Device and method for preparing hydrogen storage carbon material by adopting biomass pyrolysis gas

A technology for pyrolysis of gas and biomass, applied in the direction of chemical instruments and methods, hydrogen, carbon compounds, etc., can solve problems such as blockage of pipelines, and achieve the effect of simple and compact device structure, excellent microstructure, saving space and materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

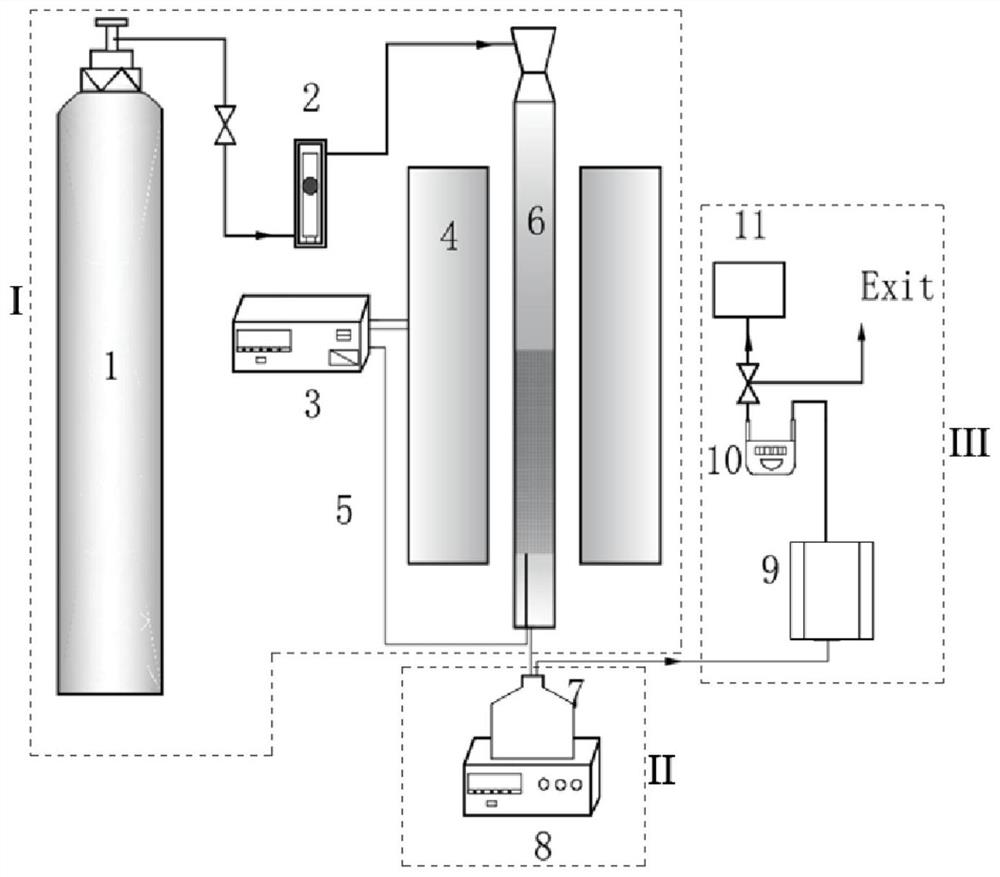

[0052] The preparation process of using biomass pyrolysis gas to prepare hydrogen storage carbon material CABC-1 in this embodiment is as follows:

[0053] (1) take by weighing 100g dry pine molding particles and place in large-scale fixed-bed pyrolysis reactor 6, under N 2 The pine wood was pyrolyzed under the atmosphere, and the pyrolysis conditions were as follows: the heating rate was 10°C / min, the pyrolysis temperature was 550°C, the holding time was 40min, N 2 The residence time in the pyrolysis zone is 1s.

[0054] (2) The pyrolysis gas produced in step (1) leads to the template solution, the template calcium acetate quality is 25g, the solvent ethanol quality is 225g, the mixing temperature is set at 150°C, and the rotating speed is 800r / min. After all the solvent in the vessel evaporated, it was cooled to room temperature, and the carbon-containing precursor was placed in an oven and dried for 12 hours.

[0055] (3) Take by weighing 10g of the mixture obtained in st...

Embodiment 2

[0060] The preparation process of biomass pyrolysis gas to prepare hydrogen storage carbon material CBBC-1 is as follows:

[0061] (1) Carry out in the same manner as step (1) in Example 1.

[0062] (2) Carry out in the same manner as step (2) in Example 1. The difference is that the template agent is calcium carbonate, and the obtained porous carbon is marked as CBBC-1.

[0063] (3) Implement in the same manner as step (3) in Example 1.

[0064] (4) Hydrogen adsorption performance test: implement according to the same method as step (4) in Example 1. The obtained CBBC-1 adsorption capacity is 121.37cm 3 g -1 .

Embodiment 3

[0066] The preparation process of the biomass pyrolysis gas to prepare the hydrogen storage carbon material CCBC-1 is as follows:

[0067] (1) Carry out in the same manner as step (1) in Example 1.

[0068] (2) Carry out in the same manner as step (2) in Example 1. The difference is that the template agent is calcium citrate dodecahydrate, and the obtained porous carbon is marked as CCBC-1.

[0069] (3) Implement in the same manner as step (3) in Example 1.

[0070] (4) Hydrogen adsorption performance test: implement according to the same method as step (4) in Example 1. The adsorption capacity of the obtained CCBC-1 was 199.79 cm3g-1. like Figure 4 Shown is the scanning electron micrograph of the hydrogen storage carbon material CCBC-1 prepared in Example 3.

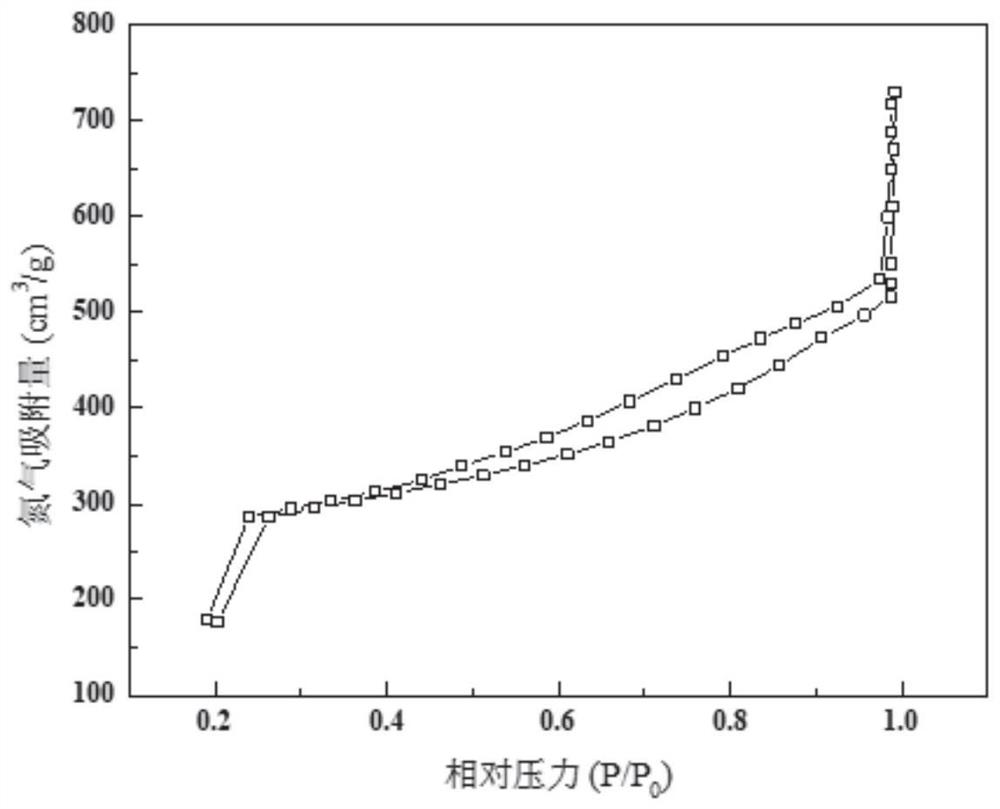

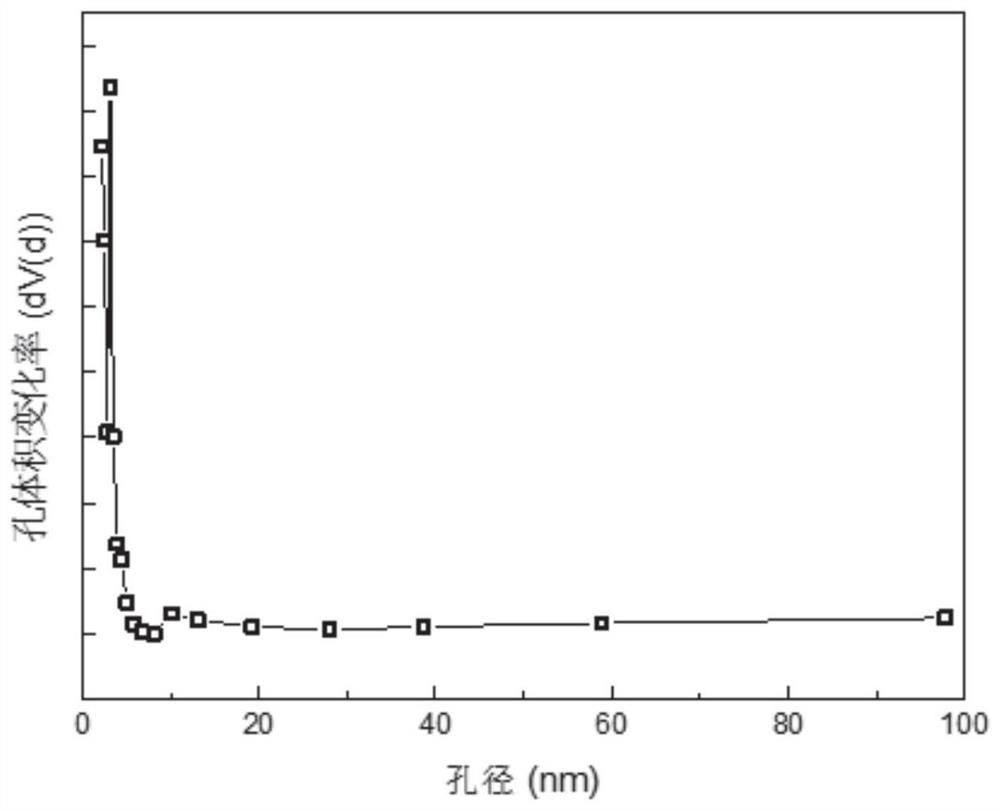

[0071] like figure 2 Shown, is the N of the hydrogen storage carbon material that embodiment one, two, three prepare 2 Adsorption-desorption isotherm diagram. N 2 The adsorption-desorption isotherm can be use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com