A method for preparing hydrogen storage magnesium-nickel alloy nanopowder based on polyol method

A technology of alloy nano and polyol method, applied in the field of materials, can solve the problems of high energy consumption, high cost, temperature rise, etc., and achieve the effect of simple process, low cost and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

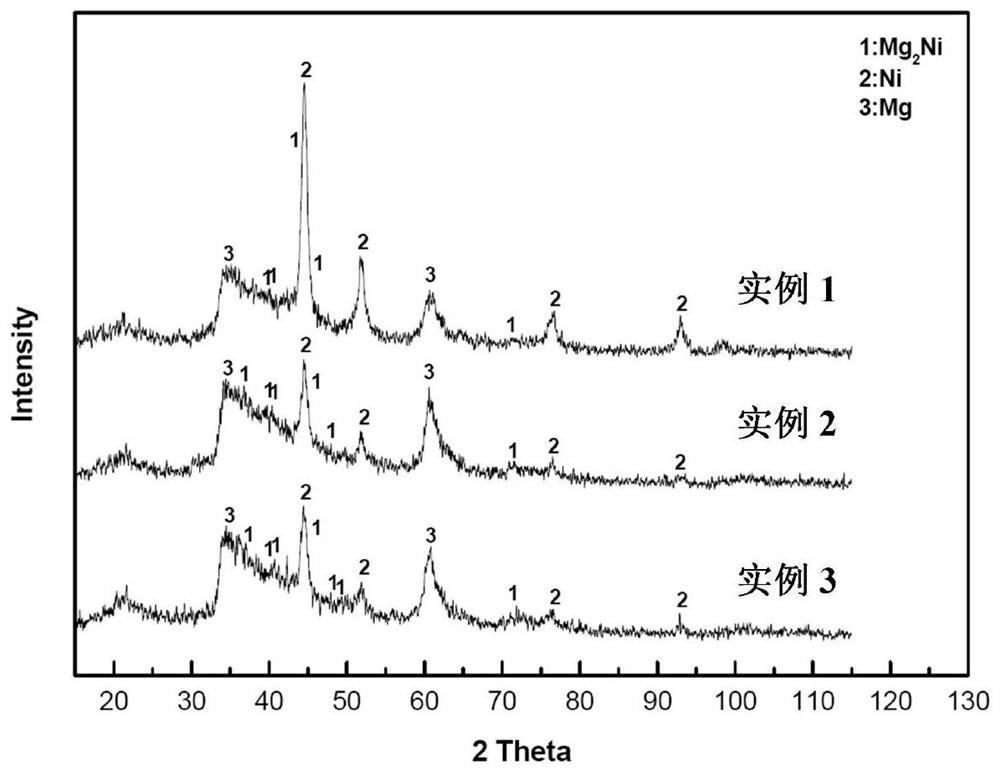

example 1

[0042] 0.04mol magnesium acetate tetrahydrate (C 4 h 6 o 4 Mg·4H 2 O) and nickel acetate tetrahydrate (C 4 h 6 o 4 Ni·4H 2 O) mixture, dissolved in 500ml ethylene glycol (purity 99%), ethylene glycol acts as a weak reducing agent, wherein the amount of magnesium-nickel precursor is 0.02mol and 0.02mol, that is, Mg:Ni is 1:1. Dissolve 10 grams of polyvinylpyrrolidone (PVP) in another cup of 500ml ethylene glycol (purity 99%), and PVP acts as a protective agent. Finally, the above two cups of 500ml solutions were mixed and then stirred by magnetic force for 30 minutes. Put the mixed solution in an environment of 180°C for reflux, and when the temperature of the solution reaches 180°C, continue to reflux for 10 minutes. Then add containing 0.02mol PdCl 2 500ml of ethylene glycol solution, when the temperature of the solution reaches 180°C again, then continue to reflux for 1 hour to generate magnesium-nickel alloy nanopowder. Then pour the solution into a beaker, cool i...

example 2

[0046] 0.04mol magnesium acetate tetrahydrate (C 4 h 6 o 4 Mg·4H 2 O) and nickel acetate tetrahydrate (C 4 h 6 o 4 Ni·4H 2 O) mixture, dissolved in 500ml ethylene glycol (purity 99%), ethylene glycol acts as a weak reducing agent, wherein the amount of magnesium-nickel precursor is 0.02mol and 0.02mol, that is, Mg:Ni is 1:1. Dissolve 20 grams of polyvinylpyrrolidone (PVP) in another cup of 500 ml of ethylene glycol (purity 99%), and PVP acts as a protective agent. Finally, the above two cups of 500ml solutions were mixed and then stirred by magnetic force for 30 minutes. Put the mixed solution in an environment of 180°C for reflux, and when the temperature of the solution reaches 180°C, continue to reflux for 10 minutes. Then add containing 0.02molPdCl 2 500ml of ethylene glycol solution, when the temperature of the solution reaches 180°C again, then continue to reflux for 1 hour to generate magnesium-nickel alloy nanopowder. Then pour the solution into a beaker, coo...

example 3

[0050] 0.04mol magnesium acetate tetrahydrate (C 4 h 6 o 4 Mg·4H 2 O) and nickel acetate tetrahydrate (C 4 h 6 o 4 Ni·4H 2 O) mixture, dissolved in 500ml ethylene glycol (purity 99%), ethylene glycol acts as a weak reducing agent, wherein the amount of magnesium-nickel precursor is 0.02mol and 0.02mol, that is, Mg:Ni is 1:1. Dissolve 30 grams of polyvinylpyrrolidone (PVP) in another cup of 500 ml of ethylene glycol (purity 99%), and PVP acts as a protective agent. Finally, the above two cups of 500ml solutions were mixed and then stirred by magnetic force for 30 minutes. Put the mixed solution in an environment of 180°C for reflux, and when the temperature of the solution reaches 180°C, continue to reflux for 10 minutes. Then add containing 0.02mol PdCl 2 500ml of ethylene glycol solution, when the temperature of the solution reaches 180°C again, then continue to reflux for 1 hour to generate magnesium-nickel alloy nanopowder. Then pour the solution into a beaker, co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com