A kind of crystal material and its preparation method and application

A technology of crystal materials and reactions, applied in the direction of polycrystalline material growth, crystal growth, chemical instruments and methods, etc., can solve problems such as complex structures, and achieve the effect of simple preparation process, good combination of reflection and radiation comprehensive performance, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

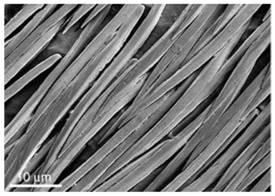

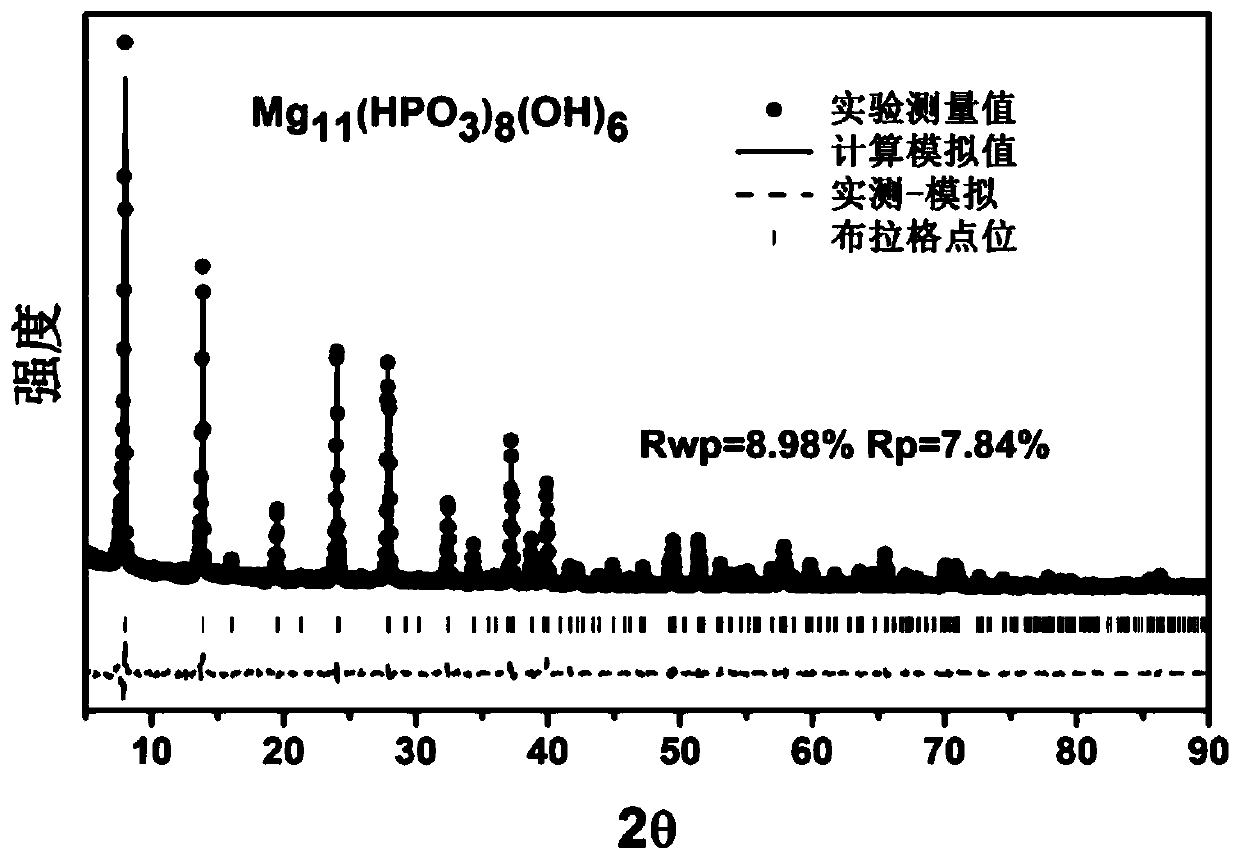

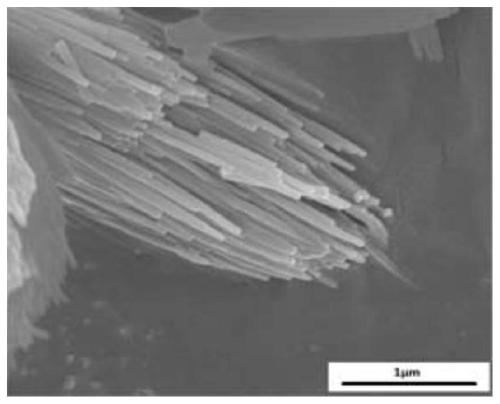

[0032] According to the molar ratio of 0.5:1, weigh 2.144g magnesium acetate tetrahydrate and 1.64g phosphorous acid solid powder, pour them into a beaker, dissolve with deionized water, add a magnetic stir bar to stir, and adjust the speed to 400 rpm After 15 minutes, add 5ml cyclohexylamine, cover with cling film and stir for 15 minutes to obtain a uniform emulsion, wherein the volume ratio of cyclohexylamine to emulsion is 1:12; the uniform emulsion The turbid liquid was put into the reaction kettle, and then the reaction kettle was placed in an oven, and the oven temperature was set to 140°C and the reaction time was 2000 minutes. After the reaction is complete, take it out, wash and filter, dry the sample on the filter paper at 80°C for 5 hours, and obtain a sample with uniform particle size after grinding.

[0033] The test result of the emissivity of the sample in the mid- and far-infrared band of 2.5-25 μm was 0.914, and the reflectivity of the 0.2-2.5 μm ultraviolet-visi...

Embodiment 2

[0038] Weigh 4.289g magnesium acetate tetrahydrate and 1.64g solid phosphorous acid powder according to the molar ratio of 1:1, pour them into a beaker, dissolve them with deionized water, add a magnetic stir bar to stir, and adjust the speed to 300 rpm After 15 minutes, add 12.5ml cyclohexylamine, cover with cling film and stir for 15 minutes to obtain a uniform emulsion. Among them, the volume ratio of cyclohexylamine to emulsion is 1:4.8; The emulsion was put into the reaction kettle, and then the reaction kettle was placed in an oven, and the oven temperature was set to 160°C and the reaction time was 2000 minutes. After the reaction is complete, take it out, wash and filter, dry the sample on the filter paper at 100°C for 3 hours, and obtain a sample with uniform particle size after grinding.

[0039] The test result of the emissivity of the sample in the mid- and far-infrared band of 2.5-25 μm is 0.928, and the reflectivity of the 0.2-2.5 μm ultraviolet-visible-near infrare...

Embodiment 3

[0042] Weigh 8.578g magnesium acetate tetrahydrate and 1.64g phosphorous solid powder according to the molar ratio of 2:1, pour them into a beaker, dissolve them with deionized water, add a magnetic stirrer to stir, and adjust the speed to 200 rpm After 20 minutes, add 10ml cyclohexylamine, cover with plastic wrap and stir for another 20 minutes to obtain a uniform emulsion. The volume ratio of cyclohexylamine to the emulsion is 1:6; the uniform emulsion The turbid liquid was put into the reaction kettle, and then the reaction kettle was placed in an oven, and the oven temperature was set to 180°C and the reaction time was 2000 minutes. After the reaction is complete, take it out, wash and filter, dry the sample on the filter paper at 110°C for 2 hours, and obtain a sample with uniform particle size after grinding.

[0043] The test result of the emissivity of the sample in the mid- and far-infrared band of 2.5-25 μm is 0.933, and the reflectivity of the 0.2-2.5 μm ultraviolet-vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com