A kind of cu/mgo catalyst that catalyzes the hydrogenolysis of glucose and its preparation method

A technology of glucose and catalyst is applied in the field of Cu/MgO catalyst and preparation of catalyzing the hydrogenolysis of glucose to produce high value-added chemicals, which can solve the problem of high local concentration of active components, low single product selectivity, small specific surface area of catalyst, etc. problems, to achieve broad industrial application prospects, to solve the effects of poor selectivity and excellent catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

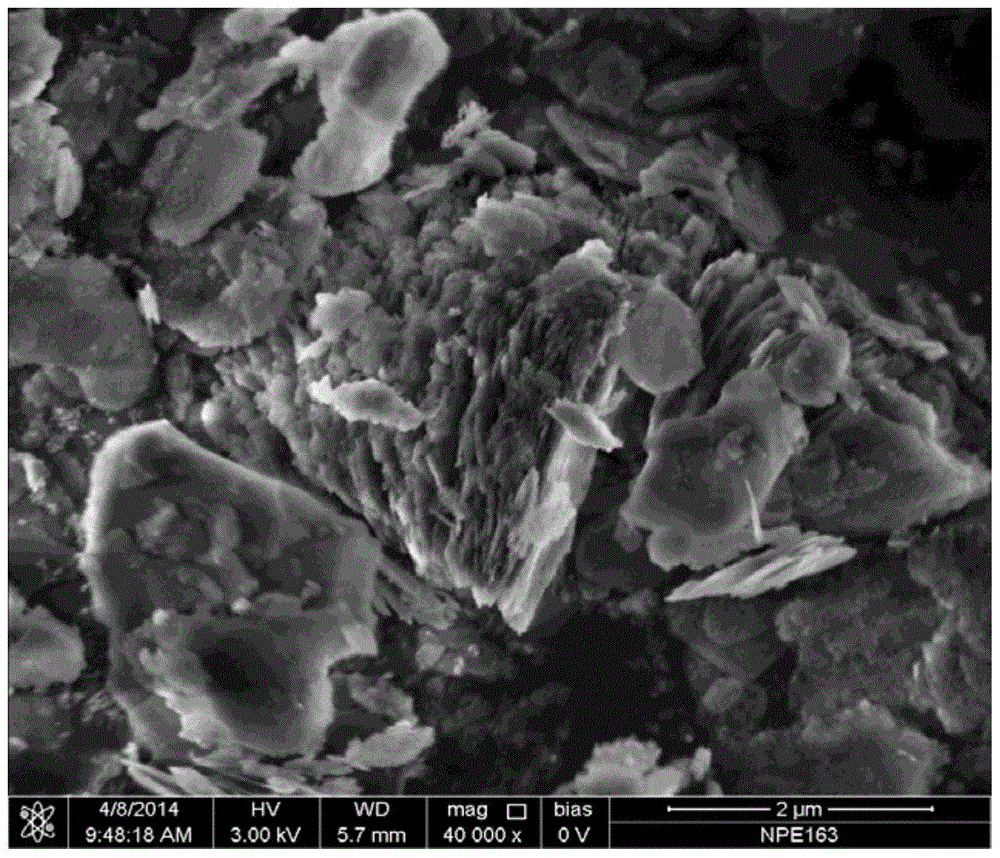

[0017] Add magnesium acetate tetrahydrate to a mixed solution of 60ML deionized water and absolute ethanol (volume ratio: 2:1, 1:1, 1:2 respectively) and stir the reaction, then add the solution to the stainless steel high pressure placed in an oven at 180°C to continue the reaction, and then the reaction solution was centrifuged, washed with corresponding proportions of deionized water and absolute ethanol, and finally dried in an oven to obtain Mg(OH) 2 , and placed in a tubular resistance furnace, calcined at 500°C in an atmosphere of argon and oxygen to obtain the MgO carrier. Considering the morphology and yield of MgO, deionized water and absolute ethanol with a volume ratio of 1:2 were selected for the reaction. The scanning electron microscope photographs of the obtained samples are shown in figure 1 .

[0018] Magnesium acetate tetrahydrate / g V 去离子水 :V 无水乙醇

Embodiment 4

[0020] Will Cu 2 O was added to a three-neck round bottom flask, 1,5-cyclooctadiene and THF were added under an argon atmosphere to stir the reaction, and then 1,1,1,5,5 , 5-hexafluoro-2,4-pentanedione and THF continue to stir and react, and filter unreacted Cu after the reaction 2 O, the resulting filtrate is distilled under reduced pressure to remove the solvent, and then the solid powder is purified by sublimation to obtain the corresponding metal organic precursor hexafluoroacetylacetone-cyclooctadiene copper (I), which is obtained by thermogravimetric analysis, The loading temperature of the monovalent copper precursor was selected to be 100°C.

Embodiment 5

[0022] Basically the same as in Example 4, except that 1,5-cyclooctadiene is not added, the corresponding metal organic precursor copper hexafluoroacetylacetonate can be obtained. According to thermogravimetric analysis, the loading temperature of the divalent copper precursor was selected as 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com