A switching light editable laser processing system and method

A laser processing and laser technology, used in lasers, laser welding equipment, laser parts and other directions, can solve the problems of component processing accuracy, excessive processing, damage to processing components, etc., to overcome excessive processing, improve processing quality, and ensure The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0024] A switching light editable laser processing system of the present invention includes a laser emitting device, processing equipment, a monitoring module, and a control center, and the processing equipment is used to process components with laser light according to the start processing signal and the end processing signal of the control center ;Laser emitting device and processing equipment can be moved and fixedly installed. The monitoring module is used to monitor the processing equipment delay time and laser delay time, and transmit the delay time to the control center. The control center controls the laser emitting device to emit laser light or stop emitting light according to the delay time The time point to ensure that the processing time of the laser at each processing point of the component is the same.

[0025] The processing equipment delay time includes the start-up delay time, and the start-up delay time is used to record the time interval from the time when th...

specific Embodiment 2

[0037] A switching light editable laser processing system of the present invention includes a laser emitting device, processing equipment, a monitoring module, and a control center.

[0038] Before the processing equipment starts processing, the control center sends the start processing signal and the laser emission signal at the same time, and the monitoring module measures the duration of the laser emitted by the laser emission device at the start processing point, which is the opening duration delay time; after the processing is completed, the control center simultaneously Send the stop processing signal and the end laser emission signal, and measure the duration of the laser after the final processing point as the termination duration delay time.

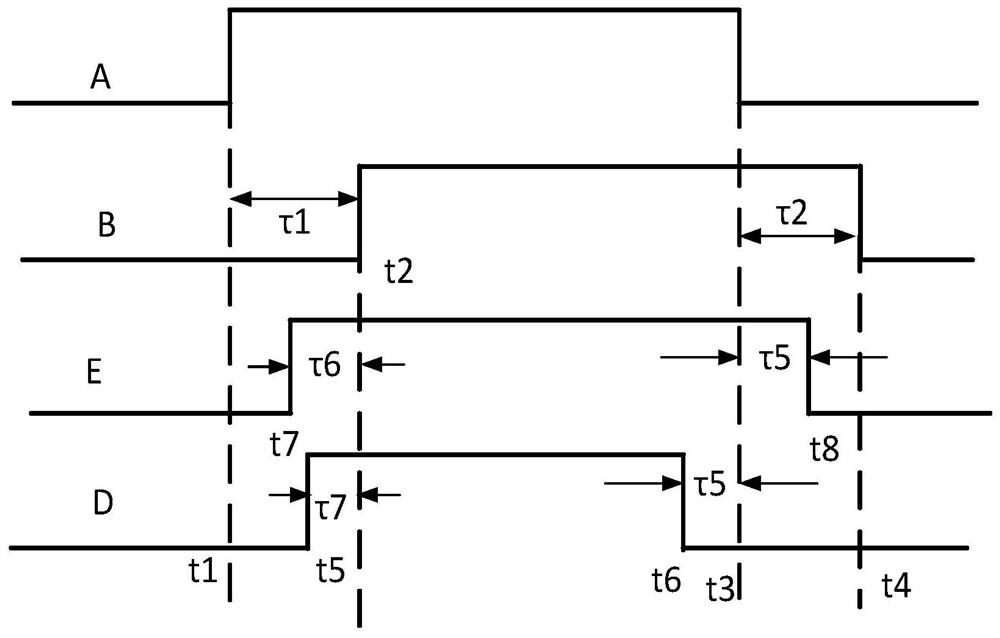

[0039] Specifically, such as figure 2 As shown, the control signal sent by the control center is shown in the A signal line in the figure, the operation sequence of the processing equipment is shown in the B signal line in the ...

specific Embodiment 3

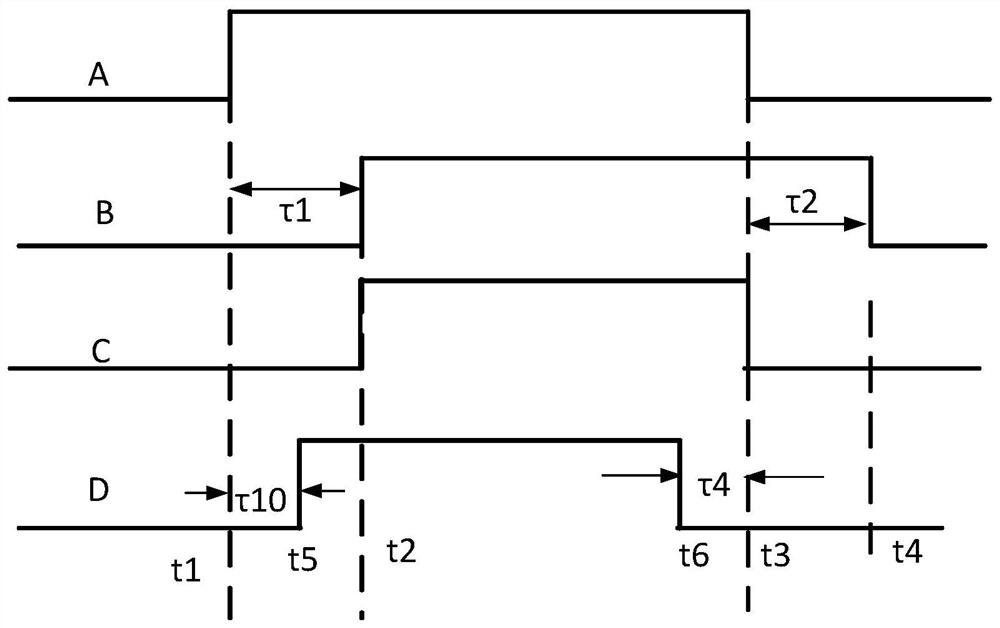

[0049] A switch light editable laser processing method of the present invention, such as figure 1 As shown, measure or calculate the start-up delay time τ1 of the laser at the starting point of the processing equipment, and the delay time τ3 of laser emission. After the start processing signal is sent, delay a start-up delay time (τ1-τ3), and control The laser is emitted, so that at time t2, the synchronization between the start of the processing equipment and the laser irradiation is realized.

[0050] Measure or calculate the termination delay time τ4 of the laser after the final processing point, and stop the delay time τ4 in advance before the t3 time before the stop processing signal is sent, that is, stop the laser emission at the t6 time, so that at the t3 time when the processing is stopped, Realize the end of laser irradiation.

[0051] The delay times in this application are all described as positive delay times, and similarly, this application is also applicable to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com