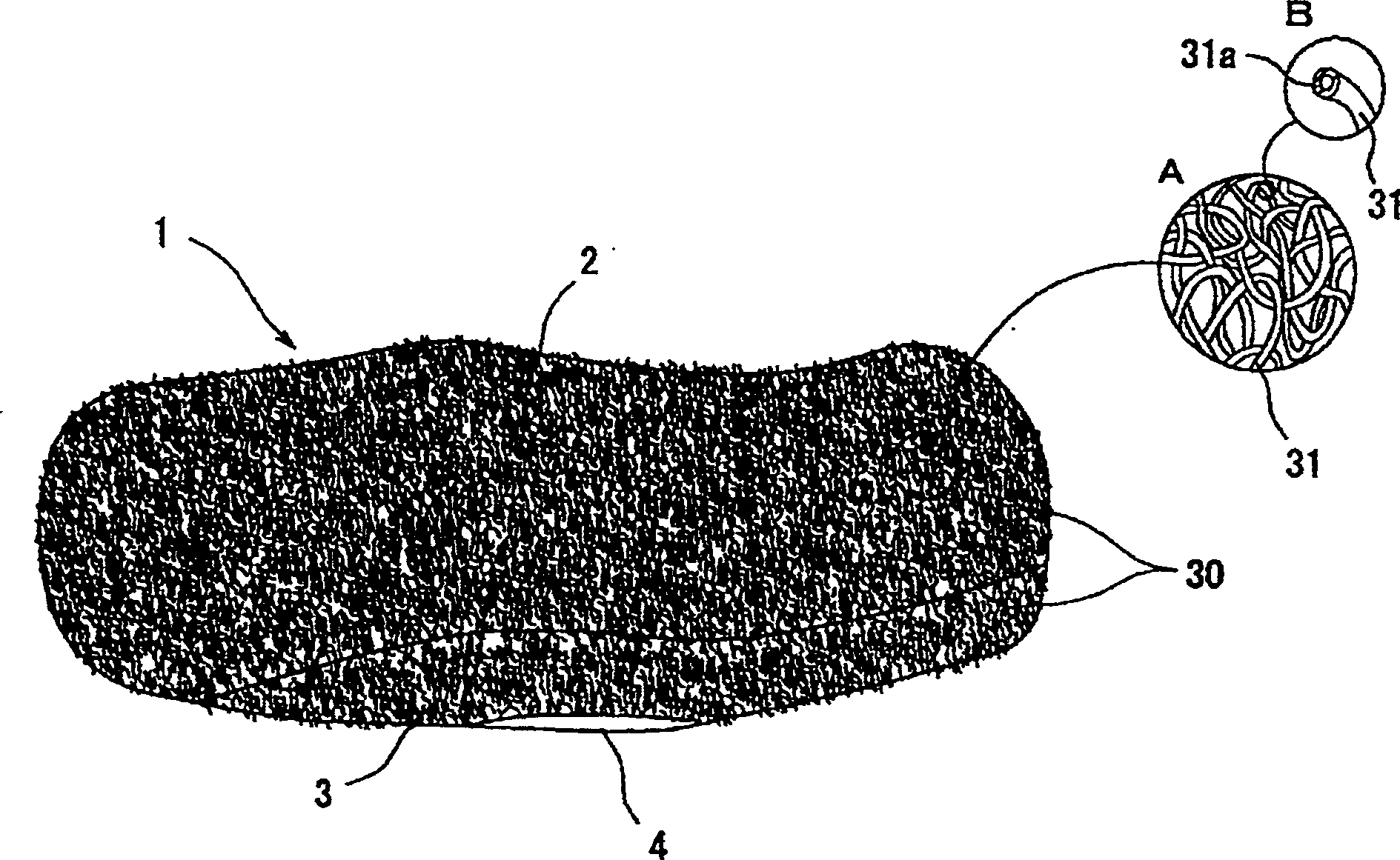

Patents

Literature

60results about How to "Small impact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Agricultural smashing machine

ActiveCN105413791ARedistribution lawImprove crushing efficiencyGrain treatmentsPulverizerAgricultural engineering

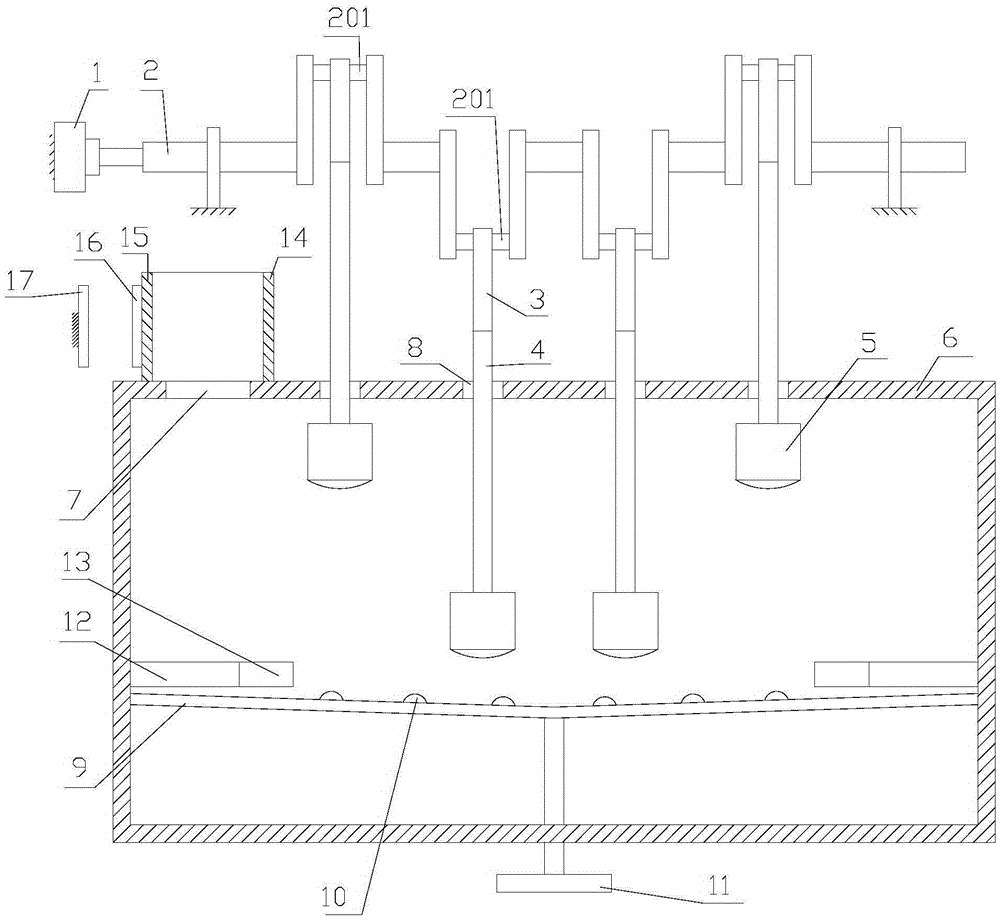

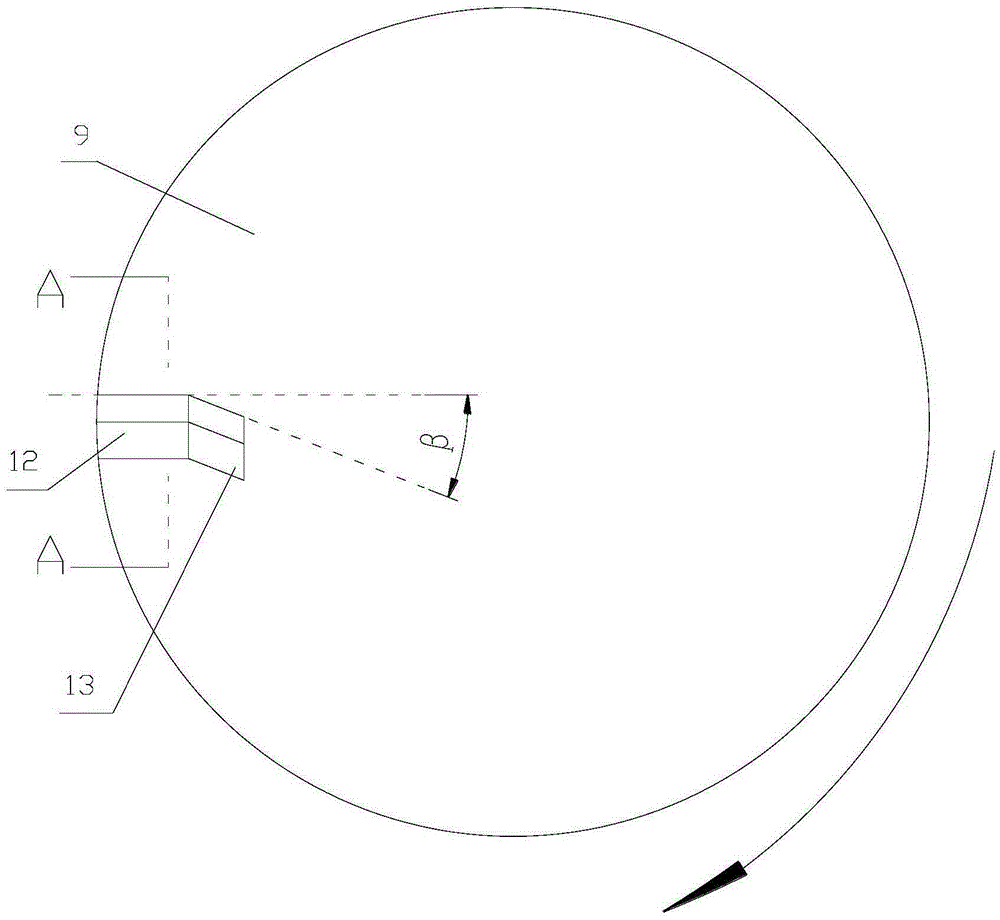

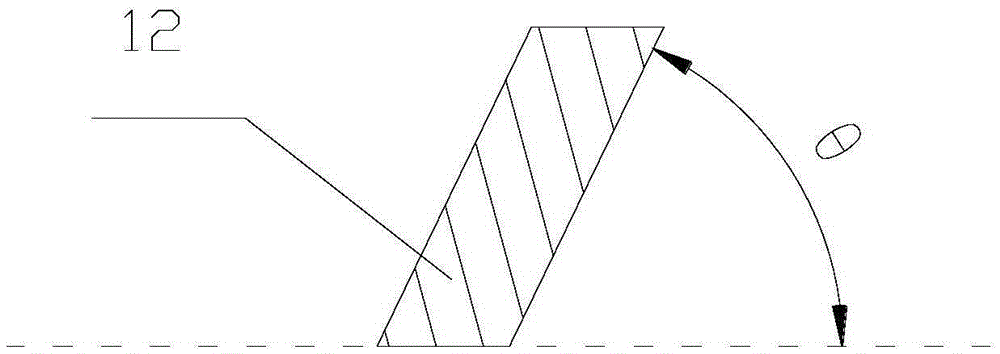

The invention discloses an agricultural smashing machine. The agricultural smashing machine comprises a driving unit, a crankshaft, N connecting pieces, N connecting rods, N striking pieces and a box; the driving unit is connected with the crankshaft in a transmission manner to drive the crankshaft to rotate; the crankshaft is horizontally arranged and comprises N connecting shaft necks; the N connecting pieces are rotationally connected with the N connecting shaft necks respectively; and one ends of the N connecting rods are rotationally connected with the N connecting pieces. The agricultural smashing machine is good in material processing effect and high in material processing efficiency.

Owner:全椒县汊河农机服务专业合作社

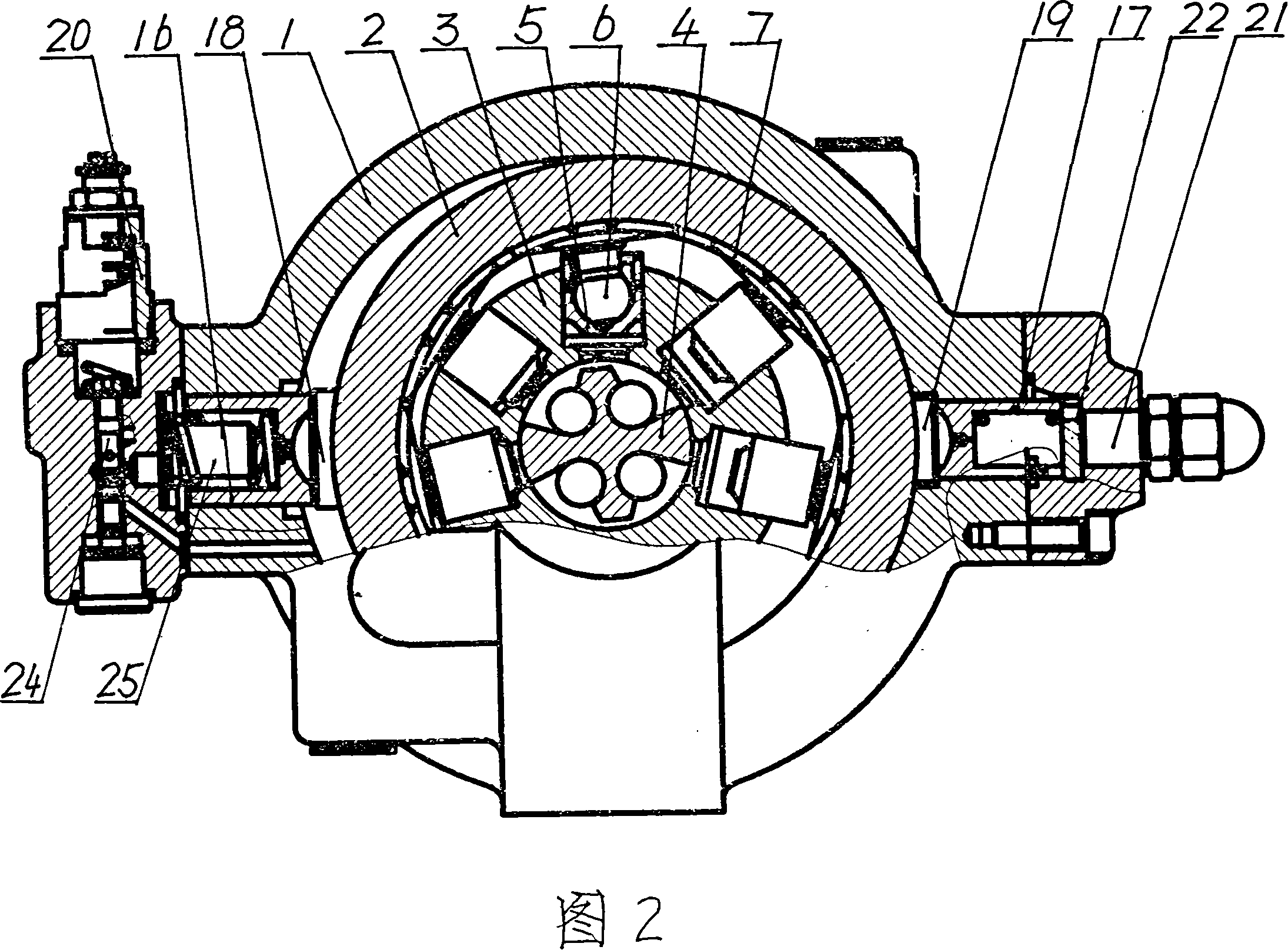

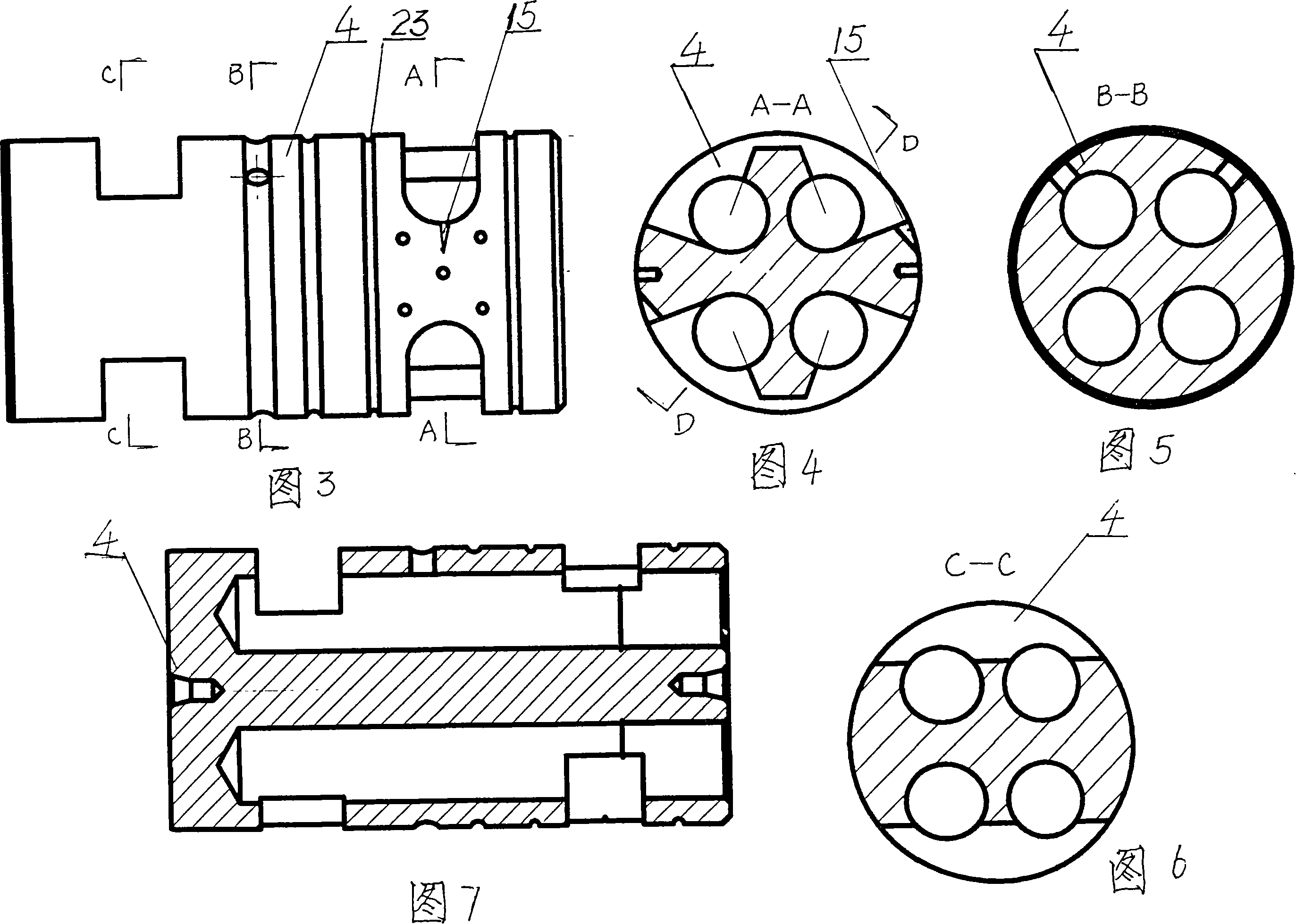

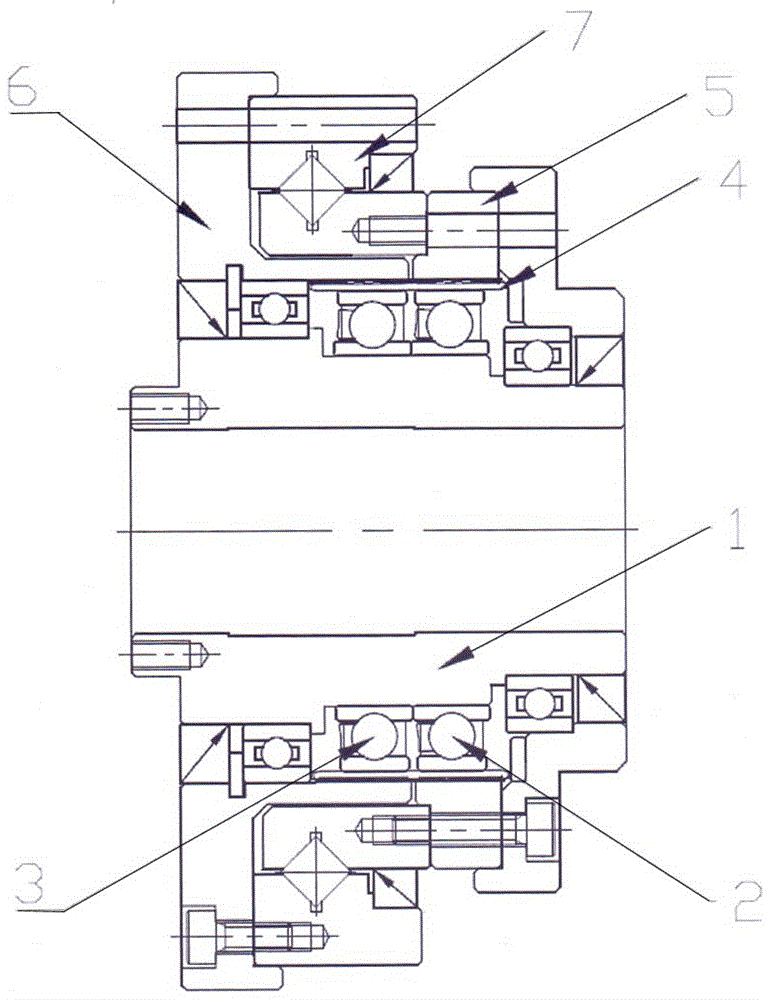

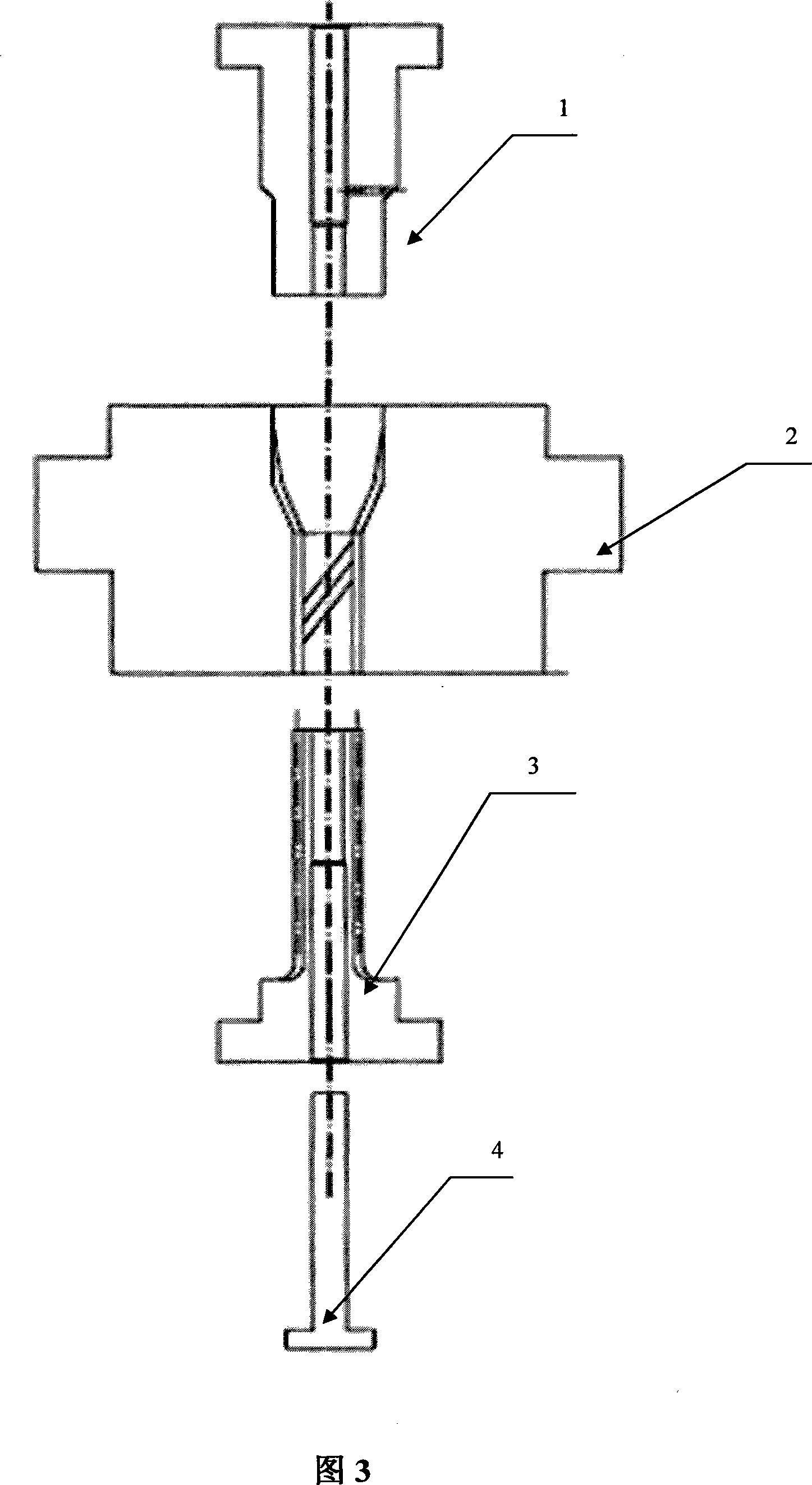

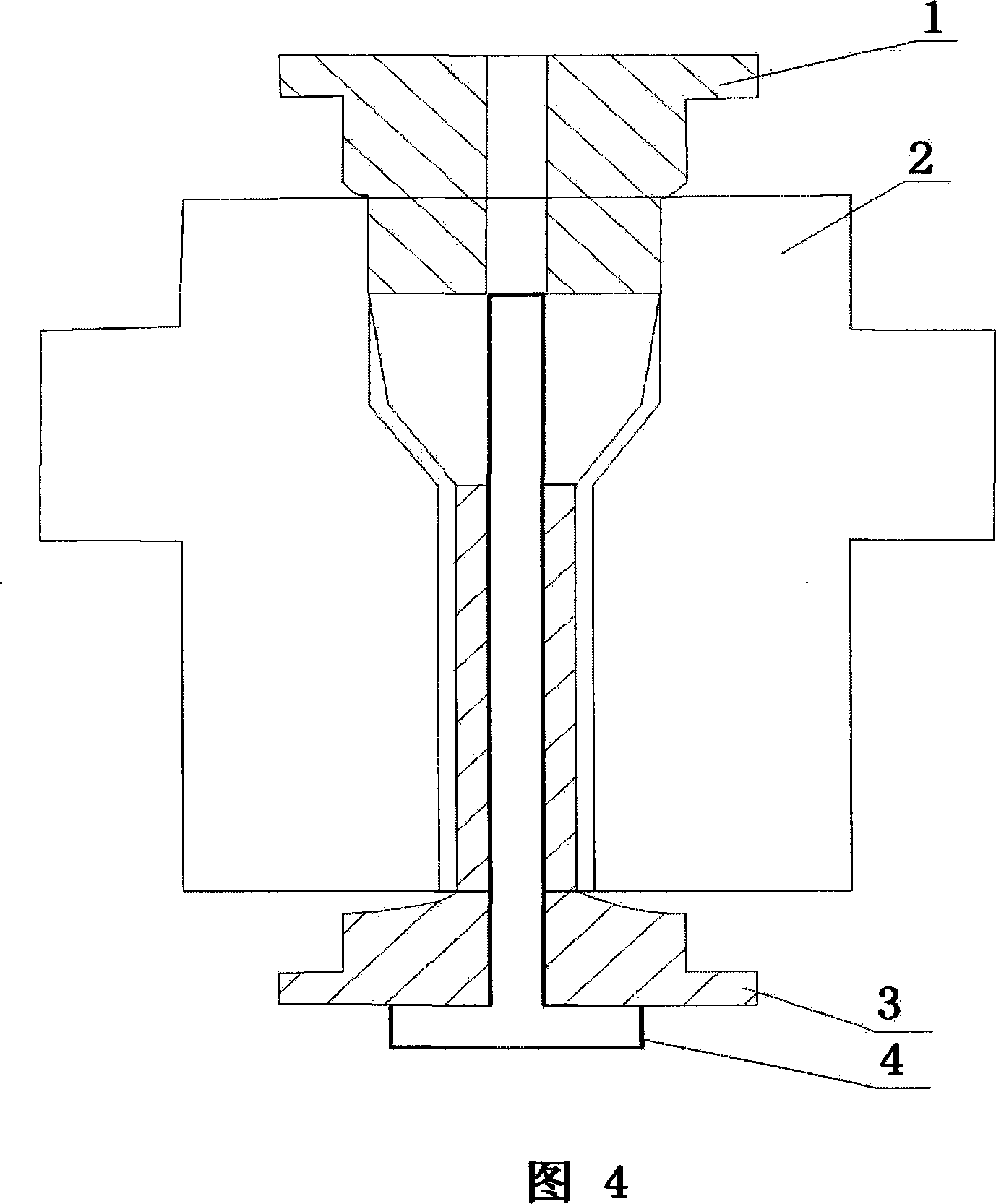

Constant-pressure variable radial-plunger pump

InactiveCN101131152ASimple structureSimple variable manipulationPositive-displacement liquid enginesMulti-cylinder pumpsLow noiseRadial piston pump

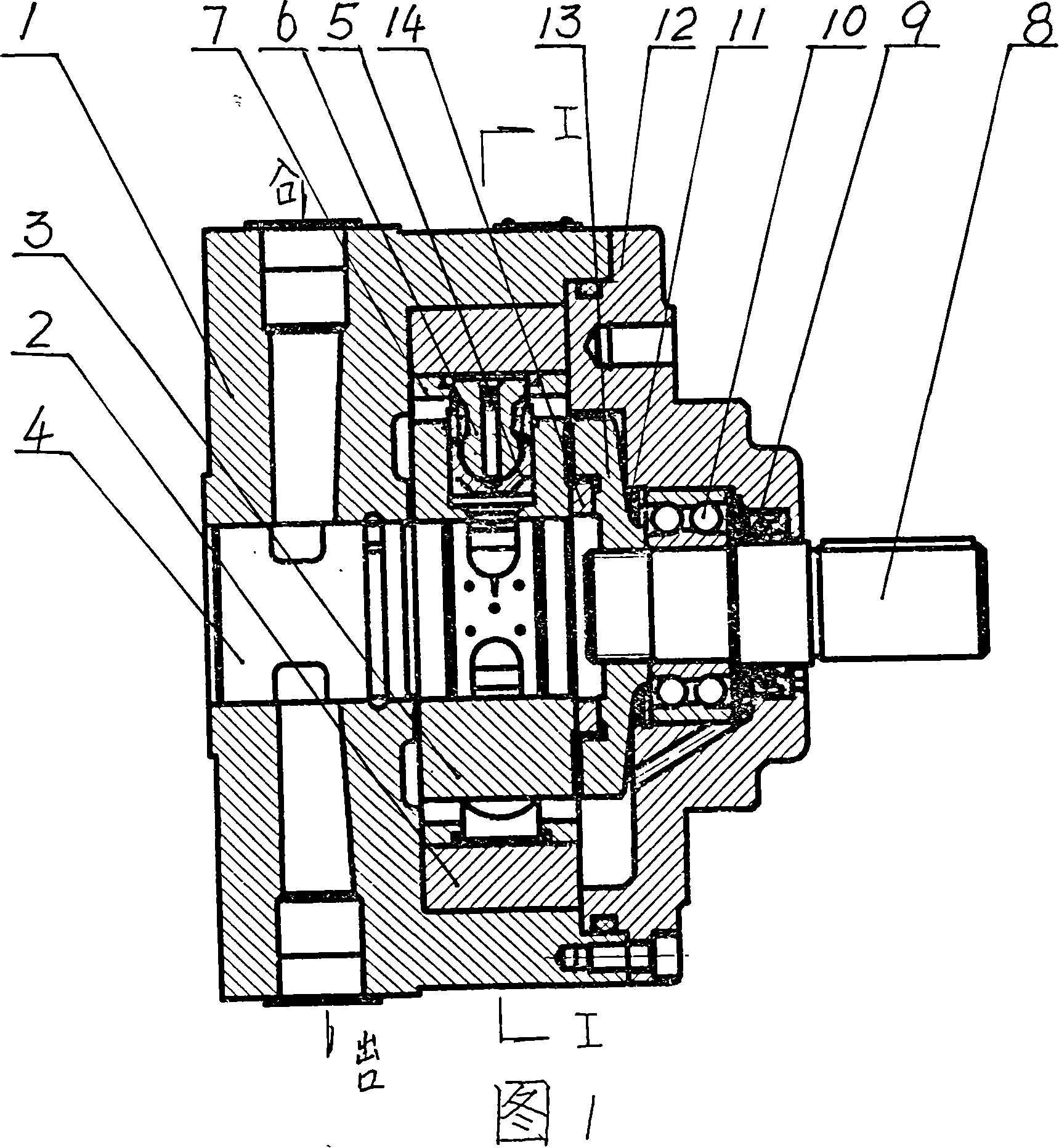

The present invention relates to one kind of constant pressure and variable displacement radial plunger pump, which has an elliptic pump shell; a stator sliding inside the shell and slide fitting to the back ring; a rotor on the flow distributing shaft and with plungers inside radial plunger holes and link rods inside the plungers; a driving shaft connected through coupling to the rotor; a flow distributing shaft with four blind holes; a large and a small control plungers pushing the stator through sliding blocks; a hand driven constant pressure and variable displacement valve to regulate oil pressure with an inner valve core to control the large control plunger and a screw bolt to control the small control plunger so as to control the eccentric distance between the stator and the rotor and determine the oil displacement. Rotating the rotor by one cycle completes once oil sucking and oil discharging. The present invention has simple structure, small size, low noise and other advantages.

Owner:董桂敏

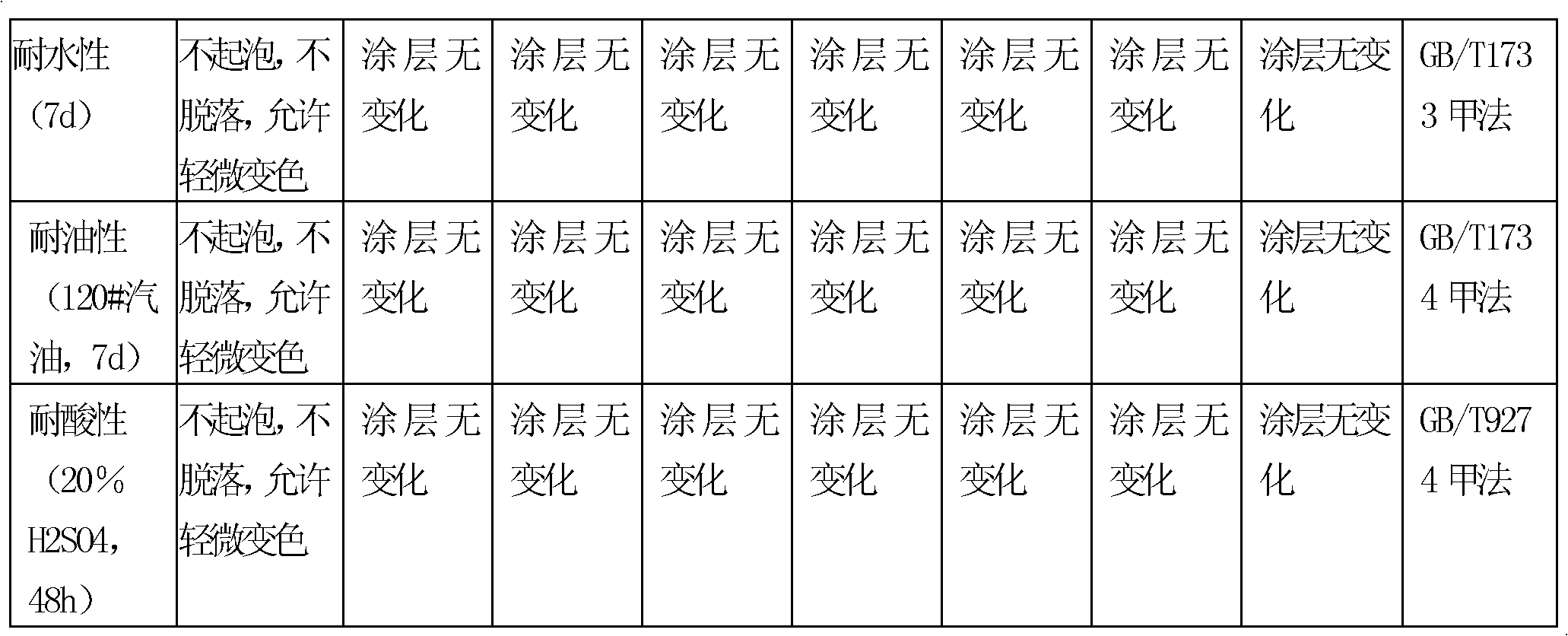

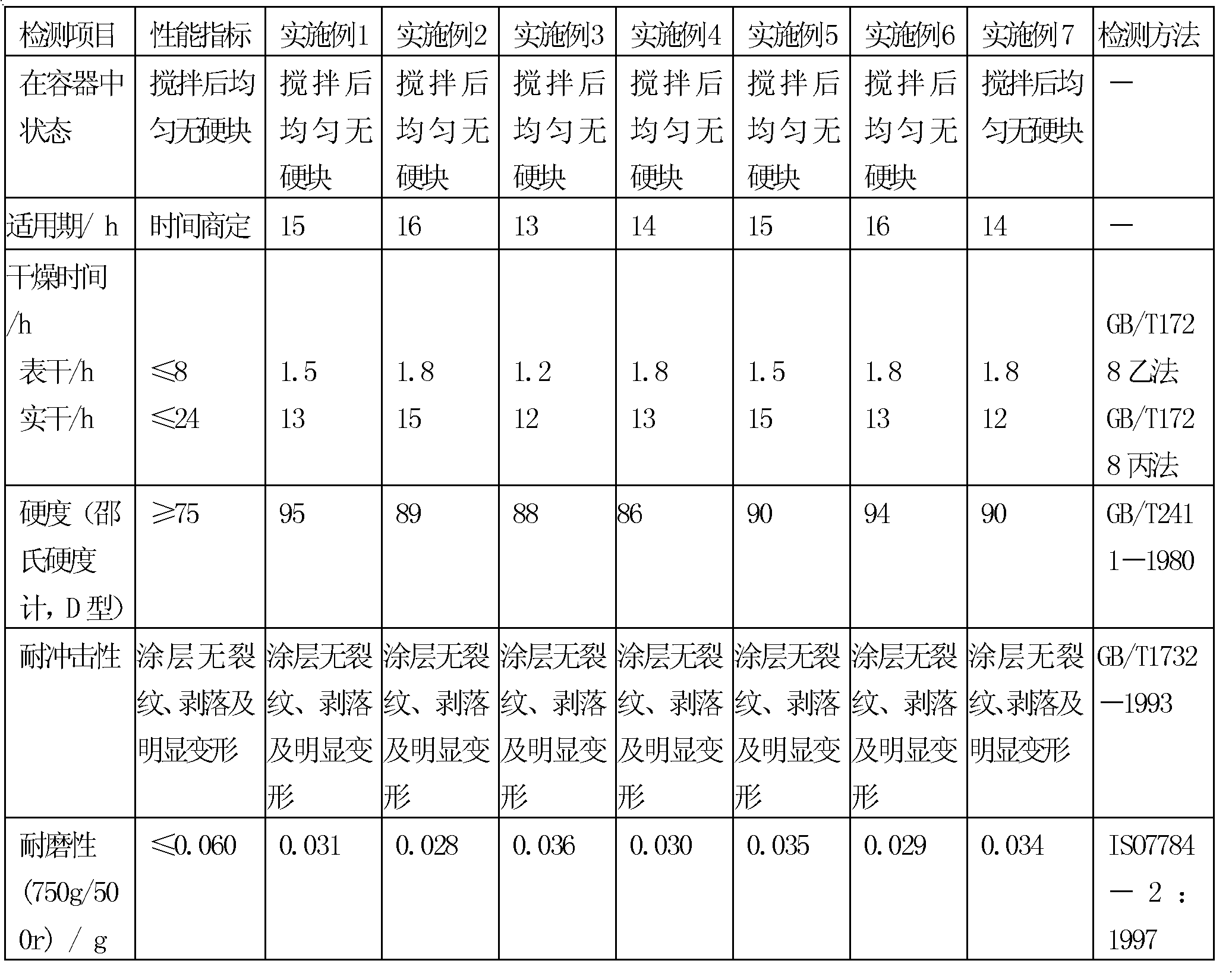

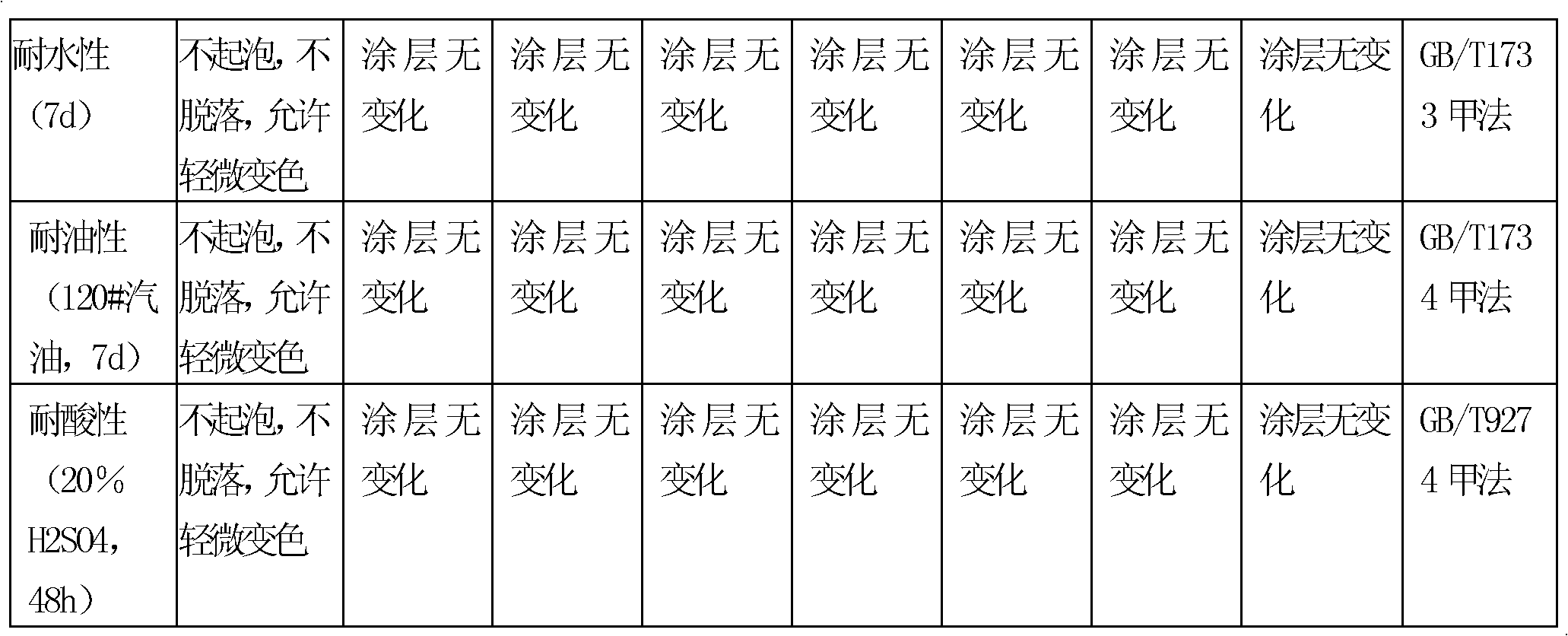

Solvent-free polyurethane wear-resistant terrace paint and preparation method thereof

The invention relates to a solvent-free polyurethane wear-resistant terrace paint and a preparation method thereof. The paint is composed of a component A and a component B, wherein the component A comprises the following components by mass parts: 60-80 parts of solvent-free hydroxyl-terminated epoxy resin, 1-13 parts of coloring pigment, 15-22 parts of wear-resistant filling material, 0.2-0.5 part of defoaming agent, 0-0.3 part of drier and 3-5 parts of oxazolidine dewatering agent; and the component B is 100 mass parts of solvent-free isocyanate-terminated prepolymer. When the paint is used, the component A finished product and the component B finished product are mixed and stirred uniformly at a ratio of 3:1 to obtain the solvent-free polyurethane wear-resistant terrace paint. According to the invention, the terrace paint can be cured at low temperature, is free of volatile organic compounds in the system, is low in residual isocyanate monomer content, can improve coating performance, and is suitable for terrace decoration and protection with wear-resistant and dustless requirements in plants, shops, guesthouses, gymnasia, stations, parking lots and other places.

Owner:CHANGZHOU GUANGHUI CHEM

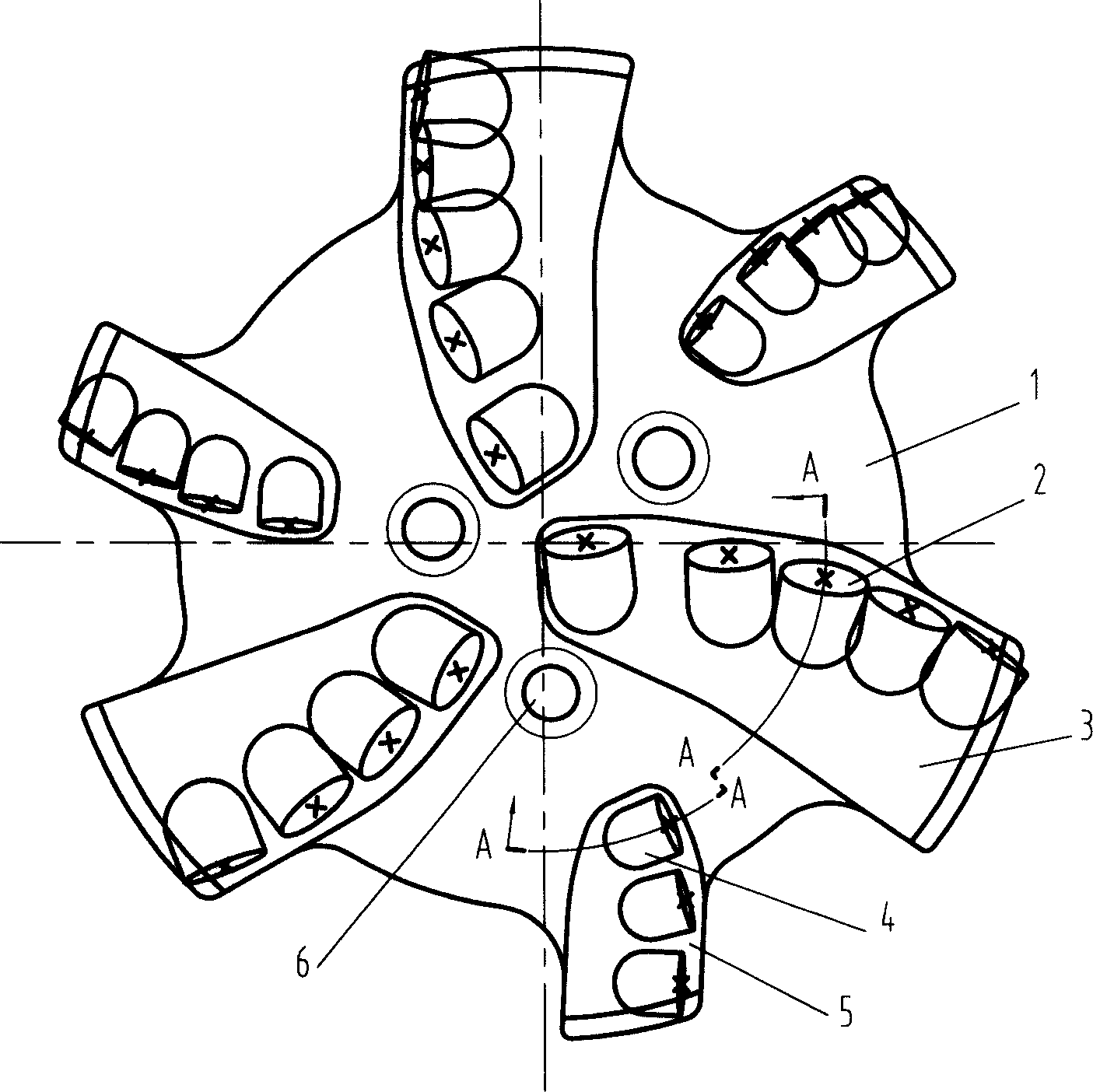

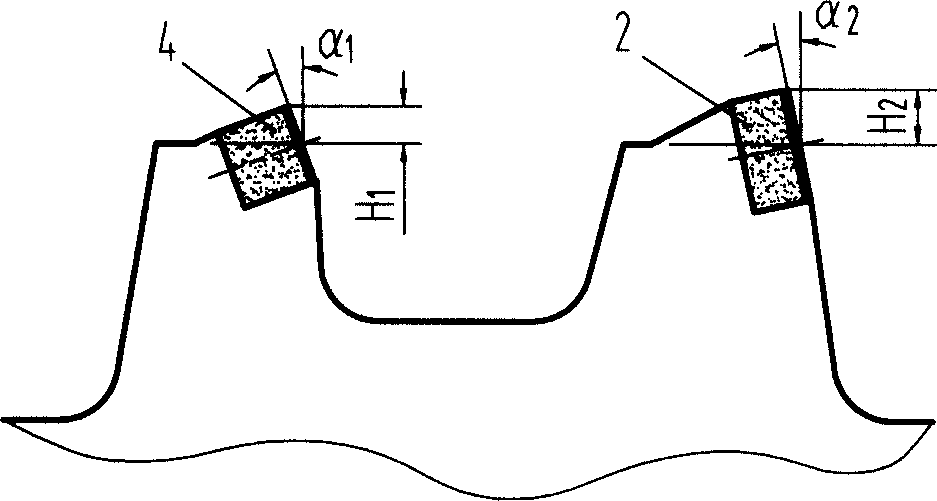

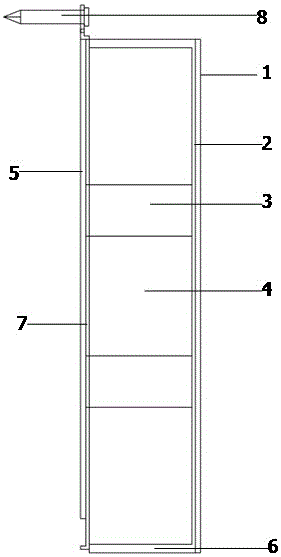

PDC bit for petroleum and natural gas drilling

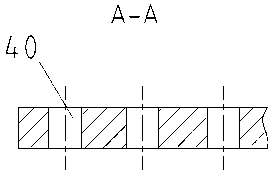

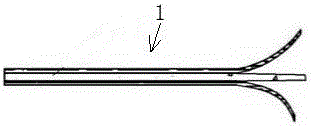

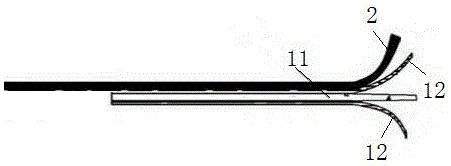

InactiveCN1763349AReduce the packing densitySmall impact resistanceDrill bitsPetroleumPetroleum engineering

The invention discloses an oil-natural gas drilling PDC drill bit, which comprises the following parts: drill body, main knife-wing, second knife-wing, big diameter PDC cutting part, small diameter PDC cutting part and nozzle, wherein the main knife-wing and second knife-wing appear in pairs and interseparate upwards on the drill; big diameter PDC cutting part is fixed on the main knife-wing and small diameter PDC cutting part is fixed on the second knife-wing; the thickness and back inclination angle of big diameter PDC cutting part are less than the small diameter PDC cutting part's; the outcropping height of big diameter PDC cutting part is higher than small diameter PDC cutting part's. The structure can drill in the alternative hard-and-soft formation effectively.

Owner:SHENGLI PETROLEUM ADMINISTRATION BUREAU DRILLING TECH ACAD SINOPEC

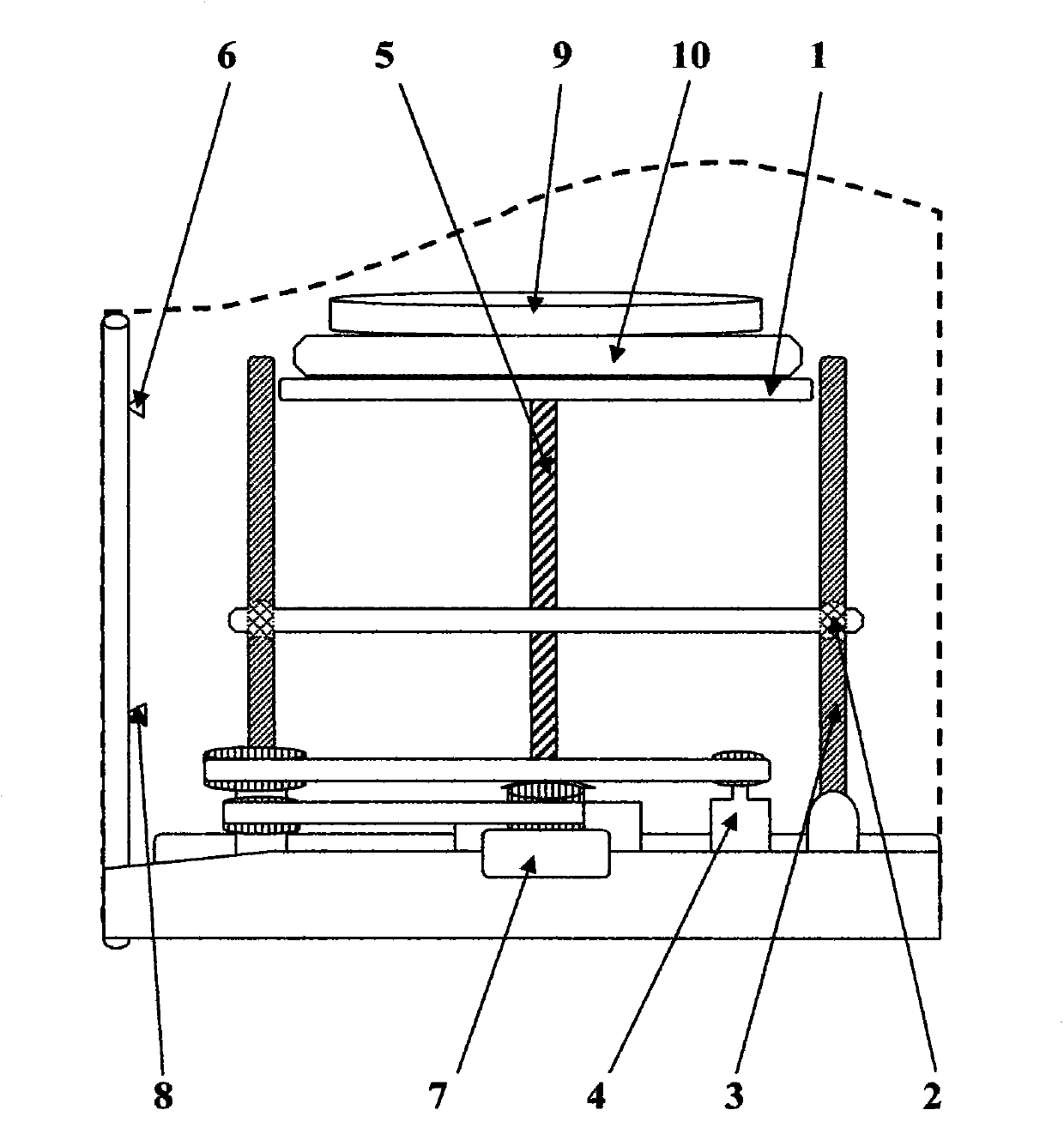

Harmonic speed reducer of improved structure

The invention discloses a harmonic speed reducer with an improved structure, which includes a cross roller bearing, an elliptical wave generator, a flexible bearing mounted on the elliptical wave generator, a circular flexible wheel installed on the flexible bearing, and an outer flexible wheel rigid wheel; the flexible bearing is a cylindrical roller flexible bearing. The invention has a reasonable structure, can greatly increase the output torque of the double rigid wheel harmonic reducer, greatly improve the load capacity and impact resistance of the harmonic reducer, and reduce the processing cost of the flexible bearing and the assembly difficulty of the harmonic reducer.

Owner:上海鑫君传动科技有限公司

Polypropylene film and multilayered laminate

InactiveCN1384848AImprove balanceReduce viscositySynthetic resin layered productsDomestic containersPolymer sciencePolyolefin

The polypropylene film of the present invention satisfies the following formula: TM≥12.5×HST-900, where TM is the tensile modulus (MPa), and HST is the heat-sealing temperature (°C). The polypropylene film has a good balance between tensile modulus and heat sealing temperature, is less tacky, and has excellent processability, clarity and impact resistance. The invention also discloses a multi-layer polyolefin resin laminated material, wherein at least one outermost layer is made of the above-mentioned polypropylene film. The laminate has a good balance between tensile modulus and heat sealing temperature, is less tacky, and has excellent slip and antiblock properties.

Owner:IDEMITSU KOSAN CO LTD

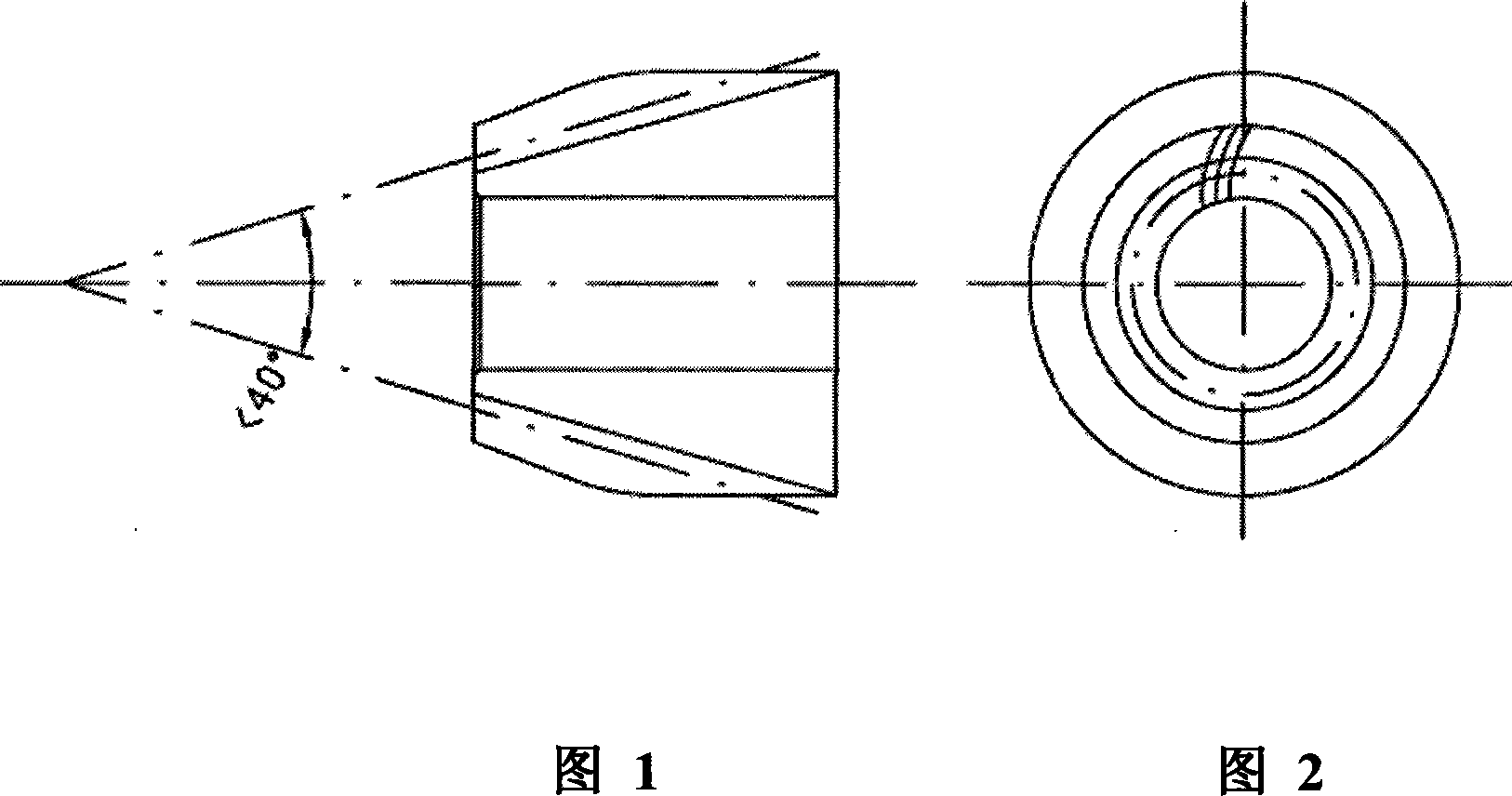

Method for manufacturing small spiral bevel gear

The invention provides a manufacture method for a small spiral bevel gear. The method prepares a screw bevel gear with a taper angle less than 40 degrees through one time sintering, overcomes the detects existed in the exiting processing technique for the small spiral bevel gear and is suitable for power metallurgy manufacture, and has the advantages of convenient and simple technique as well as low cost. The invention uniformly mixes iron powder, alloy powder and suitable lubricant according to a certain proportion, spirally pressing and spirally depanning in a master form closed cavity die space, acquires the screw bevel gear with a taper angle less than 40 degrees through one time pressing and then sinters in a sintering furnace under 1120 DEG C with a protection atmosphere of cracked ammonia or nitrogen based atmosphere. The gear acquired through the technique has the advantages of simple structure, low cost and good batch consistence, etc., and acquires the screw bevel gear with a taper angle less than 40 degrees through one time pressing.

Owner:陆海雷

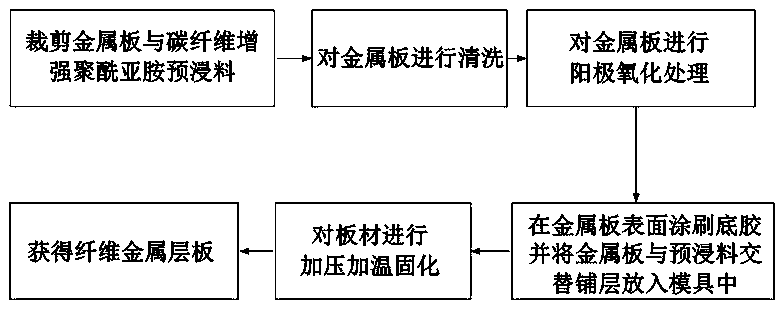

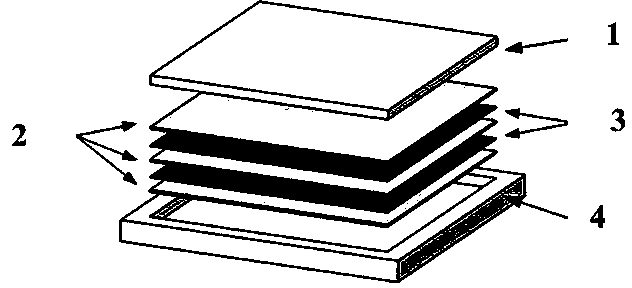

Preparation method of carbon fiber reinforced polyimide fiber metal laminate

InactiveCN104191796AExcellent high temperature and fatigue resistanceEasy to operateLaminationLamination apparatusFiber metal laminateAnodic oxidation

The invention discloses a preparation method of a carbon fiber reinforced polyimide fiber metal laminate, belonging to the technical field of composite materials. The preparation method of the carbon fiber reinforced polyimide fiber metal laminate comprises the following steps: cutting a metal plate and a carbon fiber reinforced polyimide prepreg to reach required sizes; cleaning the metal plate; performing anode oxidation on the metal plate; painting a primer on the surface of the processed metal plate and alternatively spreading and placing the metal plate coated with the primer and the prepreg in a mould, warming and pressurizing the spread metal plate and prepreg for being cured; and after curing is ended, naturally cooling to obtain the carbon fiber reinforced polyimide fiber metal laminate. The carbon fiber reinforced polyimide fiber metal laminate prepared by adopting the preparation method has excellent characteristics of high temperature resistance and fatigue resistance, has the advantages of corrosion resistance, inflame retardance, impact resistance and the like, and can be widely applied to the aerospace field; the cost of the carbon fiber reinforced polyimide fiber metal laminate is far lower than that of a carbon fiber reinforced composite material.

Owner:JIANGSU CHENGFEI PRECISION ALLOY +1

A kind of preparation method of high energy rare earth powder alloy electric contact material

The invention relates to a method for producing an electrical contact material, particularly relates to a method for producing a high-energy rare earth powder alloy electrical contact material. According to the technical scheme provided by the invention, the method for producing a high-energy rare earth powder alloy electrical contact material is characterized by comprising the following steps of: firstly, completely mixing and stirring alumina powder, silver powder, lanthanum powder, graphite powder, molybdenum powder, yttrium powder, boron powder and nickel copper powder; secondly, using anoil press to squeeze and mold the powder, and then sintering the squeezed and molded object into a vacuum high-temperature furnace and then cooling; thirdly, burning the molded object in a high-temperature furnace, then taking out and squeezing the burnt object into a panel shape by using a die on the oil press, and then cooling with cold water, and finally using a machine tool to punch the cooled object into a contact. The invention overcomes disadvantages of the prior art and provides the method for producing an environment-friendly high-energy rare earth powder alloy electrical contact material with low silver content, impact resistance, corrosion resistance, antioxidation, low resistance and good electrical conductivity.

Owner:温州银泰合金材料有限公司

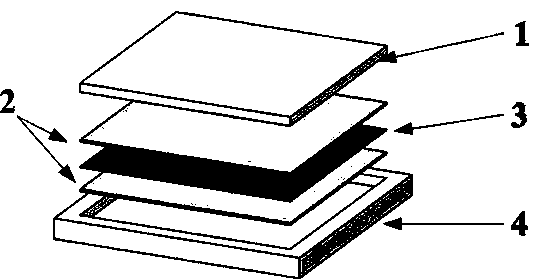

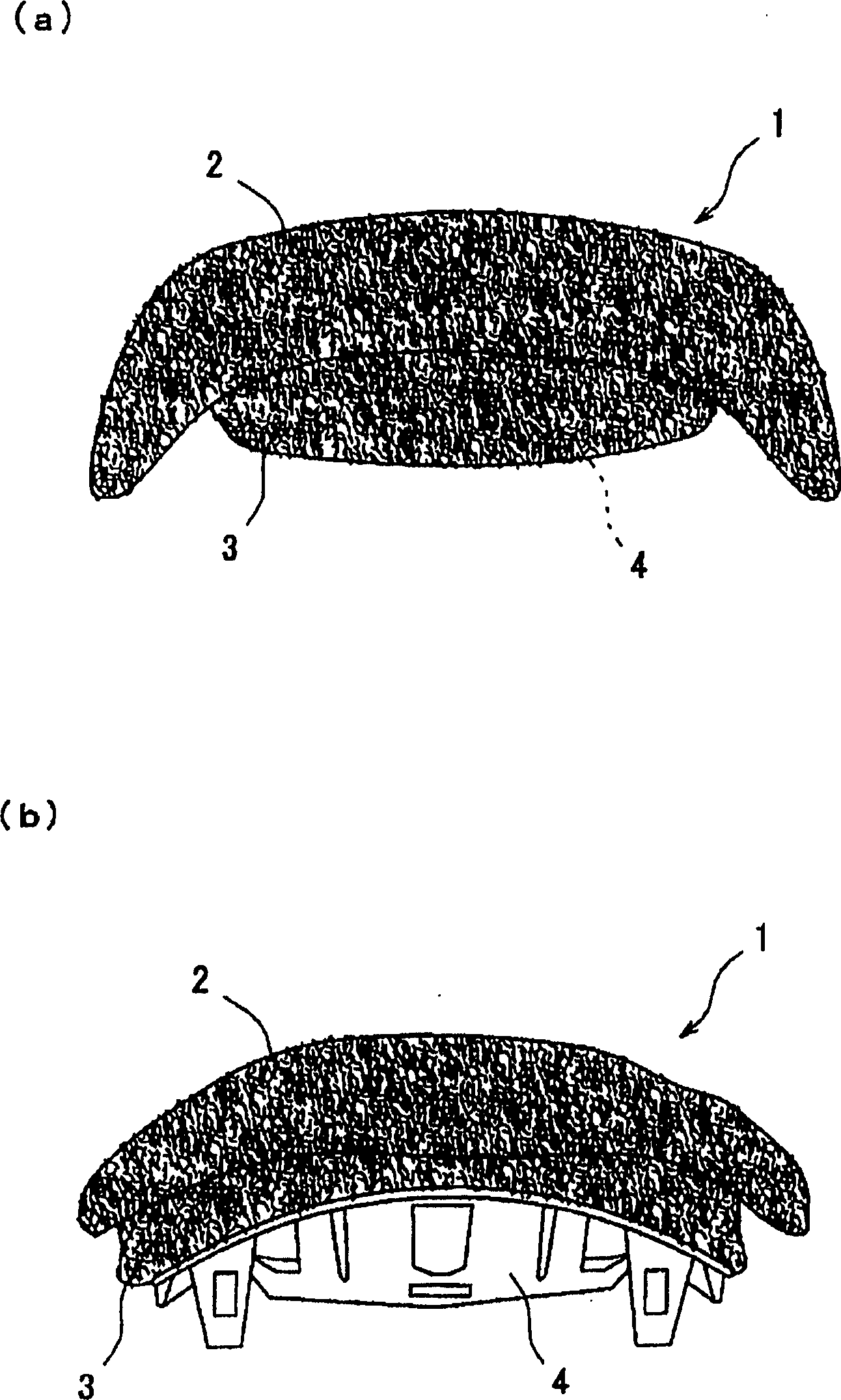

Cushion material formed of spring-structured resin-molded product, manufacturing method thereof, and mold used therefor

InactiveCN1819788ASimple molding processIncrease freedomUpholstery manufactureStuffed mattressesLoad resistanceEngineering

A cushion material formed of a spring-structured resin- molded product and a manufacturing method for the cushion material requiring less charge for processing, the cushion material being recyclable, high in the degree of freedom of shape and size, low in cost, low in sink, making it difficult for a user to get tired even if the user uses it for a long period, excellent in impact resistance and load resistance, and suitable for those on which persons seat, sleep, or ride such as seats for cars, motorcycles, bicycles, electric cars, and airplanes, saddles for horse riding, chairs, sofas, and beds.

Owner:AIN ENJINIARINGU

Preparation method of polyether-ether-ketone suitable for 3D printing

ActiveCN107383293AReduce molecular chain entanglementImprove uniformityAdditive manufacturing apparatusSolventHydroquinone Compound

The invention belongs to the technical field of macromolecular synthesis and particularly discloses a preparation method of polyether-ether-ketone suitable for 3D printing. The preparation method comprises the following steps: by taking sodium carbonate and potassium carbonate as a reaction condensating agent, hydroquinone and 4,4-diflouro diphenyl ketone as raw materials and diphenyl sulfone as a solvent, performing a temperature-raising temperature; and then performing cooling, crystallizing and impurity removal and drying to obtain the polyether-ether-ketone. In the reaction process, the solvent is excessive, and the salifying process is stable and controllable in reaction; the problem of winding the molecular chains is reduced by means of ultrasonic treatment, and the uniformity of a product is improved; the flowability of the polyether-ether-ketone product is improved, and the processing property is excellent; and performances such as strength, impact resistance, corrosion resistance, acid and alkali resistance, dimensional stability, adhesion and the like are improved.

Owner:YIBIN TIANYUAN GRP CO LTD +1

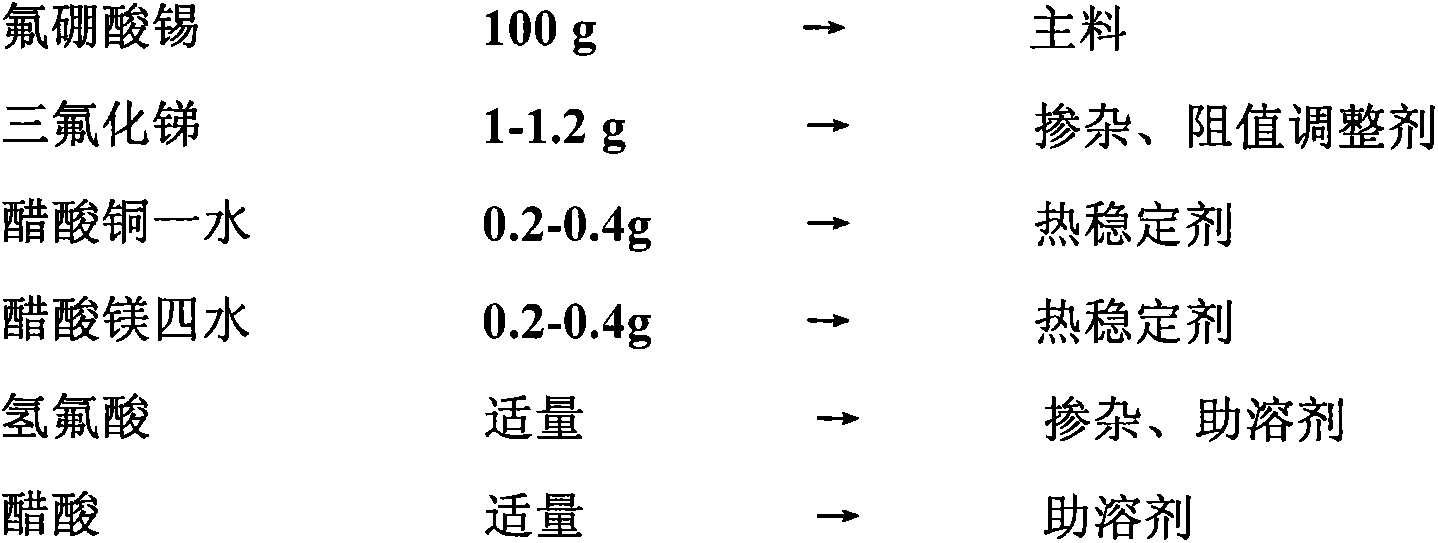

Pollution-free manufacturing method for surface electric heating elements

InactiveCN103716925AHigh electrothermal conversion rateSmall thermal inertiaOhmic-resistance heatingMagnesium Acetate TetrahydrateFluoroboric acid

A pollution-free manufacturing method for surface electric heating elements is characterized in that a formula of a surface modification solution comprises, by weight, 100g of stannous fluoroboric acid, 1-1.2g of antimony trifluoride, 0.2-0.4g of cupric acetate monohydrate, 0.2-0.4g of magnesium acetate tetrahydrate, a proper amount of hydrofluoric acid and a proper amount of acetic acid, and 100-500ml of distilled water. The pollution-free manufacturing method for the surface electric heating elements comprises the steps of (1) preparing the surface modification solution, wherein the distilled water is acidized through the acetic acid, the stannous fluoroboric acid, the cupric acetate monohydrate and the magnesium acetate tetrahydrate are weighed, stirred and melted in the acidized distilled water respectively, antimony trifluoride is quickly weighed, stirred and added in the acidized distilled water, the mixture is stirred, and all the solutions are mixed evenly, sealed and stored at a shady, cool and ventilating place for use; (2) cleaning base materials; (3) feeding the base materials into a surface modification furnace which is 550-650 DEG C to carry out surface modification on the base materials; (4) brushing silver paste at proper positions of radiant faces, and carrying out mechanical wire leading; (5) powering on to carry out aging by using voltages 1.25 times using voltages. The pollution-free manufacturing method for the surface electric heating elements is suitable for manufacturing the pollution-free surface electric heating elements.

Owner:信跃珍

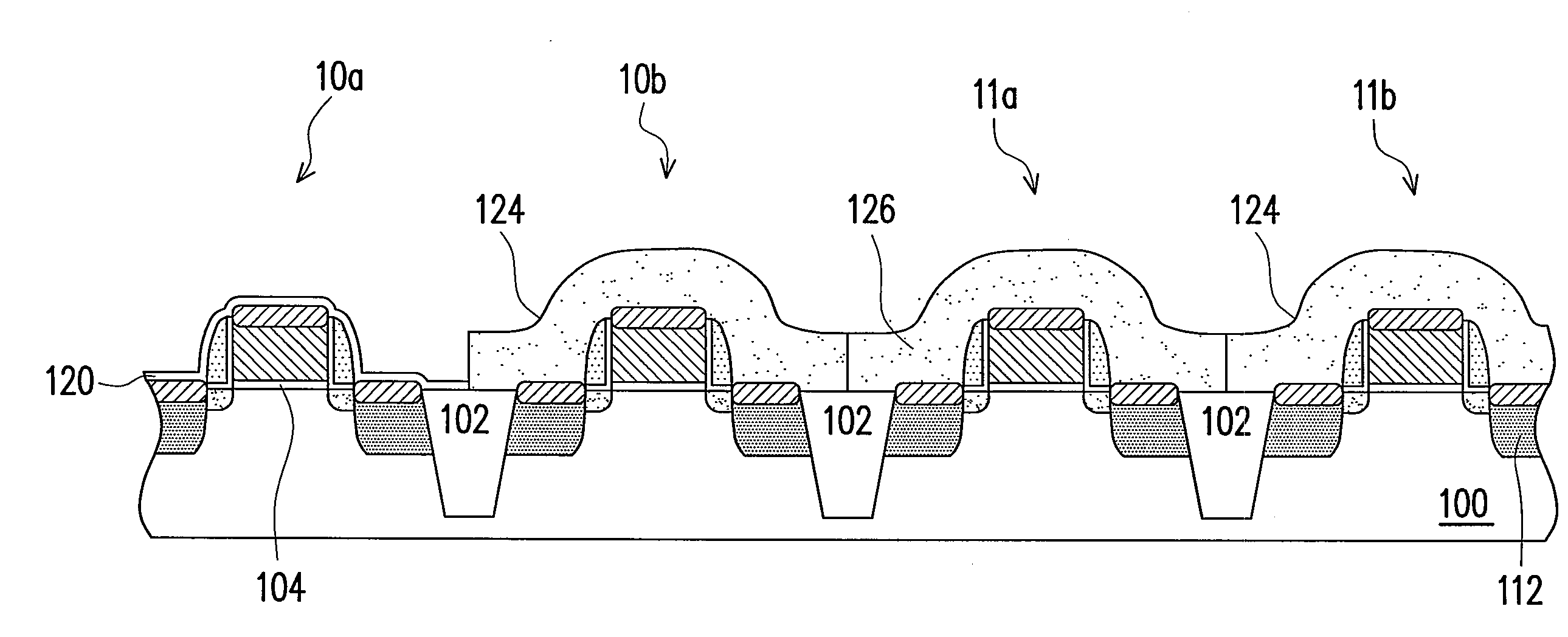

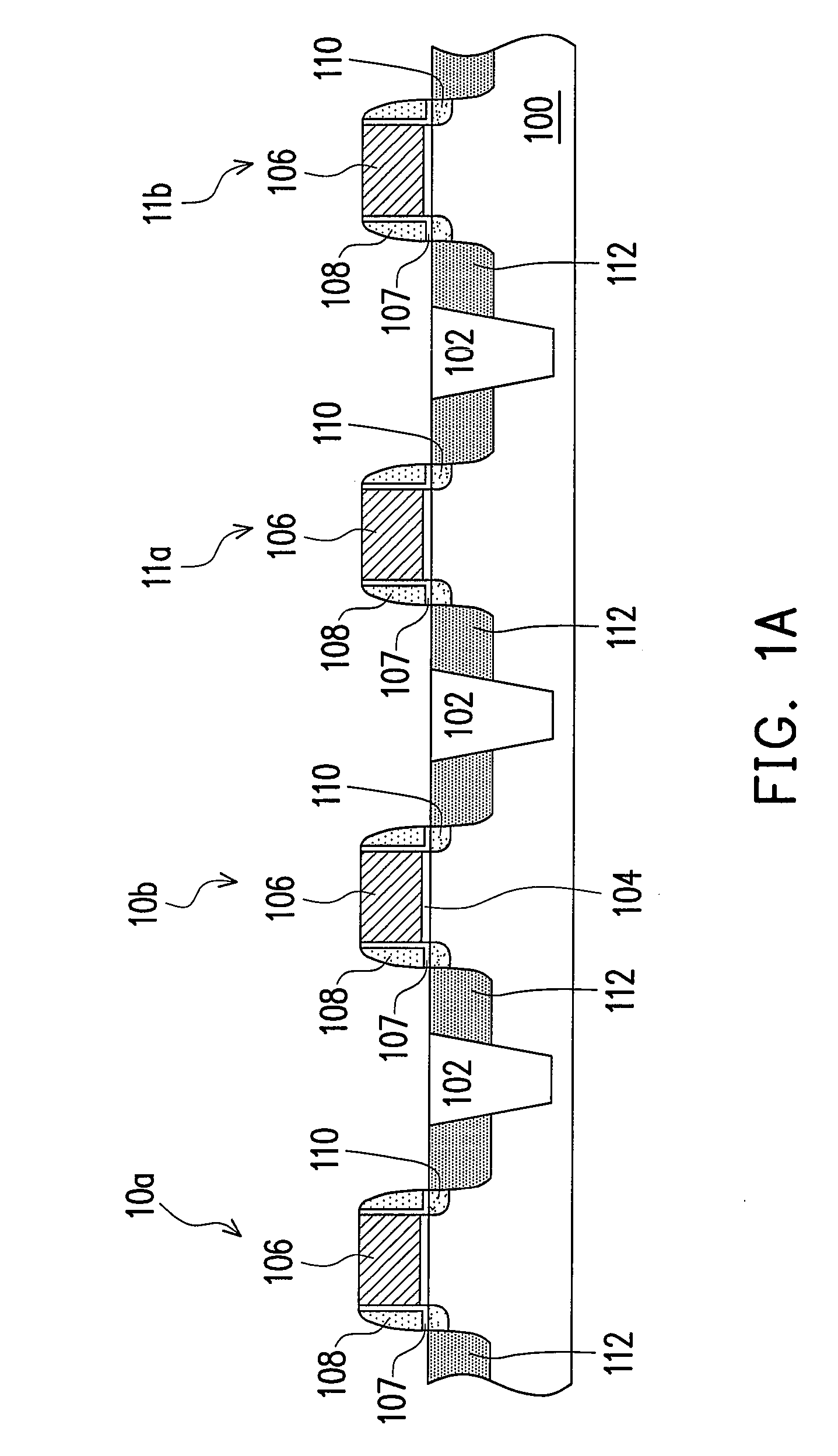

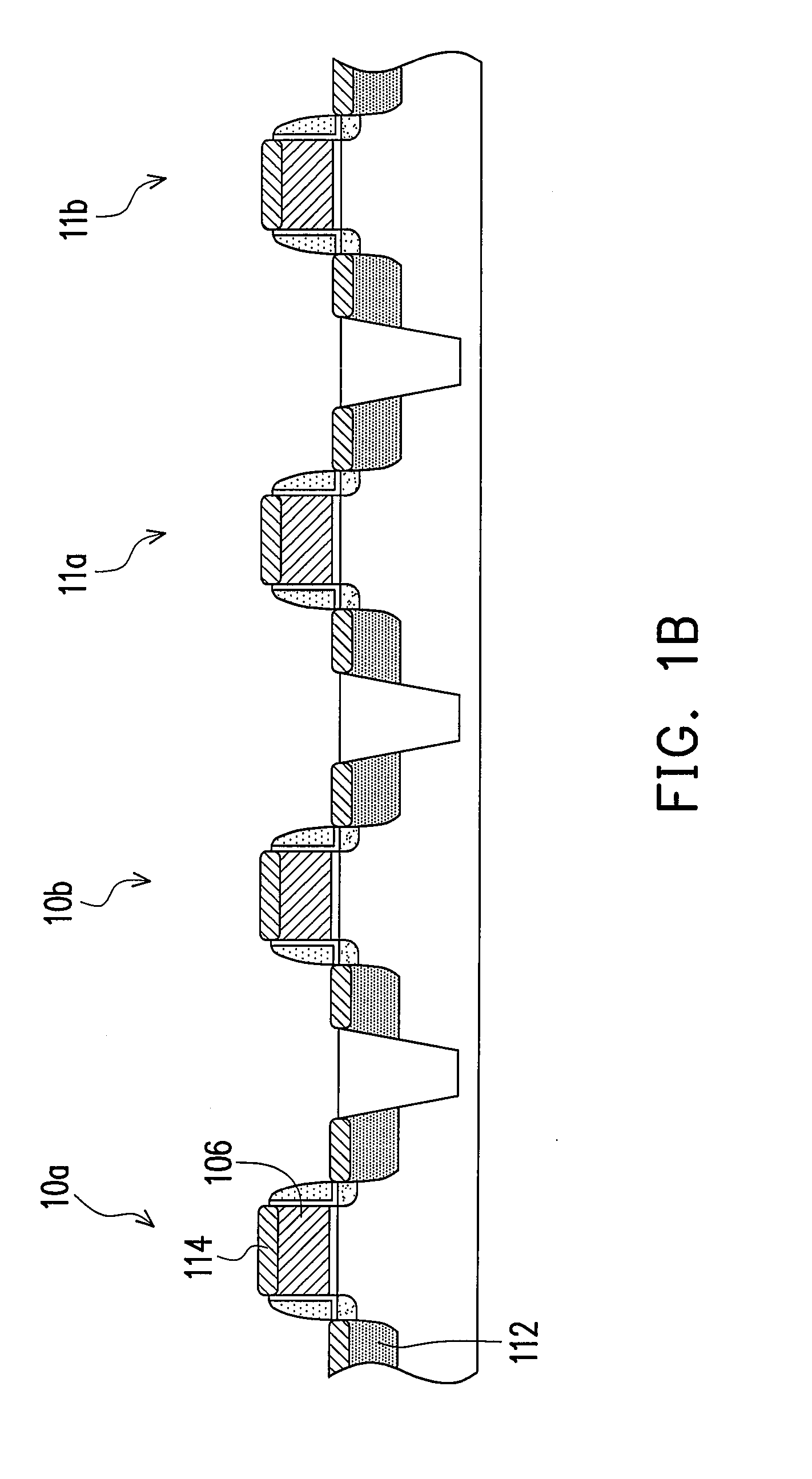

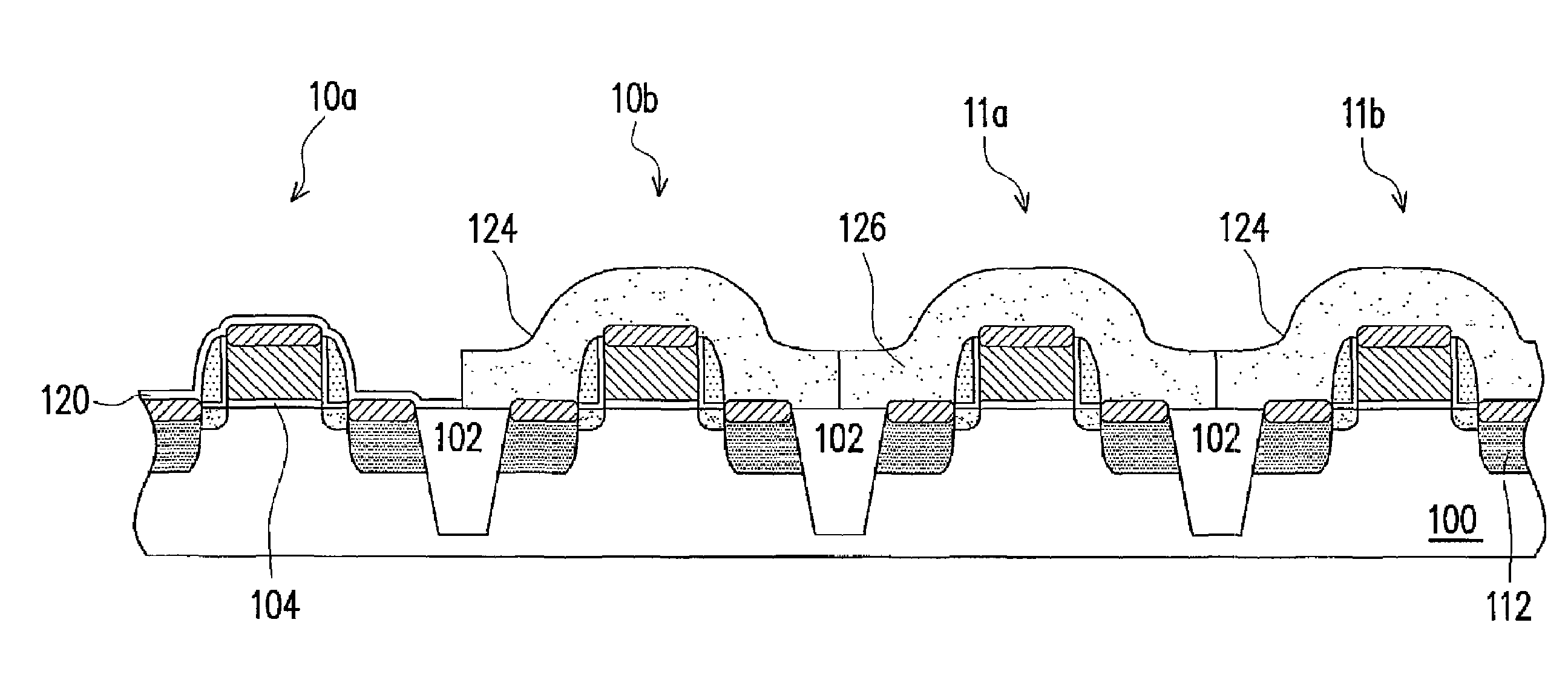

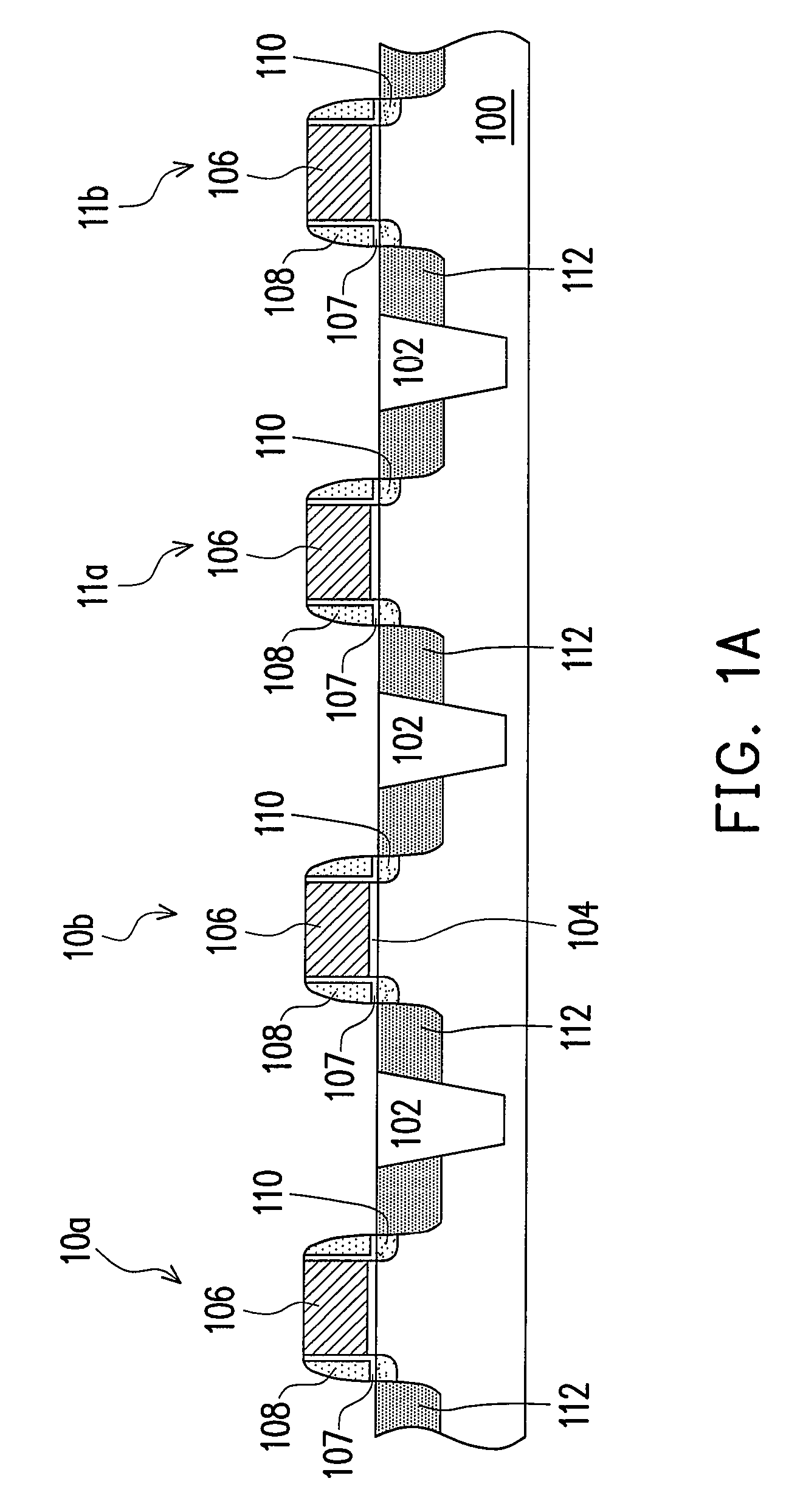

Semiconductor device and method of fabricating thereof

ActiveUS20080042210A1Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesNegative-bias temperature instabilitySemiconductor

A method of fabricating a semiconductor device is provided. A substrate is first provided, and than several IO devices and several core devices are formed on the substrate, wherein those IO devises include IO PMOS and IO NMOS, and those core devises include core PMOS and core NMOS. Thereafter, a buffer layer is formed on the substrate, and then the buffer layer except a surface of the IO PMOS is removed in order to reduce the negative bias temperature instability (NBTI) of the IO PMOS. Afterwards, a tensile contact etching stop layer (CESL) is formed on the IO NMOS and the core NMOS, and a compressive CESL is formed the core PMOS.

Owner:UNITED MICROELECTRONICS CORP

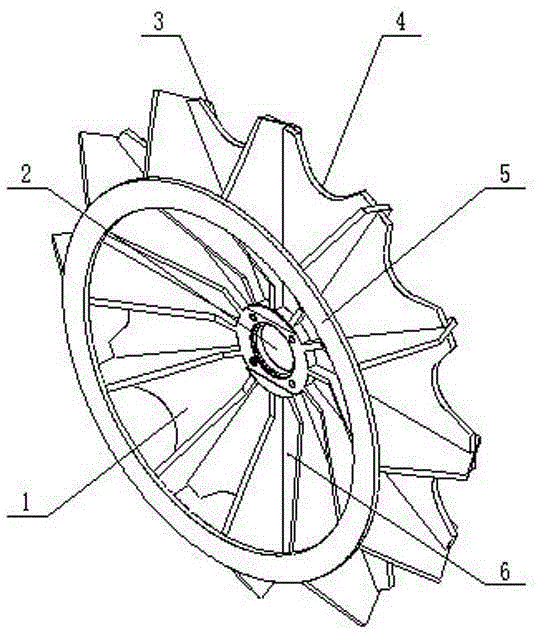

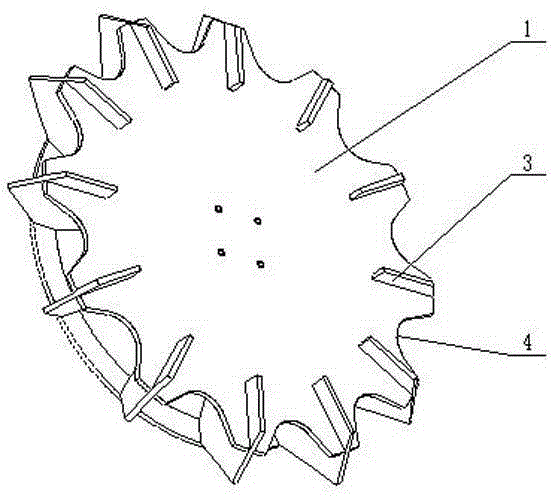

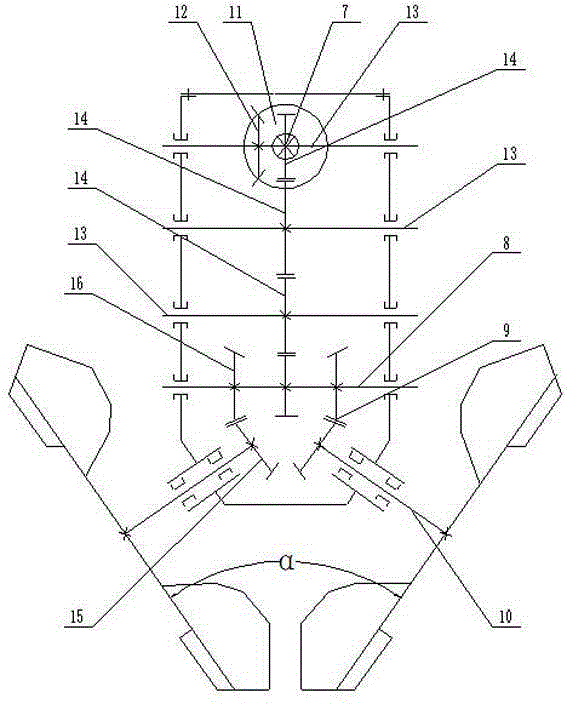

Furrow rotary excavating cutter disc and double-disc furrow rotary excavating device

ActiveCN104012199AReasonable structureIncrease stiffnessTilling equipmentsCircular discUltimate tensile strength

The invention discloses a furrow rotary excavating cutter disc. The furrow rotary excavating cutter disc comprises a cutter disc body, a shaft hole, a cutter and notches. The shaft hole is formed in the center of the cutter disc body. The cutter disc body is circular and the notches are evenly formed in the periphery of the cutter disc body at intervals, so that the structure that the notches and the outer end face of the periphery are evenly distributed in an alternating mode is formed; the cutter perpendicular to the cutter disc body is arranged on the outer end face of the periphery in the radial direction. The device is high in structural strength, high in cutting efficiency and capable of rapidly throwing cut soil out of a furrow, and therefore the furrow which is large in depth, not prone to collapse and small in soil returning amount and is provided with flat furrow banks is formed. The invention further provides a double-disc furrow rotary excavating device.

Owner:GUANGXI INST OF HYDRAULIC MACHINERY

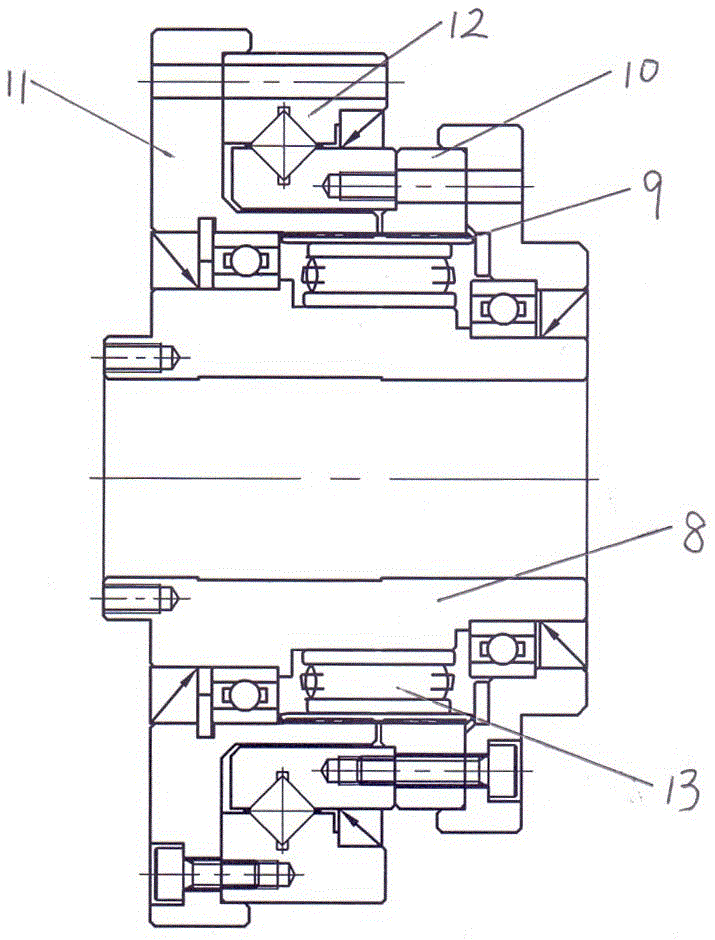

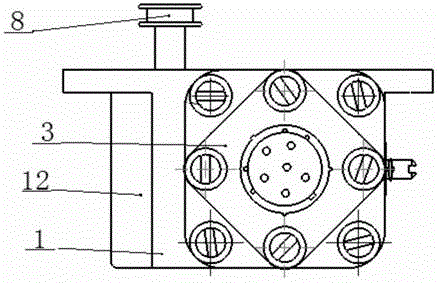

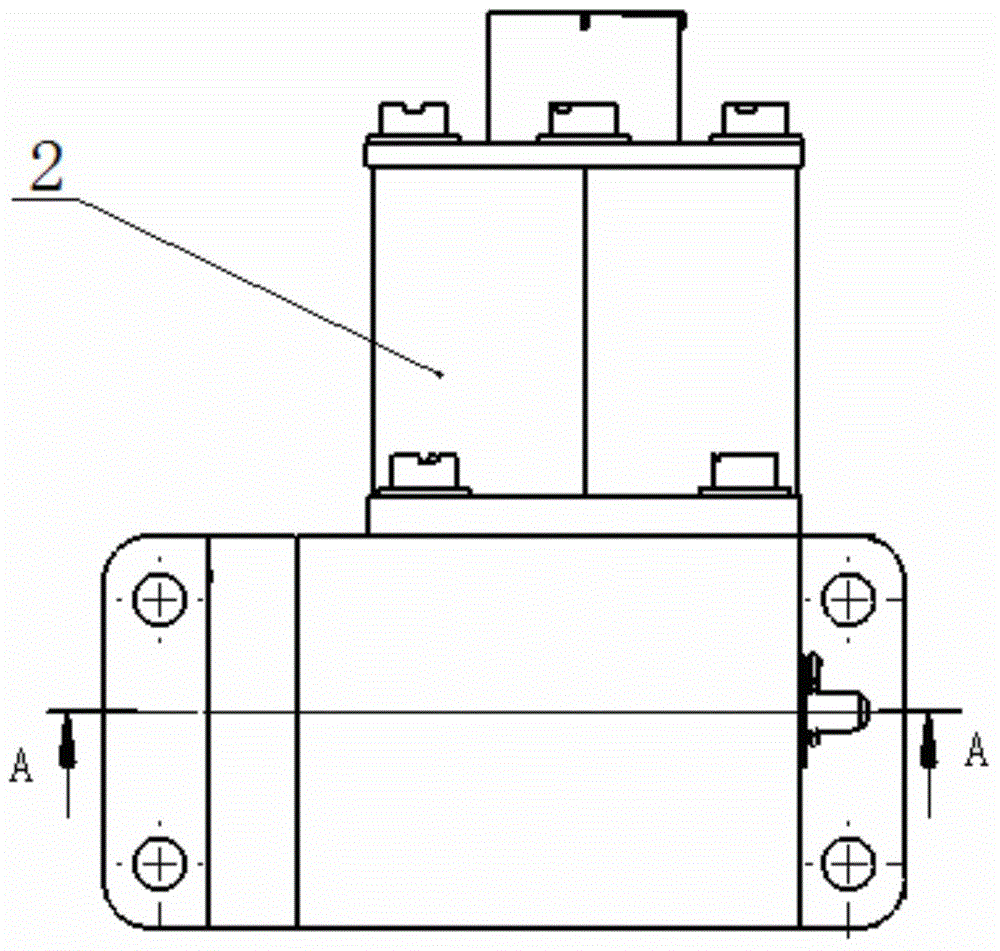

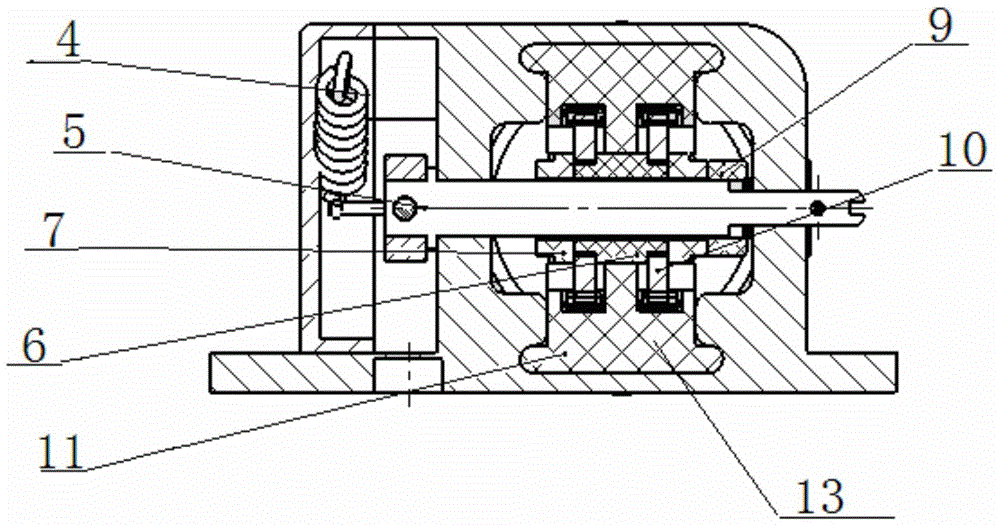

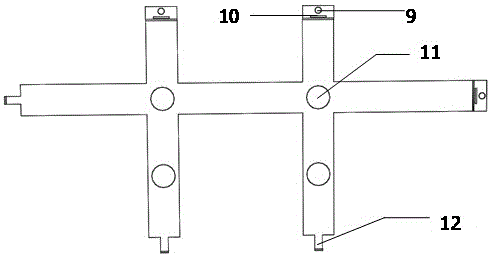

Travel switch

A travel switch comprises a substrate (1), a supporting seat (2), an electric connector (3), a spring (4), a rotating shaft component (5), a clamping block (6), a brake block (7), a piston (8), a clamping post (9), contact pieces (10), a spring plate component (11) and an end cover (12), wherein the supporting seat (2) is fixedly connected to the substrate (1), the electric connector (3) is connected with the supporting seat (2),and the rotating shaft component (5) is positioned on the inner side of the substrate (1). The travel switch has the advantages of small size and small mass; because a casing is totally made of metal, the shielding and sealing effects are good, and the travel switch is free from height change influence; the components have the advantages of higher reliability, shock resistance, vibration resistance, and good accelerating effect; outputting is performed by the connector, so that but joint with mating parts is facilitated; the spring is adopted for controlling the rotating shaft component, so that the synchronicity of the product is good, and the switching time is short; the technical performance is good, and the switch can be used at a temperature between minus 55 DEG C to 70 DEG C.

Owner:沈阳兴华航空电器有限责任公司

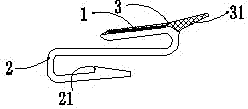

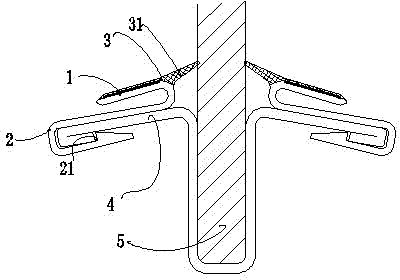

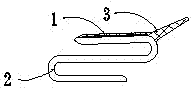

Clamping insertion strip with compound skeleton and forming process thereof

InactiveCN102359459AGood weather resistanceExtended service lifeFriction grip releasable fasteningsEscalatorsWeather resistanceEngineering

The invention relates to a clamping insertion strip with a compound skeleton, which comprises an insertion strip main body made of a hard modified PVC material. The insertion strip main body is an S-shaped structure, and one layer of clamping body made of a soft modified PVC material is compounded on the external surface of the starting straight section of the S-shaped insertion strip main body. The clamping body is provided with a clamping strip convex body for clamping a clamping body assembly in a stretching way in the extension direction of the starting straight section, and an enhancing skeleton is embedded between the clamping body and the compounding surface of the starting straight section of the insertion strip main body or in the starting straight section. The insertion strip main body, the enhancing skeleton and the clamping body are integrally compounded extrusion parts. The steel enhancing skeleton has high strength, small influence by temperature difference, small contraction distortion and strong impact resistance, and the expansion and contraction of the clamping insertion strip is reduced. The stainless steel insertion strip not only can be wrapped but also can be exposed and is beautiful in appearance. The clamping insertion strip provided by the invention has the advantages of small contraction distortion, strong impact resistance, small contraction gap in clamping insertion strip joint, good weather resistance, beautiful appearance and long service life and is an ideal substitute for the prior art.

Owner:余惠江

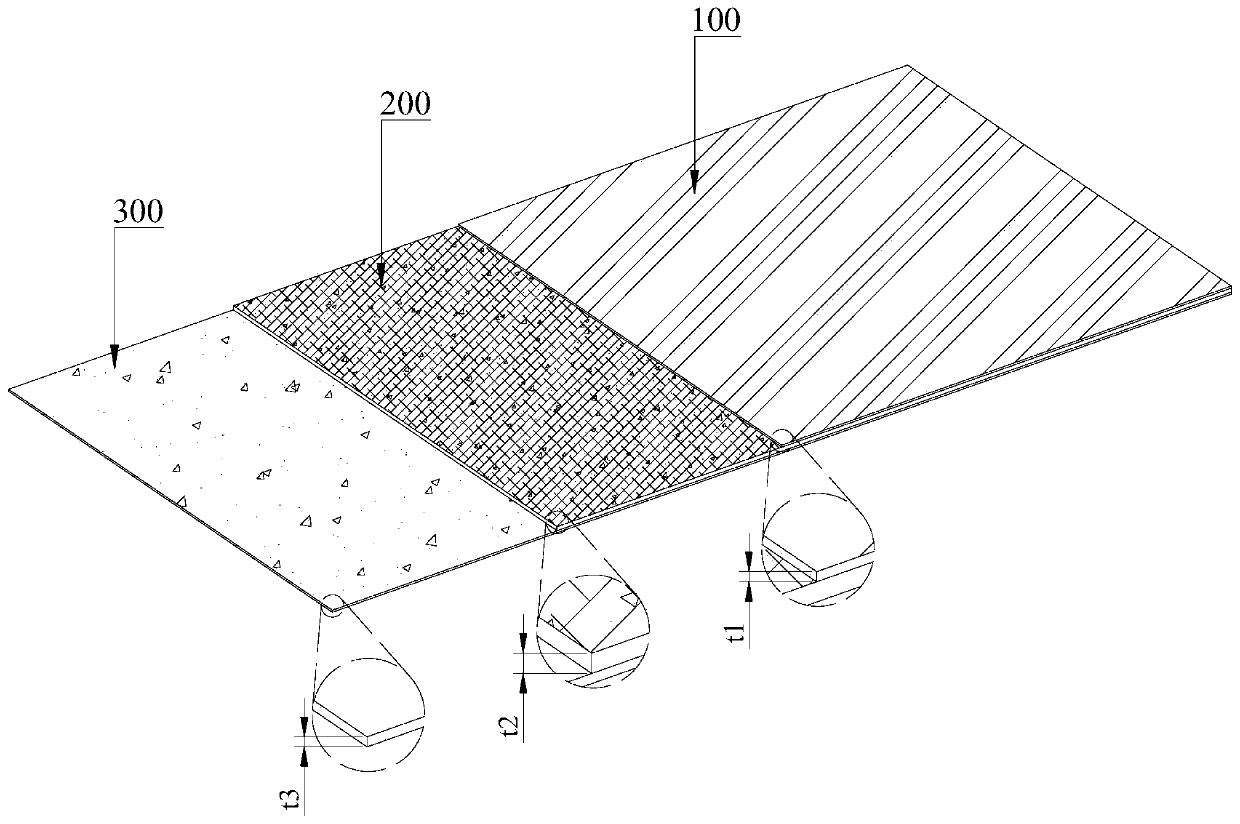

Organic fiber toughened inorganic composite artificial stone panel and preparation method thereof

InactiveCN110746152AImprove compactnessImprove production efficiencyCovering/liningsFeeding arrangmentsFiberArtificial stone

Owner:黄贺明 +1

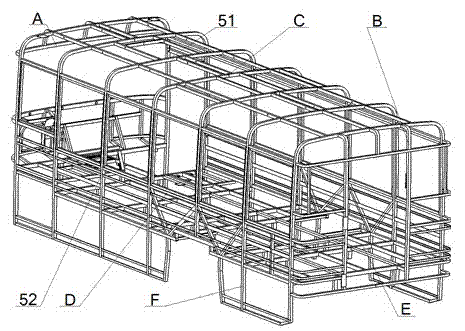

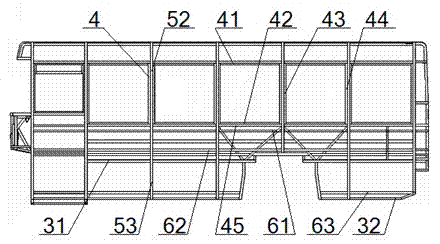

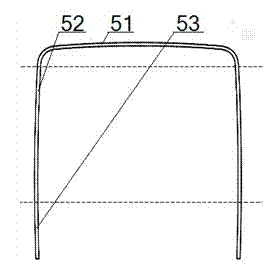

Birdcage type vehicle body skeleton structure

A birdcage type vehicle body skeleton structure comprises a front wall assembly, a rear wall assembly and a top cover assembly, wherein the two ends of the top cover assembly are connected with the upper ends of the front wall assembly and the rear wall assembly; the lower ends of the front wall assembly and the rear wall assembly are connected with a chassis assembly; the side part of the chassis assembly is connected with the top cover assembly through a side wall assembly; the top cover assembly comprises a plurality of parallel top cross beams; the side wall assembly comprises a plurality of parallel side wall vertical beams; two ends of the top cross beams are connected with tops of the side wall vertical beams, and the top cross beams and the side wall vertical beams form an integrated structure; a plurality of embedded beams are arranged on the side wall assembly and the rear wall assembly; and stiffening beams running through the periphery of a vehicle body are correspondingly arranged on the embedded beams. According to the design, the birdcage type vehicle body skeleton structure is firmer in connection and strong in impact resistance, and can disperse the impact force, reduces the deformation degree of the vehicle body and provides more survival space for passengers when being collided.

Owner:DONGFENG MOTOR CORP HUBEI

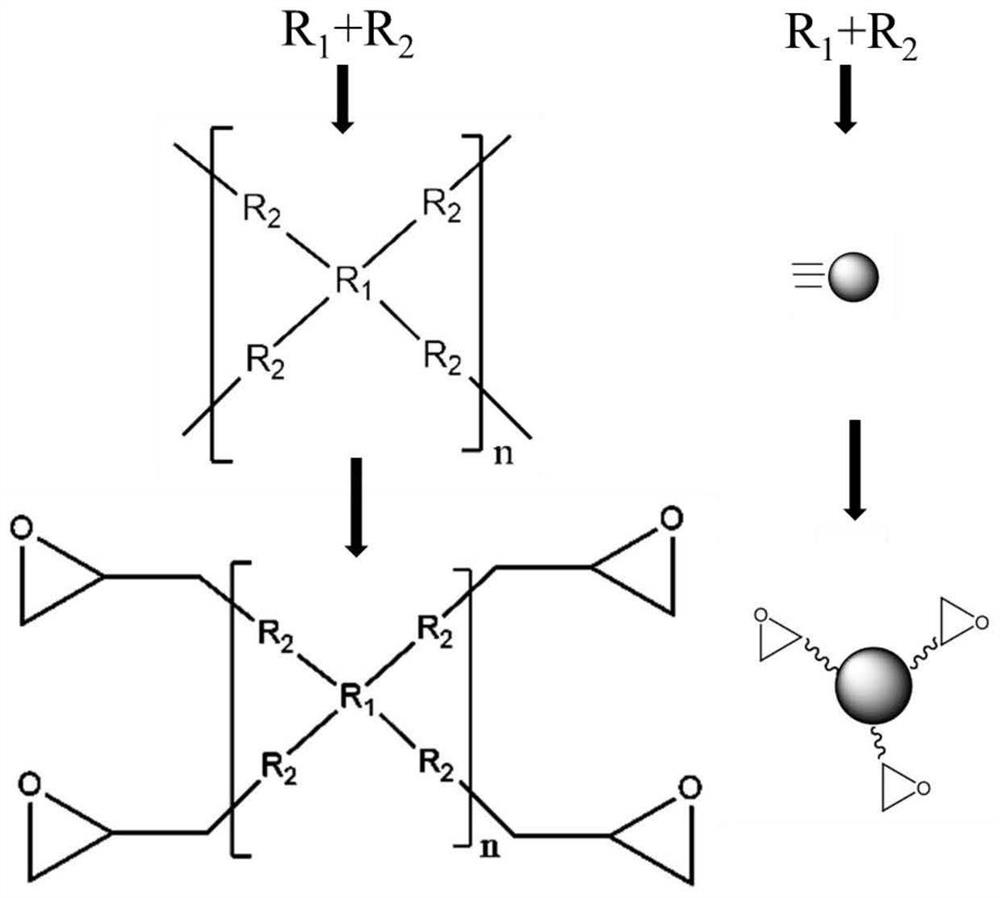

Chain drive system

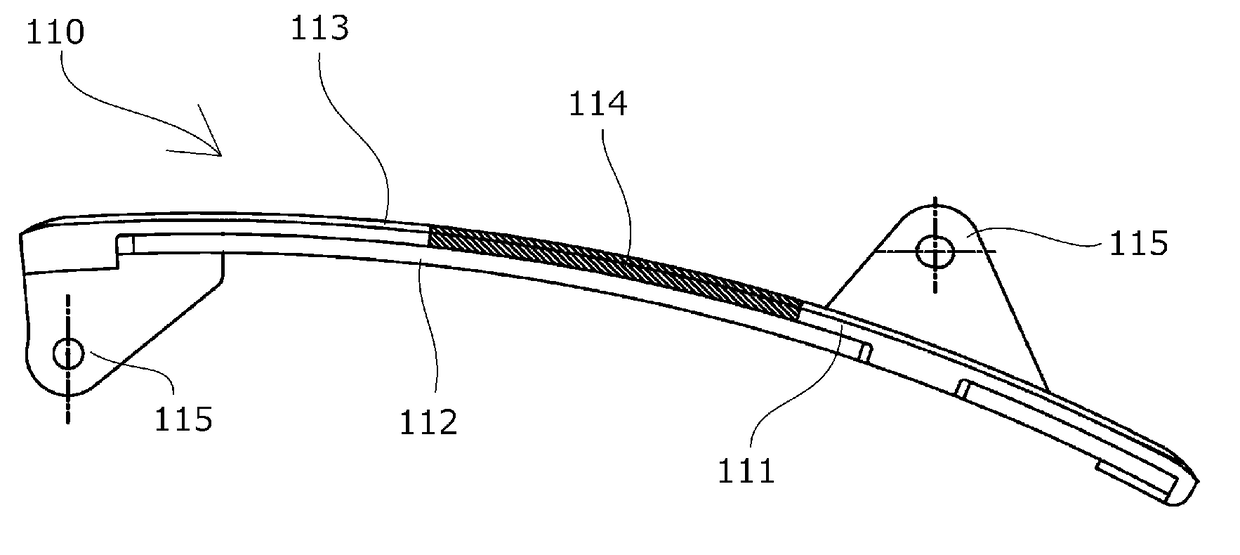

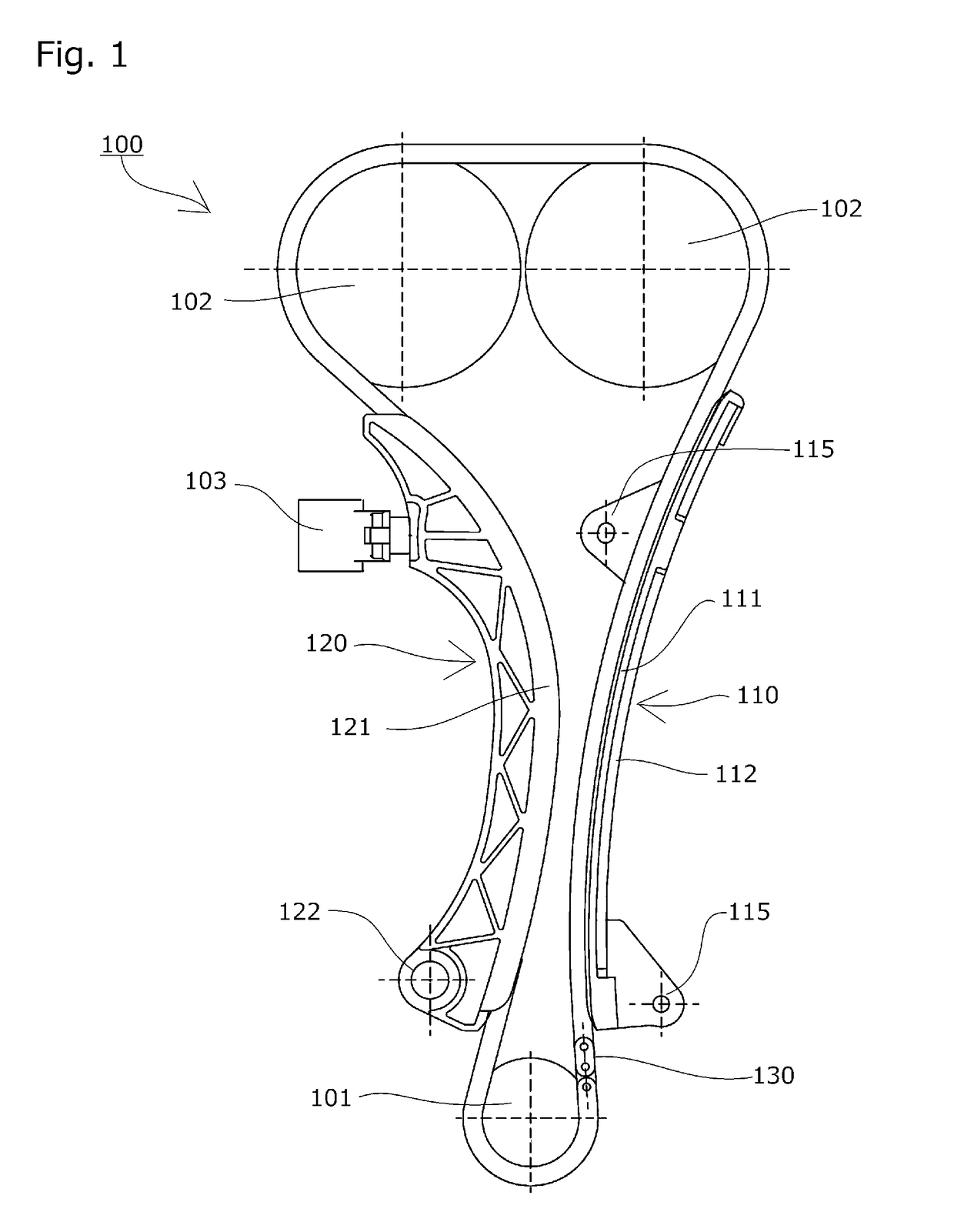

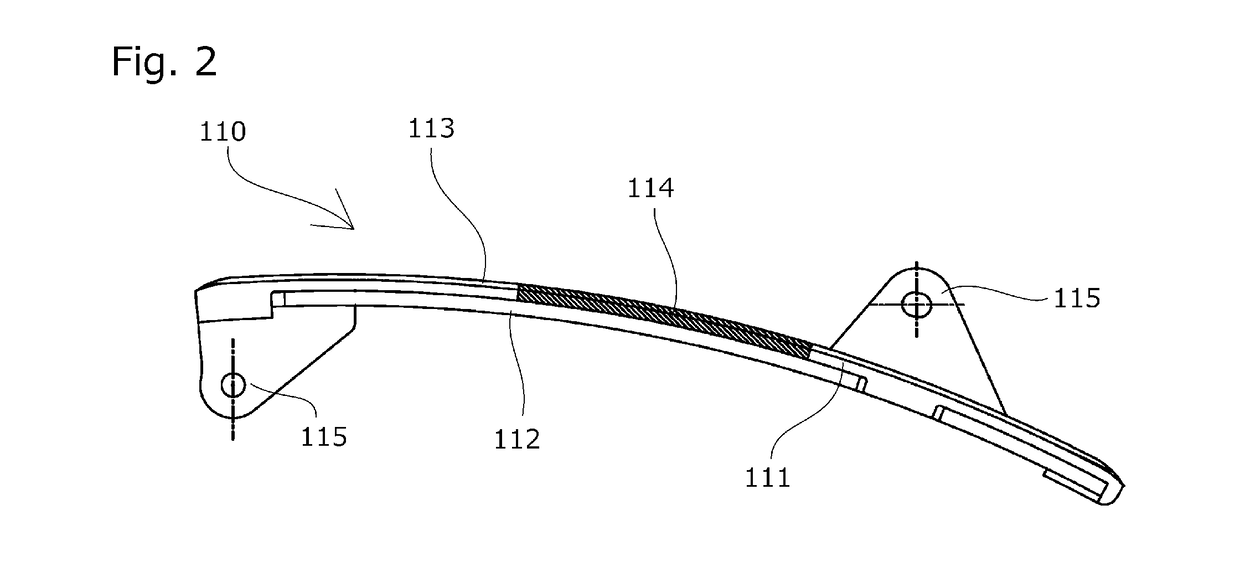

An object of the present invention is to provide a chain drive system that can reduce sliding resistance between a chain and a guide shoe, minimize increase of sliding resistance over time, and reduce production cost. Provided is a chain drive system 100 including a plurality of sprockets 101 and 102 over which a chain 130 passes over, and one or more guides 110 and 120 that guide the chain 130. The guides 110 and 120 include integral or separate guide shoes 111 and 121 each having a chain running surface. The chain running surfaces include, in part thereof, a lubricated area 114 where a solid lubricant P is held.

Owner:TSUBAKIMOTO CHAIN CO

Sandwich heat-preserving decorative board with mixed hollow porous fiber reinforced heat-preserving mortar and manufacturing method

ActiveCN105735552AStrong impact resistanceSmall impact resistanceBuilding componentsEngineeringPorous fiber

The invention relates to a sandwich heat-preserving decorative board with mixed hollow porous fiber reinforced heat-preserving mortar and a manufacturing method.A heat-preserving core veneer of the heat-preserving decorative board is a formed veneer and provided with big and round through holes; a hanging part capable of being positioned is arranged at the inner side of a back plate and tightly attached to the back face of the heat-preserving core veneer, and the same big and round through holes are formed in the positions corresponding to the big and round holes in the heat-preserving core veneer; the ends of the hanging part capable of being positioned are provided with small and round holes, square holes and right-angled hooks used for connecting, installing and lapping the heat-preserving decorative board in a positioning mode; fiber grid cloth is arranged at the inner side of a panel and is spaced from the heat-preserving core veneer by 2 mm; the mixed hollow porous fiber reinforced heat-preserving mortar is poured into the periphery of the heat-preserving core veneer through sealed formworks, the panel, the back plate and sealed edges are formed after the mortar is hardened, and bridge-cutoff shear connectors are formed in the big and round holes; the decorative board has the advantages that a good integrated space stress structure is formed through overall pouring of the panel, the back plate, the bridge-cutoff shear connectors and the sealed edges, positioning and splicing are accurate, and the fireproof performance is improved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Lifting structure applicable to high-speed printing system of bubble cap machine

InactiveCN104191617AImprove transmission efficiencyLifting transfer high speedHeat resistanceElectric machinery

The invention discloses a lifting structure applicable to a high-speed printing system of a bubble cap machine. The lifting structure is characterized by comprising a lifting driving servo main motor at the left side of a lifting structure body and a lifting-rod auxiliary motor for controlling the position of the lifting structure body, and the lifting structure body comprises a weight bearing platform, sliding pipes and lifting auxiliary screws, wherein the sliding pipes are fixedly arranged between the weight bearing platform and the lifting auxiliary screws in an H shape; a lifting main screw for controlling the lifting of the left and right sliding pipes is arranged at the middle of the horizontal plane of the left sliding pipe and the right sliding pipe, and is connected with the lifting driving servo main motor; the lifting driving servo main motor and the lifting-rod auxiliary motor are linked with the lifting main screw and the lifting auxiliary screws by synchronous wheels and a synchronous wheel belt to commonly act on the weight bearing platform to drive the weight bearing platform to go up and down; the upper end and the lower end of a frame wall rod at the left side of one lifting auxiliary screw are provided with a front limiter and a rear limiter from top to bottom. The lifting structure disclosed by the invention has the advantages that the lifting transmission is smooth, the transferred power is large, the transmission efficiency is high, the heat resistance is good, lifting transmission noise is low, the impact resistance is achieved, the electrical conductivity is good, the flexural property is good and the like.

Owner:HEFEI AIRWREN AUTOMATIC EQUIP CO LTD

Method of fabricating semiconductor device

ActiveUS7682890B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesNegative-bias temperature instabilitySemiconductor

Owner:UNITED MICROELECTRONICS CORP

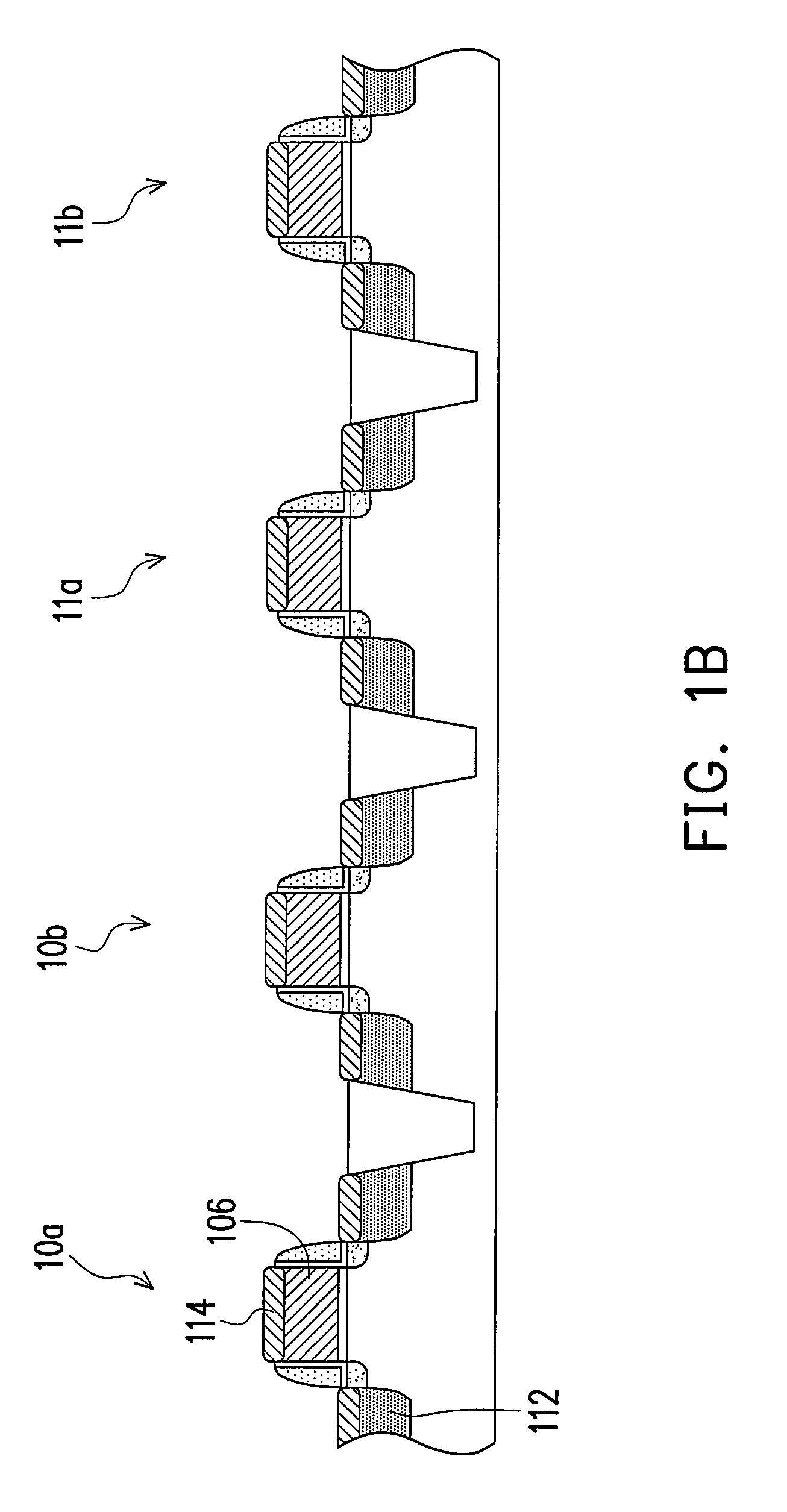

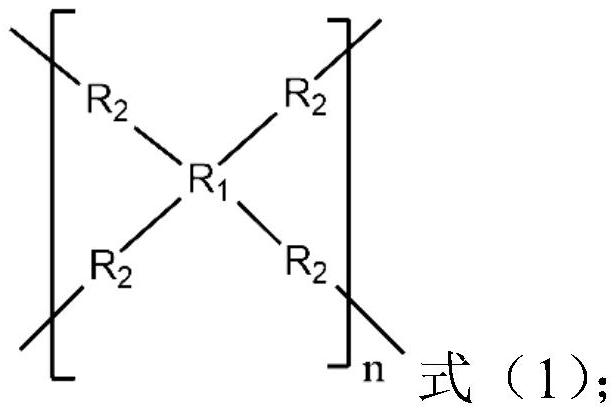

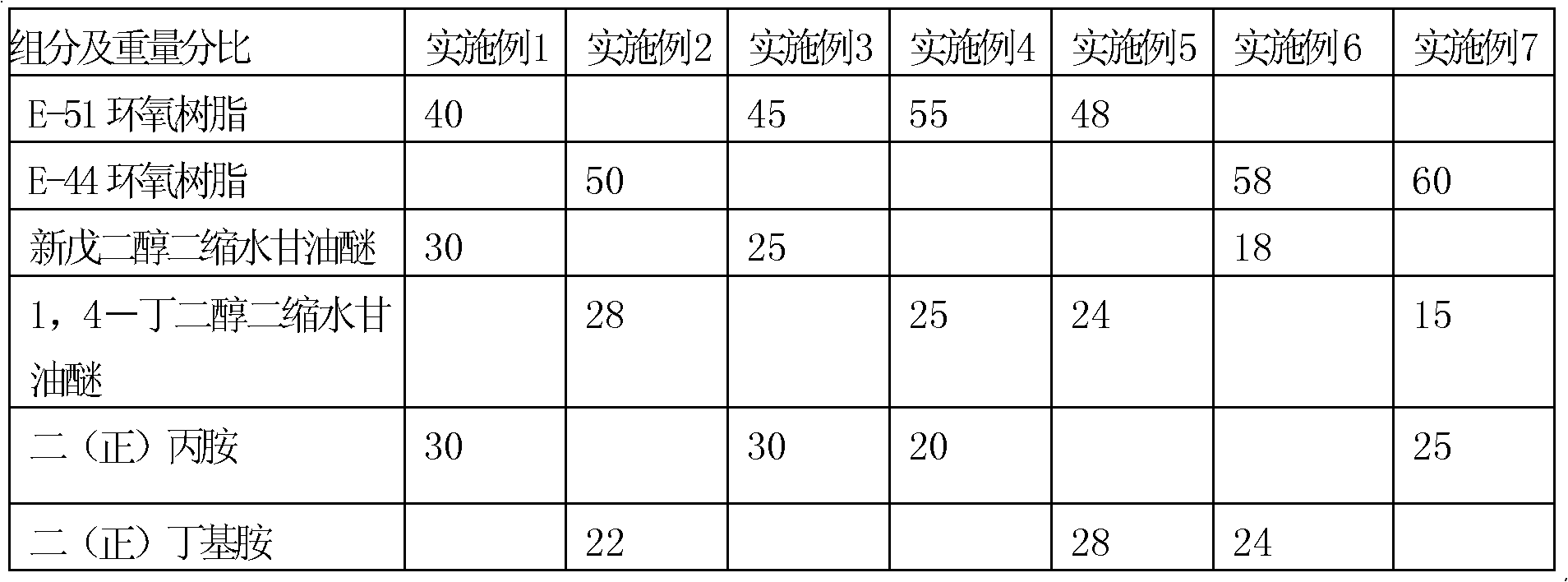

Hyperbranched epoxy resin and preparation method and application thereof

ActiveCN113354795ALow viscosityImprove toughnessOrganic chemistryPolymer chemistryEthylenediaminetetraacetic acid

The invention provides hyperbranched epoxy resin and a preparation method and application thereof. The hyperbranched epoxy resin is formed by taking ethylenediamine tetraacetic acid as a first core monomer and organic alcohol as a second monomer, synthesizing a hyperbranched polymer through esterification reaction and then polymerizing the hyperbranched polymer with an epoxy group to form the hyperbranched epoxy resin. The hyperbranched epoxy resin is controllable in structure, low in viscosity, high in toughness and resistant to high temperature, and can well meet the requirements in the fields of electronics, aerospace, structural materials and the like.

Owner:JIANGSU YANGNONG CHEM GROUP

A kind of flexible oled and preparation method thereof

ActiveCN102760846BHigh light transmittanceGood flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingFlexible organic light-emitting diodePolyethylene terephthalate glycol

The invention discloses a preparation method for a flexible organic light emitting diode (OLED), comprising the following steps: (1) a polyethylene terephthalate (PET) sheet is fixed at a support plate by binder as a base plate; the surface of the base plate is cleaned and dried; a barrier layer which is formed by successive alternating deposit of thin polymer films and thin inorganic material films with high transmittance is prepared on the base plate; the refractive index of the thin polymer films and the thin inorganic material films matches with the refractive index of the base plate; (2) an indium tin oxide (ITO) film and a metal layer are prepared at the base plate equipped with the barrier layer and etching of a metal line and an ITO line and making of polyimide (PI) patterns and RIB patterns are completed; during etching of the metal line and the ITO line, mechanical stirring or ultrasonic stirring are performed on the etching liquid; (3) then the base plate is put in an evaporation chamber for evaporation of an organic function layer and a negative electrode; (4) a thin film packaging layer is prepared on the surface of the negative electrode by vacuum evaporation and the packaging layer is formed by alternating deposit of at least one layer of organic material and at least one layer of inorganic material; and (5) the base plate is stripped off the support plate.

Owner:TRULY SEMICON

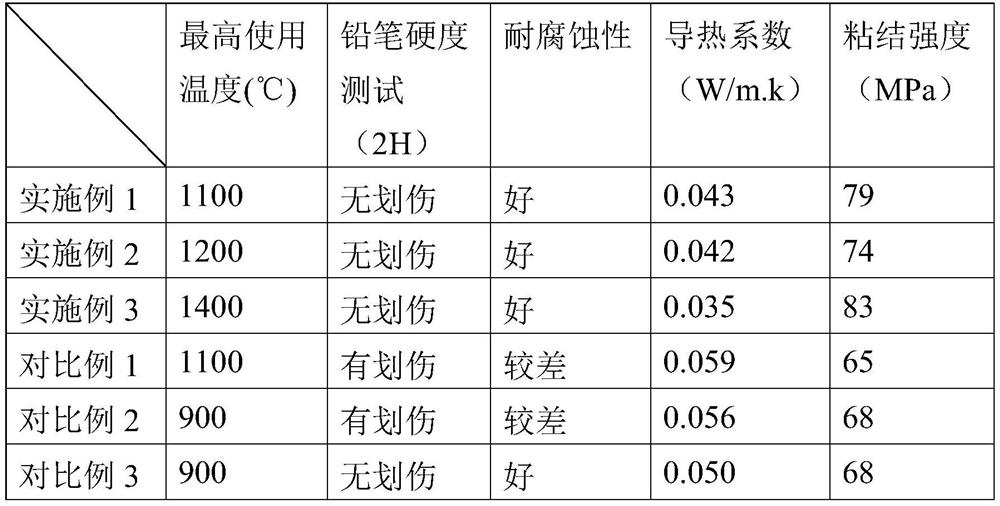

A kind of thermal insulation coating and preparation method thereof

ActiveCN113831835BImprove insulation effectLow thermal conductivityFireproof paintsAnti-corrosive paintsFiberNano silicon

The invention provides a thermal insulation coating and a preparation method thereof. The thermal insulation coating comprises 10 to 20 parts of nano silicate inorganic binder and 15 to 20 parts of organosilicon modified Solution, 10-15 parts of fumed silica gel, 25-35 parts of nano hollow microspheres, 5-15 parts of inorganic hollow fiber powder, 2-8 parts of nano-rare earth oxide, 1-5 parts of auxiliary agent, 0.5 parts of water. The thermal insulation coating provided by the present invention, through the synergistic effect of the organosilicon modification solution and other components, makes the thermal insulation coating have excellent thermal insulation performance, and also has low thermal conductivity, corrosion resistance, impact resistance, and fire prevention. It has the advantages of waterproof, simple construction, and strong adhesion to the coke oven body.

Owner:江苏龙冶节能科技有限公司

Preparation method of heat-resistant high-strength agricultural machinery adhesive

InactiveCN112358848AImprove heat stabilityImprove heat resistanceAldehyde/ketone condensation polymer adhesivesMacromolecular adhesive additivesPolyesterAdhesive

The invention relates to the technical field of adhesives, in particular to a preparation method of a heat-resistant high-strength agricultural machine adhesive, which is wide in raw material source,simple and convenient in preparation method and excellent in thermal performance, and utilizes modified polyesterimide and modified vinyl ester resin to blend, blend and crosslink. The insulating paint can be stored, has low curing temperature, can be used in occasions with high insulation grade such as agricultural machinery repair and maintenance, has good effect in repairing parts with abradedsurfaces, can replace the commonly used electric welding, electroplating and bushing processes to recover the original geometrical shapes and dimensions of the parts, and has the advantages of simpleprocess, low cost, high efficiency and the like. During repairing of agricultural machinery and tools, the repairing agent has the excellent characteristics of convenience in use, wide raw material source, heat resistance, impact resistance and high corrosion resistance, and is suitable for being applied in the range of agricultural machinery.

Owner:安徽宏翔农业机械有限公司

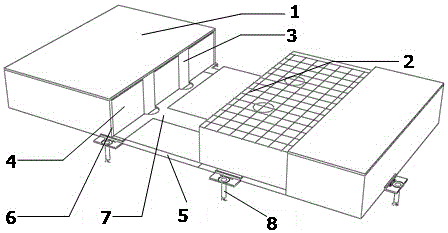

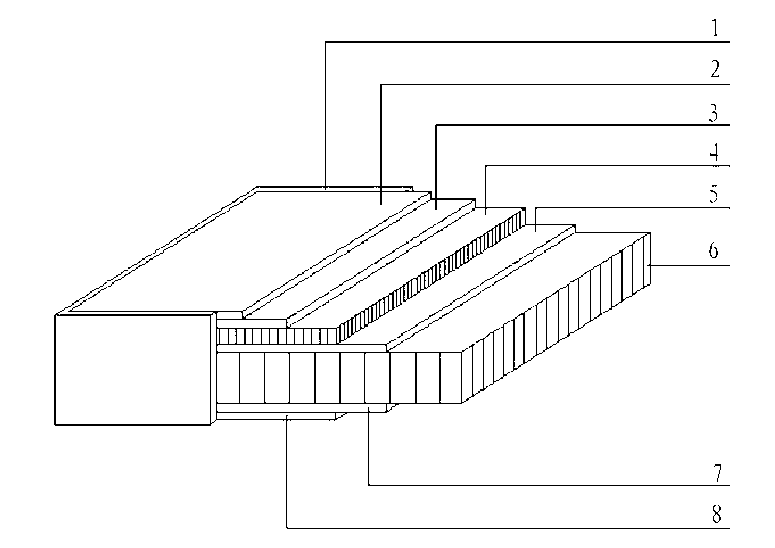

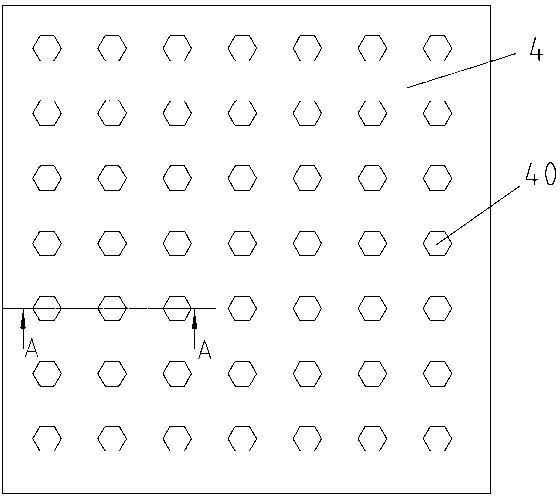

Antistatic access floor

InactiveCN103015671AReduce weightLow costSynthetic resin layered productsFlooring insulationsFlame resistanceHoneycomb

The invention discloses an antistatic access floor. The antistatic access floor is provided with an antistatic surface layer, an upper kraft paper layer, an upper honeycomb layer, a middle kraft paper layer, a lower honeycomb layer, a lower kraft paper layer and a bottom surface layer which are sequentially arranged inside the antistatic access floor from top to bottom via peripheral sealing edges; the size of the antistatic surface layer, the size of the upper kraft paper layer, the size of the upper honeycomb layer, the size of the middle kraft paper layer, the size of the lower honeycomb layer, the size of the lower kraft paper layer and the size of the bottom surfaced layer are matched with sizes of the peripheral sealing edges, and surfaces of the various layers are adhered with one another by antistatic glue; kraft paper and phenolic resin glue are compounded to form each of the upper kraft paper layer, the middle kraft paper layer and the lower kraft paper layer; the upper honeycomb layer is made of aluminum alloy materials, and first orthohexagonal through holes are fully distributed on the upper honeycomb layer from top to bottom; and the lower honeycomb layer is made of aluminum alloy materials, and second orthohexagonal through holes are fully distributed on the lower honeycomb layer from top to bottom, and the side length of each first orthohexagonal through hole of the upper honeycomb layer is smaller than that of each second orthohexagonal through hole of the lower honeycomb layer. The antistatic access floor is light, impact-resistant and soundproof, and is high in strength and flame resistance, low in water absorption and good in heat-insulation effect.

Owner:JIANGSU MEIAH DECORATIVE MATERIALS CO LTD

Method for producing anatomy car trim ceiling through dry process

InactiveCN105922663AGood molding effectAvoid scaldingLaminationLamination apparatusAdhesive glueEngineering

The invention discloses a method for producing an anatomy car trim ceiling through dry process and belongs to the technical field of automotive trim manufacturing. The method comprises the steps of heating a base material; bonding the base material with non-woven fabric through a die to form a ceiling prototype; cutting the ceiling prototype with a cutting robot, wherein the size obtained after cutting is consistent with that of the anatomy car ceiling; spraying the surface of a ceiling intermediate product with polyurethanes or neoprene misty glue, and then bonding the ceiling intermediate product with knitted fabric through the die to form an initial finished anatomy car ceiling product; sticking the knitted fabric to the back side of the ceiling intermediate product to form the finished anatomy car ceiling product. By the adoption of the technical scheme, the size and appearance quality of the anatomy car trim ceiling are both improved remarkably, and bonding between the base material and fabric as well as between the fabric and the knitted fabric is firm; meanwhile, the whole production process can be completed with one die, and profile consistency and production cost minimization are guaranteed.

Owner:芜湖正海汽车内饰件有限公司

Thermal insulating EPDM/POE waterproof coiled material and preparation method thereof

The invention relates to a thermal insulated EPDM / POE waterproof coiled material. The thermal insulated EPDM / POE waterproof coiled material is prepared from the following raw materials in parts by weight: EPDM, butyl rubber, POE, 1,3-bis(tert-butylperoxide diisopropyl) benzene, triallyl isocyanurate, stearic acid, 2-mercapto benzimidazole, lanthanum oxide, propanediol sebacate polyester, methyl triethoxysilane, citric acid, cross-linking agent TAC, gamma-trimethoxysilylpropanethiol, polyoxyethylene octylphenol ether, zinc oxide, chloroplatinic acid, boric acid, potassium hydroxide, 2,2-dithio bisbenzothiazole and deionized water. A plurality of cavities of tiny hollow microbeads are used for forming a thermal insulating layer to prevent the heat conduction, so that the heat insulating performance of the waterproof coiled material is improved.

Owner:ANHUI PUYUAN SEPARATION MACHINERY MFG CO LTD

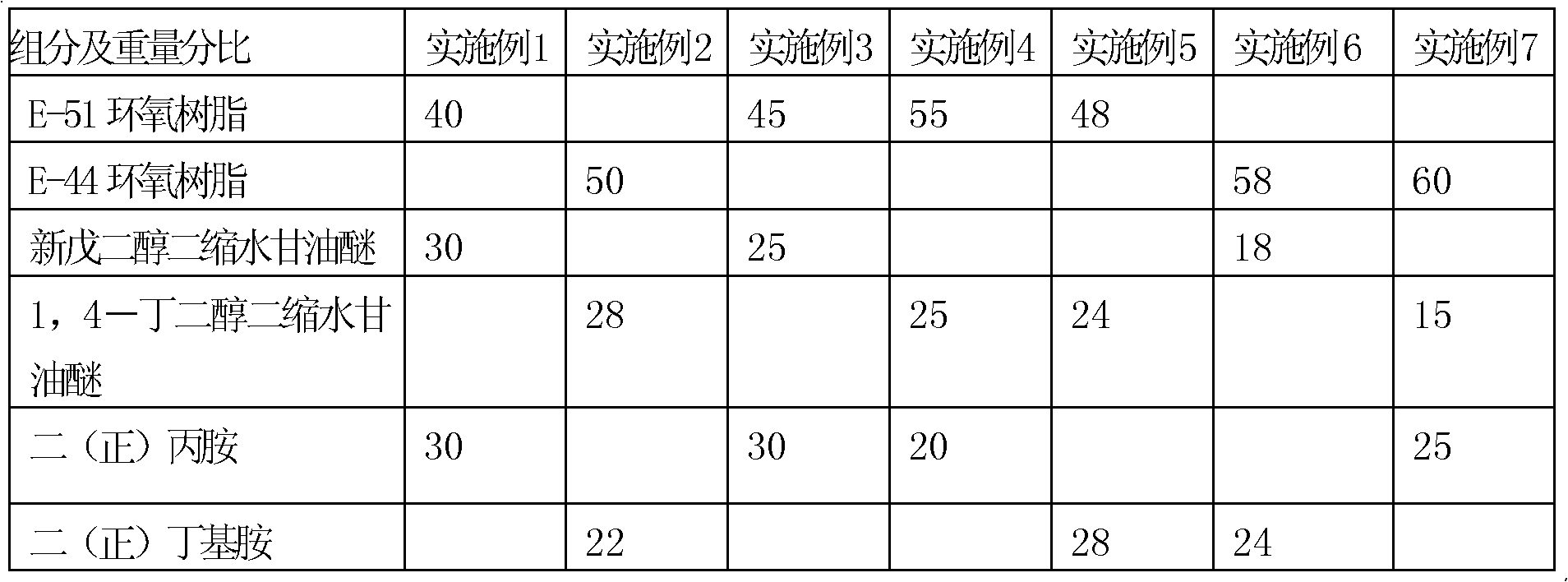

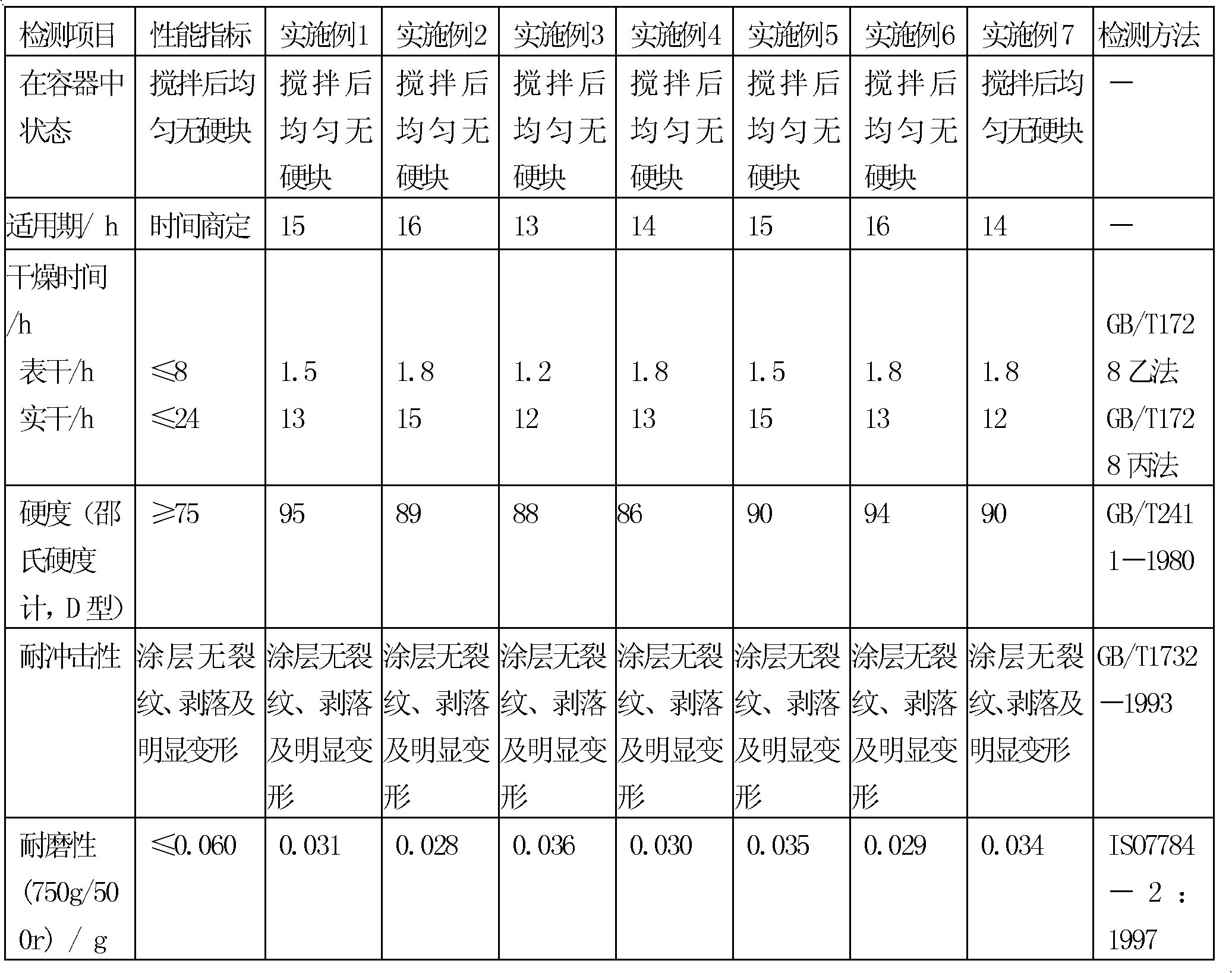

Solvent-free polyurethane wear-resistant terrace paint and preparation method thereof

The invention relates to a solvent-free polyurethane wear-resistant terrace paint and a preparation method thereof. The paint is composed of a component A and a component B, wherein the component A comprises the following components by mass parts: 60-80 parts of solvent-free hydroxyl-terminated epoxy resin, 1-13 parts of coloring pigment, 15-22 parts of wear-resistant filling material, 0.2-0.5 part of defoaming agent, 0-0.3 part of drier and 3-5 parts of oxazolidine dewatering agent; and the component B is 100 mass parts of solvent-free isocyanate-terminated prepolymer. When the paint is used, the component A finished product and the component B finished product are mixed and stirred uniformly at a ratio of 3:1 to obtain the solvent-free polyurethane wear-resistant terrace paint. According to the invention, the terrace paint can be cured at low temperature, is free of volatile organic compounds in the system, is low in residual isocyanate monomer content, can improve coating performance, and is suitable for terrace decoration and protection with wear-resistant and dustless requirements in plants, shops, guesthouses, gymnasia, stations, parking lots and other places.

Owner:CHANGZHOU GUANGHUI CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com