Electric heating coating and preparation method thereof

An electrothermal coating and raw material technology, applied in the field of coatings, can solve the problems of easy peeling of electrothermal film, poor heating efficiency, poor corrosion resistance, etc., achieve low industrial cost, simple and easy preparation process, increase flexibility and mechanical strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

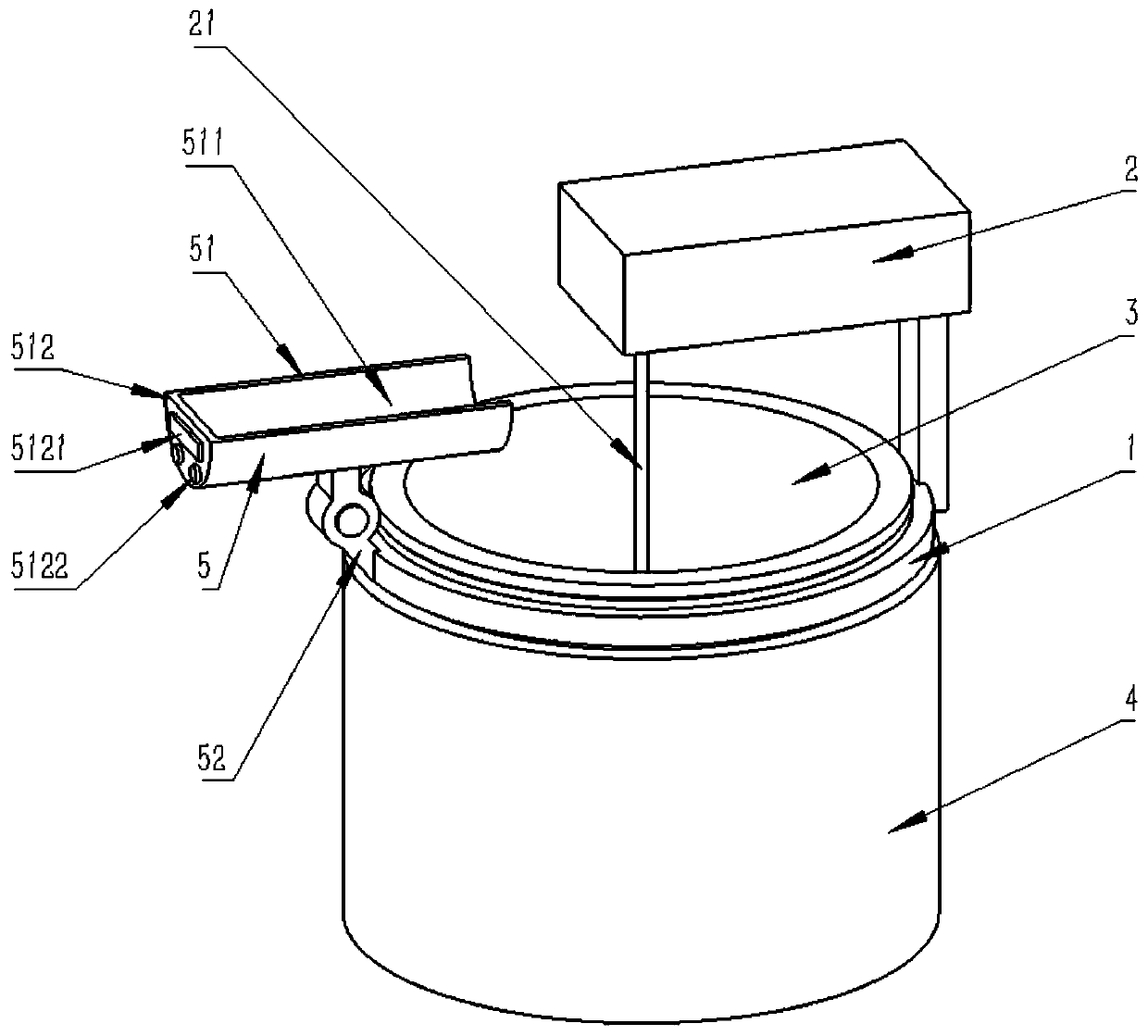

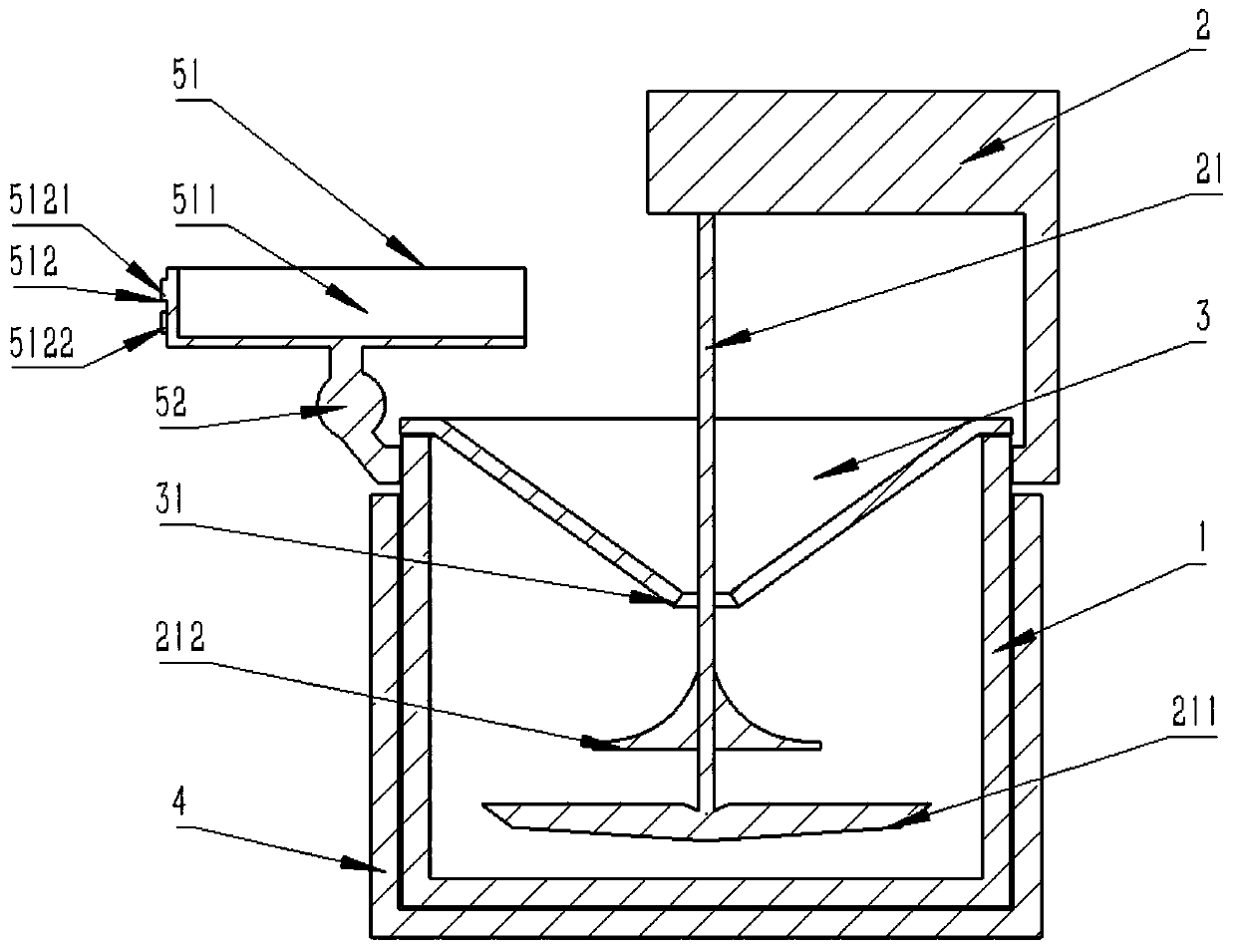

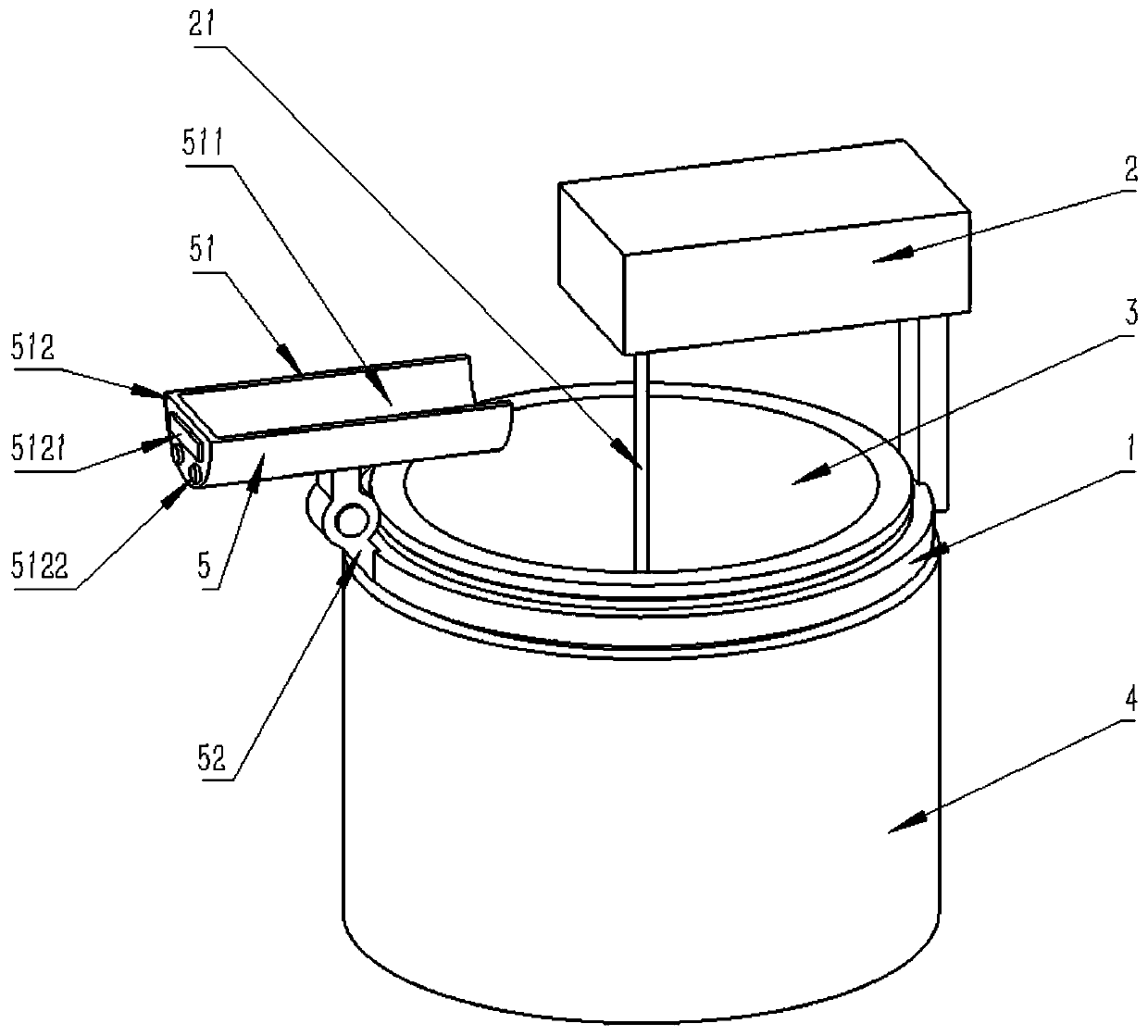

Image

Examples

experiment example 1

[0060] Group 1: An electrothermal coating, including the following raw materials by weight: m parts of graphene, 10 parts of tin dioxide octahedron, 8 parts of antimony pentoxide, 3 parts of tricobalt tetroxide, 10 parts of aluminum oxide, zinc oxide 6 parts, 3 parts of barium oxide, 3 parts of yttrium trioxide, 4 parts of zirconia, 3 parts of lithium oxide; 5 parts of boron oxide, 7 parts of silicon dioxide, 6 parts of tellurium dioxide; 8 parts of polyaniline, 8 parts of polypyrrole parts; polyacrylonitrile 8 parts, polyamide 8 parts.

[0061] Group 2: An electrothermal coating, including the following raw materials by weight: m parts of graphene, 10 parts of red gold tin dioxide, 8 parts of antimony pentoxide, 3 parts of tricobalt tetroxide, 10 parts of aluminum oxide, 6 parts of zinc, 3 parts of barium oxide, 3 parts of yttrium trioxide, 4 parts of zirconia, 3 parts of lithium oxide; 5 parts of boron oxide, 7 parts of silicon dioxide, 6 parts of tellurium dioxide; 8 parts ...

experiment example 2

[0067] An electrothermal coating, comprising the following raw materials by weight: 5 parts of graphene, n parts of corrosion inhibitor microcapsules based on graphene rolls, 10 parts of tin dioxide octahedron, 8 parts of antimony pentoxide, 3 parts of tricobalt tetroxide, 10 parts of aluminum oxide, 6 parts of zinc oxide, 3 parts of barium oxide, 3 parts of yttrium trioxide, 4 parts of zirconia, 3 parts of lithium oxide; 5 parts of boron oxide, 7 parts of silicon dioxide, 6 parts of tellurium dioxide ; 8 parts of polyaniline, 8 parts of polypyrrole; 8 parts of polyacrylonitrile, 8 parts of polyamide. The corrosion inhibitor microcapsules based on graphene rolls are prepared using 5L 8-hydroxyquinoline supersaturated solution and 5g graphene oxide using the method whose publication number is CN106904603A.

[0068] The performance of the electrothermal coating was detected, and the results are shown in Table 2. Refer to the national standard GB / T1865-2009 for artificial weathe...

experiment example 3

[0079] An electrothermal coating, comprising the following raw materials by weight: 5 parts of graphene, 3 parts of corrosion inhibitor microcapsules based on graphene rolls, x parts of magnetic fluid, 10 parts of tin dioxide octahedron, 8 parts of antimony pentoxide , 3 parts of cobalt tetroxide, 10 parts of aluminum oxide, 6 parts of zinc oxide, 3 parts of barium oxide, 3 parts of diyttrium trioxide, 4 parts of zirconia, 3 parts of lithium oxide; 5 parts of boron oxide, 7 parts of silicon dioxide, 6 parts of tellurium dioxide; 8 parts of polyaniline, 8 parts of polypyrrole; 8 parts of polyacrylonitrile, 8 parts of polyamide. The corrosion inhibitor microcapsules based on graphene rolls are prepared by using 5L of 8-hydroxyquinoline supersaturated solution and 5g of graphene oxide using the method with publication number CN106904603A.

[0080] Group 4: The electrothermal paint prepared according to the above ratio is coated on the insulating layer on the surface of the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com