Synthesis method of basic magnesium carbonate ultrathin nanosheet

A synthesis method and technology of magnesium carbonate, applied in the direction of magnesium carbonate, etc., to achieve the effect of uniform shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

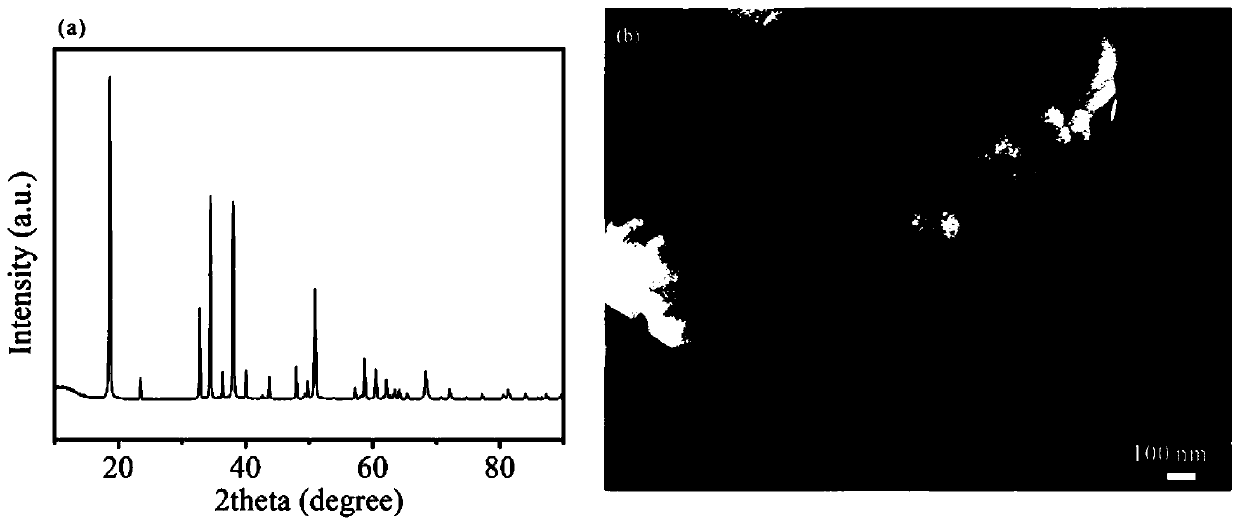

[0016] A kind of synthetic method (its size is between 0.3-0.5 μm) of basic magnesium carbonate ultrathin nanoplate: comprise the following steps, get magnesium acetate tetrahydrate (1mmol), ammonium carbonate (1.5mmol), polyvinylpyrrolidone (0.02320g ), sodium hydroxide (5.5mmol) were added to 5mL aqueous solution, and then 5mL absolute ethanol was added to the above solution, the above solution was transferred to a reaction kettle, ultrasonically dissolved, heated to 200°C in an oven, and the reaction time was 12h. The product was collected by centrifugation, and then washed several times with denatured alcohol. figure 1 Be the XRD ( figure 1 a) and SEM images ( figure 1 b). The XRD figure shows that the obtained product is basic magnesium carbonate, and the scanning electron microscope image shows that the obtained product is an ultrathin nanosheet, indicating that the size of the sheet is relatively uniform

Embodiment 2

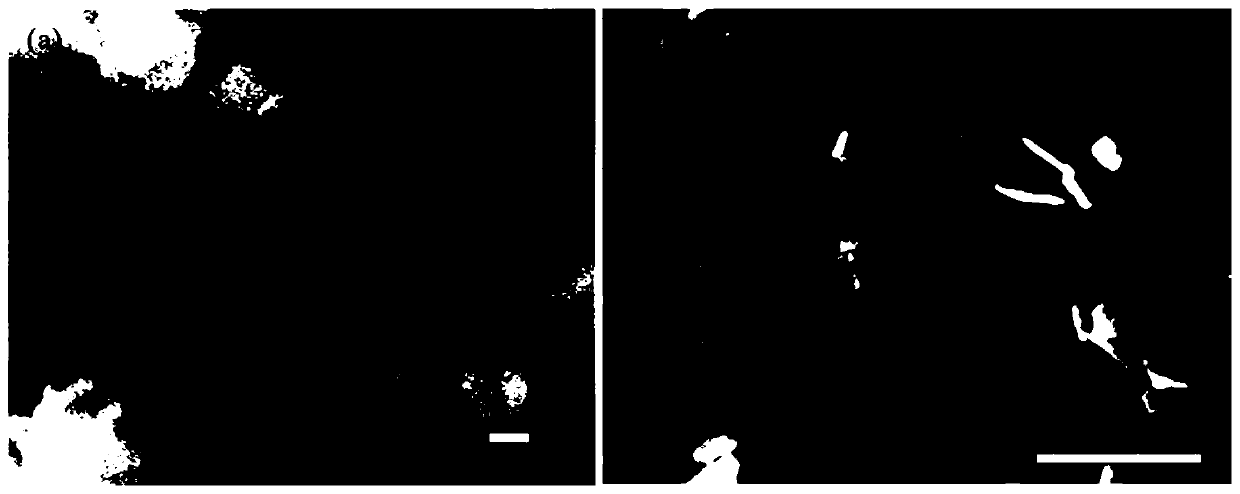

[0018] Present embodiment is on the basis of embodiment 1 (1mmol magnesium acetate tetrahydrate, 1.5mmol ammonium carbonate, 0.02320g polyvinylpyrrolidone, 5mL water and 5mL dehydrated alcohol), change the amount of sodium hydroxide to be the product that 5.5mmol obtains SEM images ( figure 2 a) and the amount of sodium hydroxide is the scanning electron micrograph of the product that 6.5mmol obtains ( figure 2 b). The scanning electron micrographs of the product obtained by changing the amount of sodium hydroxide above show that the amount of sodium hydroxide of the present invention can be obtained within the range of 5.5mmol-6.5mmol and can obtain basic magnesium carbonate nanosheets with uniform size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com