Pollution-free manufacturing method for surface electric heating elements

A technology of electric heating element and manufacturing method, which is applied in the field of semiconductor heat source, can solve the problems of poor film layer uniformity, poor bonding force, easy to fall off, etc., and achieve the effects of small thermal inertia, small pollution, and easy temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

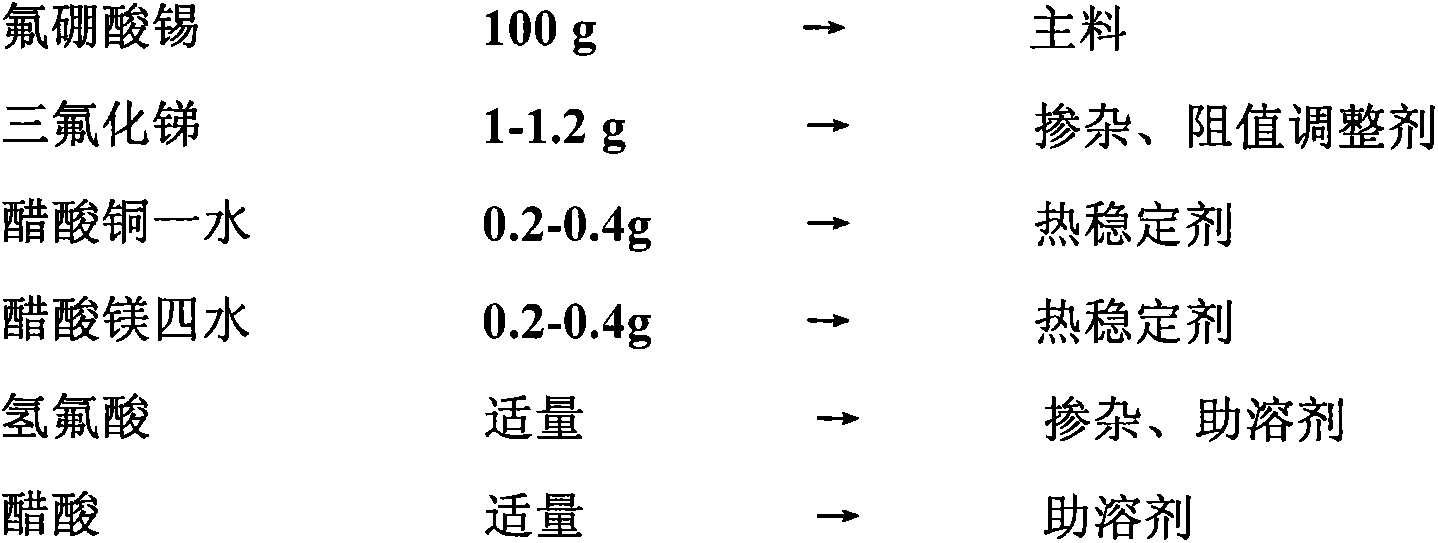

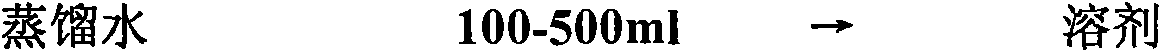

[0017] A non-polluting manufacturing method for a surface electric heating element, characterized in that the weight ratio of the surface modification solution formula is:

[0018]

[0019]

[0020] A non-polluting manufacturing method for a surface heating element as described above, the process steps include preparing a surface modification solution, cleaning the substrate, modifying the surface of the substrate, making electrode leads, and aging. It is characterized in that:

[0021] (1) Preparation of surface modification solution: ① acidify distilled water with acetic acid to prevent salt hydrolysis; Cover it in distilled water; ③Weigh antimony trifluoride quickly in a dry and ventilated place according to the measurement, and slowly add it into acidified distilled water in small amounts under stirring; ④While stirring, mix the above solutions evenly and seal , Store in a cool and ventilated place, for standby;

[0022] (2) Clean the base material: the base materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com