Magnesium acetate tetrahydrate, process for preparing same and application of magnesium acetate tetrahydrate

A preparation process and technology of magnesium acetate, applied in the field of preparation of magnesium acetate tetrahydrate, can solve the problems of high application cost, influence popularization and application, etc., and achieve the effects of low application cost, easy availability of raw materials, and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

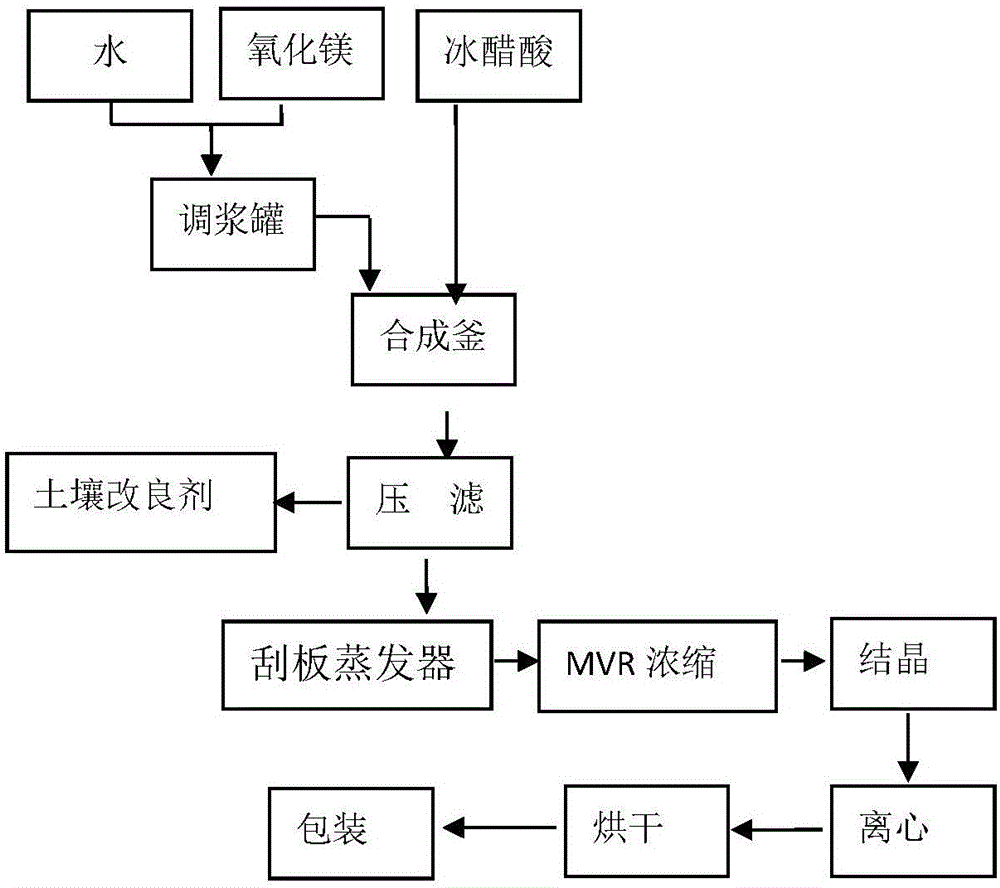

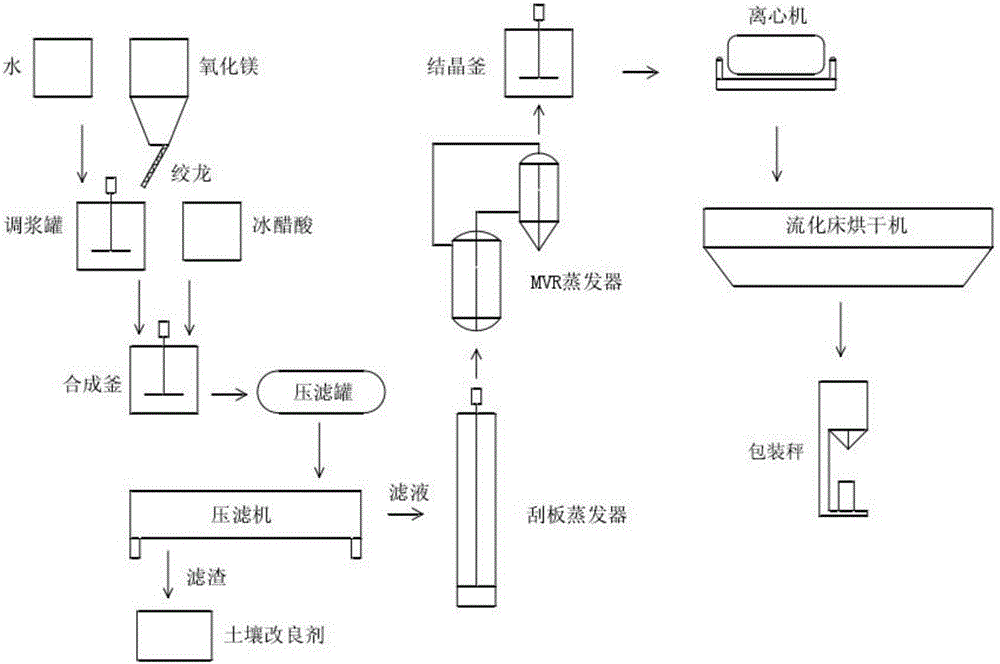

Method used

Image

Examples

Embodiment 1

[0039] (1) Synthesis: In a slurry tank filled with an appropriate amount of water, 390 kg of powdery light-burned magnesium oxide is dropped into, and stirred evenly. Then the slurry and 794kg of glacial acetic acid are dropped into the synthesis kettle, and the stirring is started. Among them: the molar ratio of light-burned magnesia and glacial acetic acid is 1:1.9. The content of magnesium oxide is 80%, and the content of glacial acetic acid is 98%.

[0040] (2) Reaction: After the feeding is completed, the reaction is exothermic, and the reaction temperature is maintained at 80-90° C., and the temperature is kept for 2-3 hours. The control reaction end point is that the pH value is between 6-7, and the Baume degree is between 15-16°Bé.

[0041] (3) Pressure filtration: filter the reacted feed liquid through a plate and frame filter press to obtain a filtrate. The filter residue obtained after pressure filtration is used to prepare soil conditioner.

[0042] (4) Scraper...

Embodiment 2

[0049] (1) Synthesis: Add 405Kg of powdery light-burned magnesium oxide to a slurry tank filled with an appropriate amount of water, and stir evenly. Then the slurry and 868kg of glacial acetic acid are dropped into the synthesis kettle, and the stirring is started. Among them: the molar ratio of light-burned magnesia and glacial acetic acid is 1:2. The content of magnesium oxide is 80%, and the content of glacial acetic acid is 98%.

[0050] (2) Controlling the reaction: After the feeding is completed, the reaction is exothermic, and the reaction temperature is kept at 80-90° C., and the temperature is kept for 2-3 hours. The control reaction end point is that the pH value is between 6-7, and the Baume degree is between 15-16°Bé.

[0051] (3) Pressure filtration: filter the reacted feed liquid through a plate and frame filter press to obtain a filtrate. The filter residue obtained after pressure filtration is used to prepare soil conditioner.

[0052] (4) Scraper evaporat...

Embodiment 3

[0059] (1) Synthesis: In a slurry tank filled with an appropriate amount of water, put 440 kg of powdery light-burned magnesium oxide into it, and stir evenly. Then the slurry and 990kg of glacial acetic acid are dropped into the synthesis kettle, and the stirring is started. Among them: the molar ratio of light-burned magnesia and glacial acetic acid is 1:2.1. The content of magnesium oxide is 80%, and the content of glacial acetic acid is 98%.

[0060] (2) Controlling the reaction: After the feeding is completed, the reaction is exothermic, and the reaction temperature is kept at 80-90° C., and the temperature is kept for 2-3 hours. The control reaction end point is that the pH value is between 6-7, and the Baume degree is between 15-16°Bé.

[0061] (3) Pressure filtration: filter the reacted feed liquid through a plate and frame filter press to obtain a filtrate. The filter residue obtained after pressure filtration is used to prepare soil conditioner.

[0062] (4) Scra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com