Green fresh rice green-embryo-skin-remaining processor

A technology of processing machine and fresh rice, applied in the direction of grain degermination, grain treatment, grain depodization, etc., can solve the problem of affecting the nutritional content of rice, and achieve the effect of avoiding excessive processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

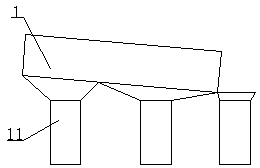

[0017] Such as figure 1 As shown, the present invention includes an inclined filter screen 1 and a multistage rice mill 11,

[0018] The inclined filter screen 1 is provided with a plurality of outlets with different calibers, and the inclined filter screen 1 is driven to rotate by a transmission.

[0019] The inlet of one group of multistage rice milling machines 11 communicates with the outlets with different calibers on the inclined filter screen 1 .

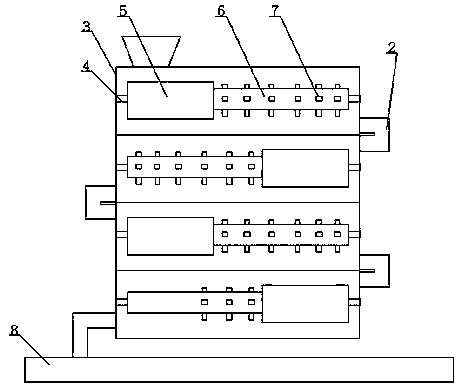

[0020] The multi-stage rice milling machine 11 comprises a plurality of rice milling machines stacked in sequence, and the upper rice milling machine communicates with the inlet and outlet of the adjacent rice milling machine through the rice bran discharge pipe 2 .

[0021] The rice milling machine includes a housing 3, a main shaft 4, a screw conveying rod 5 and a rice milling roller 6. The housing 3 is provided with an inlet and an outlet. The rod 5 and the rice milling roller 6 are arranged on the main shaft 4 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com