Snow melting agent for railway turnout and preparation method thereof

A technology of snow melting agent and turnout, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as high corrosion, reduced service life, and facility corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

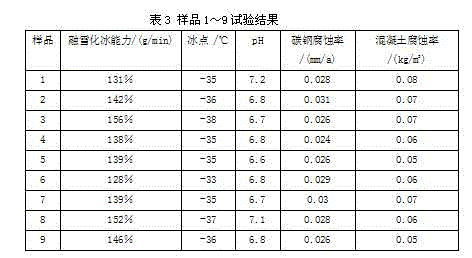

Embodiment 1

[0015] A snow melting agent for railway turnouts, which is made of the following raw materials by weight: 25~35 parts by weight of potassium acetate, 3~6 potassium nitrate, 5~10 magnesium acetate tetrahydrate, 5~10 calcium nitrate tetrahydrate, and 5~ammonium dihydrogen phosphate 10. Urea 1-5, sodium molybdate 3-8, sodium formate 25-30, sodium metasilicate 0.2-1.0, ethylene glycol 15-20 and glycerol 10-15.

[0016] The method for preparing snow melting agent for railway switch, the specific steps are as follows: a. Combine the potassium acetate, potassium nitrate, magnesium acetate tetrahydrate, calcium nitrate tetrahydrate, ammonium dihydrogen phosphate, urea, sodium molybdate, sodium formate and partial Sodium silicate was crushed and passed through a 20-mesh sieve, and then the formula was weighed and mixed to obtain mixed powder A; b. According to the formula, stir and mix ethylene glycol and glycerol to obtain mixed liquid B; c. Add the mixed powder A to the mixed liquid B a...

Embodiment 2

[0018] A snow melting agent for railway turnouts, which is made of the following parts by weight of raw materials: potassium acetate 26, potassium nitrate 4, magnesium acetate tetrahydrate 6, calcium nitrate tetrahydrate 8, ammonium dihydrogen phosphate 6, urea 3, sodium molybdate 3, Sodium formate 29, sodium metasilicate 0.4, ethylene glycol 17, and glycerol 14.

[0019] The preparation method of this embodiment is the same as that of embodiment 1.

Embodiment 3

[0021] A snow-melting agent for railway turnouts, which is made of the following parts by weight of raw materials: potassium acetate 25, potassium nitrate 6, magnesium acetate tetrahydrate 5, calcium nitrate tetrahydrate 10, ammonium dihydrogen phosphate 5, urea 5, sodium molybdate 3, Sodium formate 30, sodium metasilicate 0.2, ethylene glycol 20, and glycerol 10.

[0022] The preparation method of this embodiment is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com