Magnetic particle grinding device and process for machining inner wall of conical part

A grinding device and workpiece technology, applied in the direction of grinding drive device, grinding automatic control device, workpiece feed movement control, etc., can solve the problems of poor machining accuracy, complex device structure, high installation requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below, but the implementation scope of the present invention is not limited to the following embodiments.

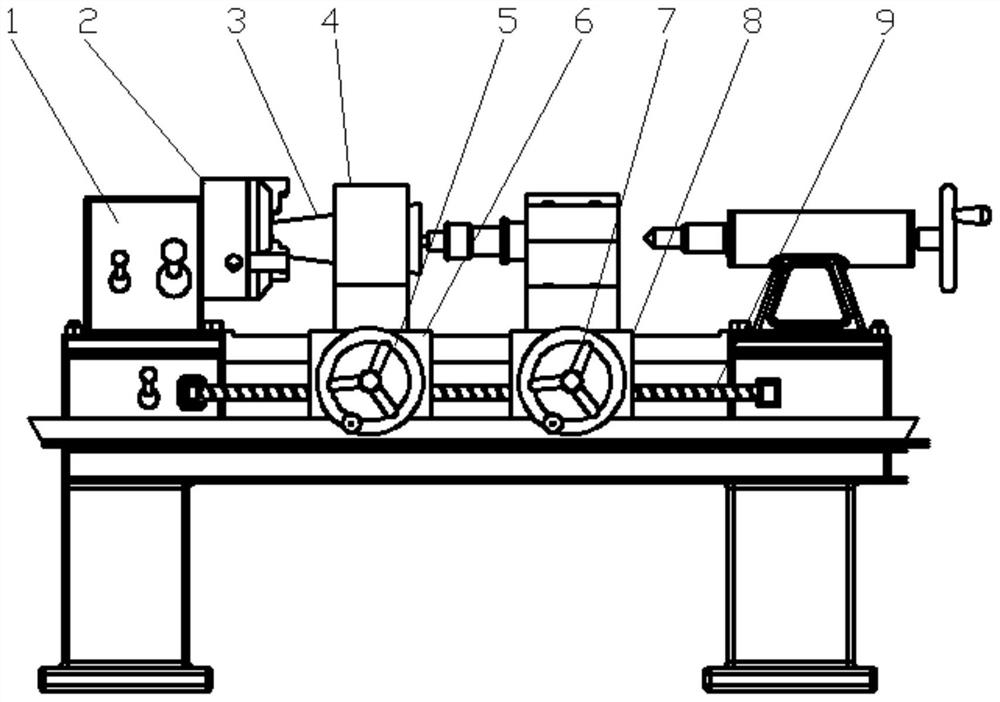

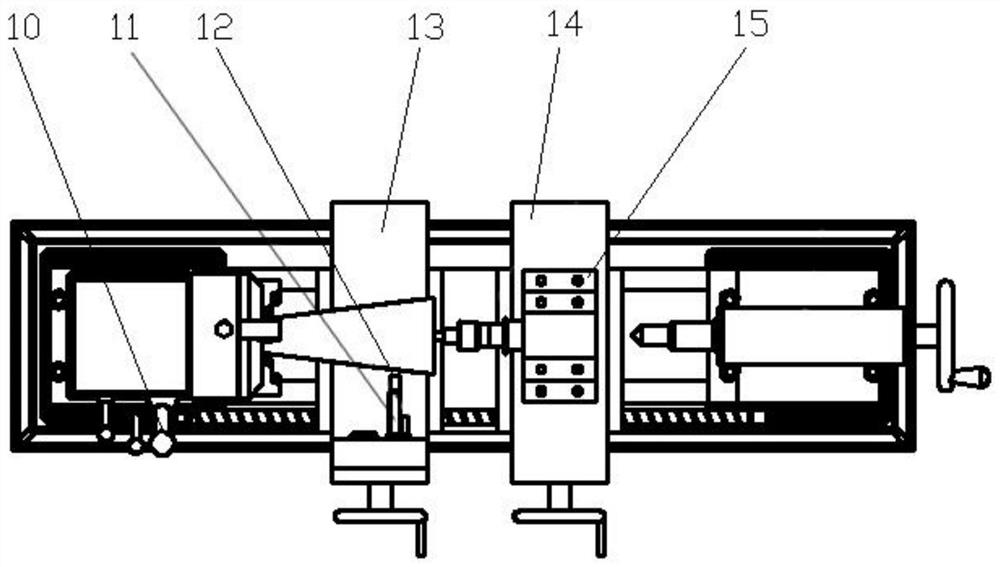

[0026] Such as Figure 1-Figure 5 As shown, a magnetic particle grinding device for processing the inner wall of a tapered part includes a machine tool 1, an external magnetic pole device, and an internal ultrasonic vibration magnetic pole device. The external magnetic pole device is arranged outside the workpiece 3 and can pass through the machine tool 1. The first sliding table 13 is driven to move axially along the workpiece 3; the internal ultrasonic vibration magnetic pole device is coaxial with the workpiece 3, and can be driven by the second sliding table 14 on the machine tool 1 to send the auxiliary magnetic pole 21 into the interior of the workpiece 3.

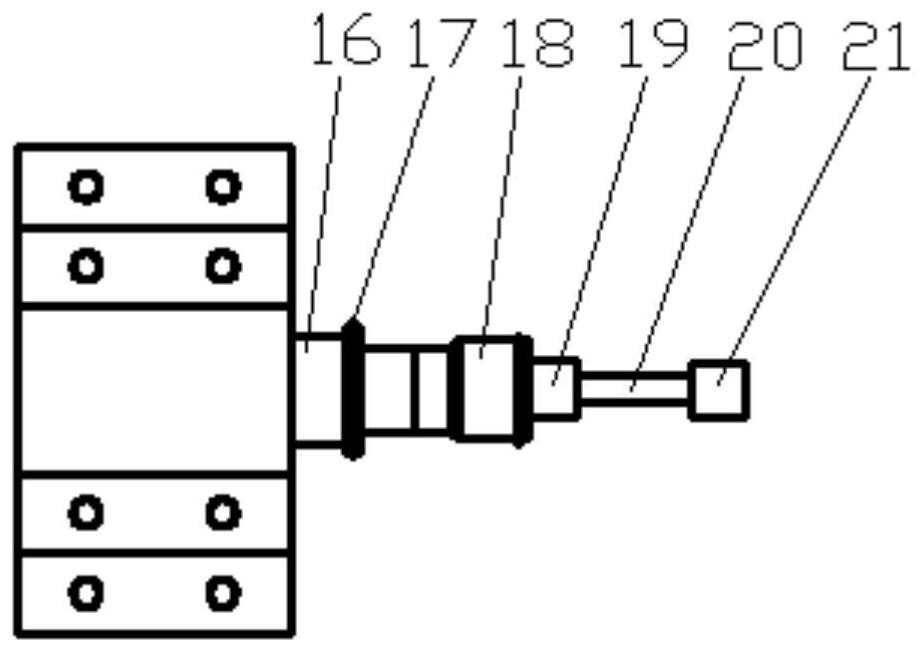

[0027] The internal ultrasonic vibration pole device includes an ultrasonic generator 16, a converter 17, a slip ring 18, a horn 19, a ball joint rod 20,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com