Method for preparing supercapacitor carbon material by adopting bio-oil

A technology for supercapacitors and bio-oils, applied in hybrid capacitor electrodes, carbon preparation/purification, etc., can solve the problems of underdeveloped mesoporous and macroporous structures, poor rate performance, uneven pore size distribution, etc., and achieve excellent electrochemical performance. , the effect of efficient conversion, excellent rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

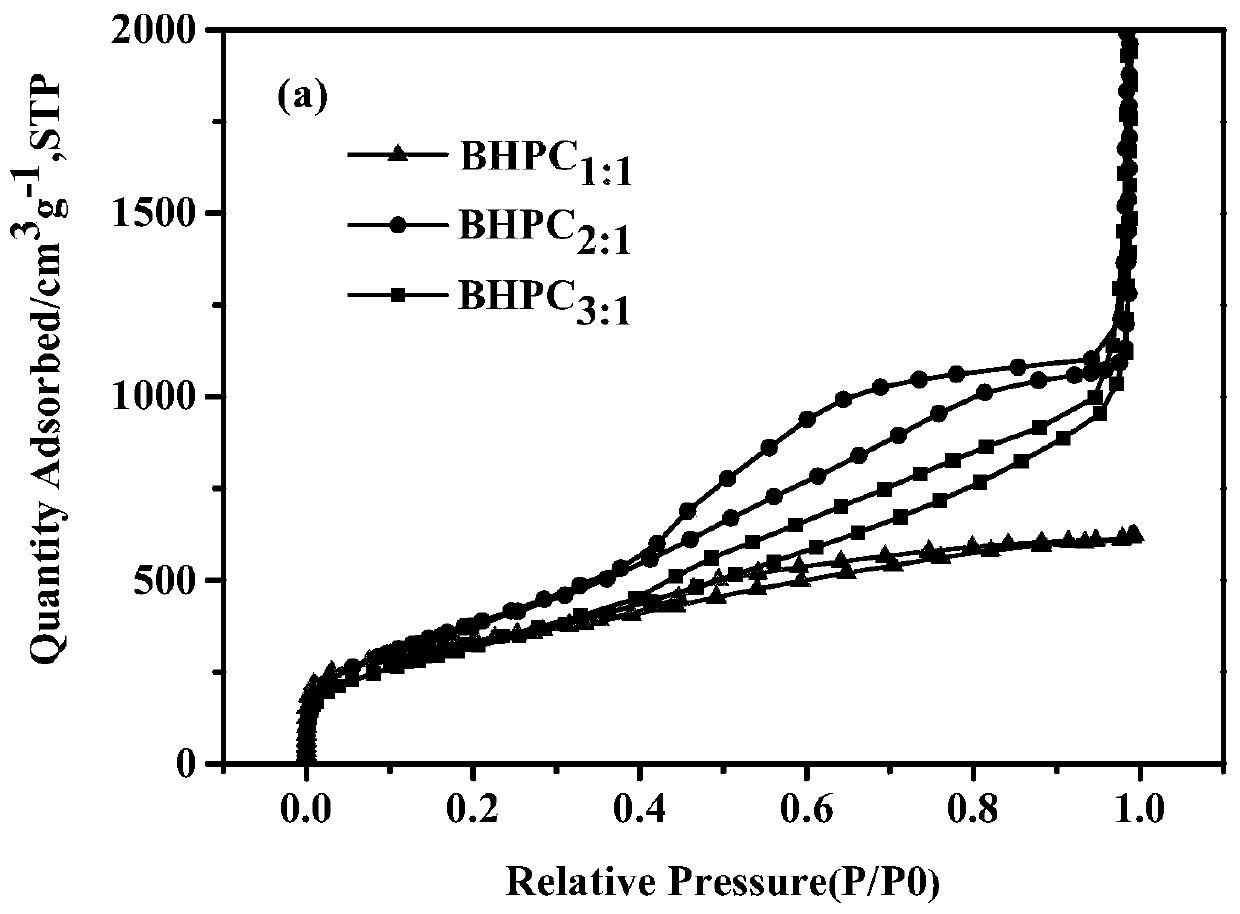

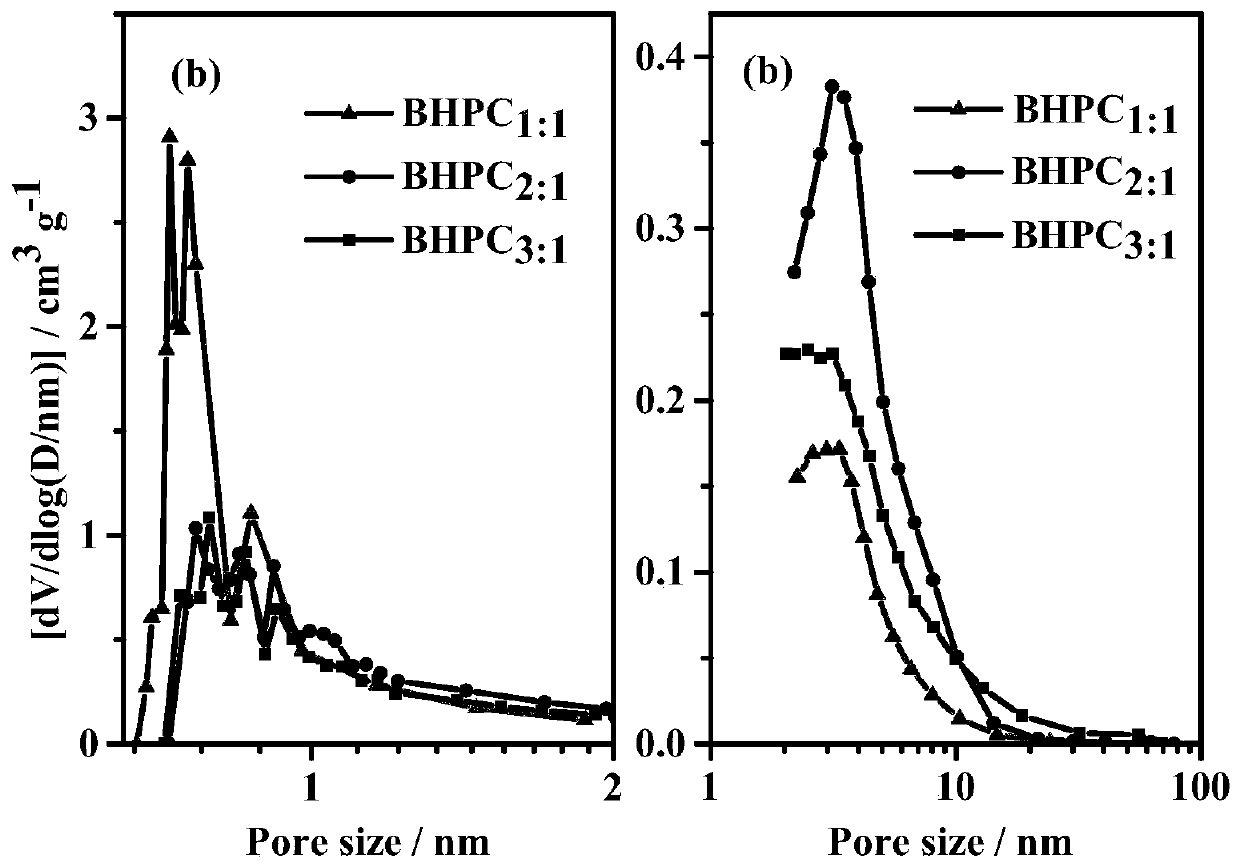

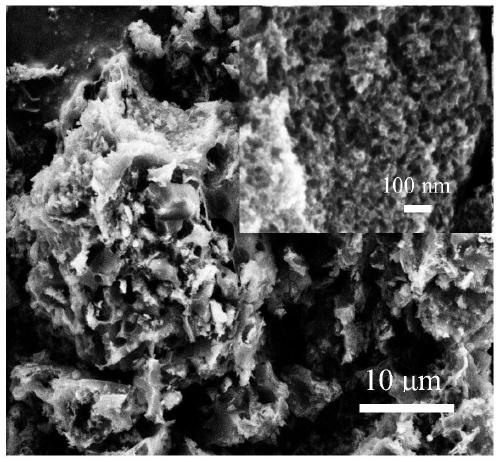

[0023] The bio-oil of this embodiment prepares supercapacitor carbon material BHPC 1∶1 The preparation process is as follows:

[0024] (1) Preparation of bio-oil: take 300g of dry pine molding particles and place them in a large fixed bed. 2 The pine wood was pyrolyzed under the atmosphere, and the condensable gas produced was condensed by condensed water at 0°C to obtain bio-oil with a mass yield of about 41.67%. Among them, the pyrolysis conditions are as follows: heating rate is 16°C / min, pyrolysis temperature is 500°C, holding time is 1h, N 2 The flow rate was 400 mL / min.

[0025] (2) Preparation of bio-oil and template mixture: Weigh 10 g of bio-oil obtained in step (1), dissolve it in 20 g of ethanol solution, and weigh 10 g of magnesium acetate tetrahydrate template and mix it with bio-oil ethanol solution, and the overall temperature is 105°C After magnetically stirring for 6 hours in an oil bath, take it out, cool to room temperature, and obtain a mixture of bio-oi...

Embodiment 2

[0029] The bio-oil of this embodiment prepares supercapacitor carbon material BHPC 2∶1 The specific preparation process is as follows:

[0030] (1) Preparation of bio-oil: implement according to the same method as step (1) in Example 1.

[0031] (2) Preparation of bio-oil and templating agent mixture: implement according to the same method as step (2) in Example 1. The difference is that the dosage of magnesium acetate tetrahydrate template is 20g, and the resulting bio-oil-based porous carbon is marked as BHPC 2∶1 .

[0032] (3) Preparation of supercapacitor carbon material from bio-oil: implement in the same manner as step (3) in Example 1.

[0033] (4) Electrochemical performance test of bio-oil-based porous carbon: the same method as step (4) in Example 1 was implemented. The resulting BHPC 2∶1 The electrode material is in 6M KOH electrolyte, at a current density of 0.5A / g, its specific capacitance is 344F / g, and at a current density of 50A / g, its specific capacitance...

Embodiment 3

[0035] The bio-oil of this embodiment prepares supercapacitor carbon material BHPC 3∶1 The specific preparation process is as follows:

[0036] (1) Preparation of bio-oil: implement according to the same method as step (1) in Example 1.

[0037] (2) Preparation of bio-oil and templating agent mixture: implement according to the same method as step (2) in Example 1. The difference is that the dosage of magnesium acetate tetrahydrate template is 30g, and the obtained bio-oil-based porous carbon is marked as BHPC 3∶1 .

[0038] (3) Preparation of supercapacitor carbon material from bio-oil: implement in the same manner as step (3) in Example 1.

[0039] (4) Electrochemical performance test of bio-oil-based porous carbon: the same method as step (4) in Example 1 was implemented. The resulting BHPC 3∶1 The electrode material is in 6M KOH electrolyte, and its specific capacitance is 207F / g at a current density of 0.5A / g, and its specific capacitance is 182F / g at a current densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com