Patents

Literature

31 results about "Magnesium Acetate Tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The hydrated acetate salt form of magnesium. Magnesium is a divalent cation essential for a number of biochemical processes involved in nerve signaling, bone mineralization and muscle contractions. About 350 enzymes involved in glycolysis and the Krebs cycle, formation of cyclic-AMP and ATP, cellular signal transduction and protein and nucleic acid synthesis are dependent on magnesium.

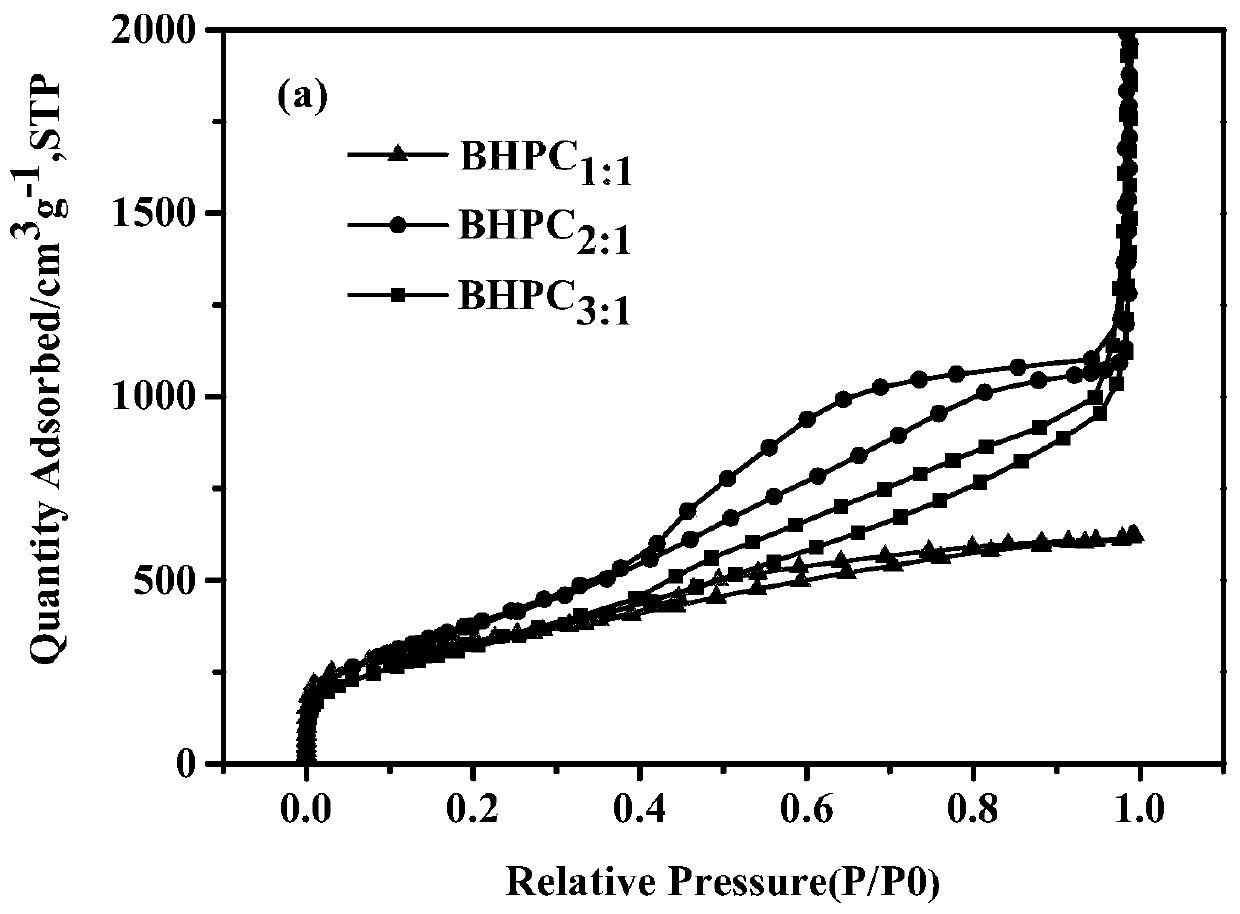

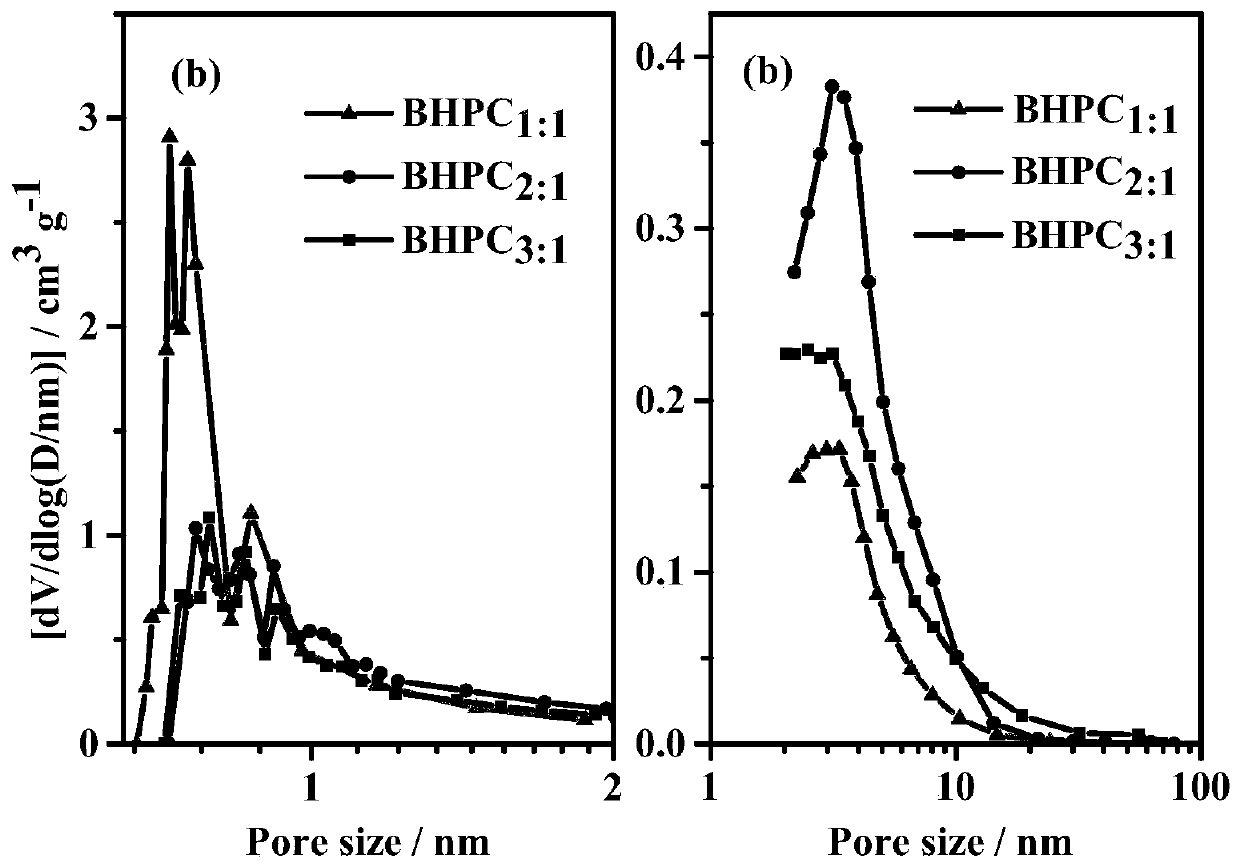

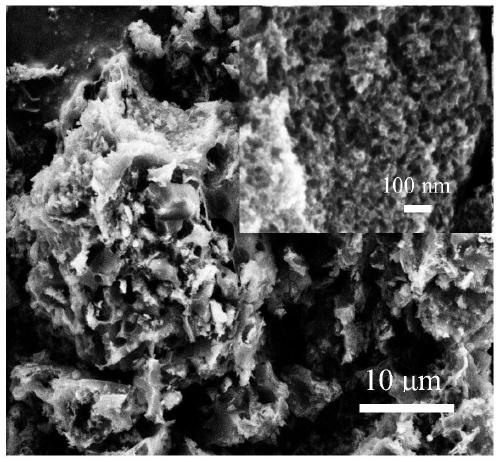

Method for preparing supercapacitor carbon material by adopting bio-oil

PendingCN110028050AInnovative high-value utilization methodsEfficient conversionHybrid capacitor electrodesCarbon preparation/purificationCapacitanceActivation method

Owner:SOUTHEAST UNIV

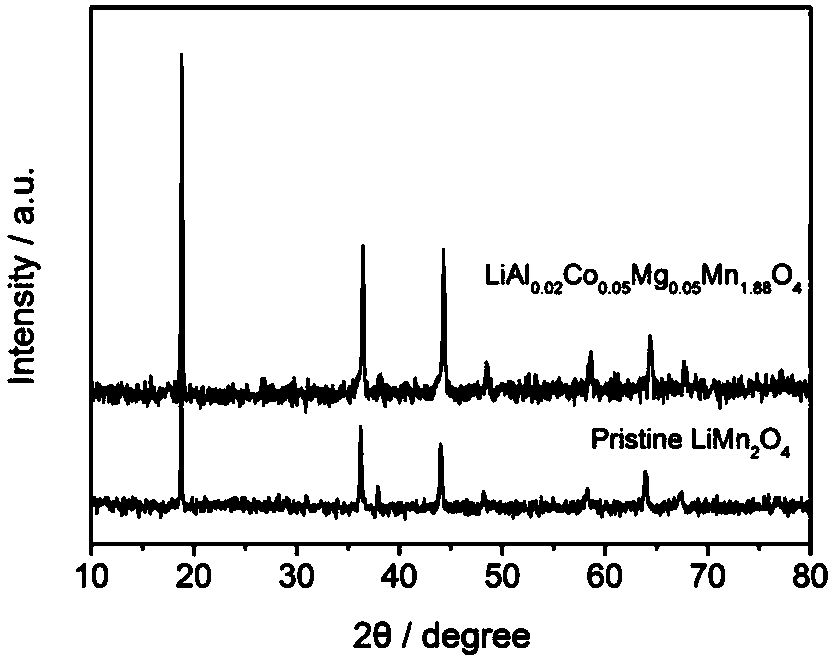

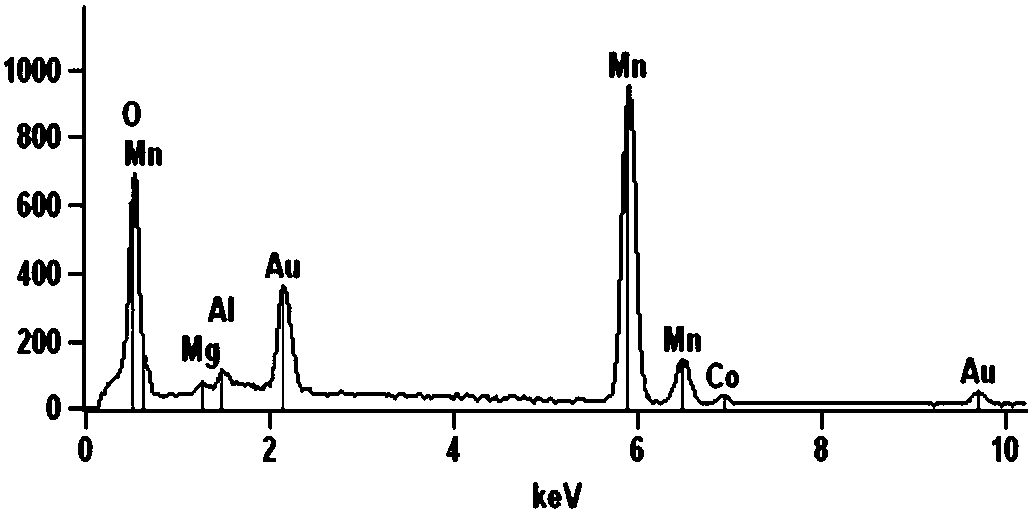

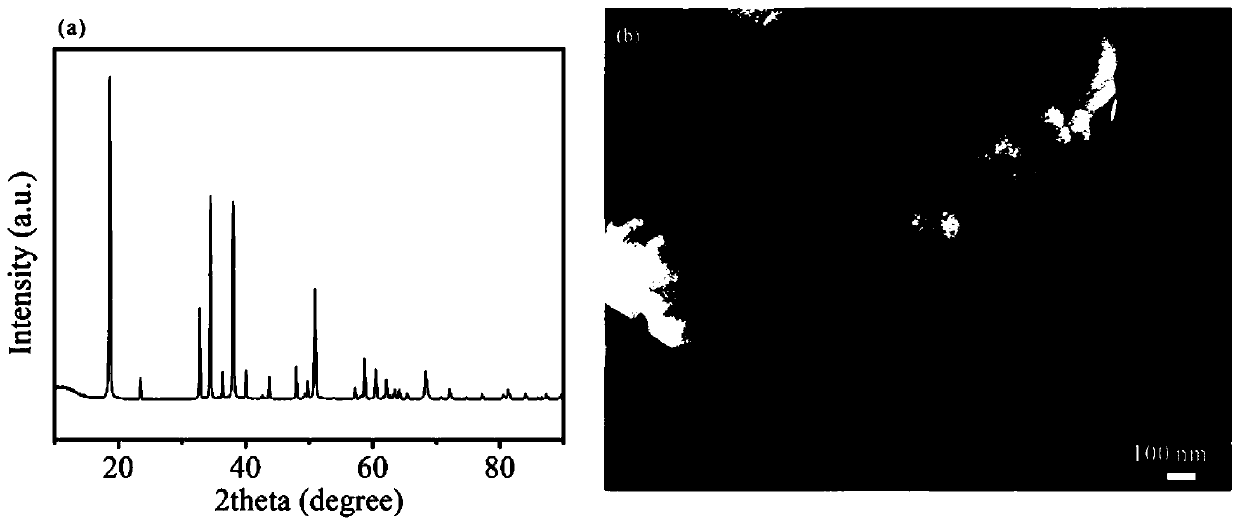

Method for preparing multi-element co-doped lithium manganate composite material

InactiveCN108539159AStable structureInhibition of Ginger-Taylor EffectCell electrodesSecondary cellsMagnesium Acetate TetrahydrateMANGANESE ACETATE TETRAHYDRATE

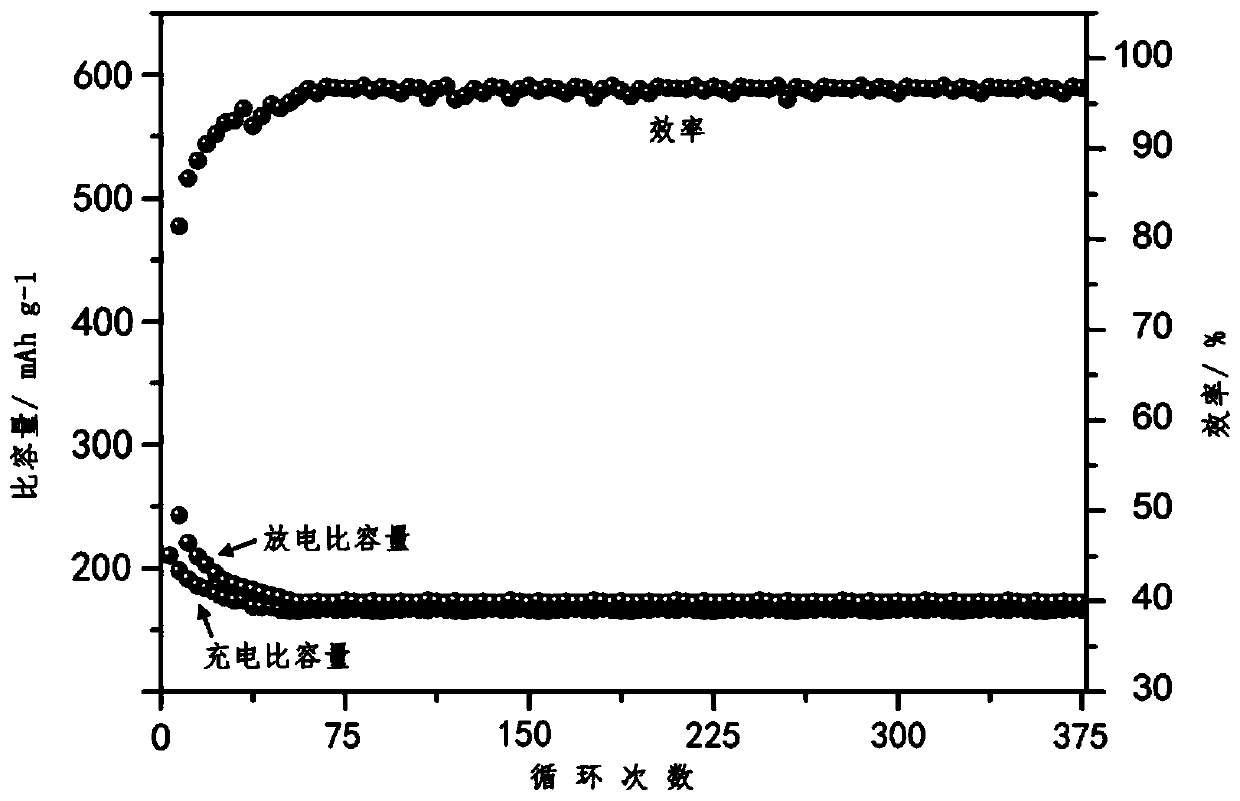

The invention discloses a method for preparing a multi-element co-doped lithium manganate composite material. The method adopts a sol-gel method, firstly, a mixed solution of manganese acetate tetrahydrate, aluminum nitrate nonahydrate, magnesium acetate tetrahydrate, and cobalt acetate tetrahydrate is slowly added dropwise to a lithium hydroxide monohydrate and citric acid mixed solution under stirring, an ammonia solution is added to adjust the pH of the solution, and the mixture is heated and stirred until a sol is formed, the sol is dried to obtain a dry gel, and the dry gel is calcined and ground into powder, and finally calcined to obtain the aluminum-cobalt-magnesium three-element co-doped lithium manganate composite material. The method has the advantages of simple process, wide source of raw materials, large output, low cost and easy control, and is favorable for large-scale industrial production, and the prepared lithium ion battery positive electrode material has excellent rate charge and discharge performance and excellent cycle service life.

Owner:NANJING UNIV OF SCI & TECH

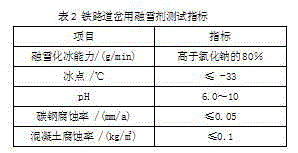

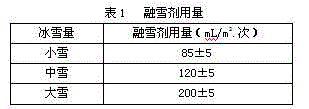

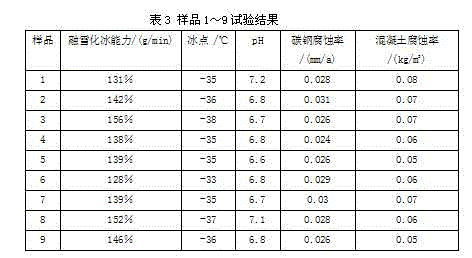

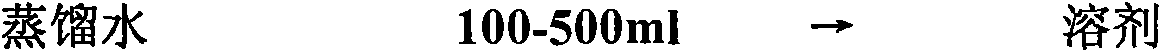

Snow melting agent for railway turnout and preparation method thereof

InactiveCN104559930APromote growthNon-toxicOther chemical processesCalcium nitrate tetrahydrateSodium metasilicate

The invention relates to a snow melting agent for a railway turnout. The snow melting agent is prepared from the following raw materials in parts by weight: 25-35 parts of potassium acetate, 3-6 parts of potassium nitrate, 5-10 parts of magnesium acetate tetrahydrate, 5-10 parts of calcium nitrate tetrahydrate, 5-10 parts of ammonium dihydrogen phosphate, 1-5 parts of urea, 3-8 parts of sodium molybdate, 25-30 parts of sodium formate, 0.2-1.0 part of sodium metasilicate, 15-20 parts of ethylene glycol and 10-15 parts of glycerin. The snow melting agent for a railway turnout provided by the invention can be used for thoroughly clearing snow on the side wall of the railway turnout and is harmless to soil while the cost is low and the snow melting effect is good.

Owner:林州市陆发重工机械有限责任公司

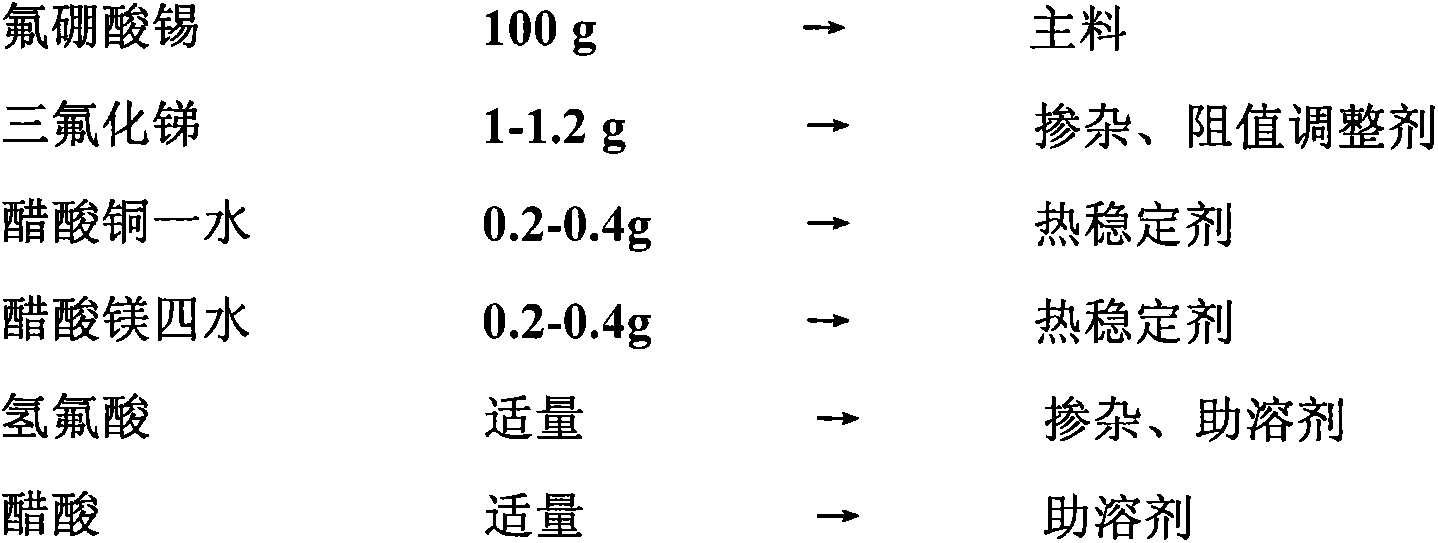

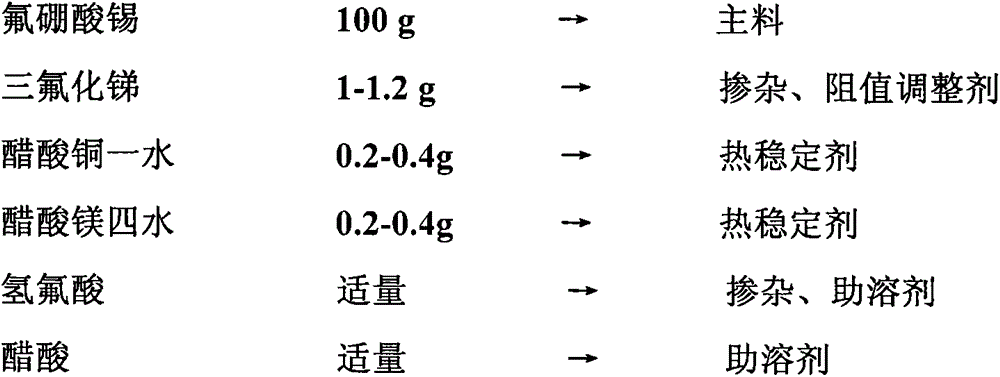

Pollution-free manufacturing method for surface electric heating elements

InactiveCN103716925AHigh electrothermal conversion rateSmall thermal inertiaOhmic-resistance heatingMagnesium Acetate TetrahydrateFluoroboric acid

A pollution-free manufacturing method for surface electric heating elements is characterized in that a formula of a surface modification solution comprises, by weight, 100g of stannous fluoroboric acid, 1-1.2g of antimony trifluoride, 0.2-0.4g of cupric acetate monohydrate, 0.2-0.4g of magnesium acetate tetrahydrate, a proper amount of hydrofluoric acid and a proper amount of acetic acid, and 100-500ml of distilled water. The pollution-free manufacturing method for the surface electric heating elements comprises the steps of (1) preparing the surface modification solution, wherein the distilled water is acidized through the acetic acid, the stannous fluoroboric acid, the cupric acetate monohydrate and the magnesium acetate tetrahydrate are weighed, stirred and melted in the acidized distilled water respectively, antimony trifluoride is quickly weighed, stirred and added in the acidized distilled water, the mixture is stirred, and all the solutions are mixed evenly, sealed and stored at a shady, cool and ventilating place for use; (2) cleaning base materials; (3) feeding the base materials into a surface modification furnace which is 550-650 DEG C to carry out surface modification on the base materials; (4) brushing silver paste at proper positions of radiant faces, and carrying out mechanical wire leading; (5) powering on to carry out aging by using voltages 1.25 times using voltages. The pollution-free manufacturing method for the surface electric heating elements is suitable for manufacturing the pollution-free surface electric heating elements.

Owner:信跃珍

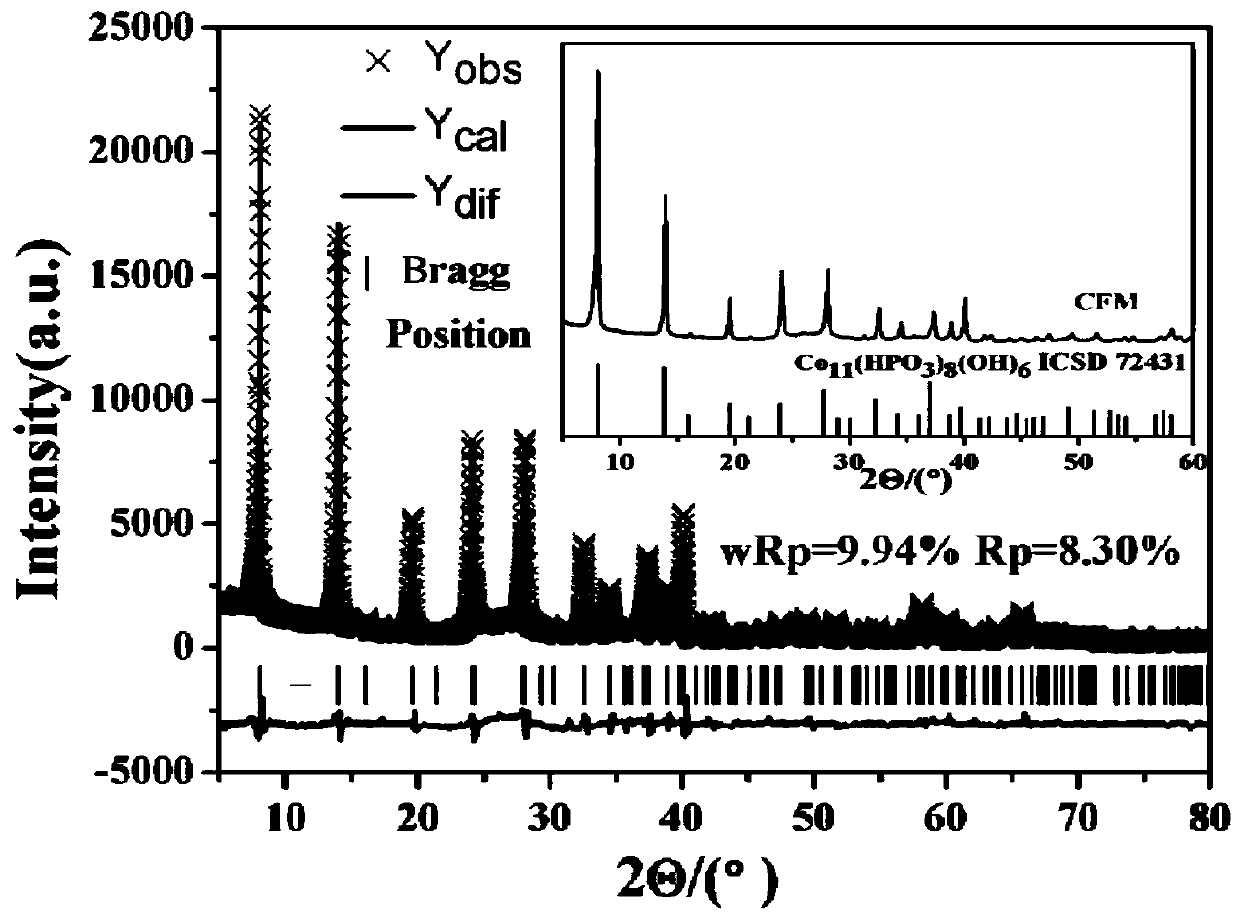

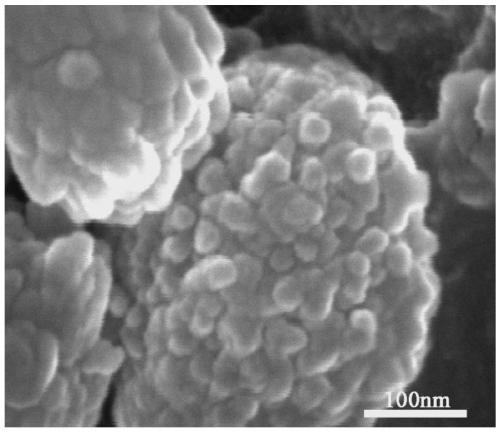

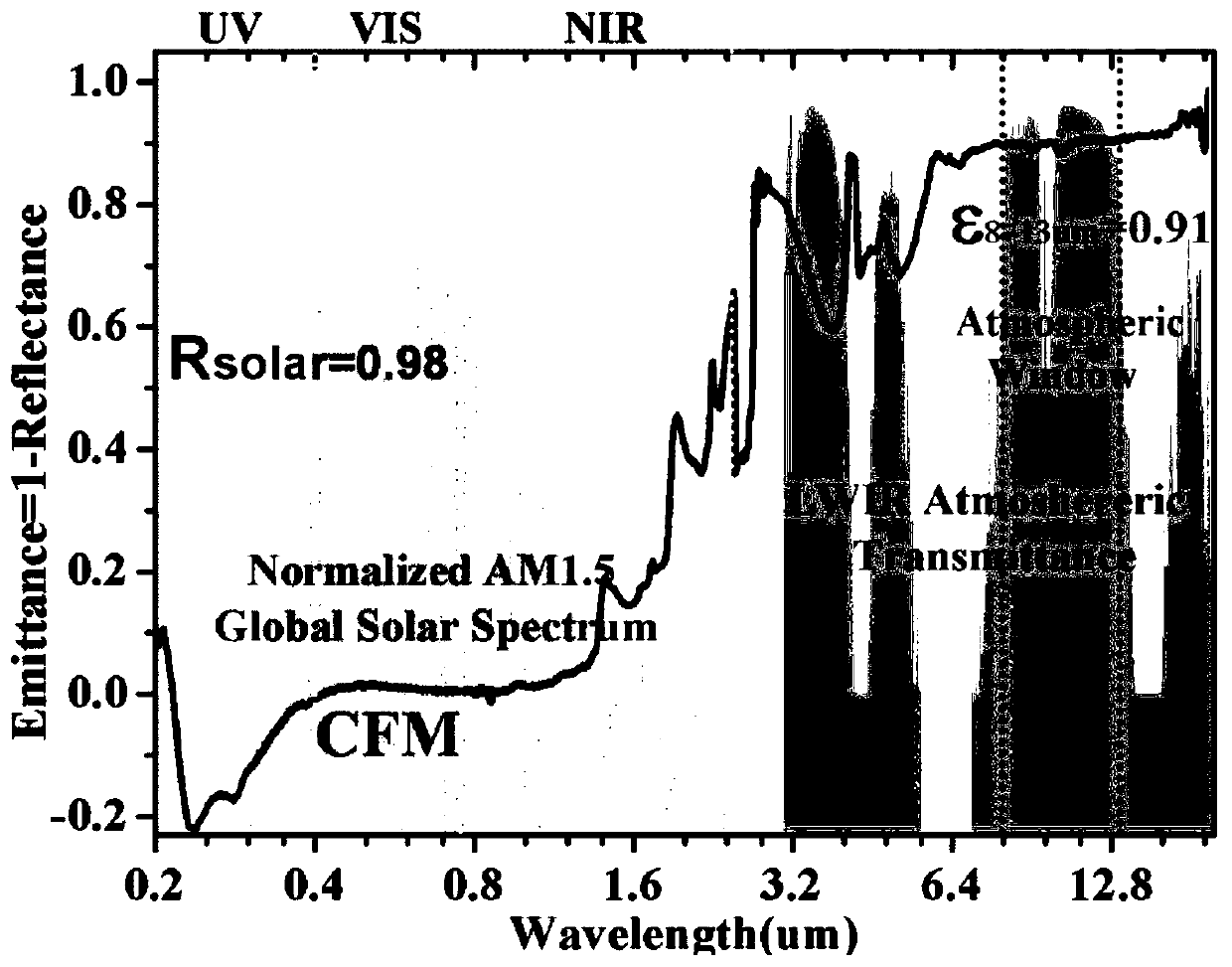

Crystal material, and preparation method and application thereof

ActiveCN108193268AHigh UV-Vis-NIR high reflectivityImprove performancePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidMagnesium Acetate Tetrahydrate

Owner:SOUTH CHINA UNIV OF TECH

Strontium magnesium silicate nanomaterial and preparation method and application thereof

ActiveCN109942004AImprove performanceLow costMaterial nanotechnologyCell electrodesMagnesium Acetate TetrahydrateAqueous ethanol

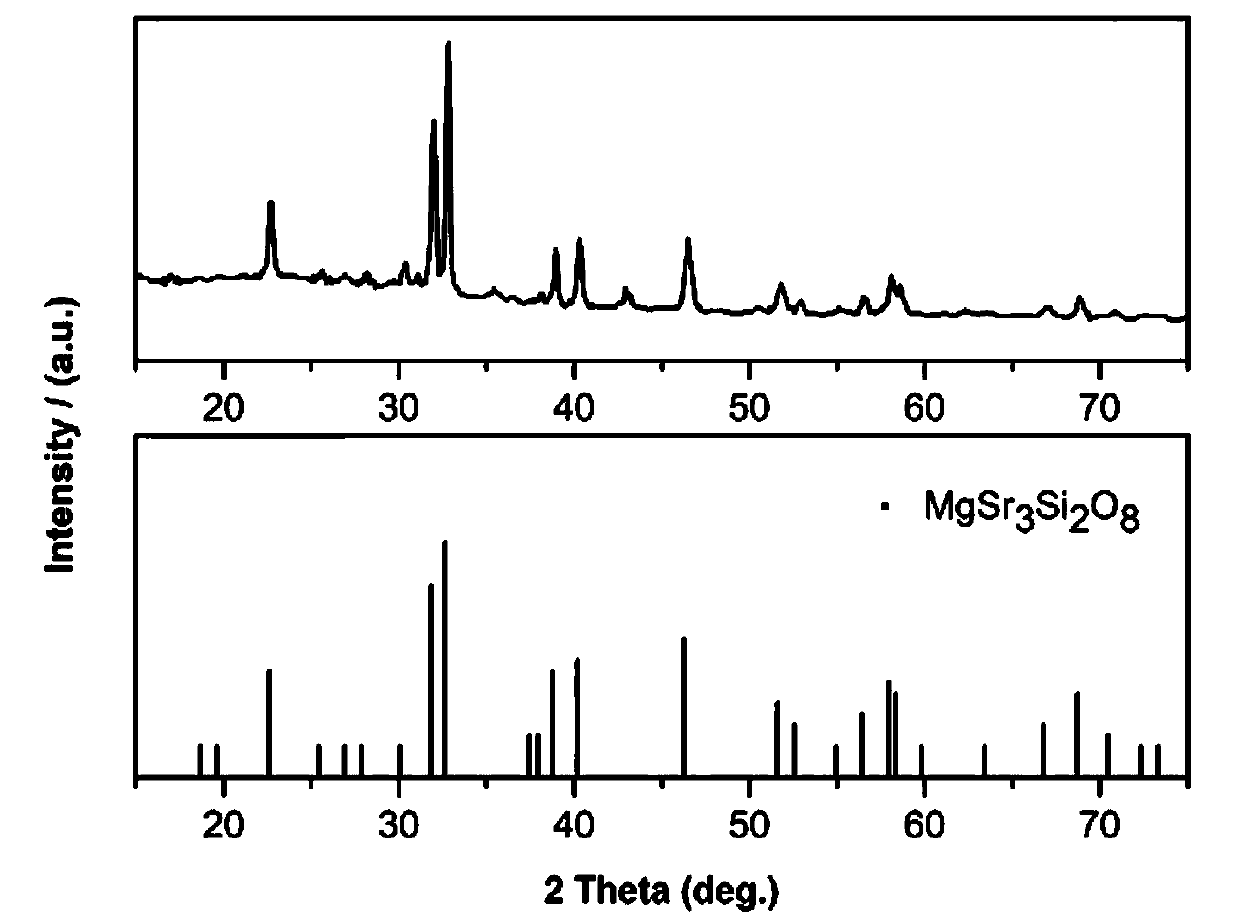

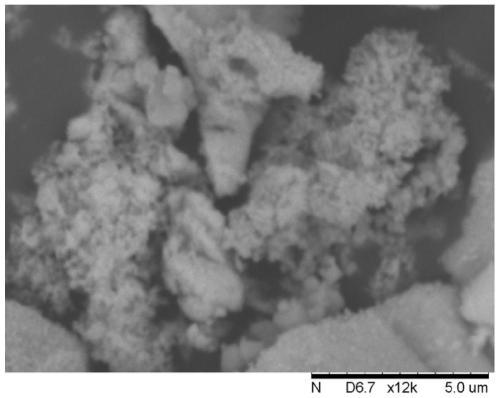

The invention discloses a strontium magnesium silicate nanomaterial and a preparation method thereof. A certain amount of magnesium acetate tetrahydrate, strontium acetate, tetraethyl silicate and urea are dissolved in a certain volume of aqueous ethanol solution and stirred; then, an obtained solution is transferred into a reaction still for a high-pressure hydrothermal reaction, a precipitate obtained after the reaction is dried, placed in a crucible, calcined in a muffle furnace and then naturally cooled to the room temperature, and the white strontium magnesium silicate nanomaterial is obtained. Electrochemical experiments show that the strontium magnesium silicate nanomaterial prepared by means of the method has a broad application prospect when used as a negative electrode material of lithium ion batteries. In the whole preparation process, the operation is simple, the raw material cost is low, the equipment investment is low, and the nanomaterial is suitable for mass production.

Owner:中镁通达新材料科技(哈尔滨)有限公司

Glucose hydrogenolysis catalysis Cu/MgO catalyst and preparation method thereof

ActiveCN104888778ASolve problems such as poor single selectivityImprove catalytic performanceOrganic compound preparationHydroxy compound preparationIonMagnesium Acetate Tetrahydrate

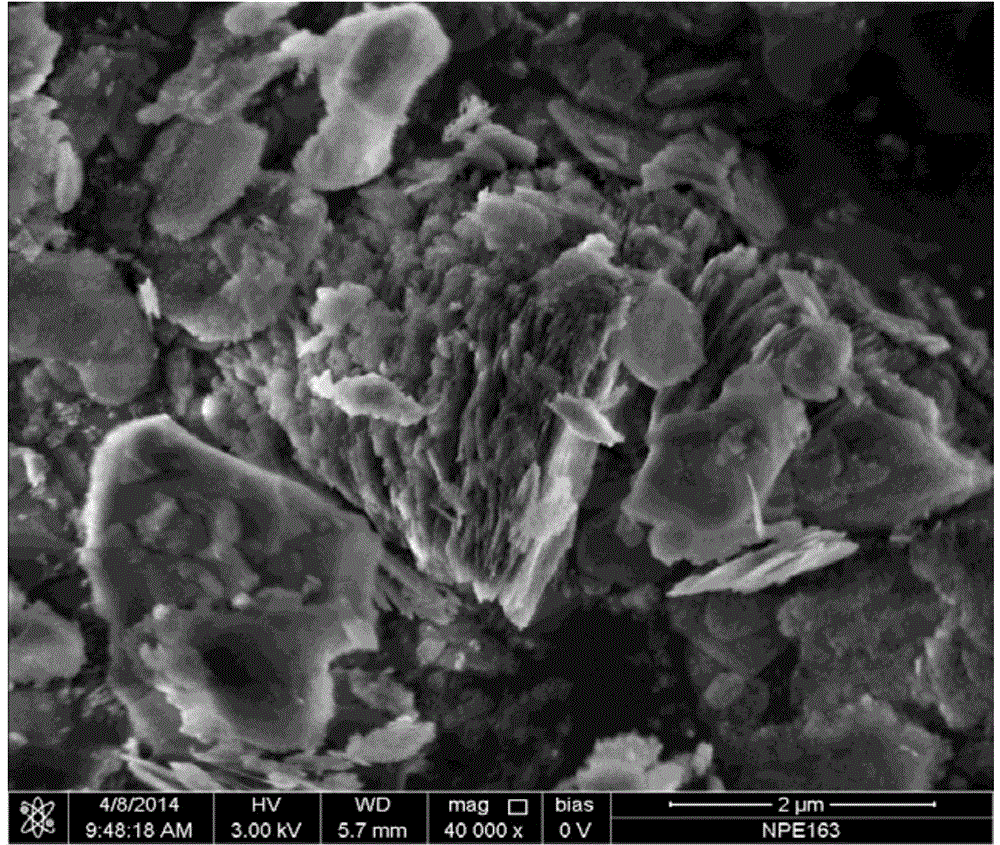

The invention discloses a glucose hydrogenolysis catalysis Cu / MgO catalyst and a preparation method thereof, and belongs to the technical field of heterogeneous catalysis. In anhydrous anaerobic conditions, by filtering, vacuum distillation and sublimation and purification of a liquid obtained by reaction of cuprous oxide, 1, 5-cyclooctadiene, and hexafluoro-acetylacetone, metal organic precursor hexafluoro-acetylacetone-cyclooctadiene copper and hexafluoro-acetylacetone copper relatively stable to air is produced. Petal shaped Mg (OH) 2 is synthesized by solvothermal method from magnesium acetate tetrahydrate as a raw material by use of a mixture of ethanol and deionized water solution as solvent, and the petal shaped Mg (OH) 2 is calcined to obtain an alkaline mesoporous MgO carrier with high specific surface area. By MOCVD (metal organic chemical vapor deposition) method, the two metal organic precursors are supported onto the MgO carrier for hydrogen reduction to obtain the copper base catalyst Cu / MgO used for glucose hydrogenolysis reaction. The glucose hydrogenolysis catalysis Cu / MgO catalyst has the advantages of simple operation process, mild reaction condition, good catalyst activity and stability, and good prospects of industrial application.

Owner:DALIAN UNIV OF TECH +1

Environmentally-friendly deicing agent and preparation method thereof

InactiveCN103865484ANot easy to freezeNo corrosionOther chemical processesSodium acetatePhosphorous acid

The invention discloses an environmentally-friendly deicing agent and a preparation method thereof. The environmentally-friendly deicing agent comprises, by weight, 50-100 parts of ethanol, 30-60 parts of glycol, 20-30 parts of sodium carbonate, 10-20 parts of sodium acetate, 5-10 parts of magnesium acetate tetrahydrate, 5-10 parts of ammonium oxalate, 5-10 parts of calcium bicarbonate, 3-5 parts of sodium hypophosphite, 3-5 parts of ammonium biphosphate and a proper amount of water. The preparation method comprises the following steps of crushing the solid raw materials, carrying out sieving so that the sieved raw material particles have the sizes less than or equal to 8mm, weighing the raw material particles according to the above ratio, carrying out stirring by a mixer to obtain a uniform mixture, carrying out weighing and carrying out split charging. The environmentally-friendly deicing agent has good deicing effects. The raw materials can absorb moisture and hydrolyze thereby releasing heat so that the thawed ice water is not frozen easily. The environmentally-friendly deicing agent does not produce corrosion and pollution and is healthy, environmentally-friendly and safe. The preparation method has simple processes, a moderate cost, is suitable for popularization and industrial production and has good benefits.

Owner:王富善

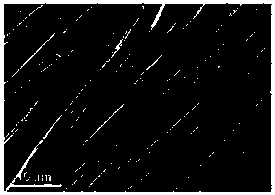

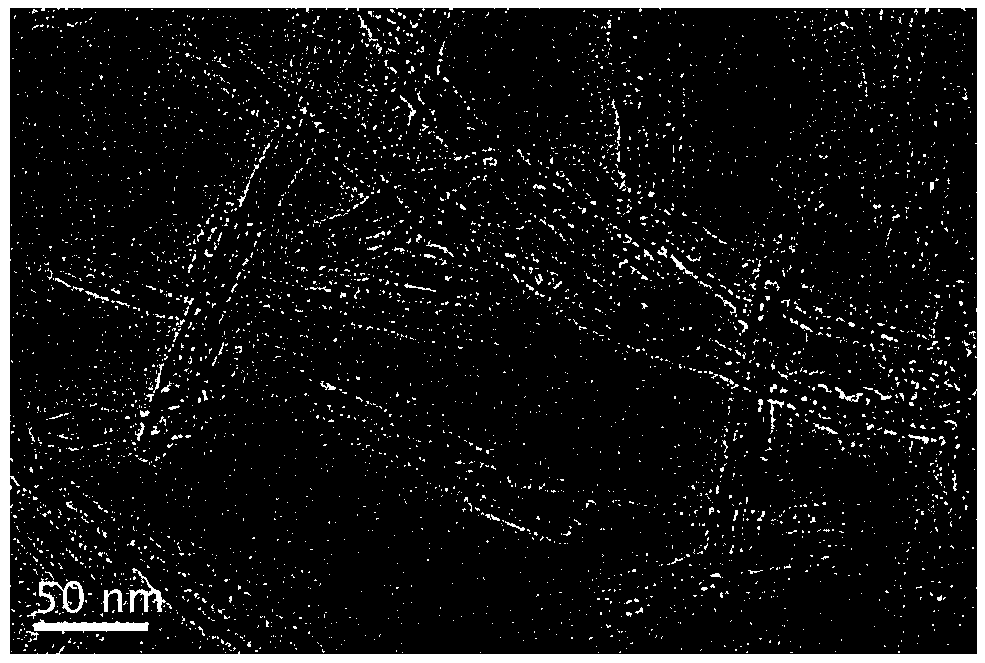

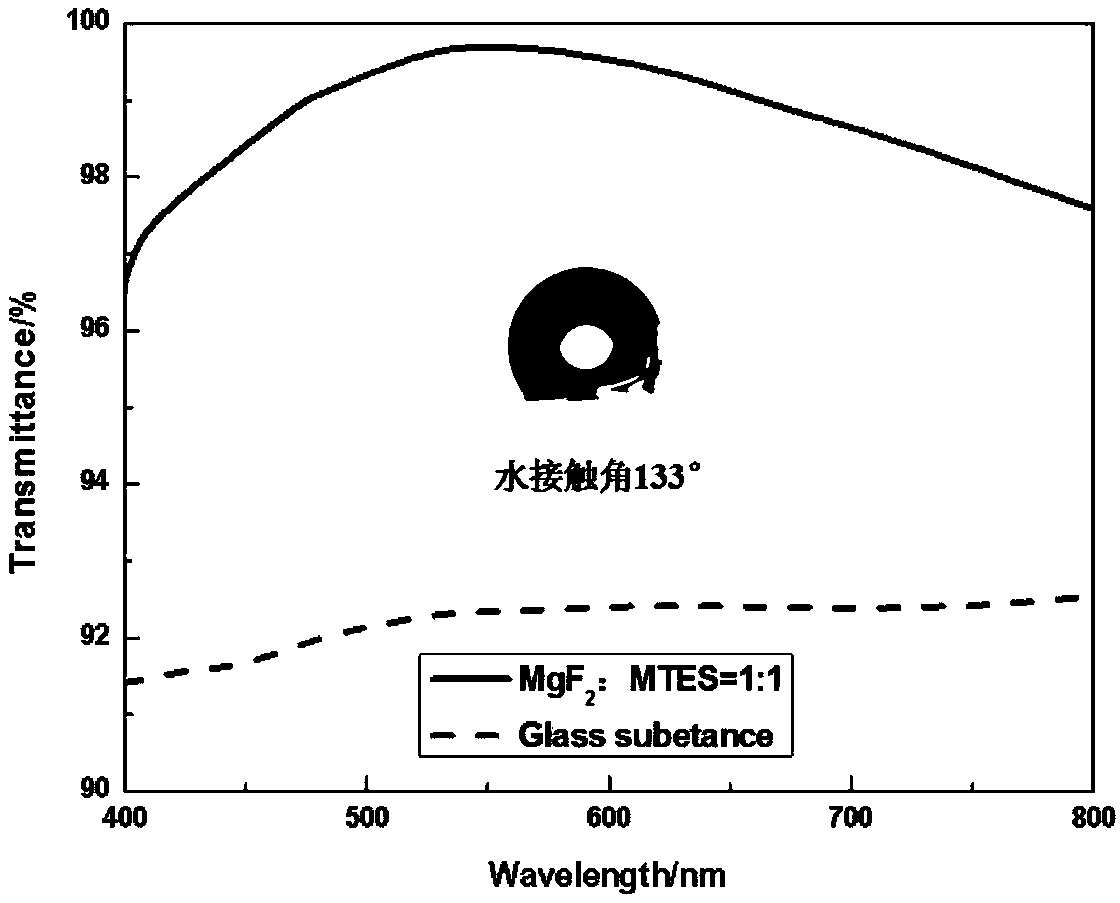

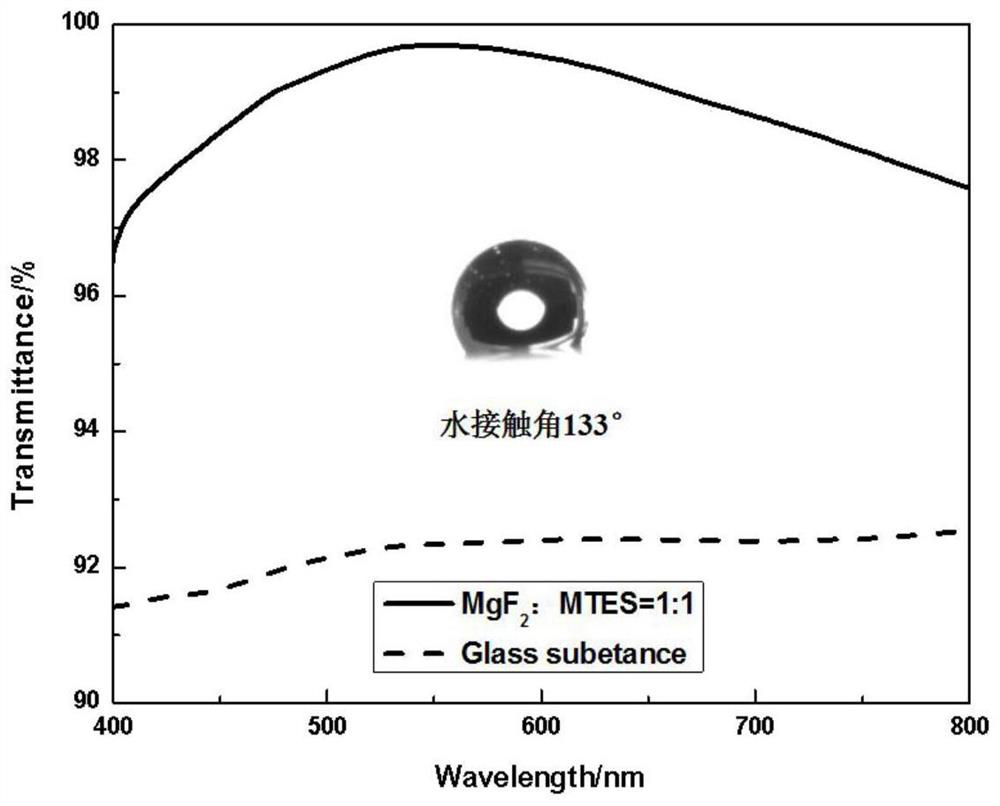

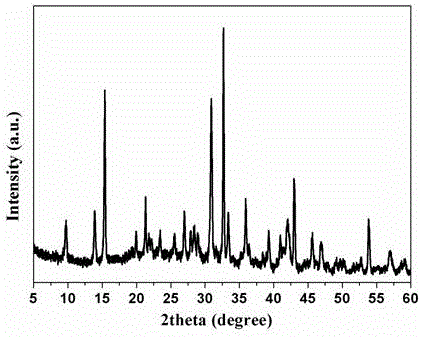

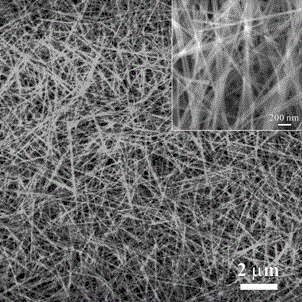

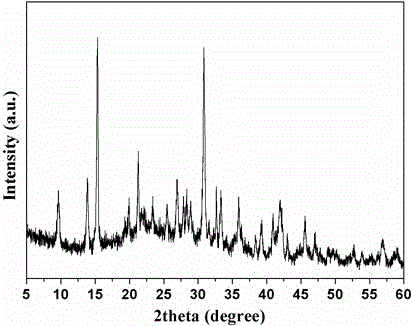

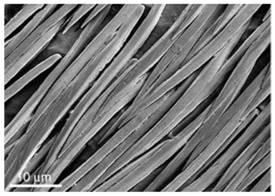

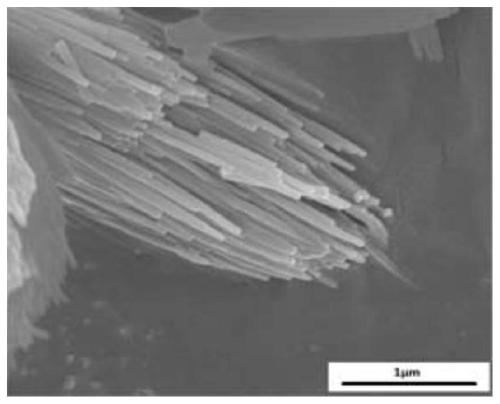

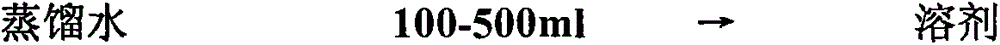

Preparation method of durable hydrophobic anti-reflection film for evacuated collector tube surface

The invention discloses a preparation method of a durable hydrophobic anti-reflection film for an evacuated collector tube surface. The method utilizes magnesium acetate tetrahydrate and hydrofluoricacid as raw materials to synthesize Mg(OH)2-xFx particle sol with a hollow rod structure by a solvothermal method, and then a hydrolysis product of Mg(OH)2-xFx and MTES is gelled through hydroxyl group condensation to obtain a CH3-SiO2-MgF2 composite particle sol. A layer of anti-reflection film is coated on the surface of glass with a light transmittance being 92% by a dipping and pulling method.After calcination at a temperature of 350 DEG C or lower, the obtained anti-reflection film has an average light transmittance of 98% or more in a visible light range and a contact angle of 133 degrees. After the anti-reflection film is irradiated for 1000 hours under 150W ultraviolet light, the average light transmittance can still be maintained 98% or more, and the contact angle can still be maintained a hydrophobic state of 120 degrees or above.

Owner:CHANGZHOU UNIV

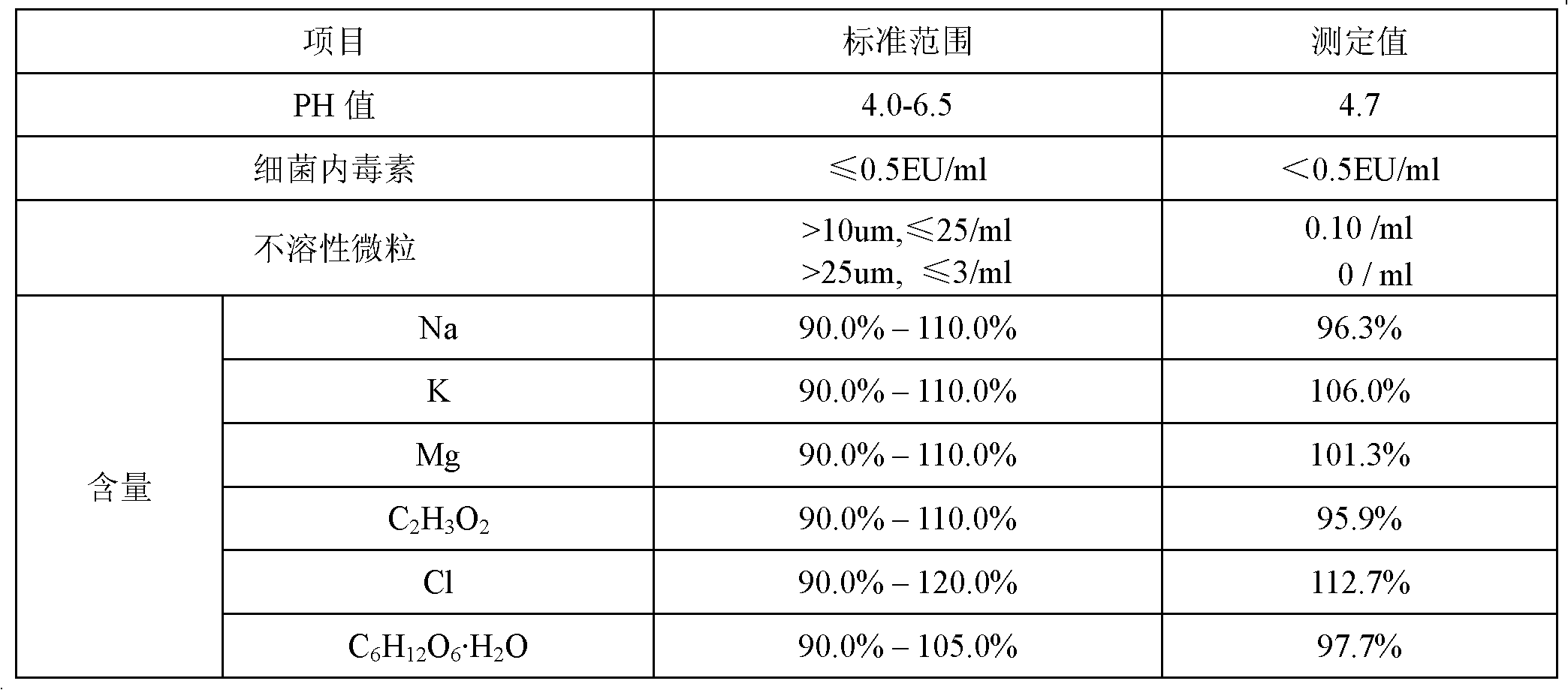

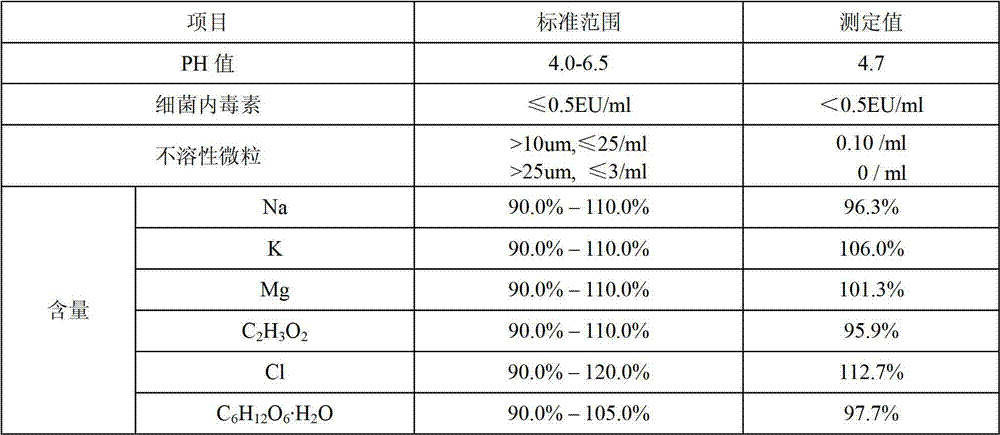

5% glucose adult nutrient solution and preparation method thereof

InactiveCN102319259ACombination medication is convenientComplete metabolismMetabolism disorderPharmaceutical delivery mechanismMagnesium Acetate TetrahydrateHigh energy

The invention belongs to the technical field of medical drugs, and particularly relates to a 5% glucose adult nutrient solution and a preparation method thereof. The invention mainly solves the defects that some glucose injections cause great fluctuation of blood sugar and are easy to cause metabolic complications. The technical scheme of the invention is that the formula of the 5% glucose adult nutrient solution is that the following components are added into 100 mL of injection water: 5000 mg of glucose, 234 mg of sodium chloride, 128 mg of potassium acetate, 32.2 mg of magnesium acetate tetrahydrate, and 30 mg of sodium pyrosulfite; and the 5% glucose adult nutrient solution is prepared by concentrated preparation, diluted preparation, filling and sterilization. The 5% glucose adult nutrient solution of the invention has the advantages of complete metabolism, high energy supply, and less blood sugar fluctuation.

Owner:SHANXI NUOCHENG PHARMA

A preparation method for durable hydrophobic anti-reflection film on the surface of vacuum heat collecting tube

ActiveCN108675648BLow refractive indexWith roughnessMagnesium Acetate TetrahydrateUltraviolet lights

The invention discloses a preparation method of a durable hydrophobic anti-reflection film for an evacuated collector tube surface. The method utilizes magnesium acetate tetrahydrate and hydrofluoricacid as raw materials to synthesize Mg(OH)2-xFx particle sol with a hollow rod structure by a solvothermal method, and then a hydrolysis product of Mg(OH)2-xFx and MTES is gelled through hydroxyl group condensation to obtain a CH3-SiO2-MgF2 composite particle sol. A layer of anti-reflection film is coated on the surface of glass with a light transmittance being 92% by a dipping and pulling method.After calcination at a temperature of 350 DEG C or lower, the obtained anti-reflection film has an average light transmittance of 98% or more in a visible light range and a contact angle of 133 degrees. After the anti-reflection film is irradiated for 1000 hours under 150W ultraviolet light, the average light transmittance can still be maintained 98% or more, and the contact angle can still be maintained a hydrophobic state of 120 degrees or above.

Owner:CHANGZHOU UNIV

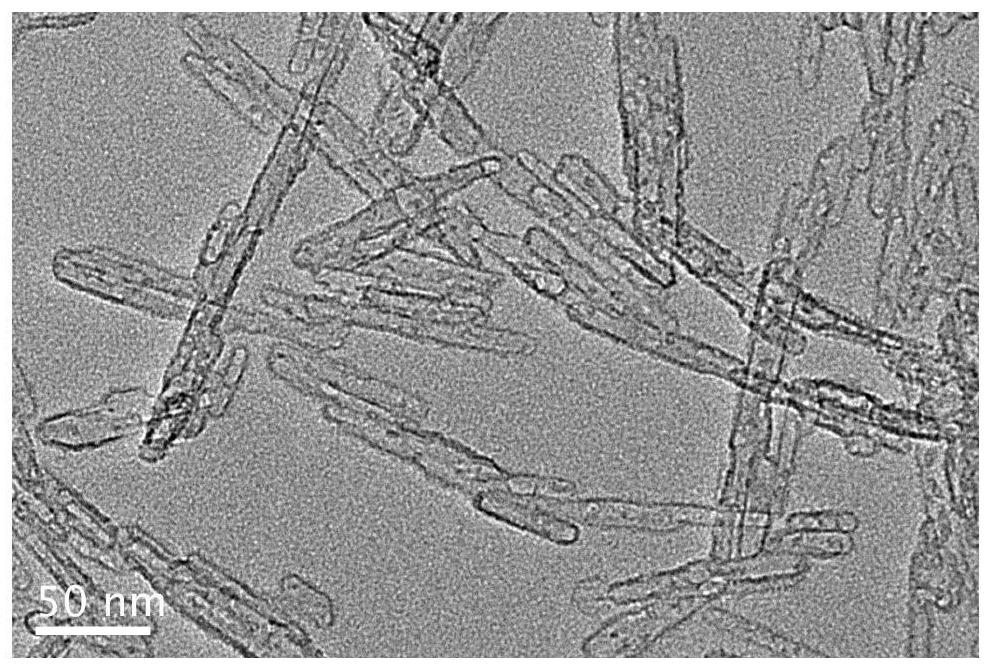

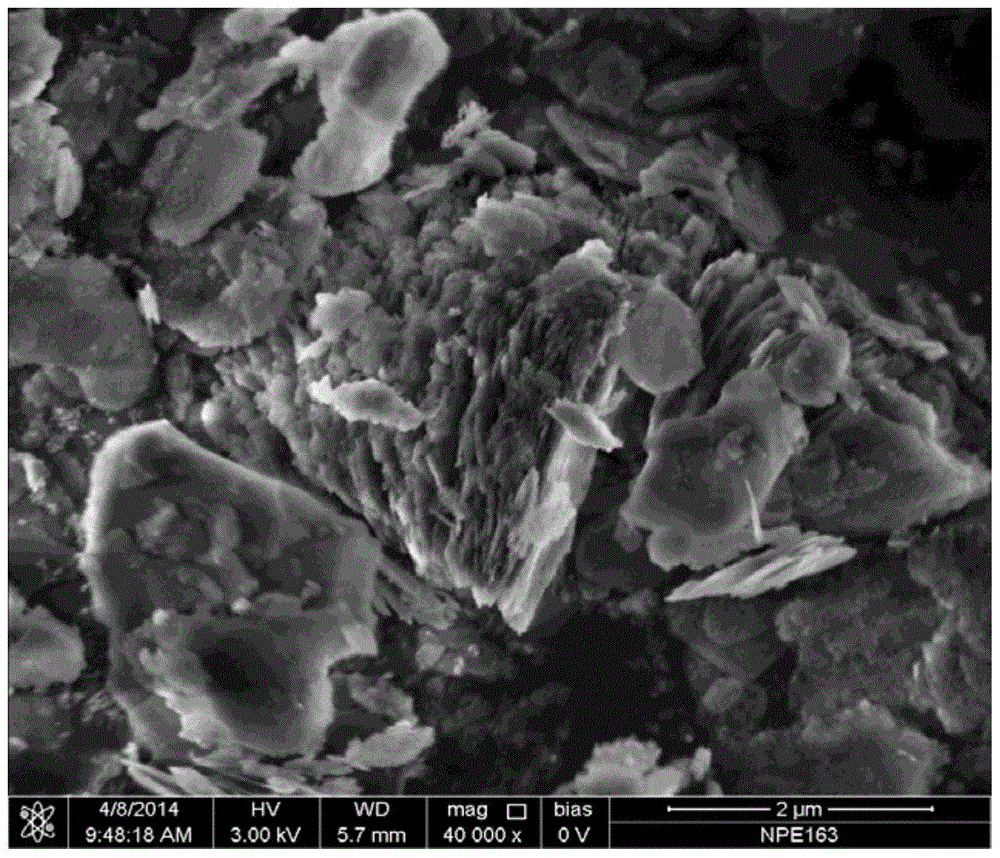

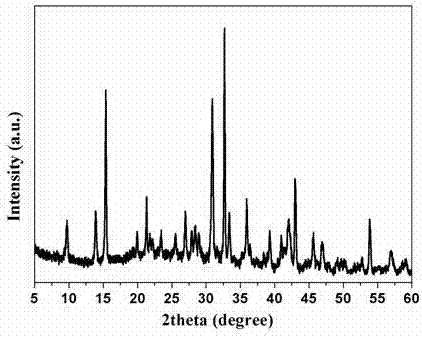

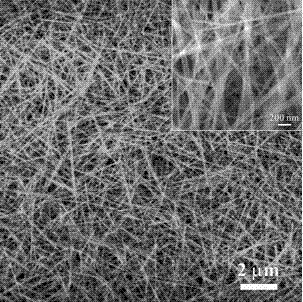

Synthesis method of controllable-length/width basic magnesium carbonate nanorods

ActiveCN105883866ARealize regulationMagnesium carbonatesNanotechnologySynthesis methodsMagnesium Acetate Tetrahydrate

The invention discloses a synthesis method of controllable-length / width basic magnesium carbonate nanorods. The synthesis method comprises the following steps: dissolving magnesium acetate tetrahydrate and ammonium carbonate in a deionized water-anhydrous ethanol mixed solution, adding cetyl trimethyl ammonium chloride and sodium hydroxide into the solution, stirring uniformly, transferring the mixed solution into a reaction kettle, and heating to the required temperature to react for the required time; and collecting the product by centrifugal separation, and washing the product with distilled water and industrial alcohol several times. The simple one-step hydrothermal method is utilized to synthesize the one-dimensional basic magnesium carbonate nanorods with uniform size. The reactant ratio is regulated to implement control on slender-rod basic magnesium carbonate to stubby-rod basic magnesium carbonate.

Owner:XUZHOU NORMAL UNIVERSITY

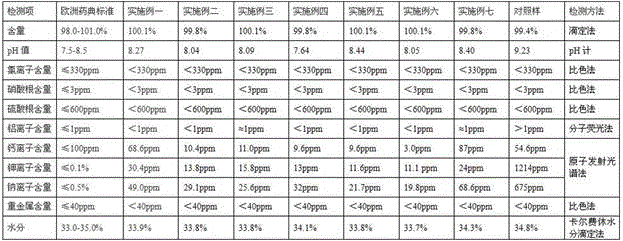

A method of preparing medicinal magnesium acetate tetrahydrate

InactiveCN106380388AQuality improvementEasy to storeOrganic compound preparationCarboxylic acid salt preparationAcetic acidMagnesium Acetate Tetrahydrate

A method of preparing medicinal magnesium acetate tetrahydrate is disclosed and belongs to the technical field of chemical bulk drug synthesis. The method includes steps of 1) weighing analytically pure magnesium hydroxide and analytically pure glacial acetic acid, adding water, heating to 75-80 DEG C, and cooling to 35 DEG C or below after the reaction is finished, 2) adjusting the pH value to 7.7-9.0 by adopting the magnesium hydroxide, filtering, and adjusting the pH value of the filtrate to 4.8-5.7 by adopting the glacial acetic acid to obtain a solution, 3) performing vacuum concentration until the density of the concentrate is 1.250-1.310, and crystallizing under stirring, 4) filtering and washing and 5) performing air blast drying to obtain a finished product. Through strictly controlling the pH value of the reaction solution, the pH value of the filtrate and the density before crystallization, the prepared magnesium acetate tetrahydrate reaches magnesium acetate tetrahydrate quality standards in the European Pharmacopoeia, and a prepared product is stable in quality and convenient to store and meets quality requirements on the magnesium acetate tetrahydrate of the medicinal grade.

Owner:HUAREN PHARMACEUTICAL CO LTD

5% glucose adult nutrient solution and preparation method thereof

InactiveCN102319259BCombination medication is convenientComplete metabolismMetabolism disorderPharmaceutical delivery mechanismMagnesium Acetate TetrahydrateHigh energy

The invention belongs to the technical field of medical drugs, and particularly relates to a 5% glucose adult nutrient solution and a preparation method thereof. The invention mainly solves the defects that some glucose injections cause great fluctuation of blood sugar and are easy to cause metabolic complications. The technical scheme of the invention is that the formula of the 5% glucose adult nutrient solution is that the following components are added into 100 mL of injection water: 5000 mg of glucose, 234 mg of sodium chloride, 128 mg of potassium acetate, 32.2 mg of magnesium acetate tetrahydrate, and 30 mg of sodium pyrosulfite; and the 5% glucose adult nutrient solution is prepared by concentrated preparation, diluted preparation, filling and sterilization. The 5% glucose adult nutrient solution of the invention has the advantages of complete metabolism, high energy supply, and less blood sugar fluctuation.

Owner:SHANXI NUOCHENG PHARMA

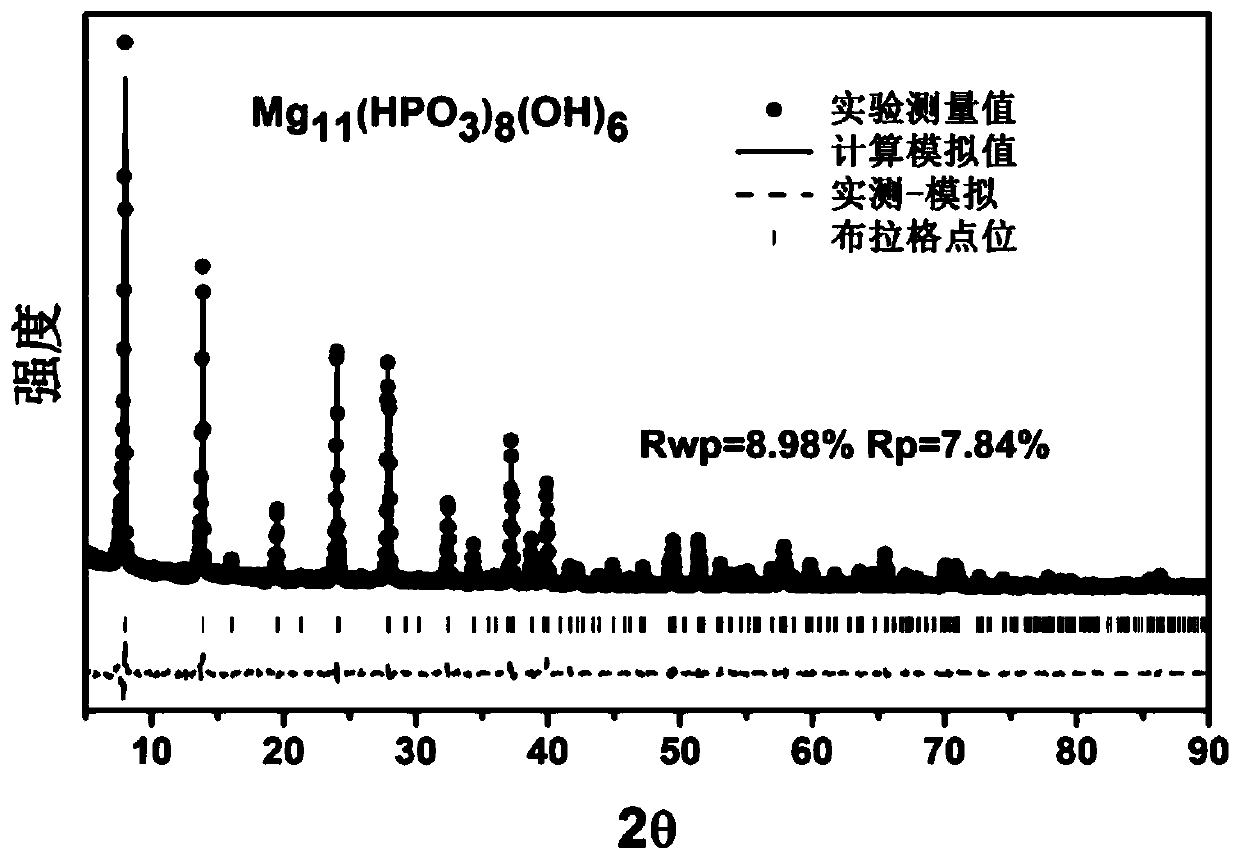

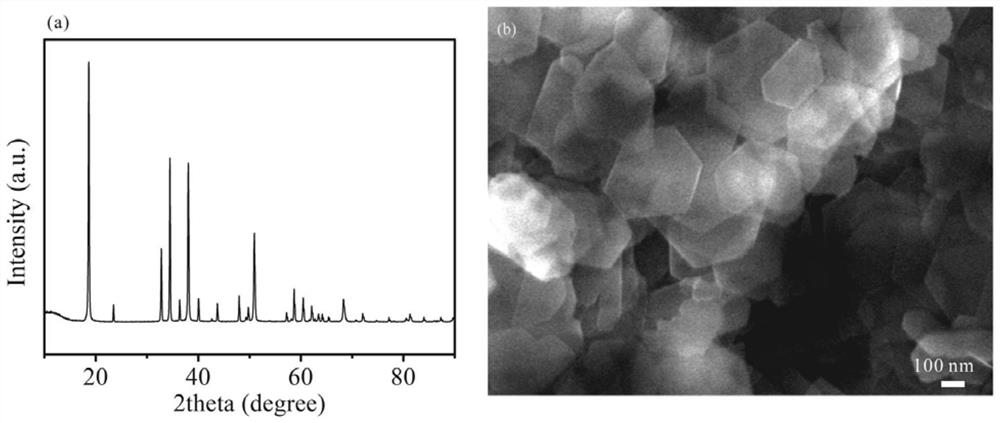

A kind of crystal material and its preparation method and application

ActiveCN108193268BHigh UV-Vis-NIR high reflectivityImprove performancePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidMagnesium Acetate Tetrahydrate

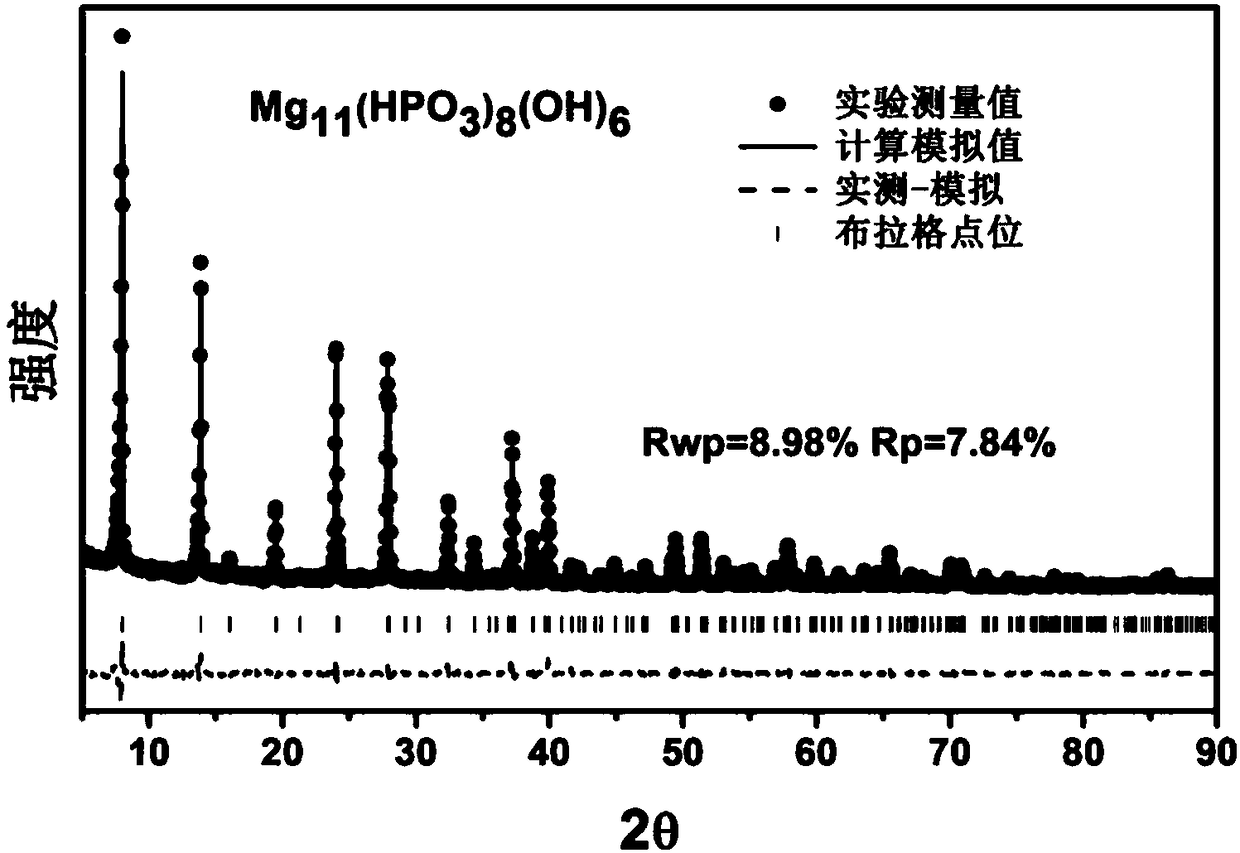

The invention discloses a crystal material. The chemical formula is Mg11(HPO3)8(OH)6, the reflectivity in an ultraviolet-visible-near infrared band of 0.2-2.5 microns is 88% or above, and simultaneously the emissivity in a far infrared band of 2.5-25 microns is 0.90 or above. The invention also discloses a preparation method of the crystal material. The preparation method comprises the following steps: on the basis of raw materials of magnesium acetate tetrahydrate and phosphorous acid, simultaneously adding a cyclohexylamine template agent, and preparing the Mg11(HPO3)8(OH)6 crystal powder bya hydrothermal synthesis method. According to the crystal material provided by the invention, comprehensive performance of reflection and radiation can be well combined, the actual cooling effect is2-10 DEG C better than the common heat reflecting material titanium dioxide in the market, and the crystal material can be well applied to the field of heat reflection infrared radiation.

Owner:SOUTH CHINA UNIV OF TECH

A kind of cu/mgo catalyst that catalyzes the hydrogenolysis of glucose and its preparation method

ActiveCN104888778BSolve problems such as poor single selectivityImprove catalytic performanceOrganic compound preparationHydroxy compound preparationMagnesium Acetate TetrahydrateSolvent

Owner:DALIAN UNIV OF TECH +1

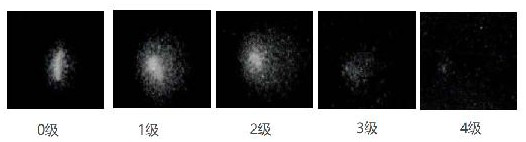

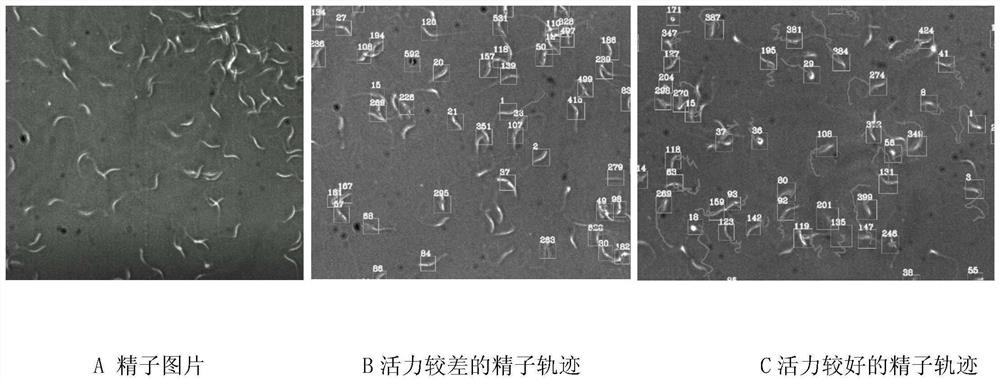

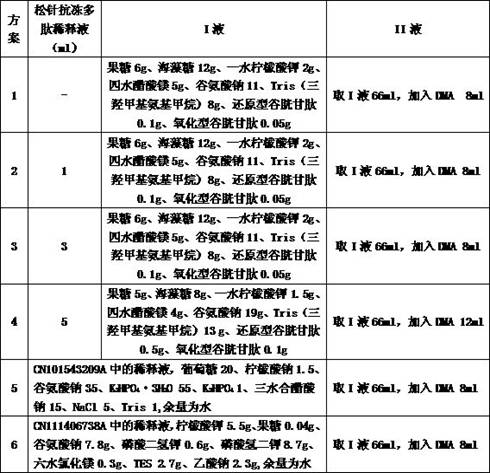

Antifreeze protein-containing diluent for improving preservation quality of chicken semen and preparation method thereof

ActiveCN114794082AReduce moistureImprove protectionDead animal preservationMonosodium glutamateMagnesium Acetate Tetrahydrate

The invention provides a diluent for cryopreservation of chicken semen. The diluent for cryopreservation of chicken semen is characterized by comprising pine needle antifreeze polypeptide, fructose, trehalose, potassium citrate monohydrate, magnesium acetate tetrahydrate, sodium glutamate, Tris (trihydroxymethyl aminomethane), reduced glutathione, oxidized glutathione and dimethylacetamide (DMA). The chicken semen cryopreservation diluent has the advantages that the raw materials are easy to obtain, the preparation is convenient, the fertilization rate reaches 80% or above, and the DNA integrity is higher. Compared with related data of fresh chicken essence, DNA integrity of the chicken essence is close to that of fresh essence, sperm motility and hatching rate of the chicken essence are slightly lower than those of the fresh essence, and the chicken essence has a wide application prospect.

Owner:贵州省种畜禽种质测定中心

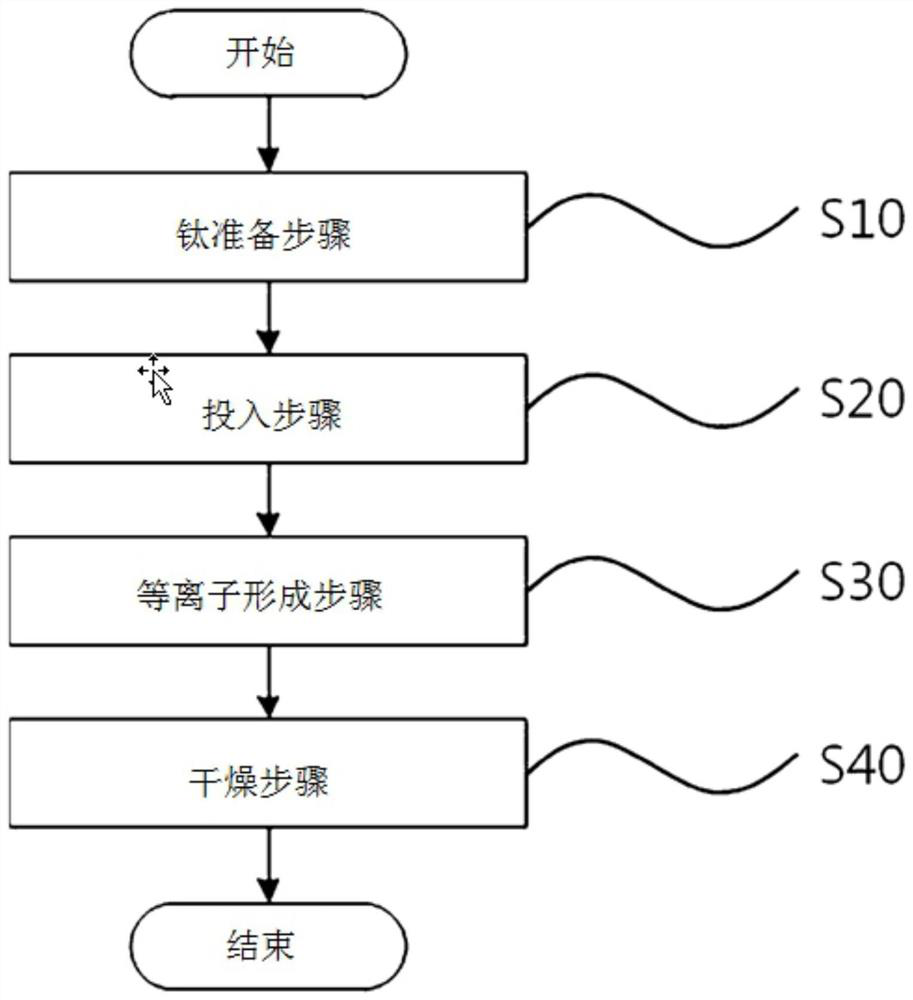

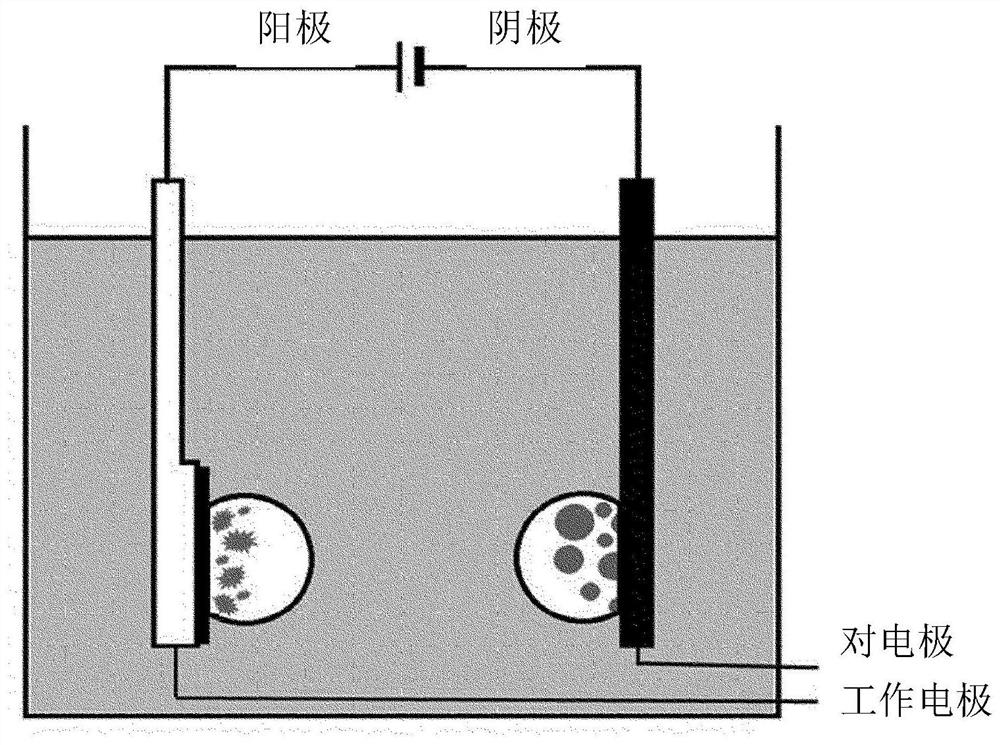

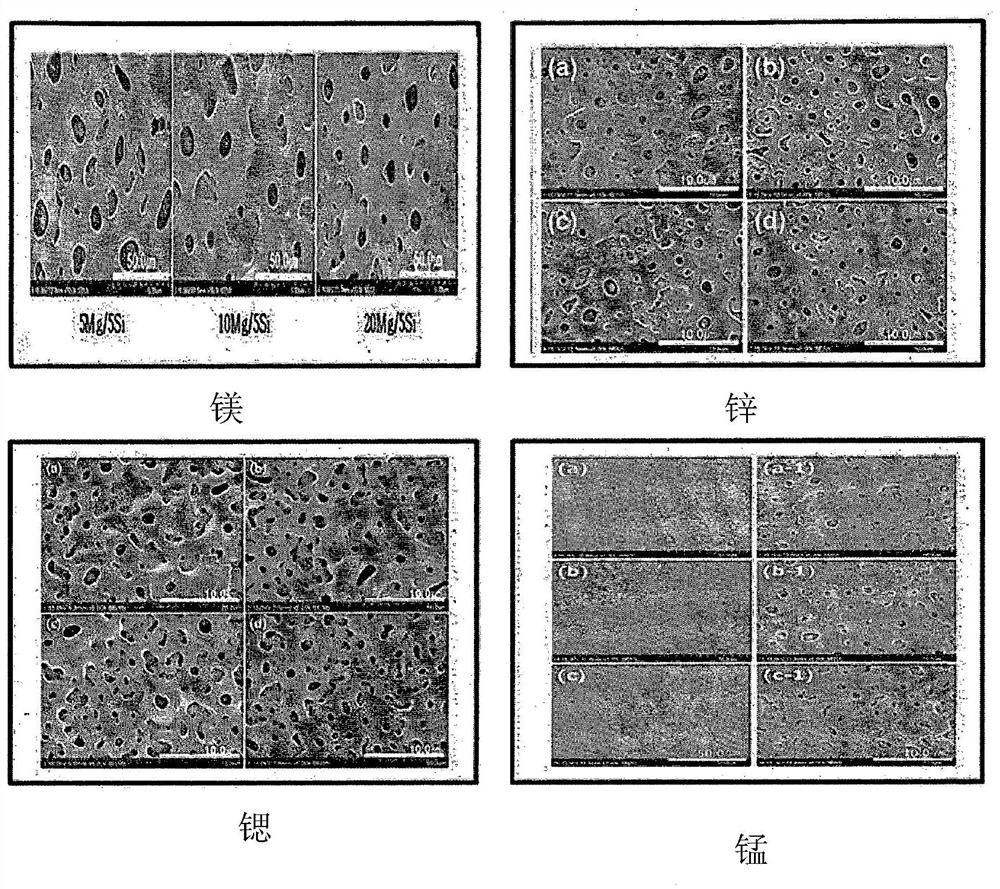

Method for producing electrolyte composition containing metal and silicon in plasma electrolytic oxidation process and dental implant

ActiveCN110494098BShorten production timeReduce healingDental implantsImpression capsCalcium Acetate MonohydrateMANGANESE ACETATE

The invention discloses an electrolyte composition and a method for manufacturing dental implants, wherein the electrolyte composition comprises calcium acetate monohydrate, calcium glycerophosphate, sodium metasilicate nonahydrate, distilled water and a metal compound to form an electrolyte solution The metal compound is one of magnesium acetate tetrahydrate, zinc acetate, strontium acetate and manganese acetate; the present invention is thicker and denser than the previous metal oxide film, and contains biologically active substances of metal ions and silicon ions. , rapidly increase the biocompatibility, thereby improving the initial fixation force of dental implants to shorten the treatment period.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

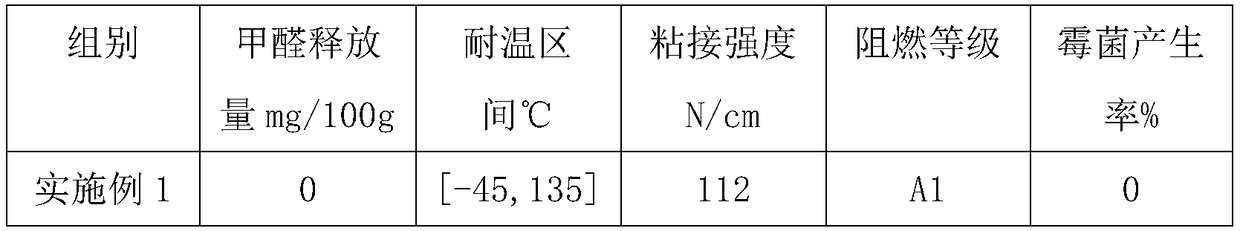

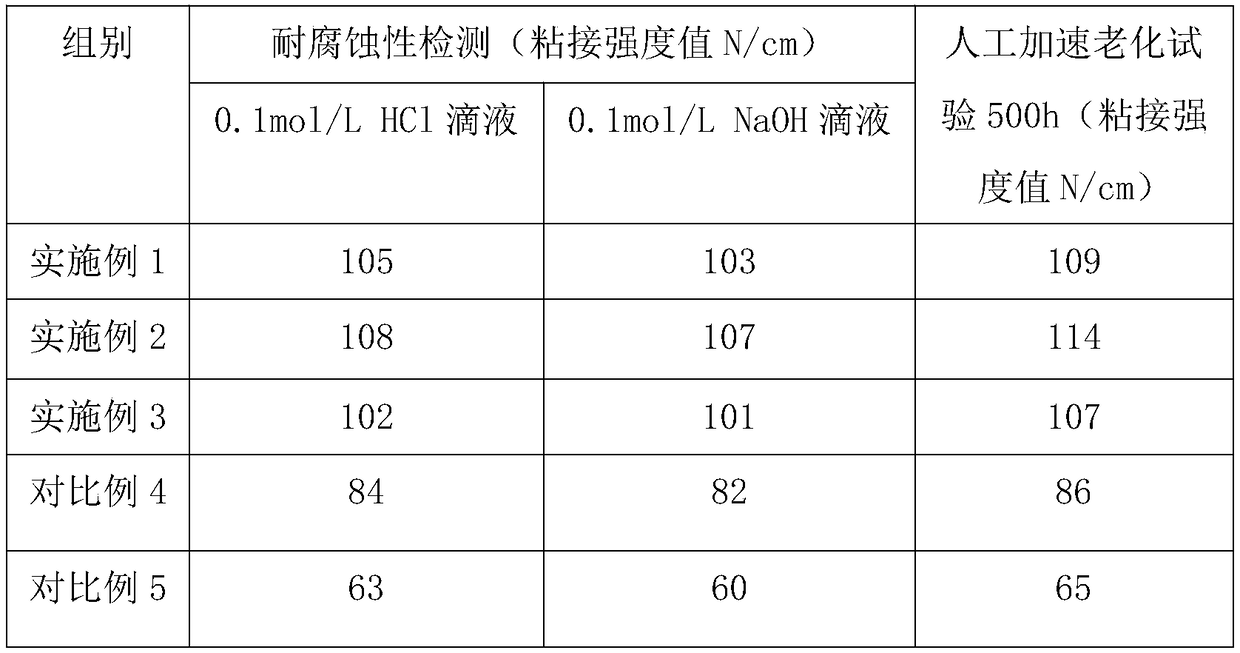

Adhesive for indoor decoration and preparation method thereof

InactiveCN108410369AEasy to prepareEasy to manufactureNon-macromolecular adhesive additivesMacromolecular adhesive additivesGlycidyl methacrylatePolymer science

The invention discloses an adhesive for indoor decoration and a preparation method thereof, which relate to the technical field of adhesive. The adhesive is prepared from the following materials: benzofuran resin, an isoprene-styrene block copolymer, hide glue, glycidyl methacrylate, methyl salicylate, benzophenone, diacetone acrylamide, magnesium acetate tetrahydrate, hydrogenated rosin, 1,3-diethyl thiourea, modified palm fibers, zeolite powder, kaolin, formamide, aluminium dihydrogen phosphate, an anti-aging agent, a crosslinking agent, plasticizer and a coupling agent. According to the preparation method, the materials are mixed, so that the adhesive is obtained. The adhesive property of the adhesive for indoor decoration disclosed by the invention is good, the solidified adhesive structure has excellent waterproof, antifreezing, flame-retardant, high temperature-resistant, strong acid corrosion-resistant, strong alkali corrosion-resistant, weather-proof and anti-aging properties,service lives of products are greatly prolonged, and the performance of the adhesive in use is improved.

Owner:合肥市晨雷思建筑材料科技有限公司

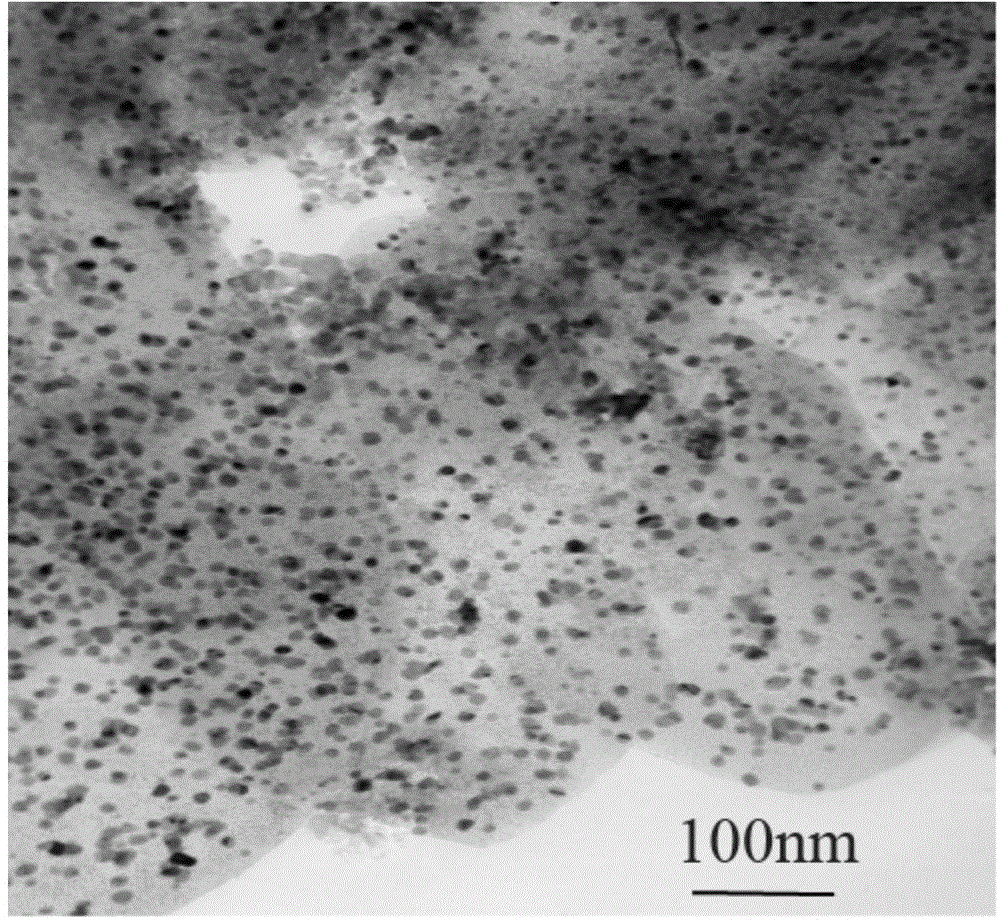

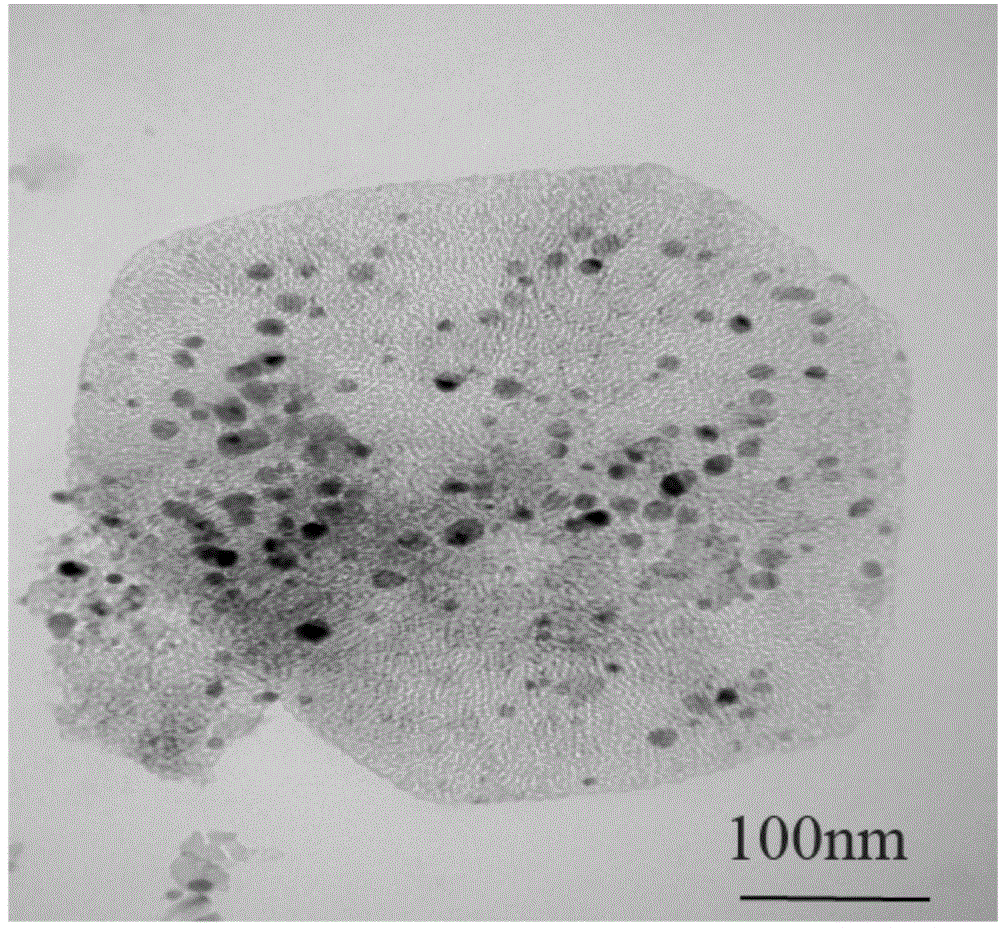

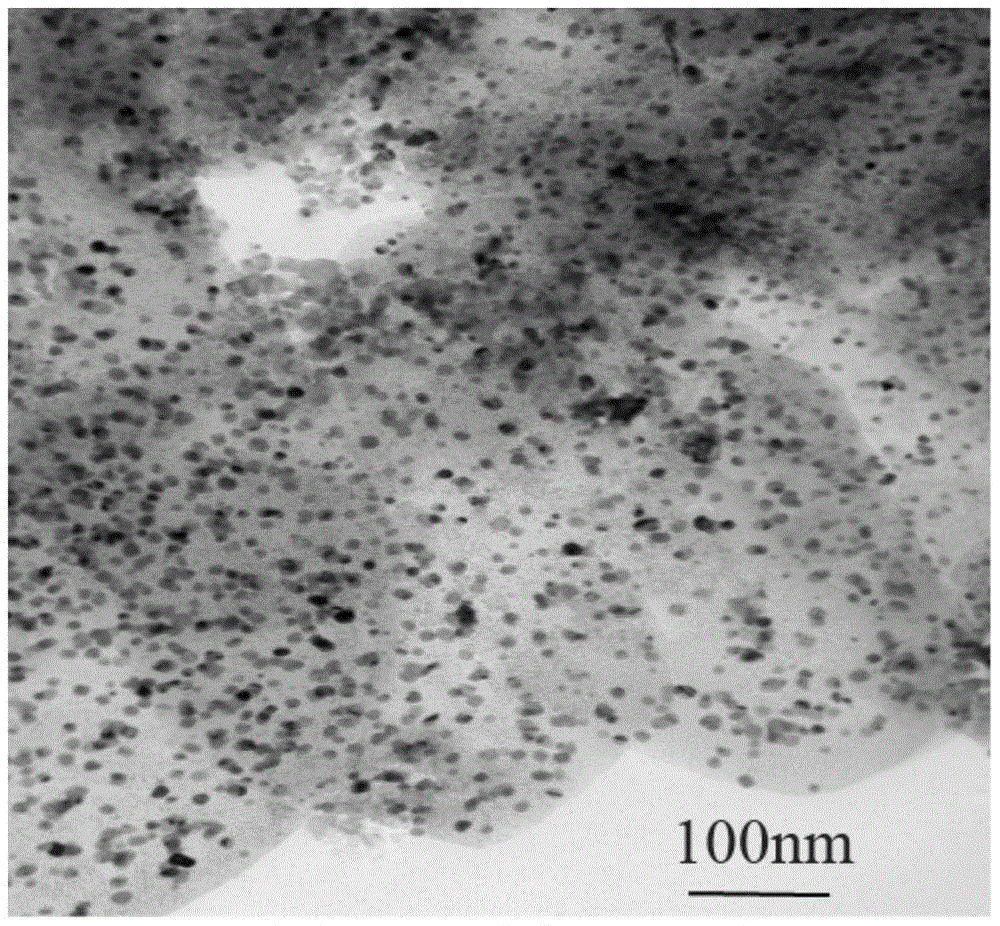

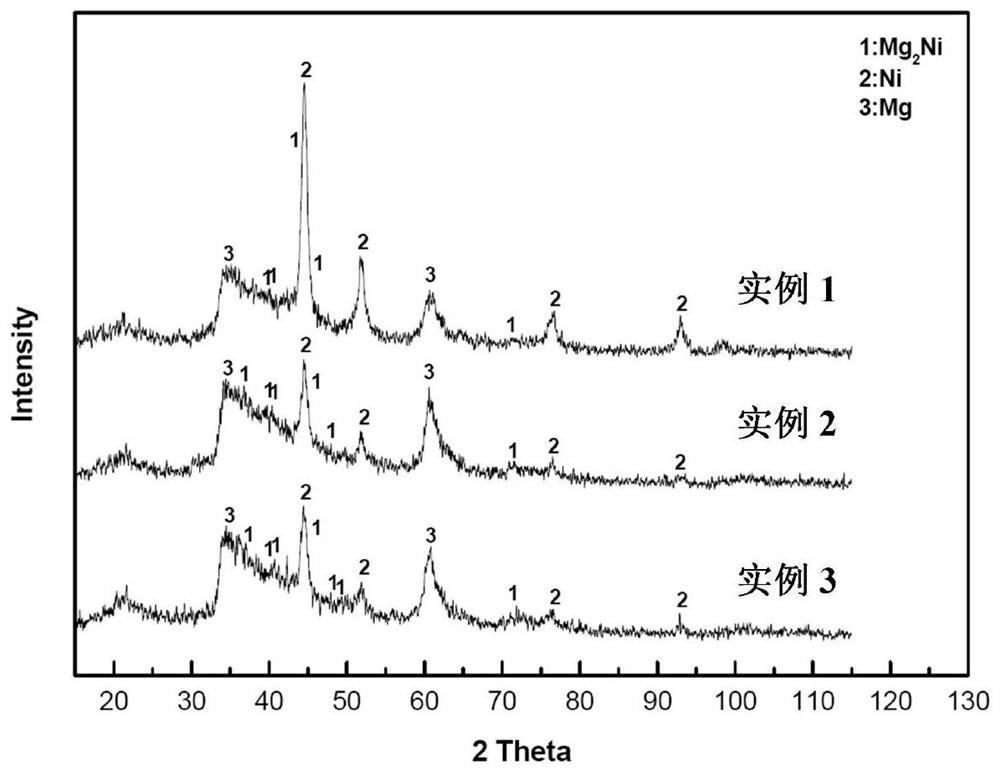

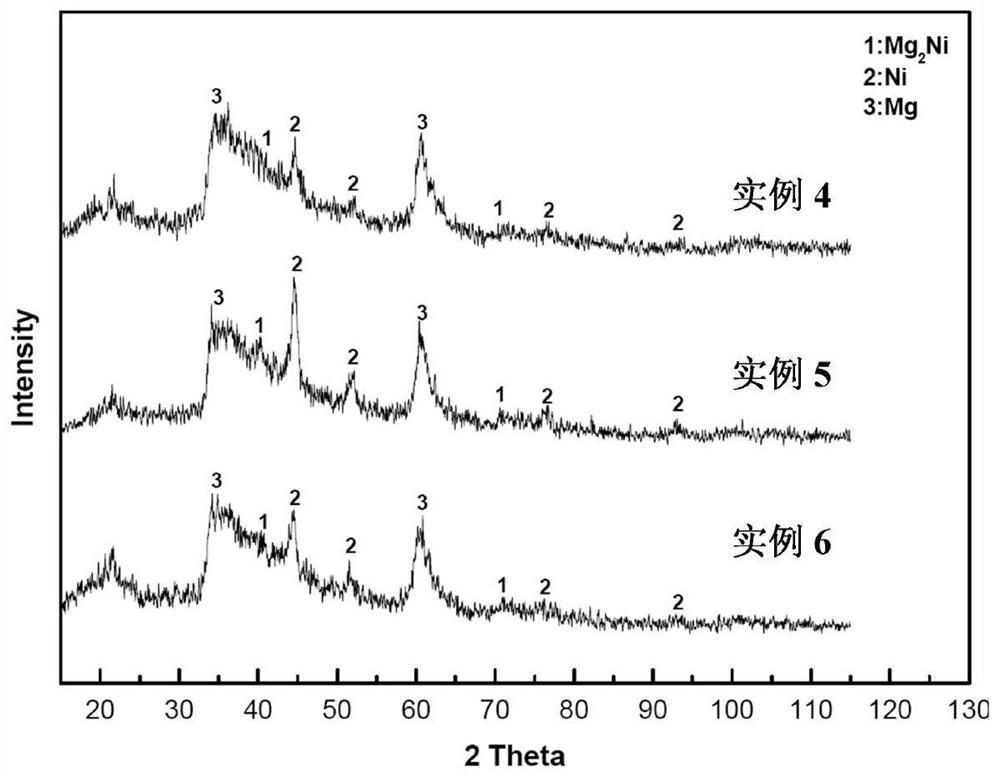

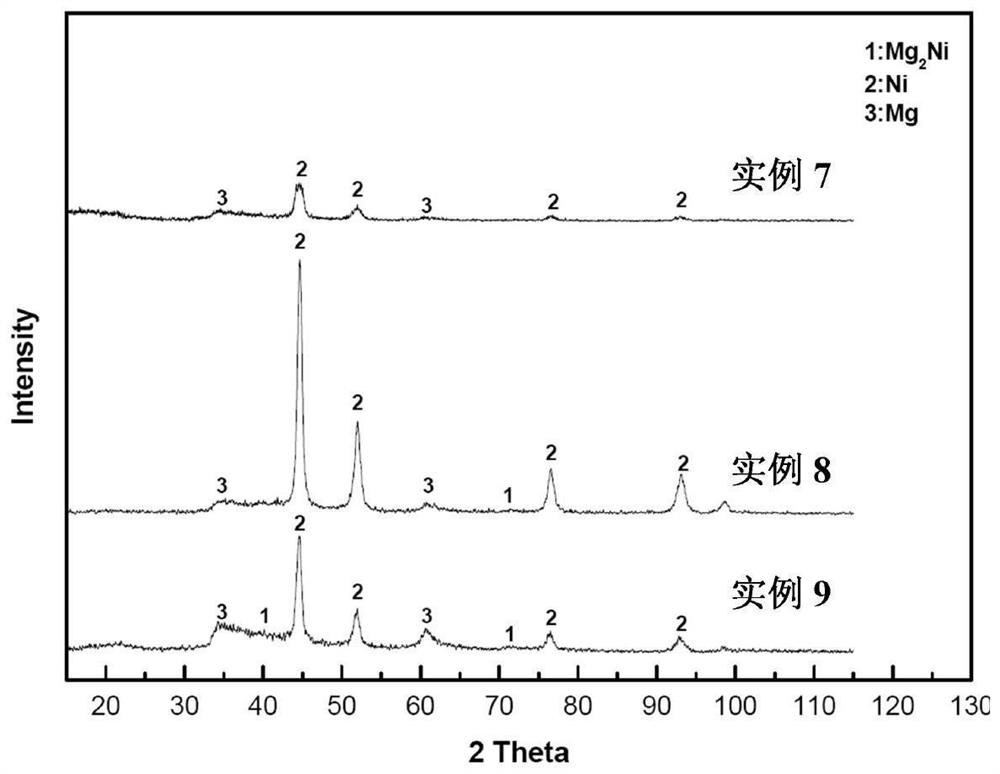

A method for preparing hydrogen storage magnesium-nickel alloy nanopowder based on polyol method

ActiveCN108941610BHigh power consumptionImprove energy consumptionMaterial nanotechnologyPolyolNickel(II) acetate

The present invention provides a method for preparing hydrogen-storing magnesium-nickel alloy nanopowder based on a polyol method and a method thereof, comprising: step 1: dissolving magnesium acetate tetrahydrate and nickel acetate tetrahydrate in ethylene glycol to obtain solution I; step 2: dissolving Dissolve polyvinylpyrrolidone in ethylene glycol to obtain solution II; step 3: mix solution I and solution II and reflux after magnetic stirring; step 4: add 2 ethylene glycol solution, when the temperature of the solution reaches 180°C, it is refluxed, washed, and dried to finally generate magnesium-nickel alloy nanopowder. In this application, the polyol method is used to prepare nano-magnesium-nickel alloy powder, which has less energy consumption, low cost, and is suitable for mass production; the process is relatively simple, and the preparation can be controlled by changing the reaction temperature, reaction time, protective agent dosage and concentration. The particle size of the alloy powder.

Owner:上海中海龙高新技术研究院

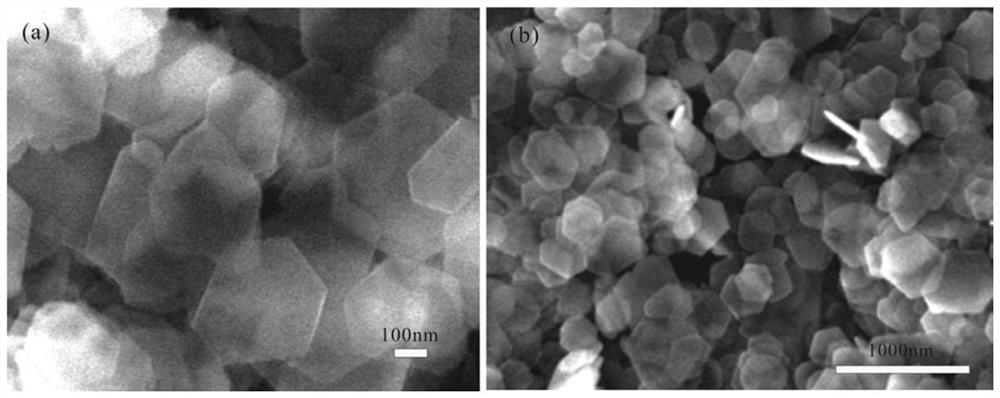

Passive refrigeration crystal, passive refrigeration coating as well as preparation method and application thereof

ActiveCN109837589AImprove performanceGood repeatabilityPolycrystalline material growthLiquid surface applicatorsPhosphorous acidCalcium Acetate Monohydrate

The invention discloses a passive refrigeration crystal, a passive refrigeration coating as well as a preparation method and application thereof, the expression formula of the crystal is CayMg11-y(HPO3)8(OH)6-xFx (1<=x<=6, and 0.3<=y<=1), the UV-visible near-infrared band reflectance is greater than 0.95, the emissivity at atmospheric window is greater than 0. 90, and a certain emission selectivity is shown in a long-wave range. Based on magnesium acetate tetrahydrate, calcium acetate monohydrate, sodium fluoride and phosphorous acid as raw materials, the passive refrigeration crystal is prepared by a hydrothermal method by adding cyclohexylamine. The passive refrigeration coating is prepared by utilizing the passive refrigeration crystal, the surface temperature is 5 DEG C lower than theenvironment temperature at the moment of high noon with direct solar radiation, the surface temperature of the wall surface of a building can be effectively reduced, and the reduced amplitude can be by more than 7 DEG C. The crystal material can alleviate the urban heat island effect to a certain extent.

Owner:SOUTH CHINA UNIV OF TECH

Heat-resistant and anti-stripping pressure-sensitive adhesive

InactiveCN105505237AKeep basic featuresImprove heat resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveMagnesium Acetate TetrahydrateAntioxidant

The invention discloses a heat-resistant and anti-stripping pressure-sensitive adhesive, which is prepared from the following raw materials in parts by weight: 90 to 110 parts of 2-ethylhexyl acrylate, 70 to 90 parts of ethyl acetate, 40 to 60 parts of diacetone acrylamide, 30 to 50 parts of castor oil, 10 to 18 parts of methyl alcohol, 10 to 18 parts of silicane, 8 to 10 parts of chlorosulfonated polyethylene, 8 to 10 parts of emulsifying agents, 4 to 6 parts of magnesium acetate tetrahydrate, 1 to 2 parts of catalysts. 0.5 to 1.5 parts of zinc dimethyldithiocarbamate, and 0.2 to 1 part of antioxidant. A preparation method of the heat-resistant and anti-stripping pressure-sensitive adhesive comprises the following steps of S1, weighing the following raw materials in parts by weight according to a mixture ratio: 90 to 110 parts of the 2-ethylhexyl acrylate, 70 to 90 parts of the ethyl acetate, 40 to 60 parts of the diacetone acrylamide, 30 to 50 parts of the castor oil, 10 to 18 parts of the methyl alcohol, 10 to 18 parts of the silicane, 8 to 10 parts of the chlorosulfonated polyethylene, and 8 to 10 parts of the emulsifying agents, and sufficiently mixing the above raw materials, to obtain a pre-emulsion A; S2, adding the pre-emulsion into a reactor. The heat-resistant and anti-stripping pressure-sensitive adhesive is simple in preparation and convenient to operate; the problem that a common pressure-sensitive adhesive is poor in heat resistance is solved; the anti-stripping property is enhanced; the heat-resistant and anti-stripping pressure-sensitive adhesive is suitable for popularization.

Owner:安徽律正科技信息服务有限公司

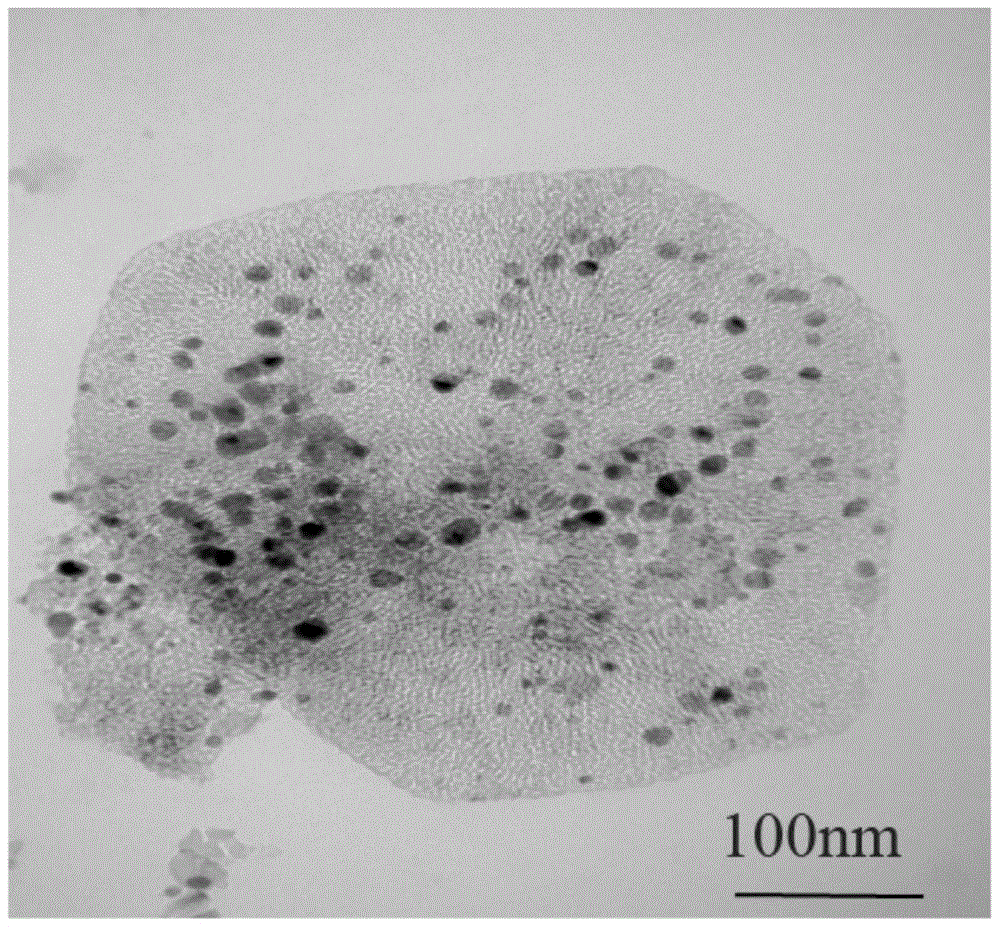

Synthesis method of basic magnesium carbonate ultrathin nanosheet

ActiveCN110937615AControl thicknessMagnesium carbonatesHydration reactionMagnesium Acetate Tetrahydrate

The invention discloses a synthesis method of a basic magnesium carbonate ultrathin nanosheet. The synthesis method comprises the following steps of: adding magnesium acetate tetrahydrate, ammonium carbonate, polyvinylpyrrolidone and sodium hydroxide into an aqueous solution, then adding absolute ethyl alcohol into the solution, transferring the solution into a reaction kettle, performing ultrasonic dissolving, heating and reacting for a period of time in a drying oven, centrifugally separating and collecting a product, and washing the product for multiple times to obtain the basic magnesium carbonate ultrathin nanosheet. According to the invention, the basic magnesium carbonate ultrathin nanosheet with uniform morphology is synthesized through one-step simple hydrothermal reaction, and the thickness of the basic magnesium carbonate ultrathin nanosheet can be regulated and controlled by regulating and controlling the amount of sodium hydroxide.

Owner:XUZHOU NORMAL UNIVERSITY

A pollution-free manufacturing method of surface electric heating element

InactiveCN103716925BHigh electrothermal conversion rateSmall thermal inertiaOhmic-resistance heatingMagnesium Acetate TetrahydrateFluoroboric acid

A pollution-free manufacturing method for surface electric heating elements is characterized in that a formula of a surface modification solution comprises, by weight, 100g of stannous fluoroboric acid, 1-1.2g of antimony trifluoride, 0.2-0.4g of cupric acetate monohydrate, 0.2-0.4g of magnesium acetate tetrahydrate, a proper amount of hydrofluoric acid and a proper amount of acetic acid, and 100-500ml of distilled water. The pollution-free manufacturing method for the surface electric heating elements comprises the steps of (1) preparing the surface modification solution, wherein the distilled water is acidized through the acetic acid, the stannous fluoroboric acid, the cupric acetate monohydrate and the magnesium acetate tetrahydrate are weighed, stirred and melted in the acidized distilled water respectively, antimony trifluoride is quickly weighed, stirred and added in the acidized distilled water, the mixture is stirred, and all the solutions are mixed evenly, sealed and stored at a shady, cool and ventilating place for use; (2) cleaning base materials; (3) feeding the base materials into a surface modification furnace which is 550-650 DEG C to carry out surface modification on the base materials; (4) brushing silver paste at proper positions of radiant faces, and carrying out mechanical wire leading; (5) powering on to carry out aging by using voltages 1.25 times using voltages. The pollution-free manufacturing method for the surface electric heating elements is suitable for manufacturing the pollution-free surface electric heating elements.

Owner:信跃珍

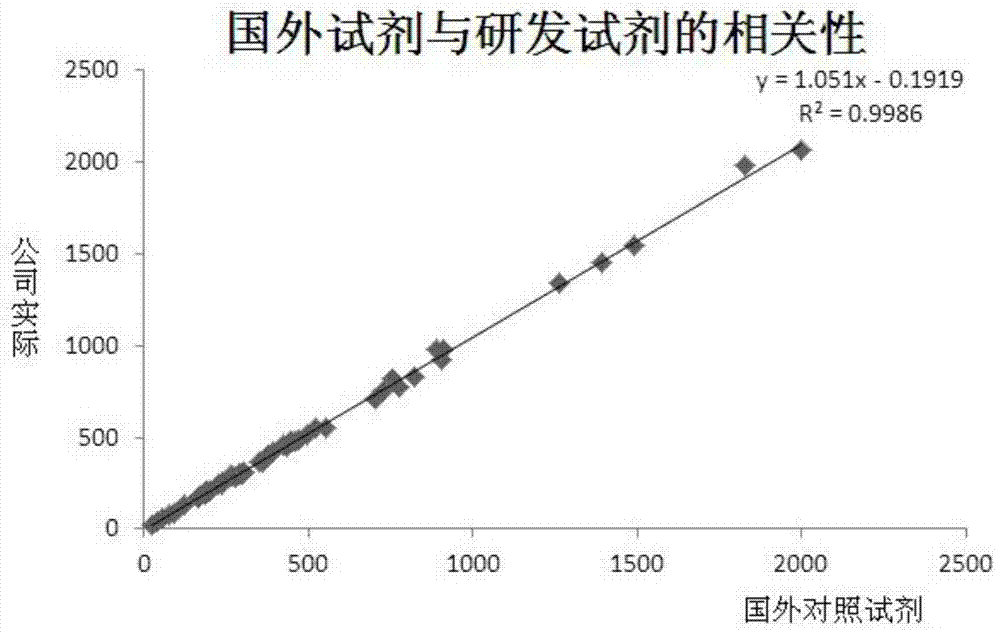

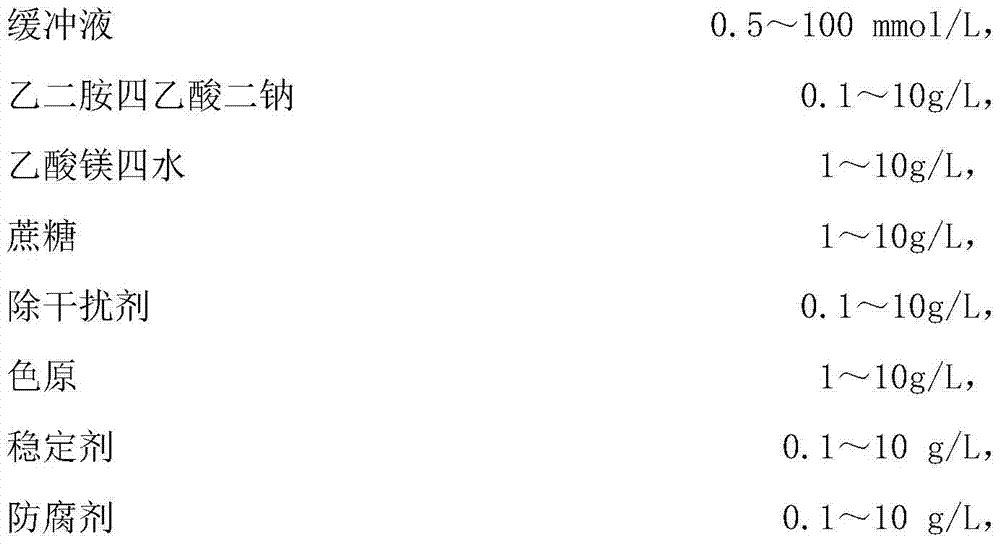

A stable uric acid detection kit

ActiveCN104198473BImprove stabilityEasy to operateMaterial analysis by observing effect on chemical indicatorMagnesium Acetate TetrahydratePeroxidase

The invention provides a stable uric acid detection kit. The stable uric acid detection kit is composed of a reagent R1 and a reagent R2, wherein the reagent R1 contains buffer solution, ethylenediamine tetraacetic acid disodium salt, magnesium acetate tetrahydrate, saccharose, an anti-interference agent, chromogen, a stabilizing agent and a preservative; the reagent R2 contains buffer solution, ethylenediamine tetraacetic acid disodium salt, 4-amino-antipyrine, peroxidase, uricase, a stabilizing agent and a preservative. The stable uric acid detection kit is used for measuring the content of blood uric acid by a colorimetric method that uricase is utilized to reduce uric acid; the method has strong specificity, has sensitivity higher than that of the chemical method, can be used for a full-automatic biochemical analyzer and can be applied clinically; and the anti-interference agent is added in the kit, the interference of ascorbic acid in the serum can be effectively removed, and the result is accurate.

Owner:上海睿康生物科技有限公司

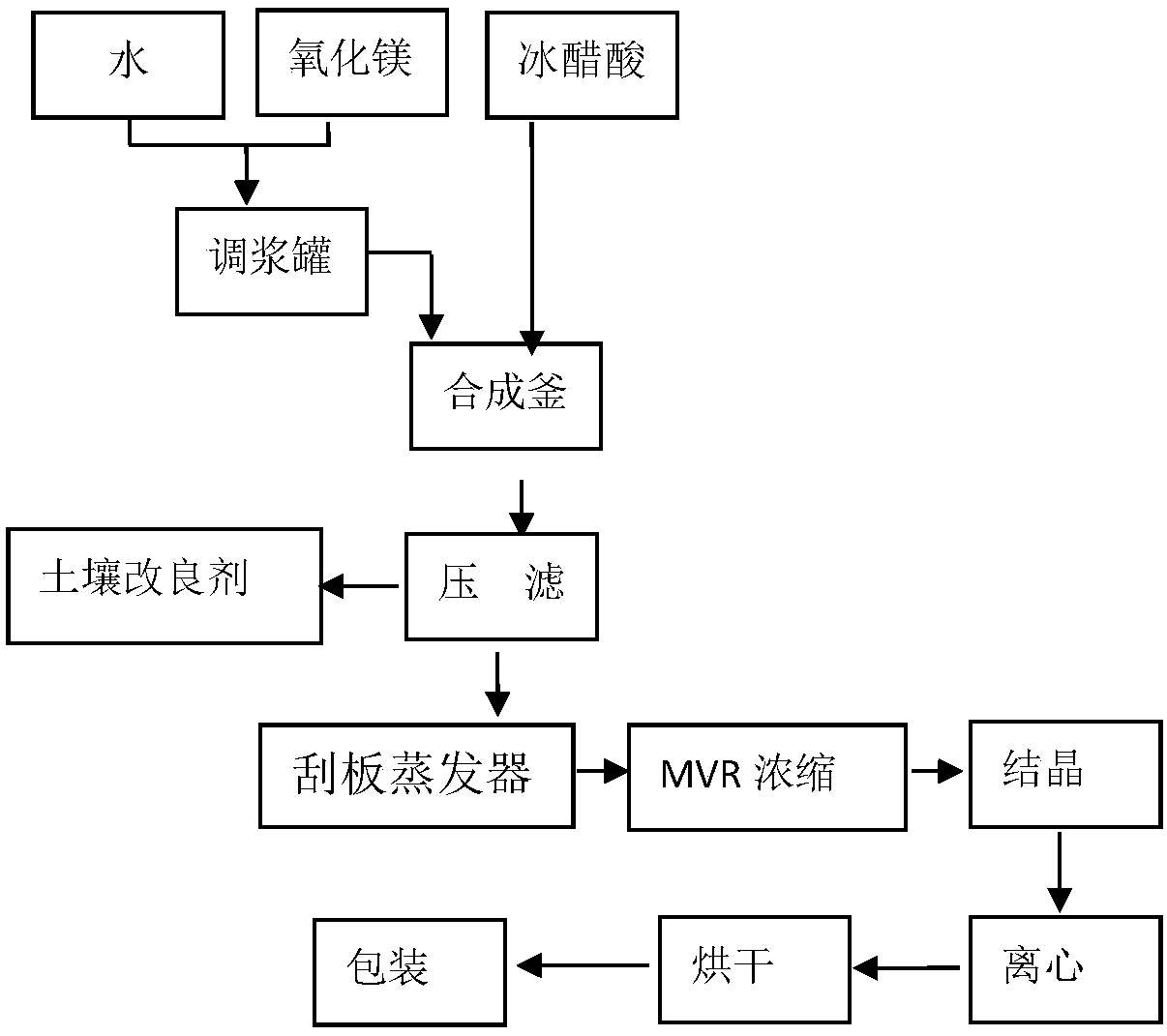

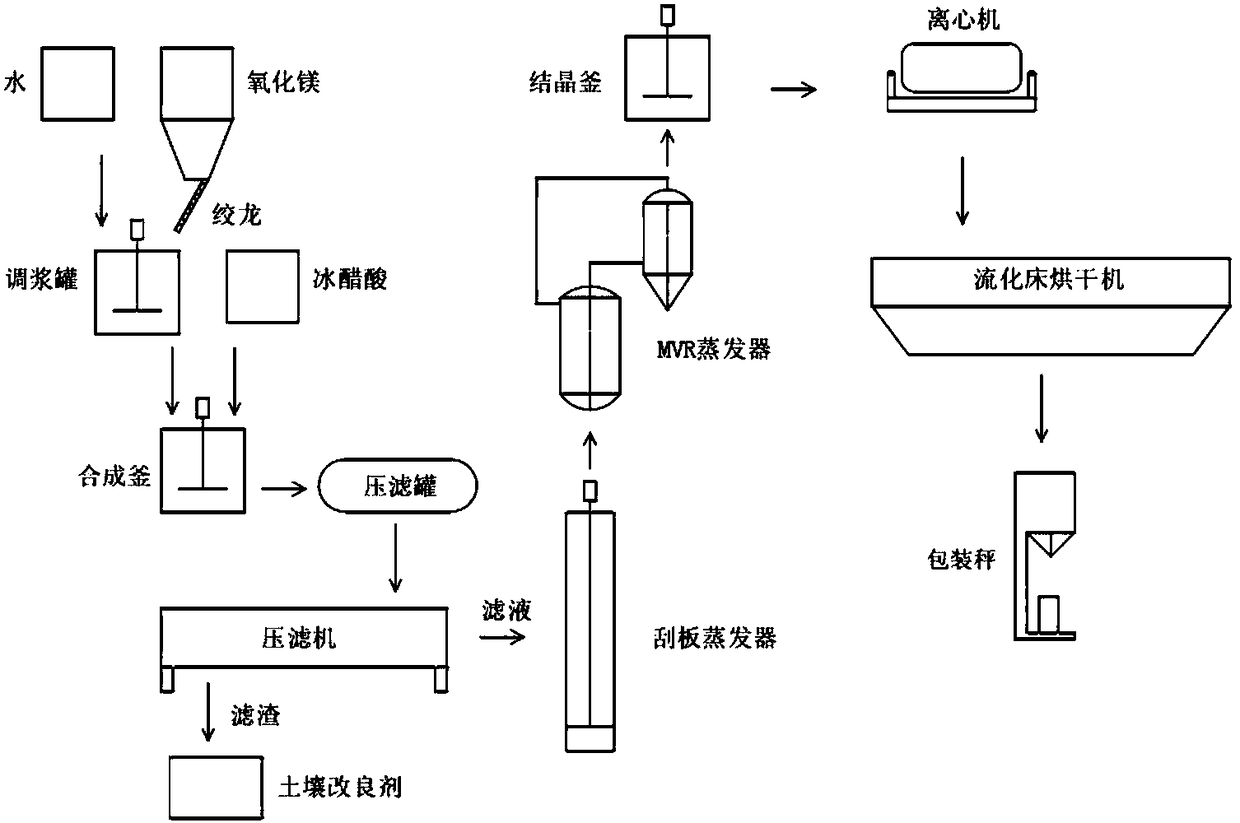

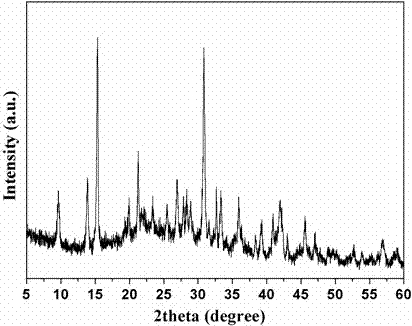

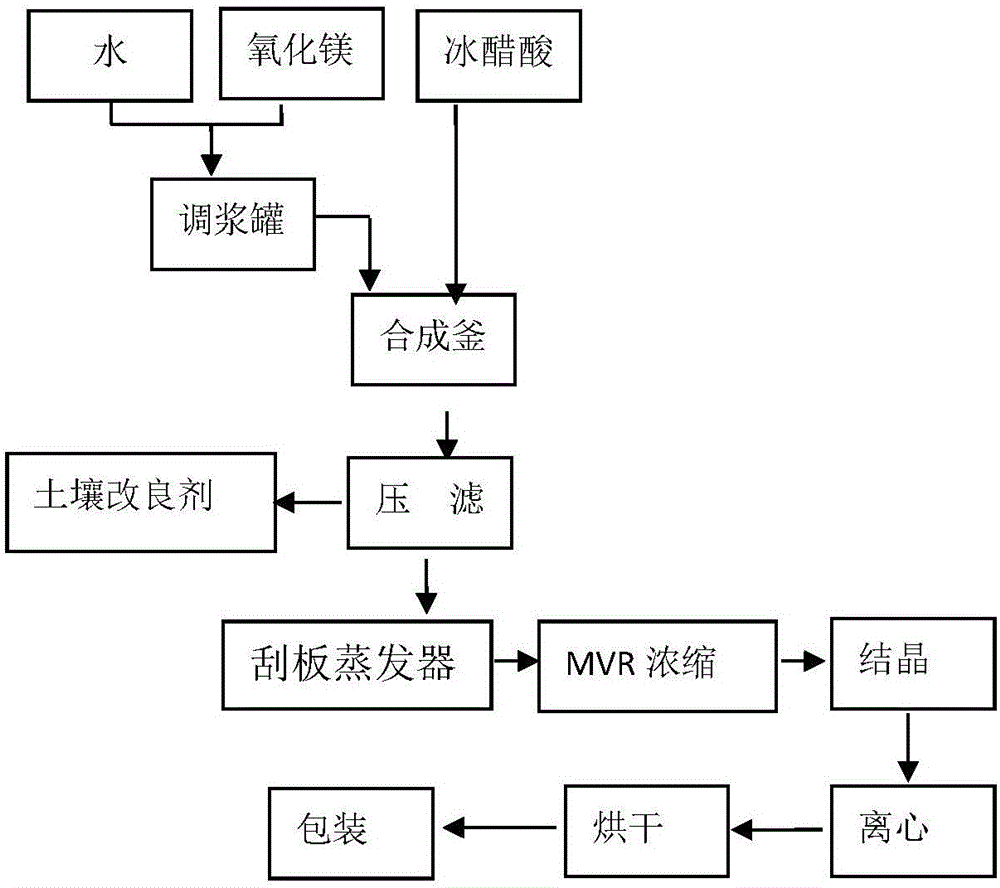

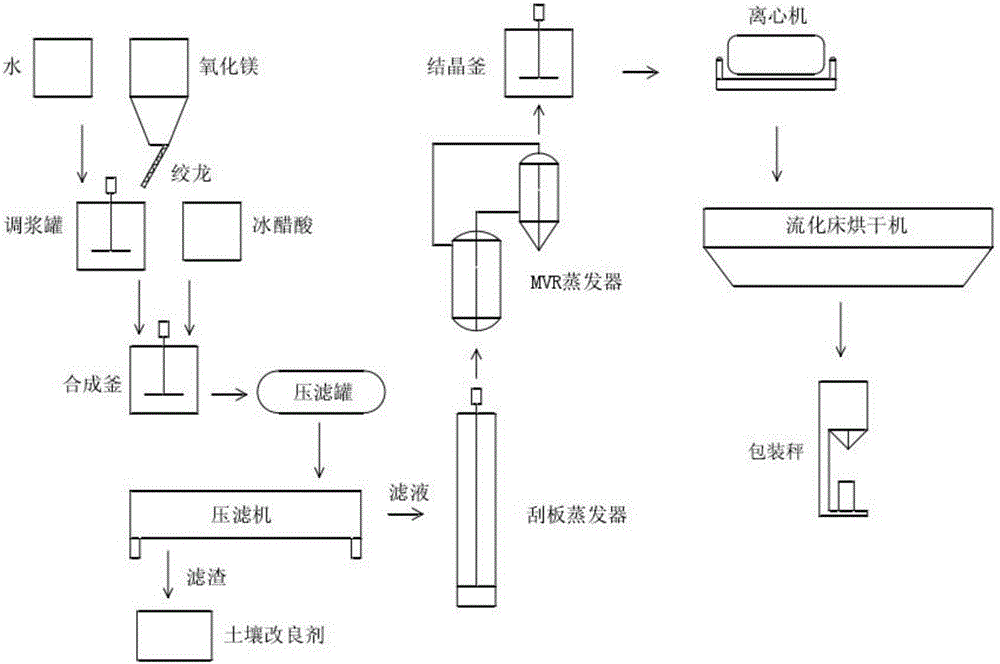

Magnesium acetate tetrahydrate and its preparation process and application

ActiveCN106316829BLow priceCheap and easy to getOrganic compound preparationOrganic chemistry methodsOrganic synthesisMagnesium Acetate Tetrahydrate

The invention discloses magnesium acetate tetrahydrate, a process for preparing the same and application of the magnesium acetate tetrahydrate. The process includes steps of synthesis, reaction, pressure filtration, concentration, re-concentration, crystallization, centrifugal discharging, drying and packaging. The magnesium acetate tetrahydrate, the process and the application have the advantages that concentration is divided into two portions, accordingly, energy can be saved, the process is high in efficiency and is simple, procedures are easy to control, raw materials for the magnesium acetate tetrahydrate are low in cost and are easily available, and the magnesium acetate tetrahydrate is low in production cost; the magnesium acetate tetrahydrate prepared by the aid of the process is a white crystal in appearance and is stable in quality; a molecular formula of the magnesium acetate tetrahydrate is C4H14O8Mg, the molecular weight of the magnesium acetate tetrahydrate is 214.46, the density of the magnesium acetate tetrahydrate is 0.8 g / l, and the melting point of the magnesium acetate tetrahydrate is 72-80 DEG C; the content of the magnesium acetate tetrahydrate is higher than 98%, the content of chlorine is 320-350 ppm, and a pH (potential of hydrogen) value of the magnesium acetate tetrahydrate is stable and keeps ranging from 7 to 9; the magnesium acetate tetrahydrate can be used for feed additives, cosmetics, catalysts and organic synthesis intermediates, can be applied to preparing magnesium uranyl acetate for measuring sodium and can be applied to the aspects of deodorization, sterilization, preservatives, textile dyeing, eosin staining, nigrosine immobilizing and the like.

Owner:LAIZHOU LAIYU CHEM CO LTD

A kind of synthesis method of basic magnesium carbonate nanorod with controllable length and width

ActiveCN105883866BRealize regulationMagnesium carbonatesNanotechnologyHydration reactionMagnesium Acetate Tetrahydrate

The invention discloses a synthesis method of controllable-length / width basic magnesium carbonate nanorods. The synthesis method comprises the following steps: dissolving magnesium acetate tetrahydrate and ammonium carbonate in a deionized water-anhydrous ethanol mixed solution, adding cetyl trimethyl ammonium chloride and sodium hydroxide into the solution, stirring uniformly, transferring the mixed solution into a reaction kettle, and heating to the required temperature to react for the required time; and collecting the product by centrifugal separation, and washing the product with distilled water and industrial alcohol several times. The simple one-step hydrothermal method is utilized to synthesize the one-dimensional basic magnesium carbonate nanorods with uniform size. The reactant ratio is regulated to implement control on slender-rod basic magnesium carbonate to stubby-rod basic magnesium carbonate.

Owner:XUZHOU NORMAL UNIVERSITY

Magnesium acetate tetrahydrate, process for preparing same and application of magnesium acetate tetrahydrate

ActiveCN106316829ALow priceCheap and easy to getOrganic compound preparationOrganic chemistry methodsFiltrationOrganic synthesis

The invention discloses magnesium acetate tetrahydrate, a process for preparing the same and application of the magnesium acetate tetrahydrate. The process includes steps of synthesis, reaction, pressure filtration, concentration, re-concentration, crystallization, centrifugal discharging, drying and packaging. The magnesium acetate tetrahydrate, the process and the application have the advantages that concentration is divided into two portions, accordingly, energy can be saved, the process is high in efficiency and is simple, procedures are easy to control, raw materials for the magnesium acetate tetrahydrate are low in cost and are easily available, and the magnesium acetate tetrahydrate is low in production cost; the magnesium acetate tetrahydrate prepared by the aid of the process is a white crystal in appearance and is stable in quality; a molecular formula of the magnesium acetate tetrahydrate is C4H14O8Mg, the molecular weight of the magnesium acetate tetrahydrate is 214.46, the density of the magnesium acetate tetrahydrate is 0.8 g / l, and the melting point of the magnesium acetate tetrahydrate is 72-80 DEG C; the content of the magnesium acetate tetrahydrate is higher than 98%, the content of chlorine is 320-350 ppm, and a pH (potential of hydrogen) value of the magnesium acetate tetrahydrate is stable and keeps ranging from 7 to 9; the magnesium acetate tetrahydrate can be used for feed additives, cosmetics, catalysts and organic synthesis intermediates, can be applied to preparing magnesium uranyl acetate for measuring sodium and can be applied to the aspects of deodorization, sterilization, preservatives, textile dyeing, eosin staining, nigrosine immobilizing and the like.

Owner:莱州市莱玉化工有限公司

Preparation method of spherical nano magnesium oxide

PendingCN114477246ALow costEasy to makeNanotechnologyMagnesiaOXALIC ACID DIHYDRATEMagnesium Acetate Tetrahydrate

The invention discloses a preparation method of spherical magnesium oxide nano powder, and belongs to the field of nano materials, and the specific process is as follows: taking magnesium acetate tetrahydrate as a magnesium source, preparing a magnesium acetate solution with the concentration of 0.5-2.5 mol / L, and adding 0.1-1.5% of a surfactant; in an ultrasonic environment, slowly adding an oxalic acid solution into the solution, and continuously stirring until a white solution is formed; putting the mixture into a magnetic constant-temperature stirring instrument, and reacting at 30-90 DEG C for 1-3 hours; and centrifuging, drying, calcining in a muffle furnace at 550-650 DEG C, cooling, and taking out to obtain the nano magnesium oxide powder. According to the method provided by the invention, the prepared nano magnesium oxide is spherical, uniform in particle size, good in dispersity and free of agglomeration; and the method is simple to operate, low in raw material price, low in equipment requirement, green and environment-friendly.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

A kind of synthetic method of basic magnesium carbonate ultrathin nanosheet

ActiveCN110937615BControl thicknessMagnesium carbonatesHydration reactionMagnesium Acetate Tetrahydrate

A method for synthesizing basic magnesium carbonate ultra-thin nanosheets, comprising: adding magnesium acetate tetrahydrate, ammonium carbonate, polyvinylpyrrolidone, and sodium hydroxide to an aqueous solution, then adding absolute ethanol to the above solution, and dissolving the above solution Transfer to a reaction kettle, ultrasonically dissolve, heat and react in an oven for a period of time, collect the product by centrifugation, and wash several times to obtain ultrathin nanosheets of basic magnesium carbonate. The invention synthesizes basic magnesium carbonate ultra-thin nano-sheets with uniform appearance through one-step simple hydrothermal reaction, and can realize regulation and control of the thickness of basic magnesium carbonate ultra-thin nano-sheets by adjusting the amount of sodium hydroxide.

Owner:XUZHOU NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com