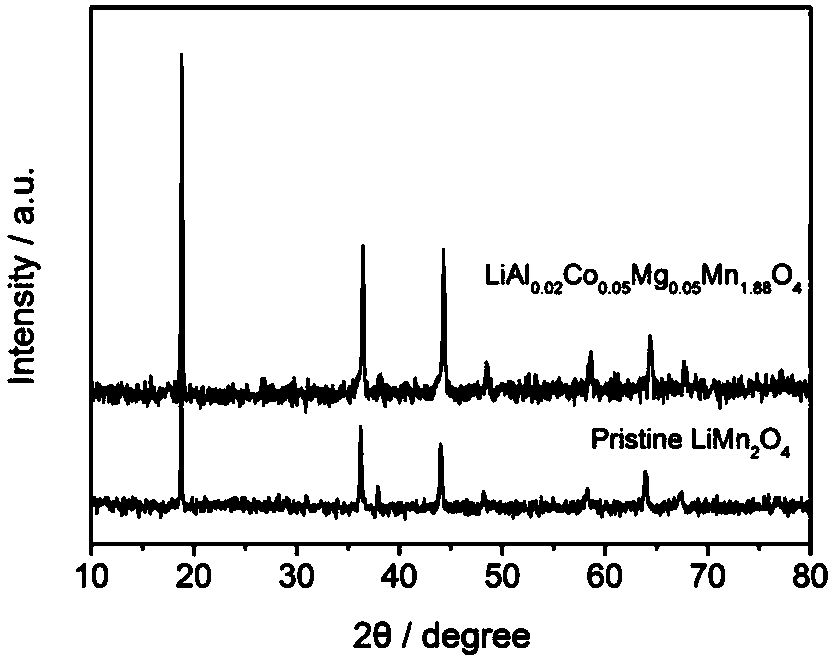

Method for preparing multi-element co-doped lithium manganate composite material

A technology of lithium heteromanganate and composite materials, which is applied in the field of new energy material preparation, can solve the problems of poor electrochemical performance, low initial discharge capacity, and low discharge capacity, and achieve low cost, low synthesis temperature, and improved rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

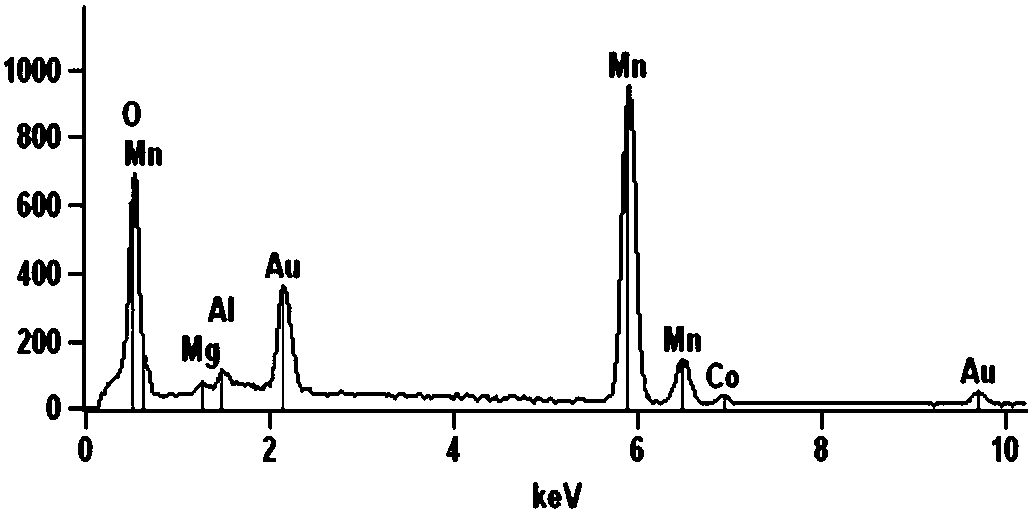

Embodiment 1

[0029] (1) Preparation of lithium salt and citric acid solution: when preparing the solution, LiOH·H 2 O and citric acid monohydrate were dissolved in 25ml of deionized water at a molar ratio of 1.02:1, and stirred until completely dissolved;

[0030] (2) Preparation of manganese salt, aluminum salt, cobalt salt, and magnesium salt mixture: after weighing manganese acetate tetrahydrate, aluminum nitrate nonahydrate, magnesium acetate tetrahydrate, and cobalt acetate tetrahydrate, dissolve them in 50ml deionized water, and magnetically Stir well;

[0031] (3) Solution mixing: under constant magnetic stirring at 50°C, slowly drop the prepared mixture of manganese salt, aluminum salt, cobalt salt, and magnesium salt into the mixed solution of lithium salt and citric acid, and stir magnetically for 10 minutes. , adjust the pH of the mixed solution to be 8 with ammonia water;

[0032] (4) Preparation of sol and xerogel: continuously stir the above mixed solution on a magnetic heati...

Embodiment 2

[0043] This example is basically the same as Example 1, the only difference is that in the mixing process of (3) the solution, the stirring temperature is 45°C, which is almost the same as the electrochemical performance of the sample prepared at the stirring temperature of 50°C, but stirring is required A little longer.

Embodiment 3

[0045] This example is basically the same as Example 1, the only difference is that in the mixing process of (3) the solution, the stirring temperature is 55°C, which is almost the same as the electrochemical performance of the sample prepared at the stirring temperature of 50°C, and the stirring time similar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com