A preparation method for durable hydrophobic anti-reflection film on the surface of vacuum heat collecting tube

A technology of vacuum heat collection tube and hydrophobicity, which is applied in the field of preparation of durable hydrophobic anti-reflection film on the surface of vacuum heat collection tube, can solve the problems of durability and other problems, and achieve the goal of improving mechanical strength, large cavity volume, and excellent self-cleaning ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

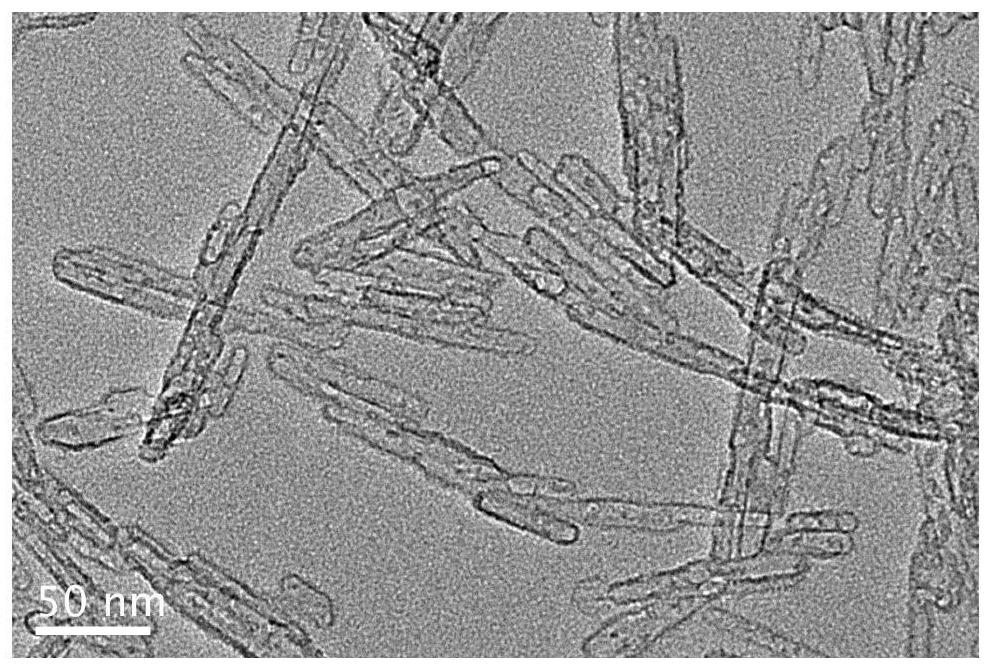

[0018] (1) 1.73g C 4 h 6 MgO 4 4H 2 O solid was added to 38.3 g of anhydrous CH 3 OH solvent, stirred until the solid was completely dissolved, as solution A. Add 0.645g HF solution (mass fraction is 40%) to 9.3g anhydrous CH 3 OH, mixed well, as solution B. Then solution B was added dropwise to solution A to obtain a mixed solution. Finally, the mixed solution was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, and after solvothermal reaction at 240° C. for 10 h, the solution was cooled and taken out. Finally, Mg(OH) with a hollow rod-like structure is obtained 2-x f x particle sol.

[0019] (2) to the Mg(OH) prepared in step (1) 2-x f x Add 2 mL of oxalic acid solution with a concentration of 0.01 mol / L as a catalyst in the sol, and use Mg(OH) 2-x f x Methyltriethoxysilane (MTES) solution was added dropwise to the MTES at a molar ratio of 1:0.8 for hydrolysis. During hydrolysis, the pH should be adjusted to keep it at 4, and aged for 10 da...

Embodiment 2

[0022] (1) 1.73g C 4 h 6 MgO 4 4H 2 O solid was added to 38.3 g of anhydrous CH 3 OH solvent, stirred until the solid was completely dissolved, as solution A. Add 0.645g HF solution (mass fraction is 40%) to 9.3g anhydrous CH 3OH, mixed well, as solution B. Solution B was then added dropwise to solution A. Finally, the mixed solution was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, and after solvothermal reaction at 240° C. for 14 hours, the solution was cooled and taken out. Finally, Mg(OH) with a hollow rod-like structure is obtained 2-x f x particle sol.

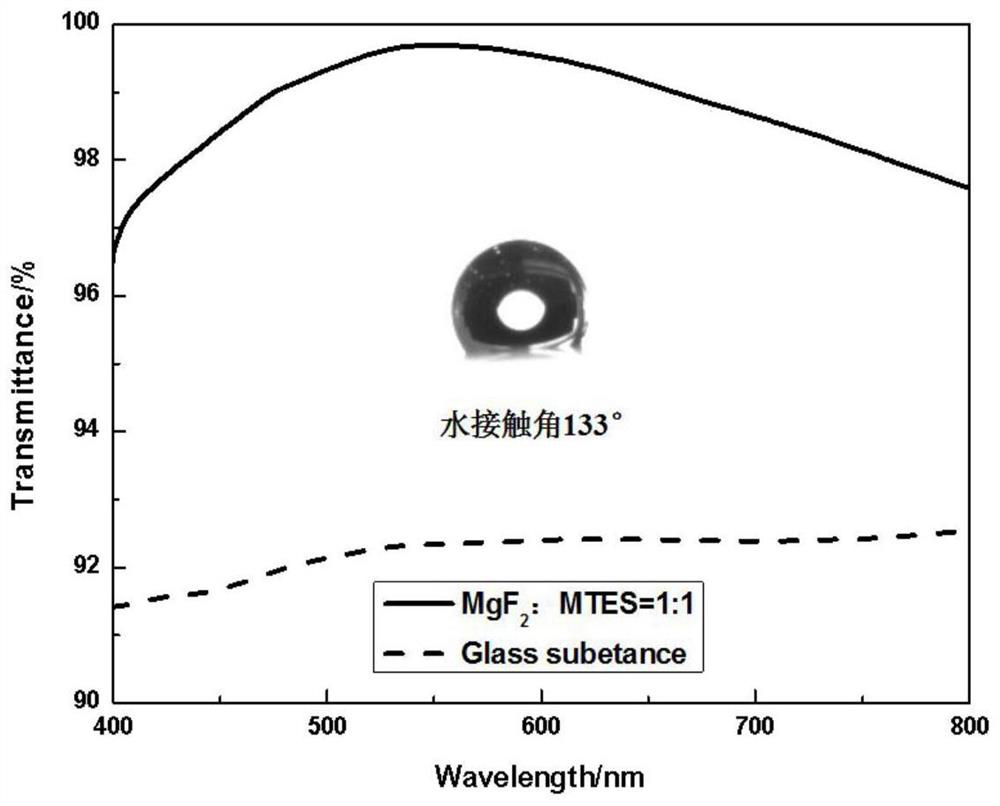

[0023] (2) to the Mg(OH) prepared in step (1) 2-x f x Add 2 mL of oxalic acid solution with a concentration of 0.01 mol / L as a catalyst in the sol, and use Mg(OH) 2-x f x Methyltriethoxysilane (MTES) solution was added dropwise to MTES at a molar ratio of 1:1 for hydrolysis reaction. During hydrolysis, the pH should be adjusted to keep it at 5, and aged for 10 days after hydrolysis. ...

Embodiment 3

[0026] (1) 1.73g C 4 h 6 MgO 4 4H 2 O solid was added to 38.3 g of anhydrous CH 3 OH solvent, stirred until the solid was completely dissolved, as solution A. Add 0.645g HF solution (mass fraction is 40%) to 9.3g anhydrous CH 3 OH, mixed well, as solution B. Solution B was then added dropwise to solution A. Finally, the mixed solution was transferred to a polytetrafluoroethylene hydrothermal reaction kettle, and after solvothermal reaction at 240° C. for 16 hours, the solution was cooled and taken out. Finally, Mg(OH) with a hollow rod-like structure is obtained 2-x f x particle sol.

[0027] (2) to the Mg(OH) prepared in step (1) 2-x f x Add 2 mL of oxalic acid solution with a concentration of 0.01 mol / L as a catalyst in the sol, and use Mg(OH) 2-x f x Methyltriethoxysilane (MTES) solution was added dropwise to MTES at a molar ratio of 1:0.6 to carry out hydrolysis reaction. During hydrolysis, the pH needs to be adjusted to keep it at 6, and aged for 20 days afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com