Fast molding mechanism for negative angle of die processing product

A mold processing and forming mechanism technology, applied in the field of molds, can solve the problems of difficult to accurately control the forming size and angle of parts, and difficult processing, so as to achieve the effects of high production efficiency, low force, and avoiding over-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

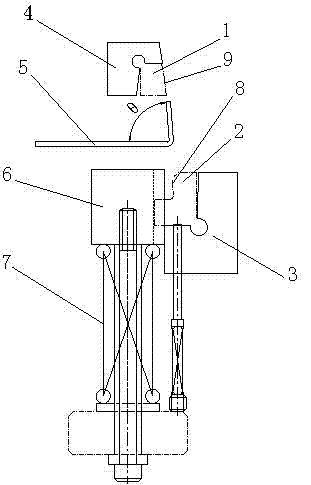

[0012] see figure 1 , the negative angle rapid prototyping mechanism of the mold processing product of the present invention comprises: upper die forming block 1, lower die forming block 2, lower die forming block swivel mechanism 3, upper die forming block swivel mechanism 4, pressing block 6 and spring Mechanism 7, the lower mold forming block 2 is located below the upper mold forming block 1 and is connected with the lower mold forming block swing mechanism 3, and the upper mold forming block 1 is connected with the upper mold forming block swing mechanism 4, the pressing block 6 is located under the upper molding block 1, the spring mechanism 7 is located under the pressing block 6 and connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com