Synthesis method of controllable-length/width basic magnesium carbonate nanorods

A synthetic method, magnesium carbonate technology, applied in the direction of magnesium carbonate, nanotechnology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

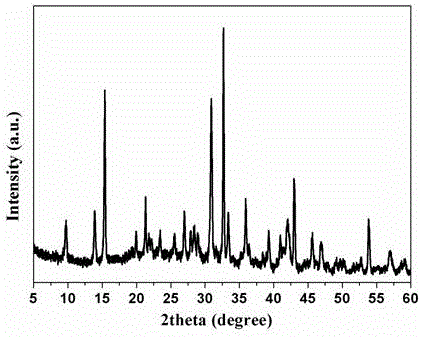

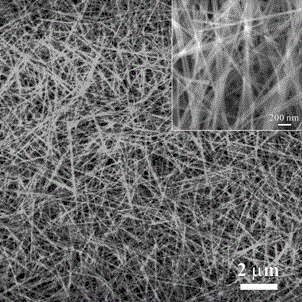

[0017] Specific embodiment one: as figure 1 with figure 2 As shown, a preparation method of basic magnesium carbonate nanorods (width between 30-60 nm) with controllable length and width includes the following steps: take magnesium acetate tetrahydrate (5 mmol) and ammonium carbonate (5.5 mmol) to dissolve In a mixed solution of deionized water (5 mL) and ethanol (5 mL ), add cetyltrimethylammonium bromide (CTAC, 0.232 g) and sodium hydroxide (1 mmol) to the above solution, stir homogeneous, the above mixed solution was transferred to a reaction kettle, heated to 200 ° C, and the reaction time was 12 h. The product was collected by centrifugation, and then washed several times with distilled water and industrial alcohol.

[0018] The XRD figure shows that the product obtained is basic magnesium carbonate, and the scanning electron microscope figure shows that the product obtained is an elongated nanowire, and its enlarged view ( figure 2 top right) indicates that the slen...

specific Embodiment 2

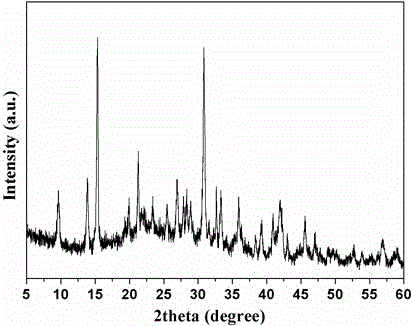

[0019] Specific embodiment two: as image 3 with Figure 4 As shown, a preparation method of basic magnesium carbonate nanorods (width between 65-85 nm) with controllable length and width includes the following steps: take magnesium acetate tetrahydrate (4.5 mmol) and ammonium carbonate (5.5 mmol) to dissolve In a mixed solution of deionized water (5 mL) and ethanol (5 mL ), add cetyltrimethylammonium bromide (CTAC, 0.182 g) and sodium hydroxide (3 mmol) to the above solution, stir homogeneous, the above mixed solution was transferred to a reaction kettle, heated to 200 ° C, and the reaction time was 12 h. The product was collected by centrifugation, and then washed several times with distilled water and industrial alcohol.

[0020] The XRD figure shows that the product obtained is basic magnesium carbonate, and the scanning electron microscope figure shows that the product obtained is a nanowire with moderate thickness, and its enlarged view ( Figure 4 top right) indicate...

specific Embodiment 3

[0021] Specific embodiment three: as Figure 5 with Image 6 As shown, a preparation method of basic magnesium carbonate nanorods (width between 85-100nm) with controllable length and width includes the following steps: take magnesium acetate tetrahydrate (5 mmol) and ammonium carbonate (5.5 mmol) and dissolve them with In a mixed solution of deionized water (5 mL) and ethanol (5 mL ), add cetyltrimethylammonium bromide (CTAC, 0.1 g) and sodium hydroxide (3 mmol) to the above solution, stir well , the above mixed solution was transferred to a reaction kettle, heated to 200 ° C, and the reaction time was 12 h. The product was collected by centrifugation, and then washed several times with distilled water and industrial alcohol.

[0022] The XRD figure shows that the product obtained is basic magnesium carbonate, and the scanning electron microscope figure shows that the product obtained is a nanowire with moderate thickness, and its enlarged view ( Image 6 top right) indica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com