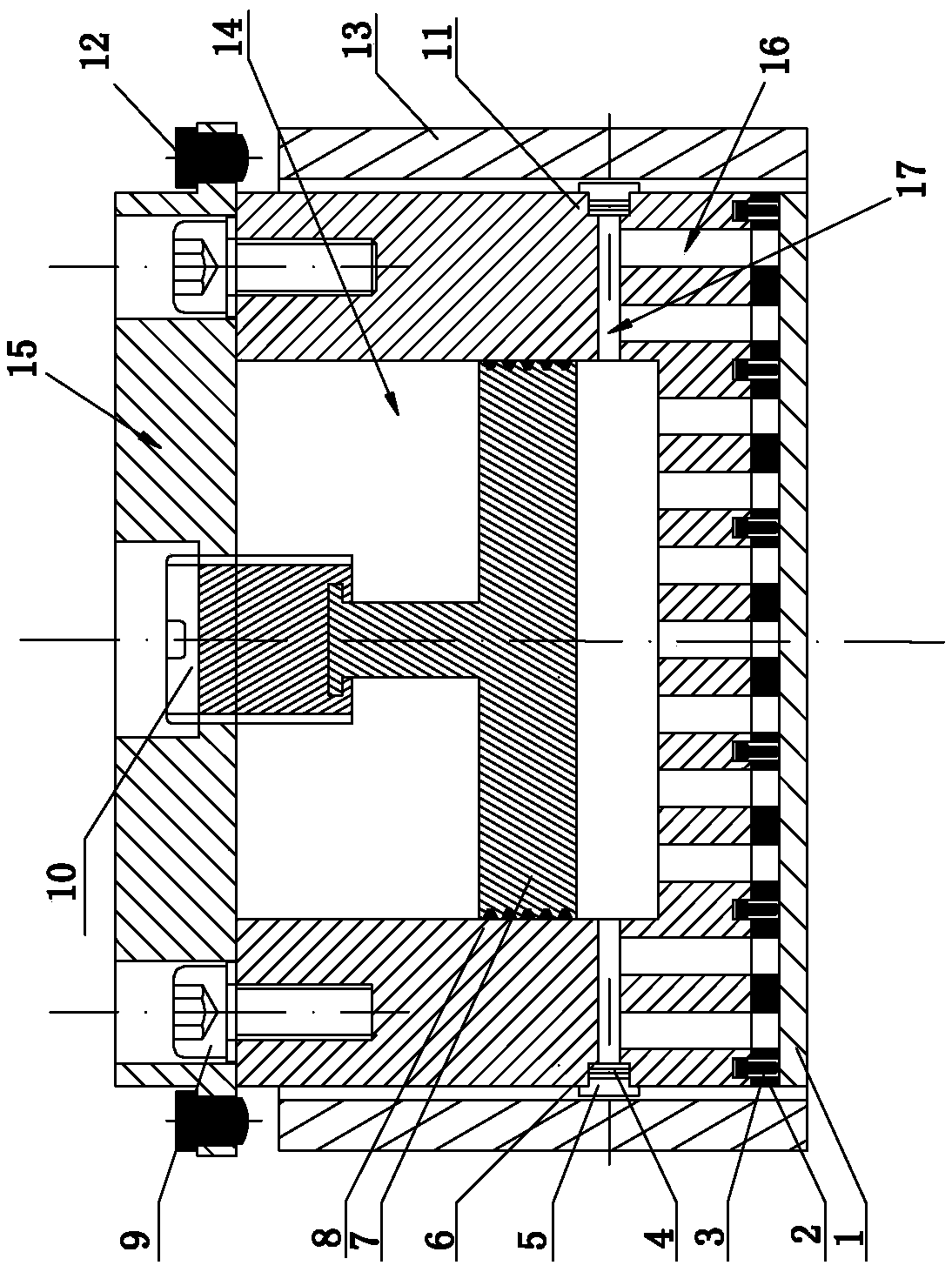

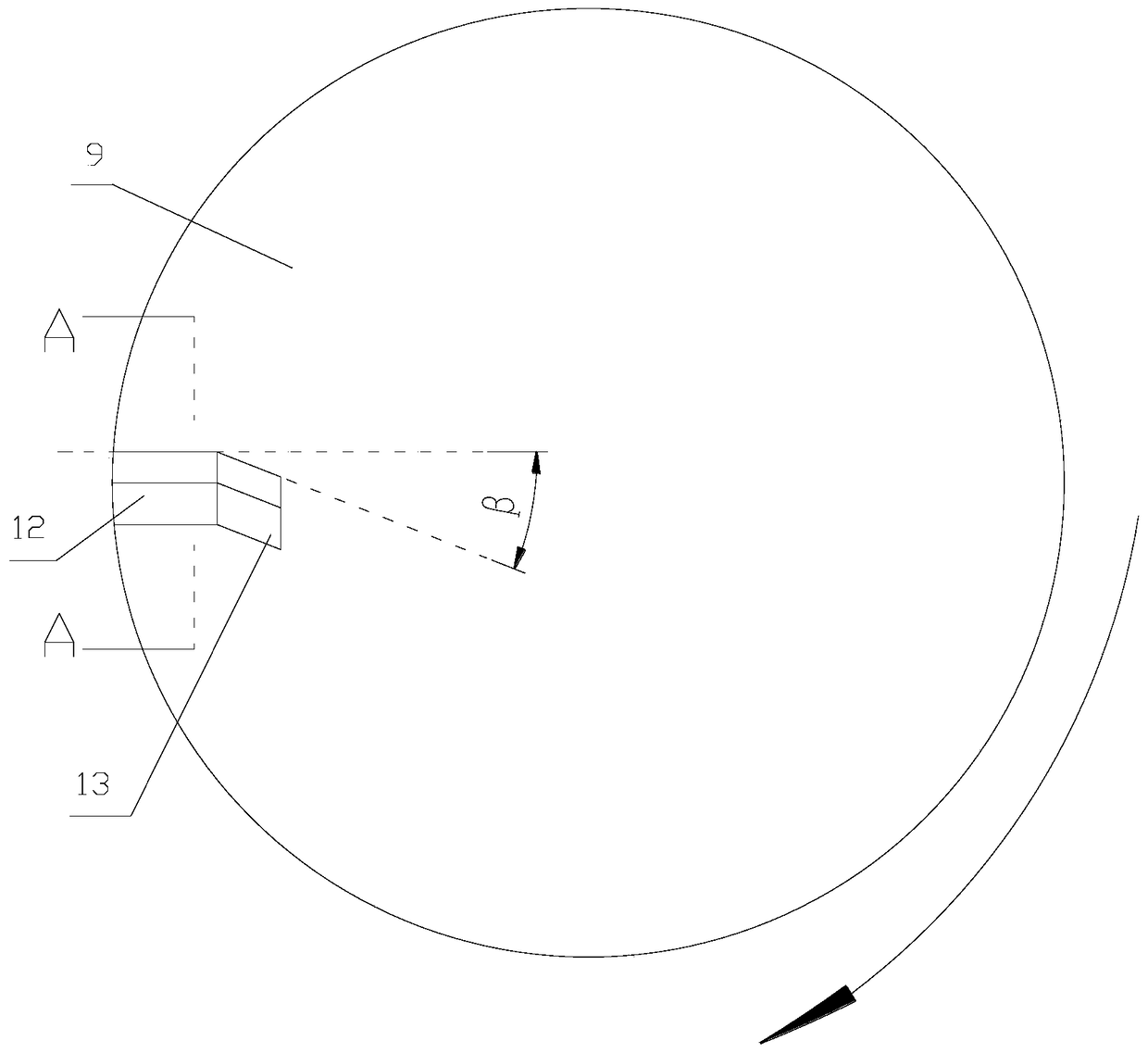

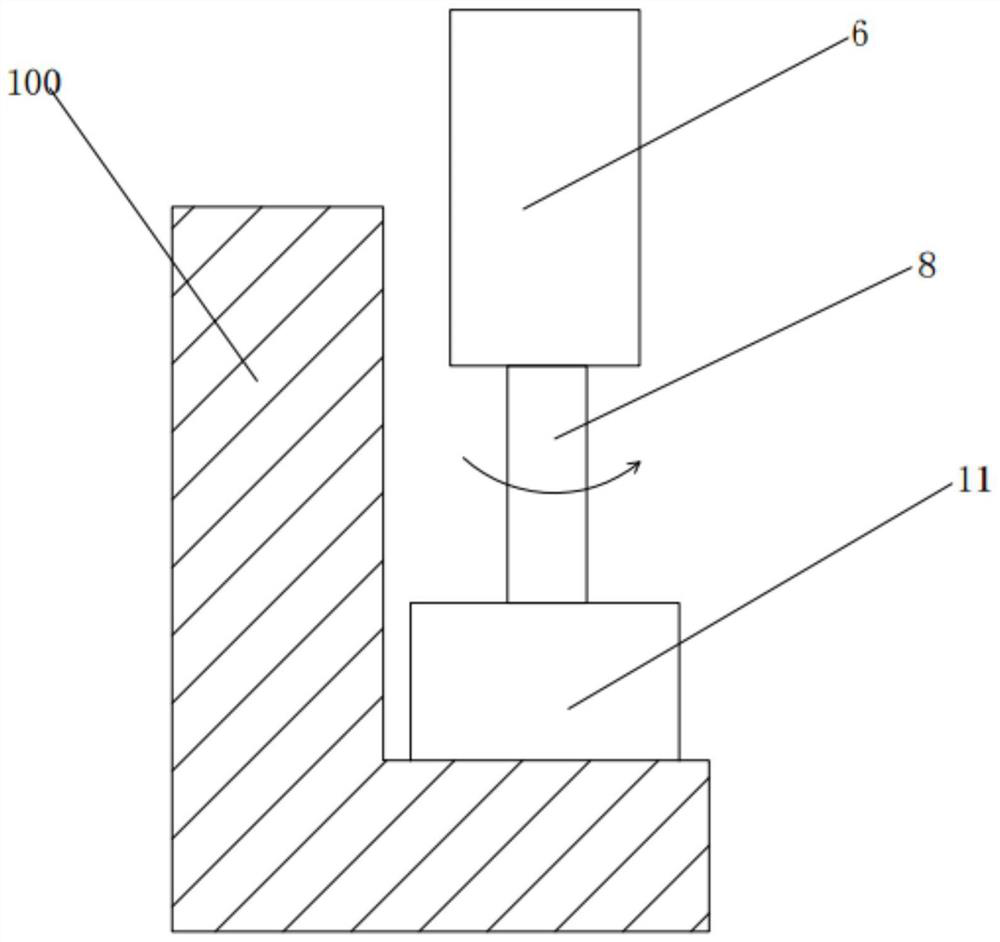

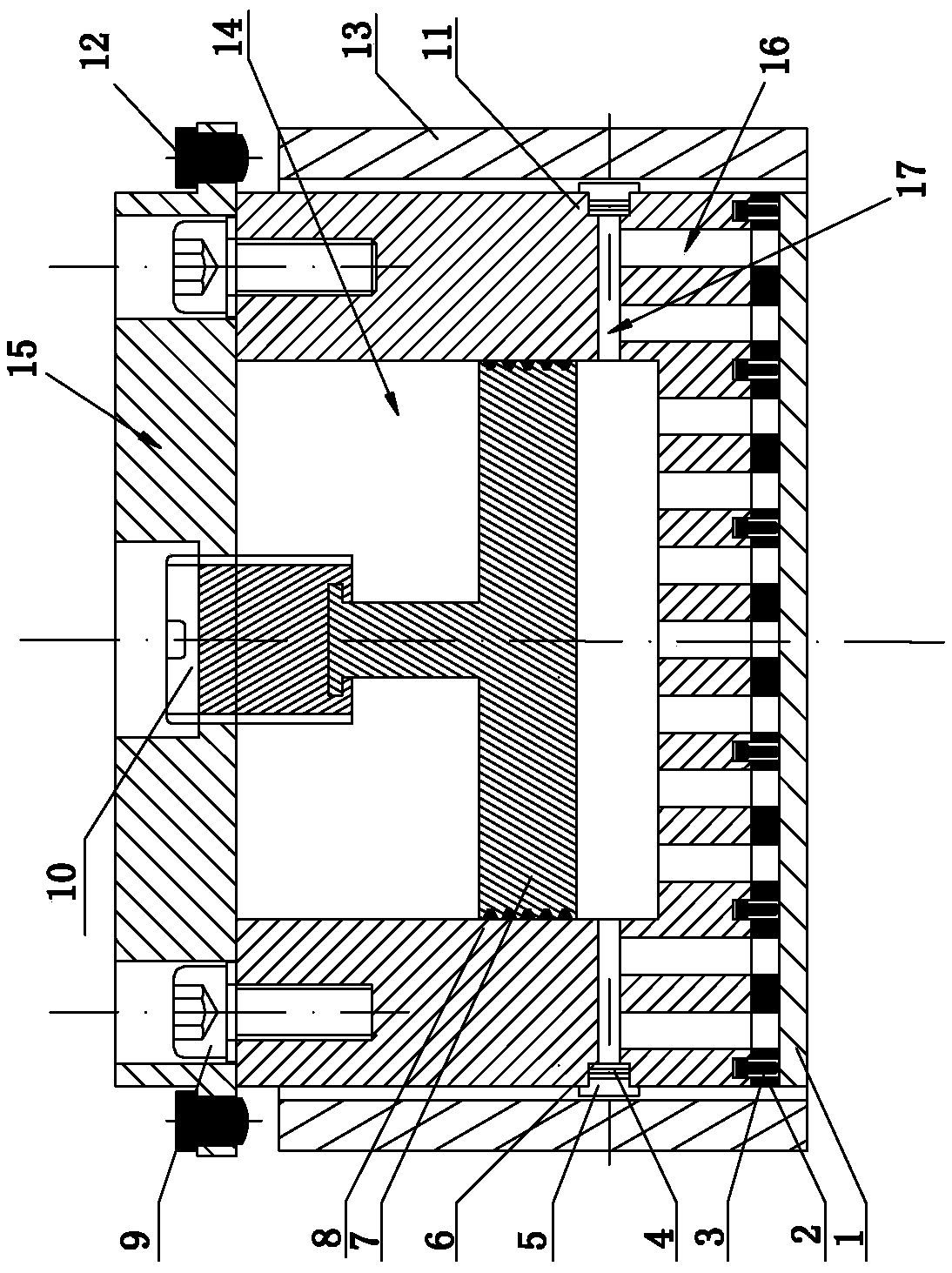

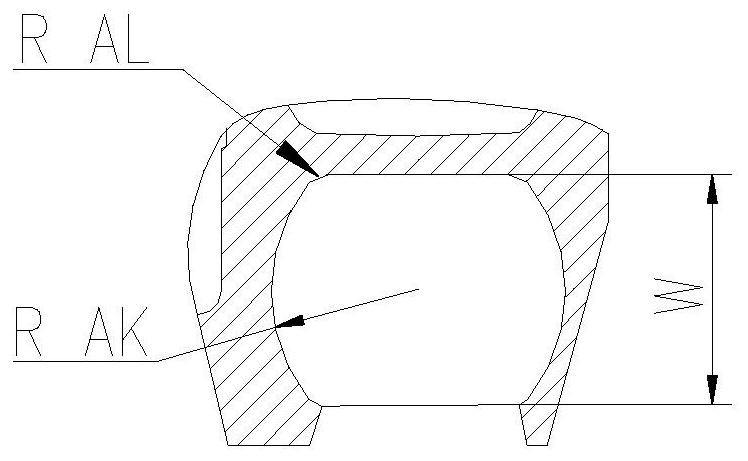

Air-aspiration type adhesive-free workpiece bearing device for one-side polishing

ActiveCN108393793ALess consumablesReduce processing costsWork carriersRelative displacementMicrometer

The invention relates to an air-aspiration type adhesive-free workpiece bearing device for one-side polishing. The air-aspiration type adhesive-free workpiece bearing device comprises a sucking disc (11). The air-aspiration type adhesive-free workpiece bearing device is characterized in that a piston cavity (14) is formed in the center of the sucking disc (11), a piston (7) is installed in the piston cavity (14), the piston (7) is connected with a cylinder cover (15) by virtue of an adjusting spiral body (10) on which a micrometer component is installed, and the position of the piston in the piston cavity (14) can be adjusted by rotating the adjusting spiral body (10), so that the pressure in the piston cavity under the piston is adjusted; an air suction hole (16) is formed in the lower part of the piston cavity (14), and a workpiece (1) which is installed on the lower part of the sucking disc (11) is sucked by negative pressure generated by the air suction hole; and a displacement sensor (12) which is used for measuring the relative displacement of the sucking disc (11) so as to determine the workpiece polishing amount is installed on the cylinder cover (15). The air-aspiration type adhesive-free workpiece bearing device has the advantages of the simple structure, reliability in bonding and convenience in assembly and disassembly.

Owner:HENAN INST OF SCI & TECH

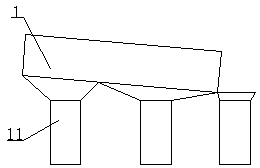

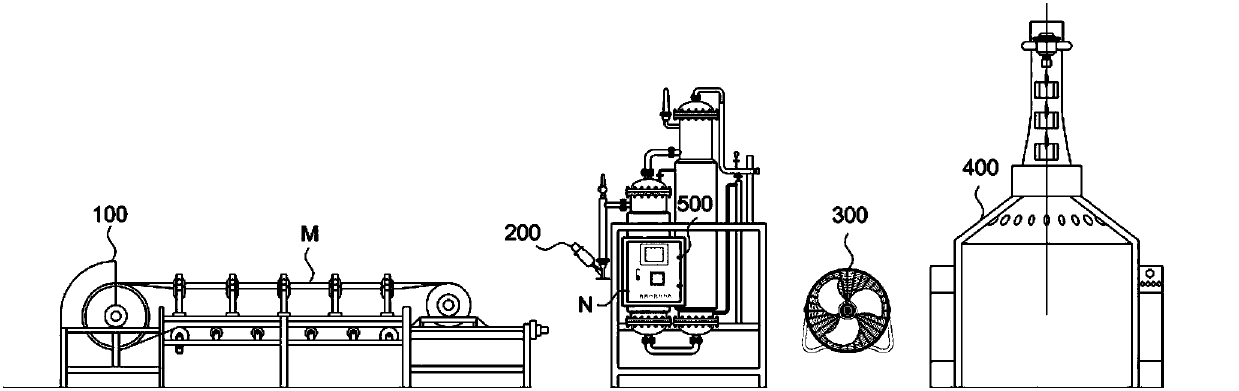

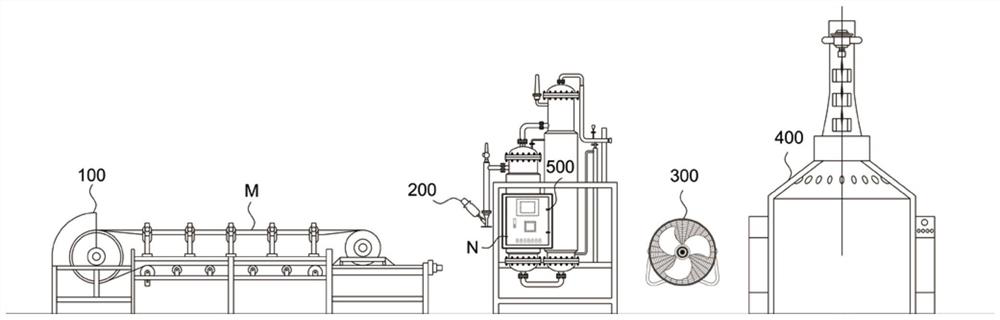

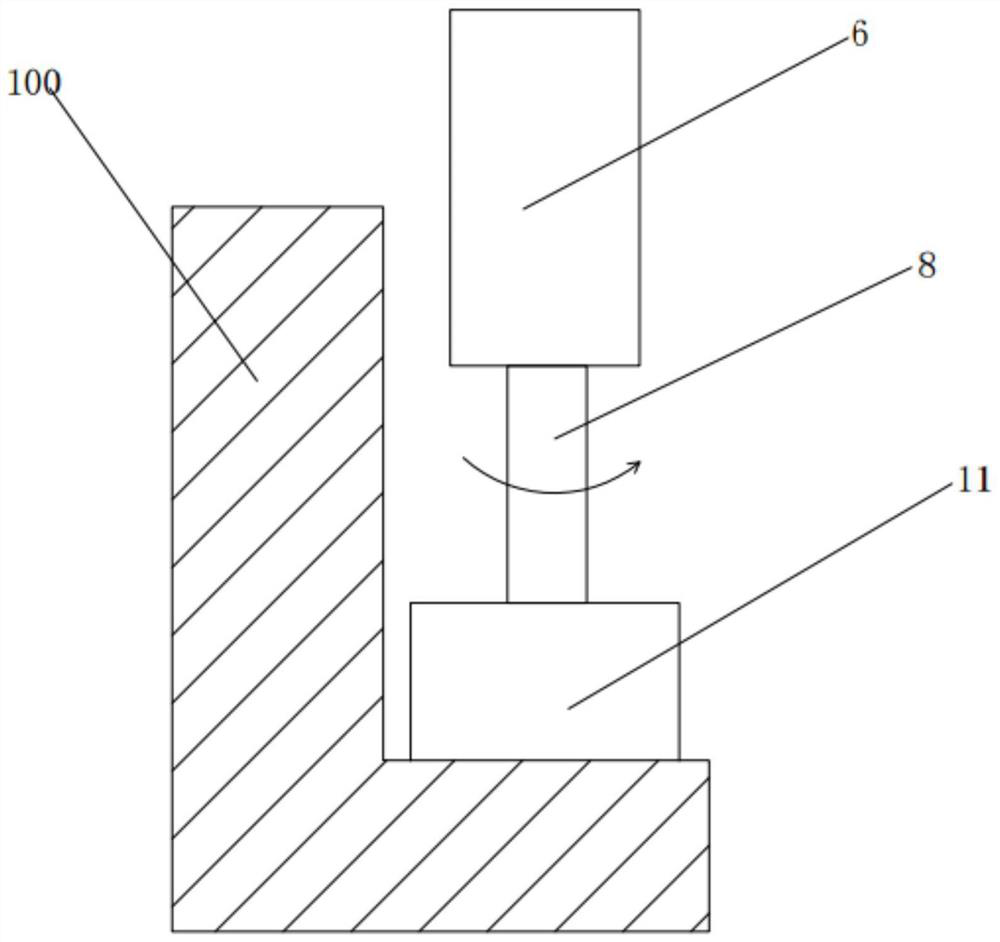

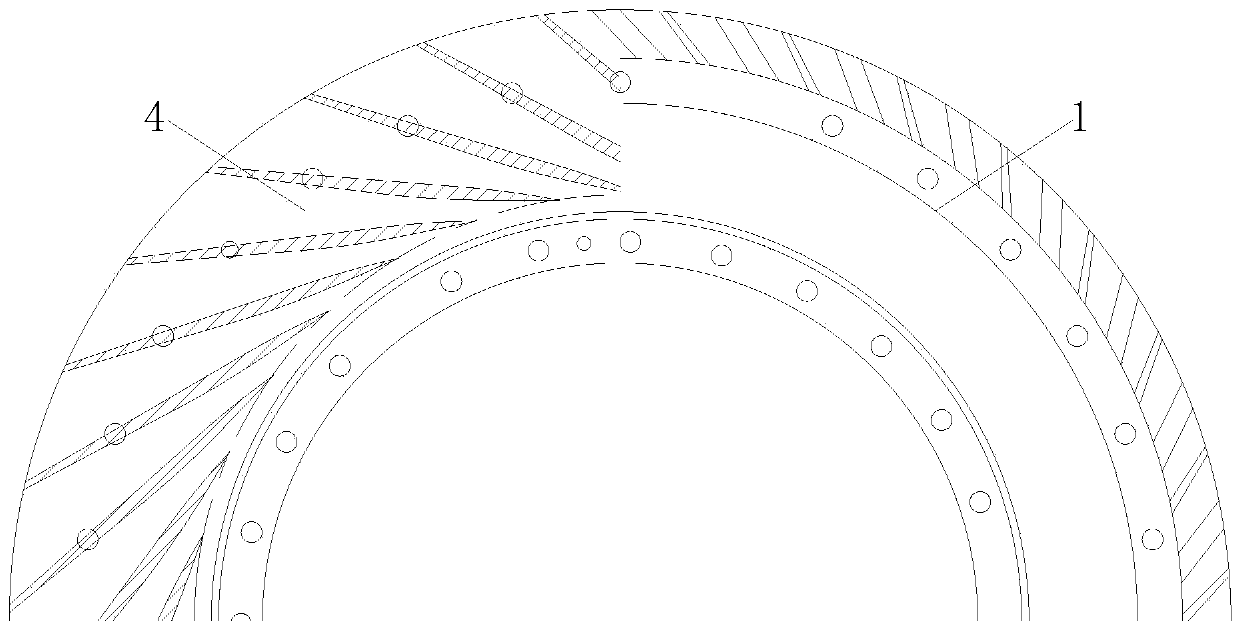

Green fresh rice green-embryo-skin-remaining processor

InactiveCN109126937AReproduce natural green nutritionAvoid over processingGrain huskingGrain polishingNutritionMechanical equipment

The invention relates to the field of mechanical equipment, in particular to a green fresh rice green-embryo-skin-remaining processor. The green fresh rice green-embryo-skin-remaining processor comprises an inclined filter screen (1) and multi-stage rice husking machines (11), the inclined filter screen (1) is provided with a plurality of outlets with different diameters, the inclined filter screen (1) is driven to rotate by a driving motor, and a group of inlets of the multi-stage rice husking machines (11) communicate with the multiple outlets of different diameters on the inclined filter screen (1).. The green fresh rice green-embryo-skin-remaining processor has the advantages that the rice grain processing link avoids excessive processing, the green embryo skin of rice is remained, polishing is prohibited, and the natural green nutrition of the grain is reproduced.

Owner:HUBEI YEWEI OILS GRP MACHINERY +1

Method for degrading aflatoxin of peanuts

ActiveCN107625028AAvoid over processingPrecise control of processing timeFood scienceAflatoxin degradationBiology

The invention discloses a method for degrading aflatoxin of peanuts. The method comprises the following steps of cleaning peanut granules, and regulating the moisture content of the peanut granules and the temperature of the peanut granules; regulating the piling thickness of peanut granule materials to be treated, and coprocessing the peanut granule materials through ultraviolet rays and electronbeams. According to the method disclosed by the invention, the ultraviolet rays and the electron beams are in synergy, and inside and outside detoxification is performed at the same time, so that thedegradation rate of the aflatoxin is obviously increased, the equipment is convenient to operate, and the method is suitable for processing reality of enterprises.

Owner:JIANGNAN UNIV

Dog food composition and preparation method thereof

InactiveCN109329634APhysically fitImprove immunityAnimal feeding stuffAccessory food factorsBiotechnologyFood additive

The invention embodiment discloses a dog food composition. The composition is prepared from the following raw materials in parts by weight: 400-600 parts of duck breast meat, 600-800 parts of chickenbreast meat, 40-60 parts of mutton, 40-60 parts of salmons, 10-30 parts of chicken livers, 100-200 parts of potatoes, 40-60 parts of cheese, 40-60 parts of cereals, 40-60 parts of sweet potatoes, 150-250 parts of carrots, 40-60 parts of pumpkin, 40-60 parts of cucumbers, 40-60 parts of broccoli, 40-60 parts of Chinese cabbage, 40-60 parts of spinach, 40-60 parts of tofu, 40-60 parts of cabbage, 40-60 parts of pakchoi, 40-60 parts of okra, 40-60 parts of oilseed rape, 100-200 parts of duck skin, and 7-13 parts of olive oil. The dog food composition contains various components such as meat, fish, vegetables, cereals, milk and the olive oil, is scientific in formula and comprehensive in nutrients, does not contain any food additive, and satisfies various nutrients required for dog growth. Theinvention also discloses a preparation method of the dog food composition, and the method is simple and easy for manufacturing, and avoids excessive processing of dog food.

Owner:吴月明

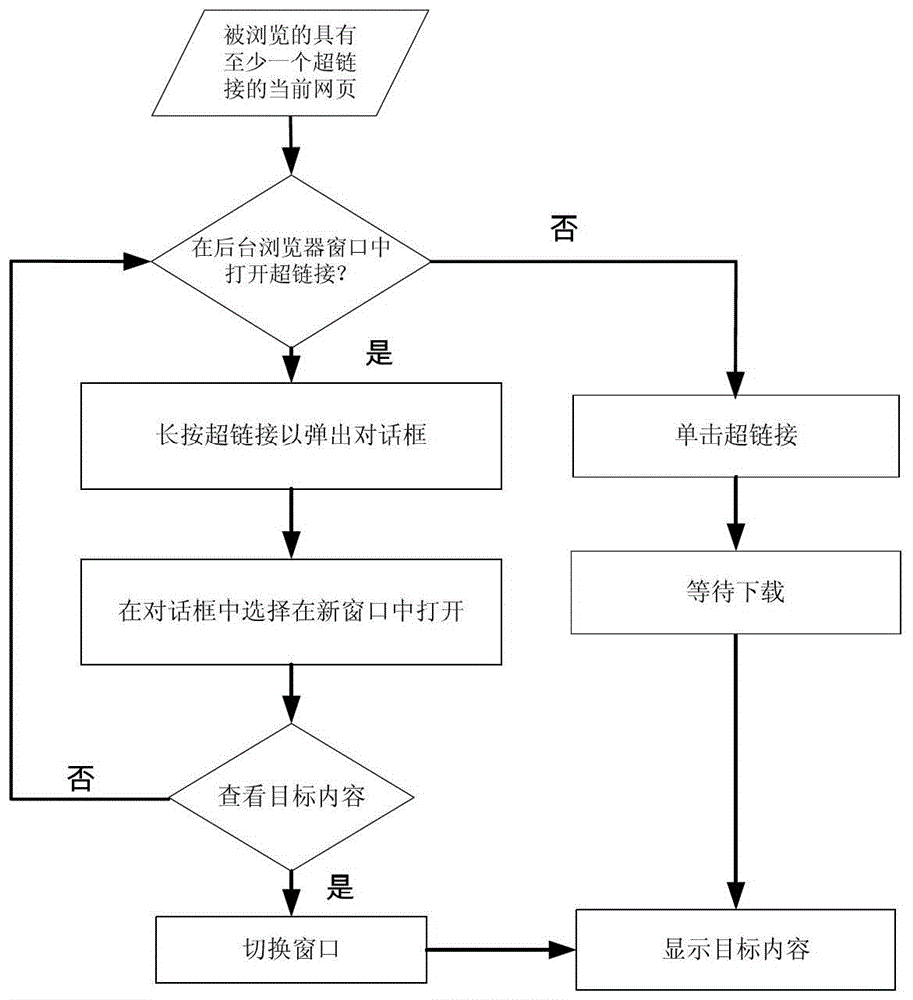

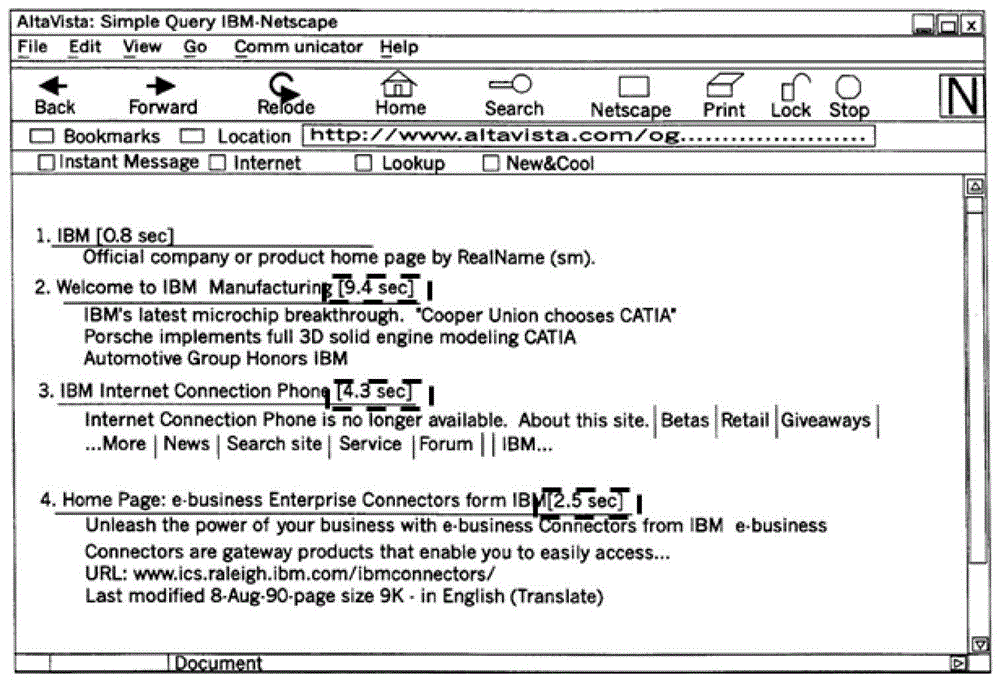

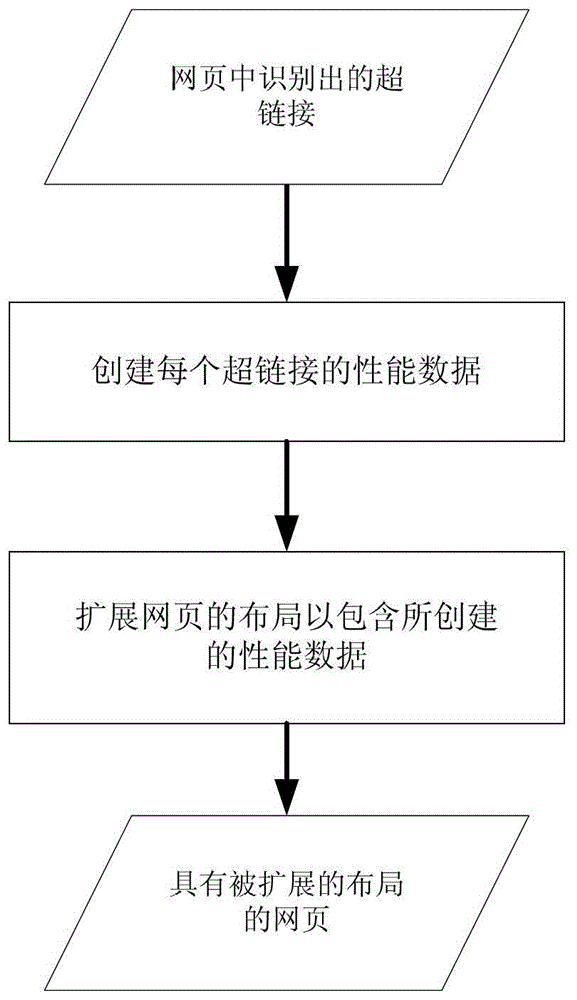

Web page operation method and device, web page presentation method and device, and electronic device

ActiveCN103778132BEasy to operateImprove browsing experienceTransmissionSpecial data processing applicationsHyperlinkWeb page

The invention discloses a method and device for webpage operation, a method and device for webpage presentation and an electronic device. A method for opening target contents from a current webpage is provided, the current webpage comprises at least one hyperlink, and every hyperlink respectively corresponds to one target content. The method comprises the steps of comparing expected response time of one clicked hyperlink with a predetermined threshold when a user clicks the hyperlink, determining whether the target content corresponding to the clicked hyperlink is downloaded and presented in a background browser window or a current browser window of the current webpage on the basis of comparison results, and enabling the background browser window to be different from the current browser window.

Owner:CANON KK

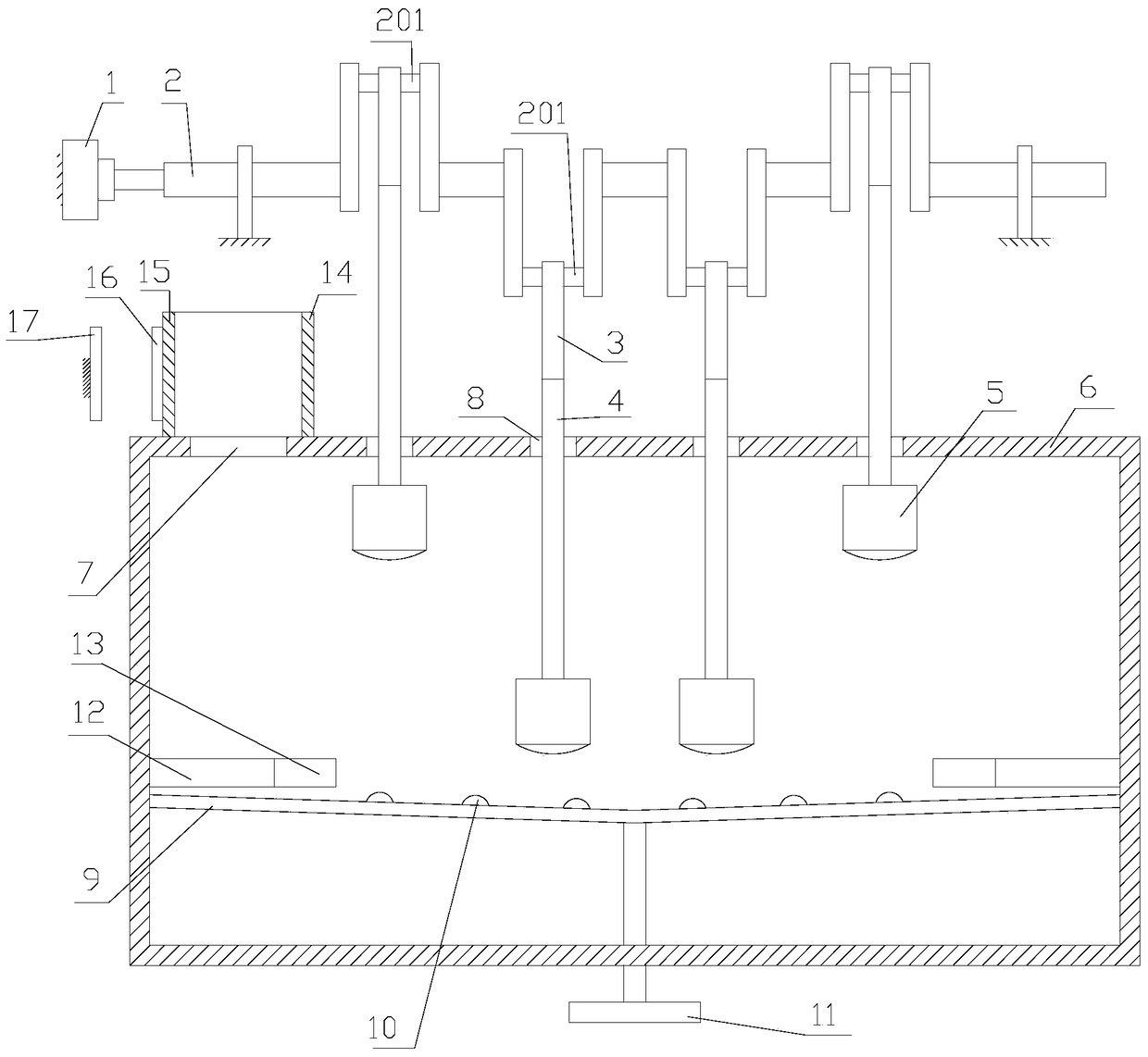

A kind of agricultural pulverizer

ActiveCN105413791BRedistribution lawImprove crushing efficiencyGrain treatmentsAgricultural engineeringCrusher

The invention discloses an agricultural smashing machine. The agricultural smashing machine comprises a driving unit, a crankshaft, N connecting pieces, N connecting rods, N striking pieces and a box; the driving unit is connected with the crankshaft in a transmission manner to drive the crankshaft to rotate; the crankshaft is horizontally arranged and comprises N connecting shaft necks; the N connecting pieces are rotationally connected with the N connecting shaft necks respectively; and one ends of the N connecting rods are rotationally connected with the N connecting pieces. The agricultural smashing machine is good in material processing effect and high in material processing efficiency.

Owner:全椒县汊河农机服务专业合作社

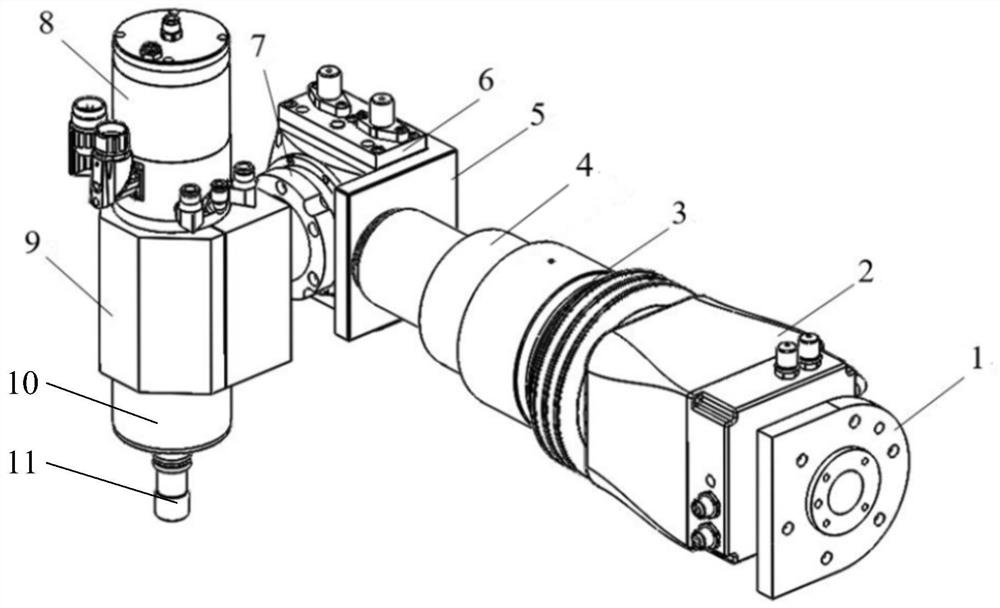

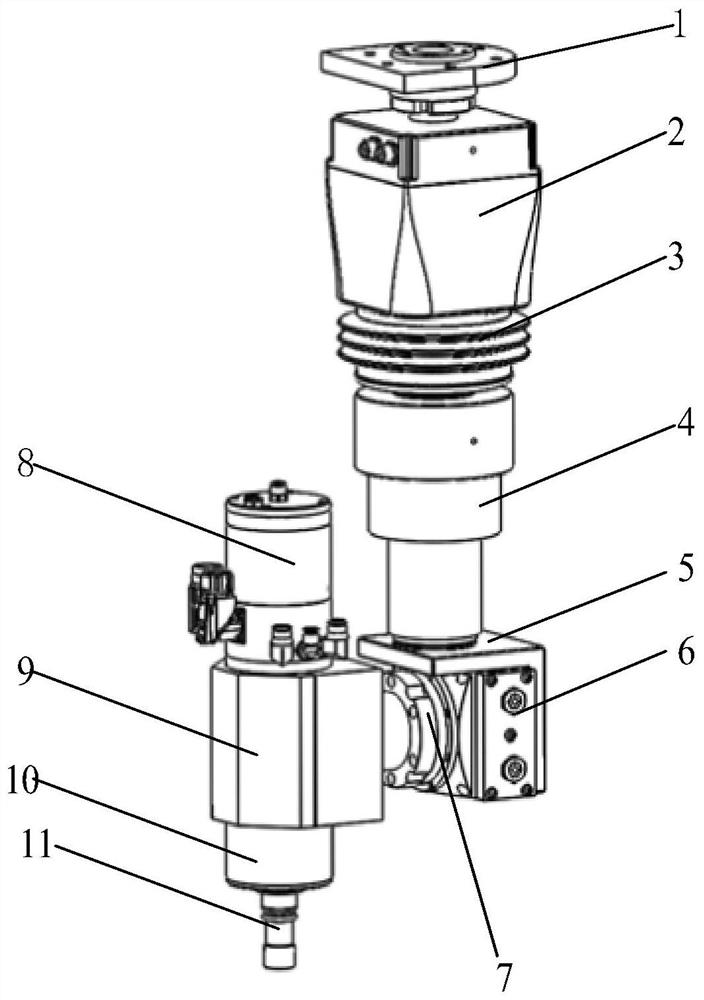

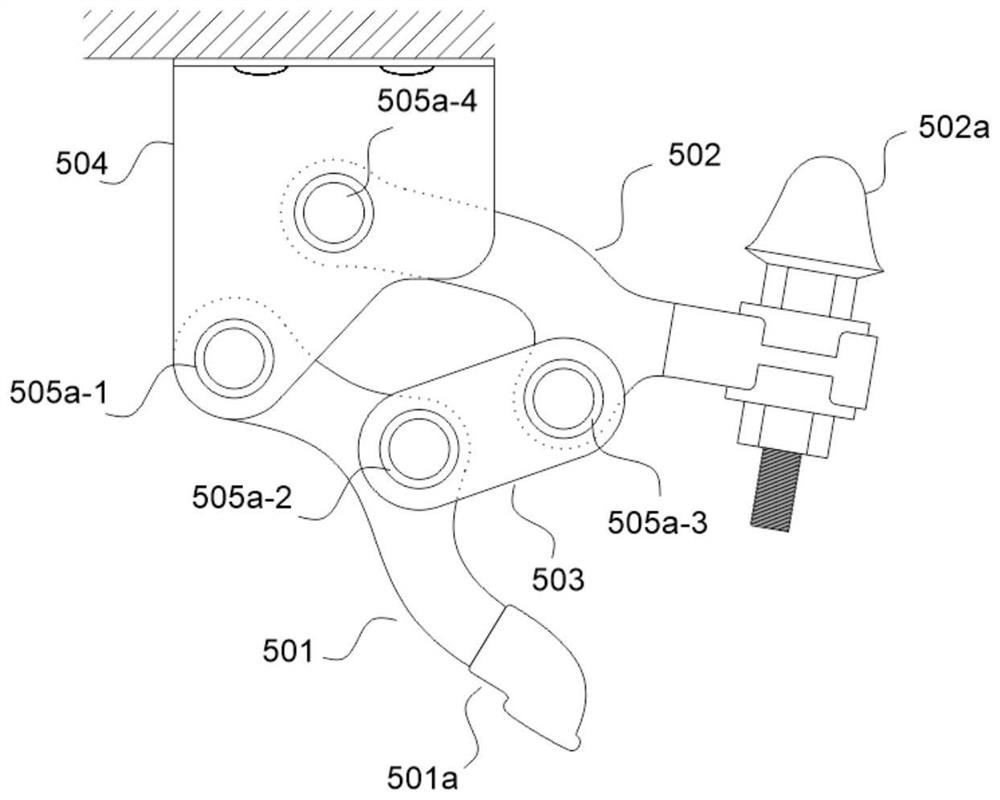

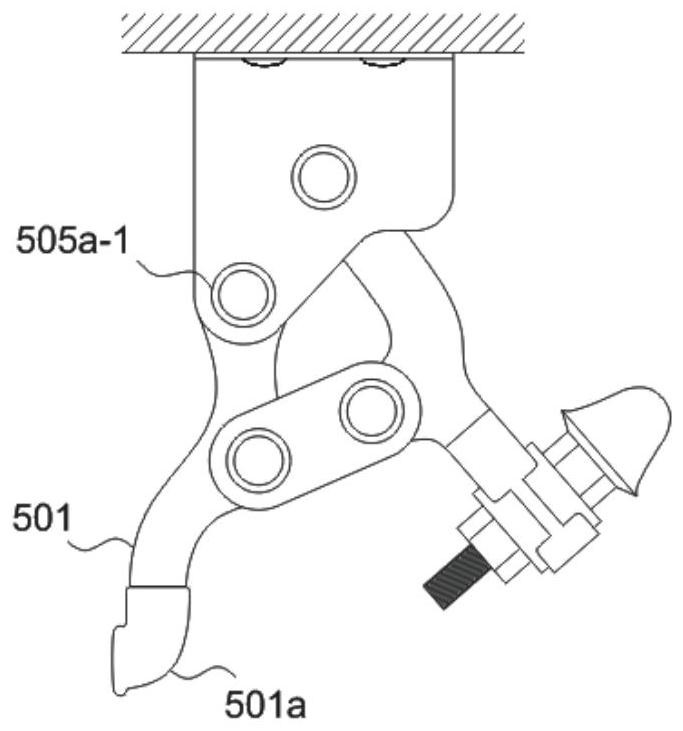

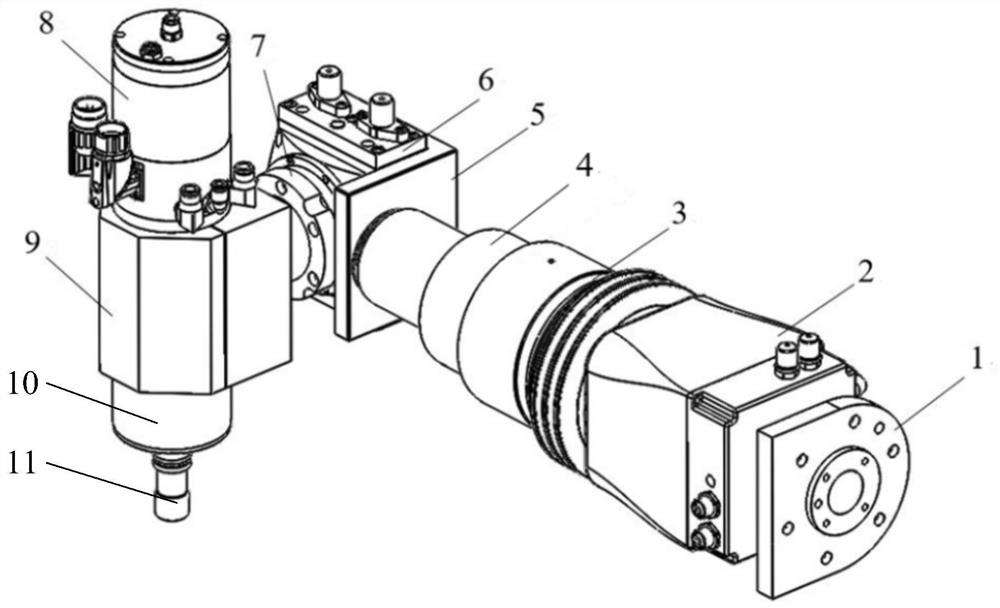

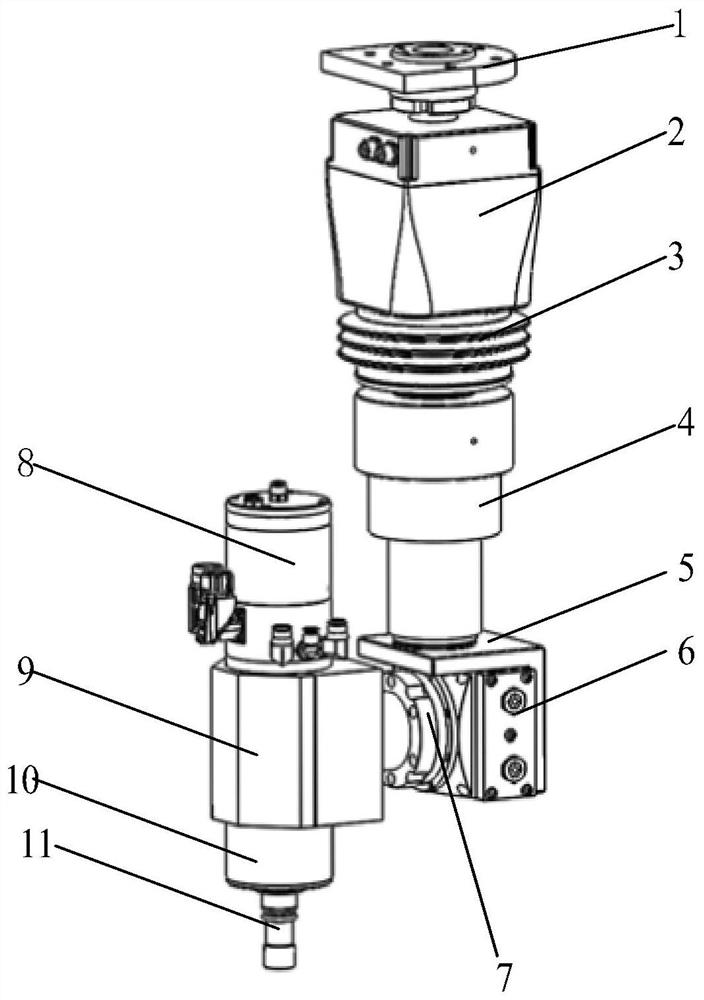

Robot end effector and robot

ActiveCN113070743ALeave in timeReduce wearGrinding drivesAutomatic grinding controlConstant forceControl engineering

The invention discloses a robot end effector and a robot, and belongs to the technical field of grinding machining. The robot end effector is used for grinding a workpiece and comprises an execution tool, a rotation unit, a rotating unit, an ultrasonic vibrator and a constant force control assembly, one end of the rotation unit is connected with the execution tool, and the rotation unit is used for driving the execution tool to do rotational motion; the rotating unit is used for driving the rotation unit to do rotary motion, and the rotary motion direction and the rotation motion direction are not in the same direction; the ultrasonic vibrator is connected with the rotating unit and is used for driving the rotation unit and the execution tool to axially vibrate; and the constant force control assembly is used for keeping constant contact pressure between the execution tool and the workpiece. The robot comprises the robot end effector. According to the robot end effector, through structural design and constant contact pressure control, the structure is simplified, the control difficulty is reduced, and the machining quality and the working efficiency are improved.

Owner:SHANGHAI AIRCRAFT MFG

Method for processing reshaped small purple sweet potatoes

Owner:产学研共同体(山东)科技成果转化有限公司

A method for degrading peanut aflatoxin

ActiveCN107625028BAvoid over processingPrecise control of processing timeFood scienceAflatoxin degradationElectron bunches

The invention discloses a method for degrading aflatoxin of peanuts. The method comprises the following steps of cleaning peanut granules, and regulating the moisture content of the peanut granules and the temperature of the peanut granules; regulating the piling thickness of peanut granule materials to be treated, and coprocessing the peanut granule materials through ultraviolet rays and electronbeams. According to the method disclosed by the invention, the ultraviolet rays and the electron beams are in synergy, and inside and outside detoxification is performed at the same time, so that thedegradation rate of the aflatoxin is obviously increased, the equipment is convenient to operate, and the method is suitable for processing reality of enterprises.

Owner:JIANGNAN UNIV

An air-suction non-adhesive single-sided polishing workpiece carrying device

ActiveCN108393793BEasy loading and unloadingImprove efficiencyWork carriersRelative displacementMicrometer

Owner:HENAN INST OF SCI & TECH

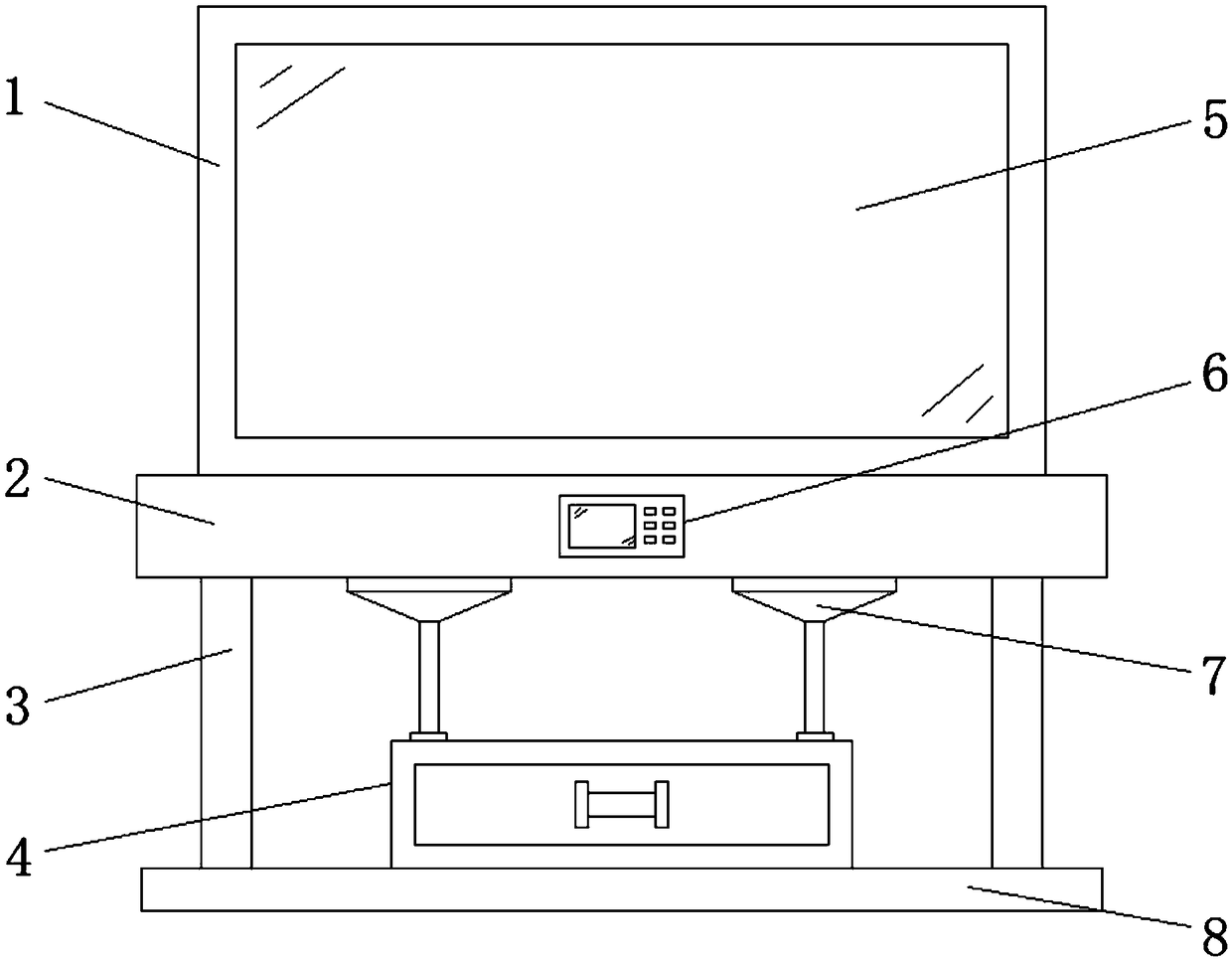

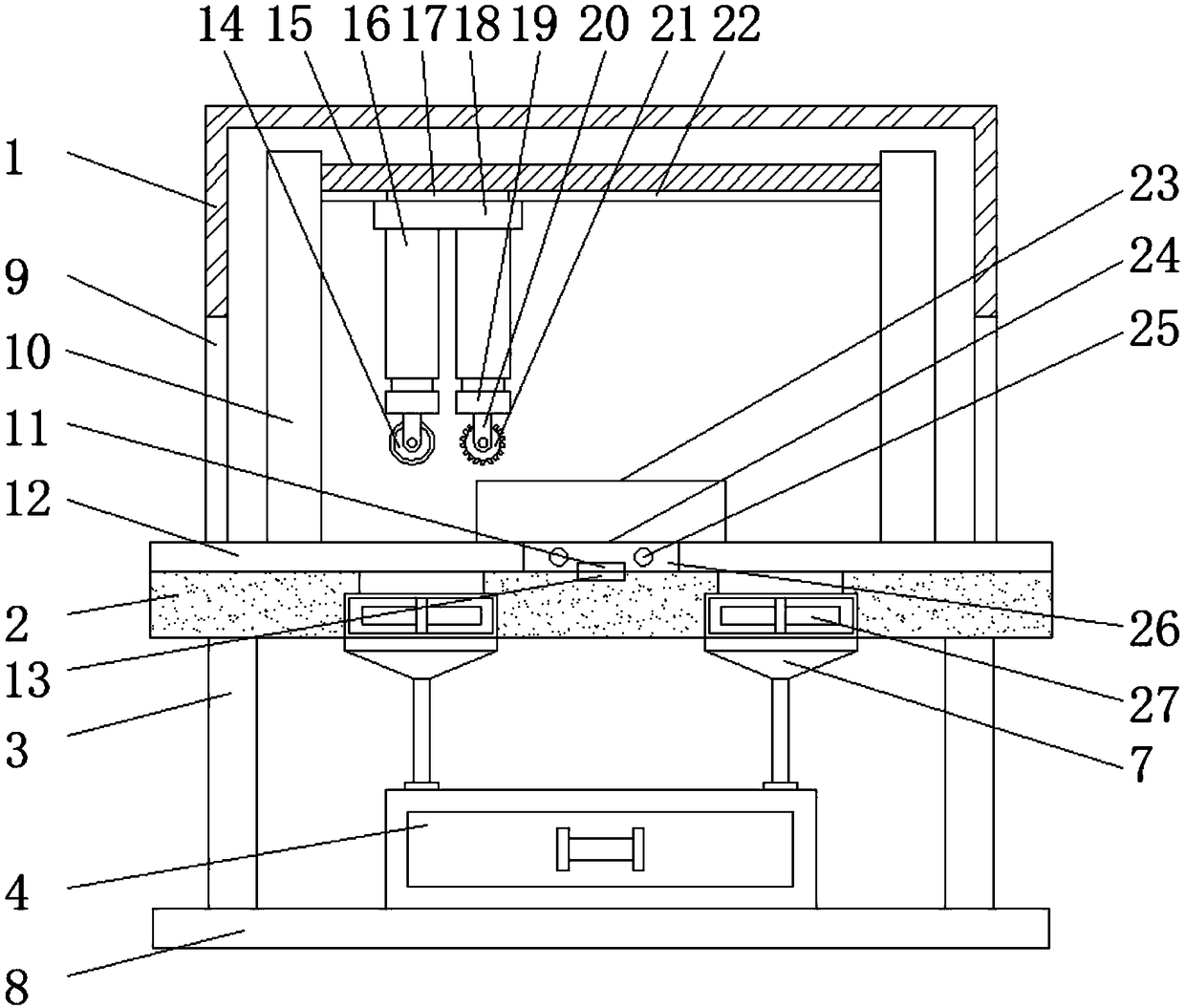

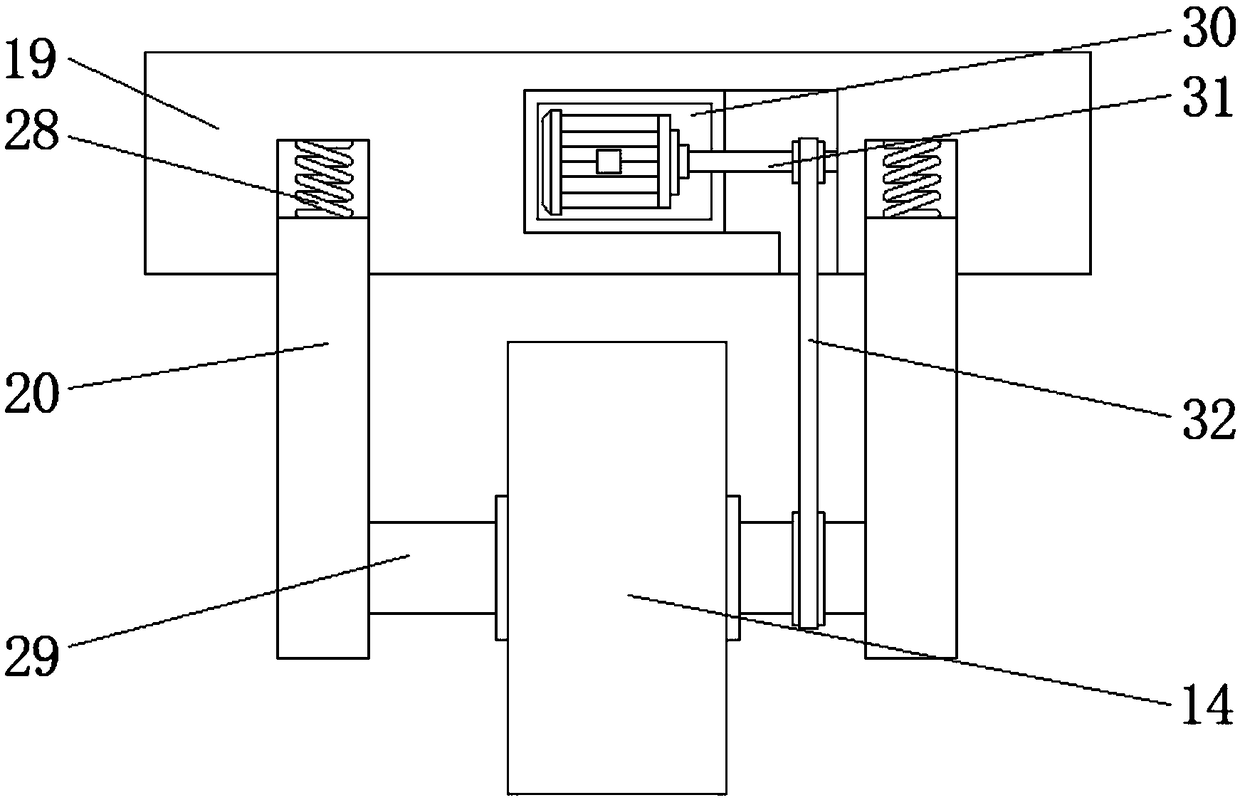

Four-axis bearing tile cover production line

PendingCN108908126AEasy to fixAvoid over processingPolishing machinesGrinding machinesProduction lineEngineering

The invention relates to a four-axis bearing tile cover production line, comprising an insulating cover, a console and a base, wherein the top of the base is provided with the console through a bracket, the top of the console is provided with the insulating cover, the center of the top of the console is internally uniformly provided with a fan, the top of the console on the two sides of the fan isprovided with a first chute, second adjusting seats are installed inside the first chute and are fixedly connected with each other by screw rods, and a clamp seat is evenly mounted between the screwrods on the sides of the second adjusting seats through first adjusting seats. The four-axis bearing tile cover production line is provided with the insulating cover, the console and the base, the fanis uniformly installed in the center of the top of the console, and the bottom end of a collection hopper at one side of the fan is fixedly connected with a waste box through a pipeline, so that crushed aggregates and dust generated during processing are sucked into the waste box through the fan and are easy to collect, the environmental pollution caused by flying waste is reduced, and the use ofdevices is facilitated.

Owner:盐城市精派组合机床有限公司

A nutritionally fortified food rich in omega 3 fatty acids mainly composed of coralline algae

The invention discloses an omega III fatty acid-rich nutrient enrichment food taking kappaphycus as main material. The nutrient enrichment food is mainly prepared from the following raw materials in parts by weight: 50-70 parts of kappaphycus, 5-12 parts of chia seeds, 5-12 parts of flaxseeds, 7-15 parts of wood of shinyleaf yellowhorn, 7-15 parts of sea-buckthorn and 3-7 parts of chitosan oligosaccharide. The nutrition comprehensiveness of the nutritional food can be improved, so that the nutritional food contains rich mineral substances, protein, amino acids, vitamins, calcium, other phytochemicas and trace elements; particularly, the omega III fatty acid is organically combined with ionized calcium, so that the important matters which are rare to the human health can be obtained in the daily dietary process without overly processing natural food, and therefore, the nutrient enrichment food is an enriched food capable of more comprehensively supplementing the nutritive value.

Owner:颐麦科技(北京)有限公司

Trigger switch structure, housing structure of electronic equipment and electronic equipment

ActiveCN106922090BReduce space consumptionAvoid over processingCasings with display/control unitsKey pressingUltimate tensile strength

The invention discloses a trigger switch structure, a shell structure of electronic equipment, and the electronic equipment. The trigger switch structure can comprise a circuit board, wherein a connector, which is connected to a main board on the electronic equipment, extends from the inner side of the circuit board; a plurality of bumps are formed on the outer side of the circuit board; a corresponding trigger switch is arranged on the surface of each bump, wherein the bumps are bent downwardly to be perpendicular to the circuit board; and therefore, when the circuit board is pasted on the top side of a frame of the shell structure of the electronic equipment, the bumps can be inserted into a preset cavity in the frame through openings in the top side of the frame, so as to enable keys which extend in the preset cavity to be matched with the corresponding trigger switches on the bumps. By virtue of the technical scheme disclosed by the invention, the trigger switch structure can be matched with narrow frames of the electronic equipment, and excessive influence to the strength of the frame structure can be avoided.

Owner:XIAOMI INC

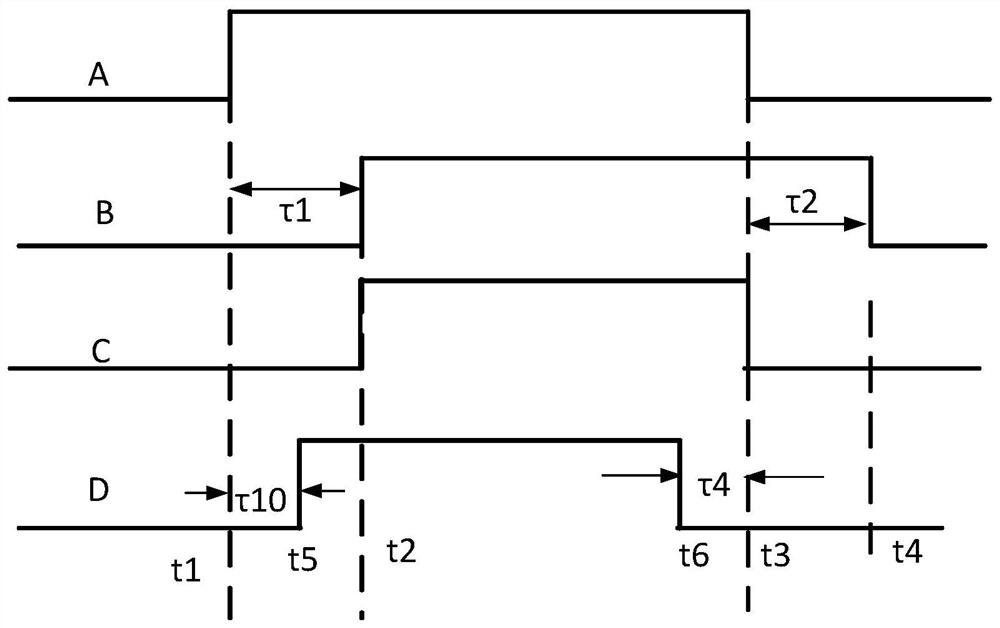

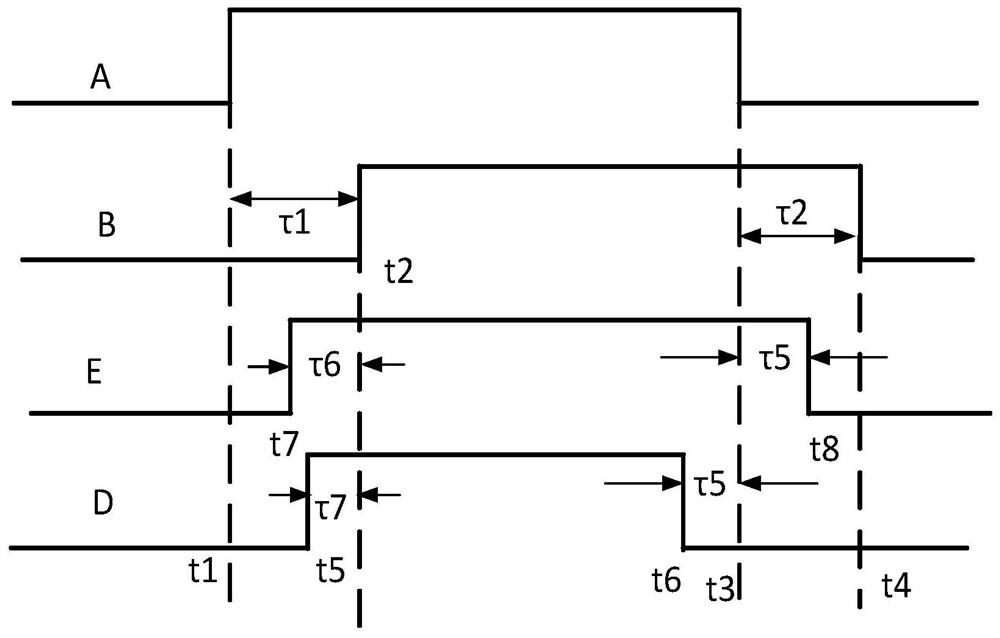

A switching light editable laser processing system and method

ActiveCN112247342BGuaranteed accuracyAvoid over processingLaser detailsLaser beam welding apparatusLaser processingEngineering

The invention discloses a switching light editable laser processing system and method. The system includes a laser emitting device, processing equipment, a monitoring module, and a control center. The processing equipment is used to adopt laser processing components, and the monitoring is used to measure the processing equipment Delay time, laser delay time, the control center controls the time point when the laser emitting device emits laser light or stops emitting light according to the delay time. This application calculates or measures the mechanical delay time of the processing equipment, according to the delay time, appropriately sets the light-emitting time and the end time of the laser equipment, reduces the duration of the laser after the starting point and the ending point, and ensures that no excessive Processing phenomenon, improve processing accuracy, reduce loss.

Owner:北京卓镭激光技术有限公司

Trigger switch structure, shell structure of electronic equipment, and electronic equipment

ActiveCN106922090AReduce space consumptionAvoid over processingCasings with display/control unitsEngineeringMotherboard

The invention discloses a trigger switch structure, a shell structure of electronic equipment, and the electronic equipment. The trigger switch structure can comprise a circuit board, wherein a connector, which is connected to a main board on the electronic equipment, extends from the inner side of the circuit board; a plurality of bumps are formed on the outer side of the circuit board; a corresponding trigger switch is arranged on the surface of each bump, wherein the bumps are bent downwardly to be perpendicular to the circuit board; and therefore, when the circuit board is pasted on the top side of a frame of the shell structure of the electronic equipment, the bumps can be inserted into a preset cavity in the frame through openings in the top side of the frame, so as to enable keys which extend in the preset cavity to be matched with the corresponding trigger switches on the bumps. By virtue of the technical scheme disclosed by the invention, the trigger switch structure can be matched with narrow frames of the electronic equipment, and excessive influence to the strength of the frame structure can be avoided.

Owner:XIAOMI INC

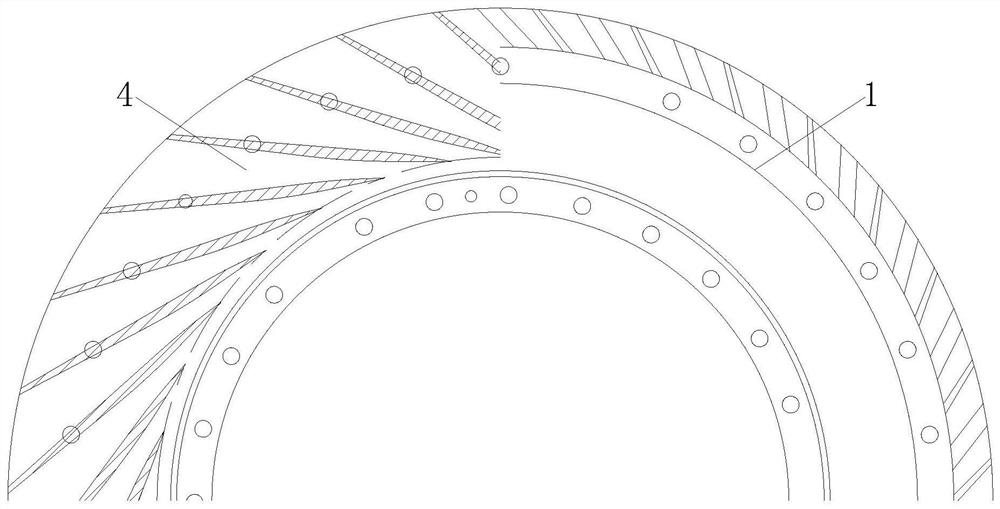

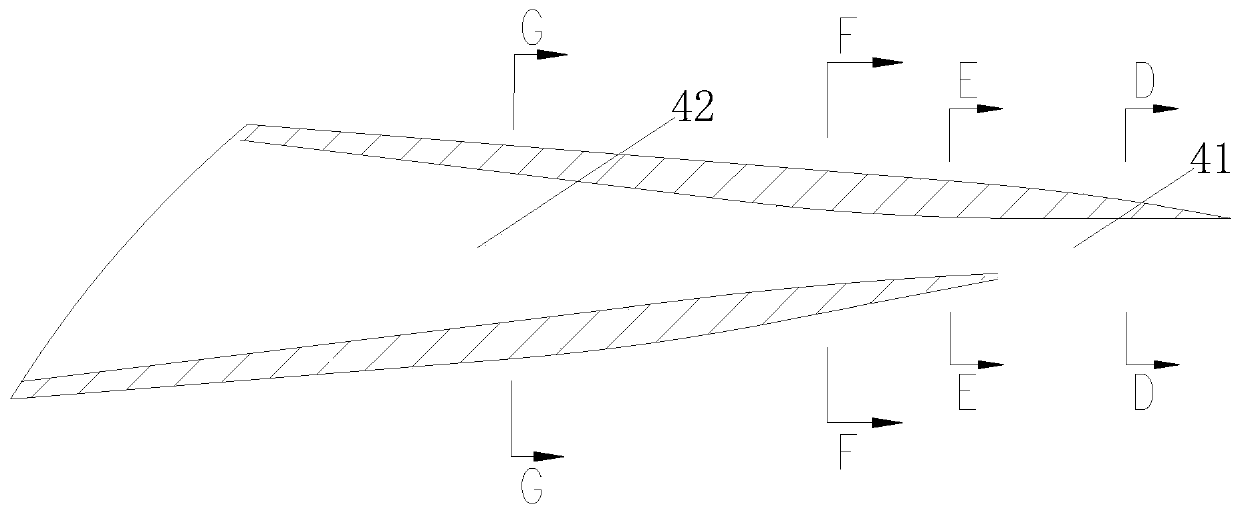

Radial diffuser channel pretreatment method

ActiveCN110076408BEliminate to get throughAvoid getting burnedElectrochemical machining apparatusPretreatment methodMachining

The invention provides a radial diffuser channel pretreatment method. The method comprises the following steps that S21, an electrolytic machining environment is prepared; S22, a through-hole cathodeis used for carrying out vibration feeding electrolytic machining on a channel of a radial diffuser at the feeding speed of 5mm / min-6mm / min, and the channel is broken through by using a burr working section of the through-hole cathode; and S23, the through-hole cathode is used for carrying out vibration feeding electrolytic machining on the channel of at the feeding speed of 3mm / min-4mm / min, uneven allowance on the inner wall of the channel is eliminated by using an inner wall working section of the through-hole cathode. Burrs can be eliminated through the burr working section of the through-hole cathode to break through the channel, the problem that a short circuit is generated by contact between a forming cathode and burrs when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided, the uneven allowance on the inner wall of the channel can be eliminated by using the inner wall working section of the through-hole cathode, and the problem that a short circuit is generated by contact between a forming cathode and the inner wall of the channel when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

A kind of robot end effector and robot

ActiveCN113070743BLeave in timeReduce wearGrinding drivesAutomatic grinding controlConstant forceEngineering

The invention discloses a robot end effector and a robot, belonging to the technical field of grinding and processing. The end effector of the robot is used for grinding and processing the workpiece, including the execution tool, the rotary unit, the rotation unit, the ultrasonic vibrator and the constant force control component, wherein, one end of the rotary unit is connected with the execution tool, and the rotary unit is used to drive the execution tool to rotate Movement; the rotary unit is used to drive the rotary unit to perform rotary motion, and the direction of the rotary motion is not in the same direction as the rotary motion direction; the ultrasonic vibrator is connected to the rotary unit, and the ultrasonic vibrator is used to drive the rotary unit and the execution tool to vibrate axially; constant force control components Used to maintain a constant contact pressure between the implement and the workpiece. A robot includes the above-mentioned robot end effector. The robot end effector provided by the invention simplifies the structure, reduces the difficulty of control, and improves the processing quality and work efficiency through structural design and constant contact pressure control.

Owner:SHANGHAI AIRCRAFT MFG

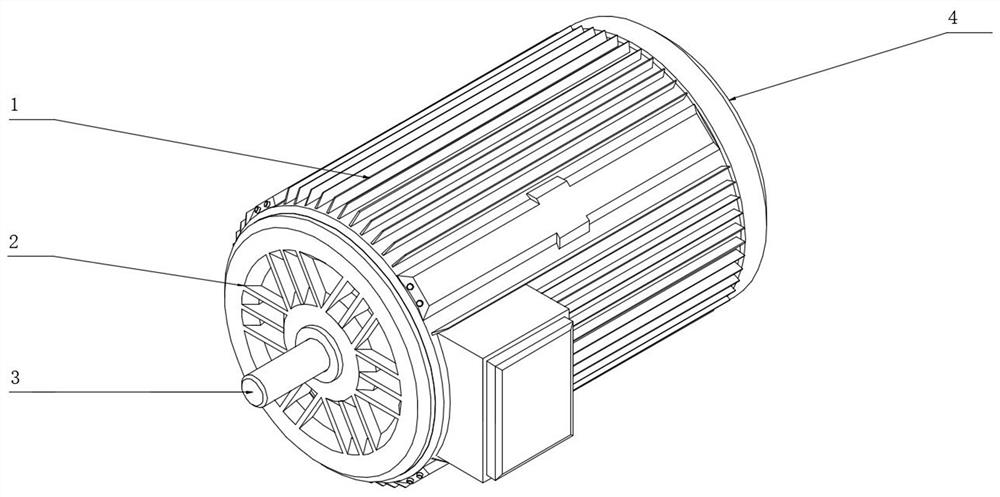

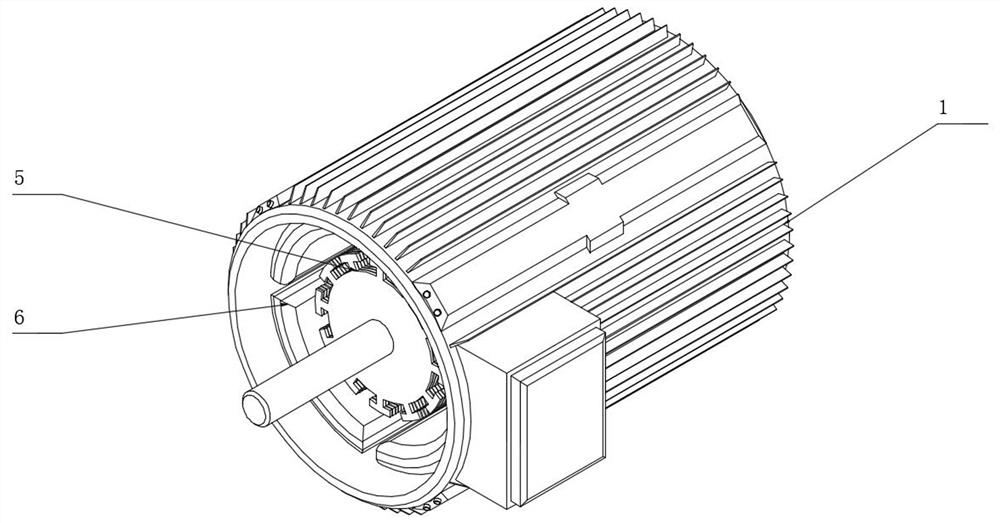

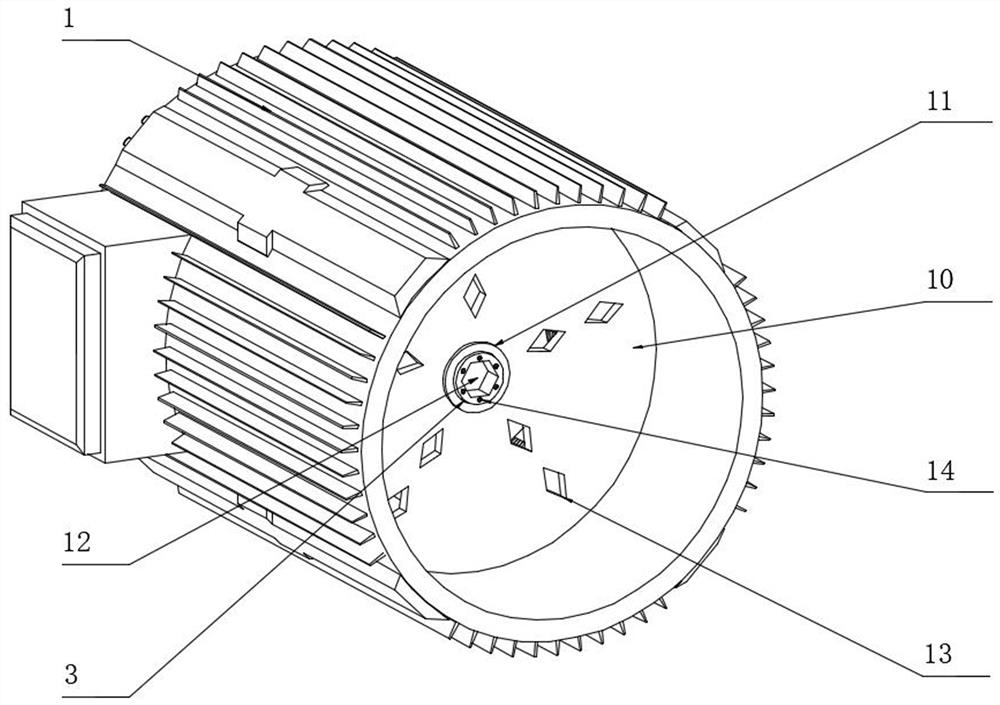

A drive motor braking mechanism for cnc machining center

ActiveCN114654286BReduce speedFast brakingDriving apparatusMaintainance and safety accessoriesControl engineeringElectric machinery

Owner:SHENZHEN JUJIANG TECH CO LTD

Radial diffuser channel pretreatment method

ActiveCN110076408AEliminate to get throughAvoid getting burnedElectrochemical machining apparatusPretreatment methodElectrolysis

The invention provides a radial diffuser channel pretreatment method. The method comprises the following steps that S21, an electrolytic machining environment is prepared; S22, a through-hole cathodeis used for carrying out vibration feeding electrolytic machining on a channel of a radial diffuser at the feeding speed of 5mm / min-6mm / min, and the channel is broken through by using a burr working section of the through-hole cathode; and S23, the through-hole cathode is used for carrying out vibration feeding electrolytic machining on the channel of at the feeding speed of 3mm / min-4mm / min, uneven allowance on the inner wall of the channel is eliminated by using an inner wall working section of the through-hole cathode. Burrs can be eliminated through the burr working section of the through-hole cathode to break through the channel, the problem that a short circuit is generated by contact between a forming cathode and burrs when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided, the uneven allowance on the inner wall of the channel can be eliminated by using the inner wall working section of the through-hole cathode, and the problem that a short circuit is generated by contact between a forming cathode and the inner wall of the channel when the forming cathode carries out vibration feeding electrolytic machining on the channel is avoided.

Owner:CHINA HANGFA SOUTH IND CO LTD

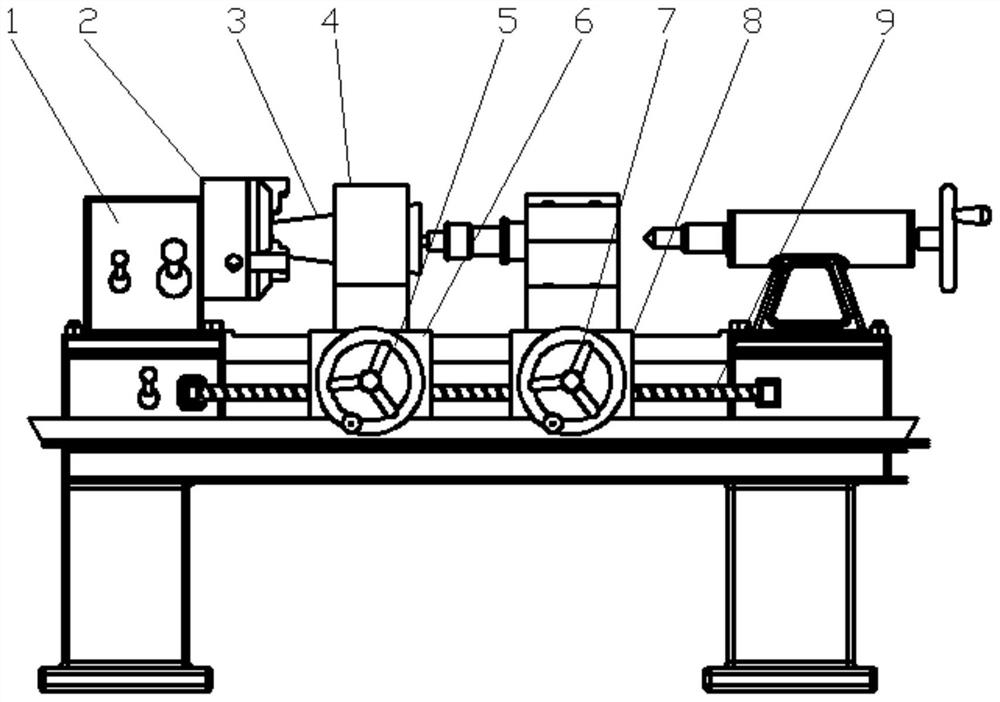

Magnetic particle grinding device and process for machining inner wall of conical part

PendingCN112123032AGuaranteed distanceGood grinding effectGrinding drivesGrinding feed controlMagnetic polesEngineering

The invention aims at providing a magnetic particle grinding device and process for machining the inner wall of a conical part. The device comprises a machine tool, an external magnetic pole device and an internal ultrasonic vibration magnetic pole device; the external magnetic pole device is arranged outside a workpiece and is capable of being driven by a first sliding table on the machine tool to move in the axial direction of the workpiece; and the internal ultrasonic vibration magnetic pole device is coaxial with the workpiece and is capable of being driven by a second sliding table on themachine tool to feed an auxiliary magnetic pole into the workpiece. According to the magnetic particle grinding device and process, finishing machining of conical inner walls can be achieved, the surface quality and the service life of the workpiece can be improved, and the grinding speed and quality are effectively improved.

Owner:UNIV OF SCI & TECH LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com