Electromagnetic induction heating system for injection molding machine

A technology of heating system and electromagnetic induction coil, applied in the direction of induction heating, induction heating control, induction heating device, etc., can solve the problems of shortening oil seal, service life of oil pump, short service life of heating coil, oil leakage and unstable pressure, etc. Achieve the effects of easy control of heating temperature, short preheating time and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

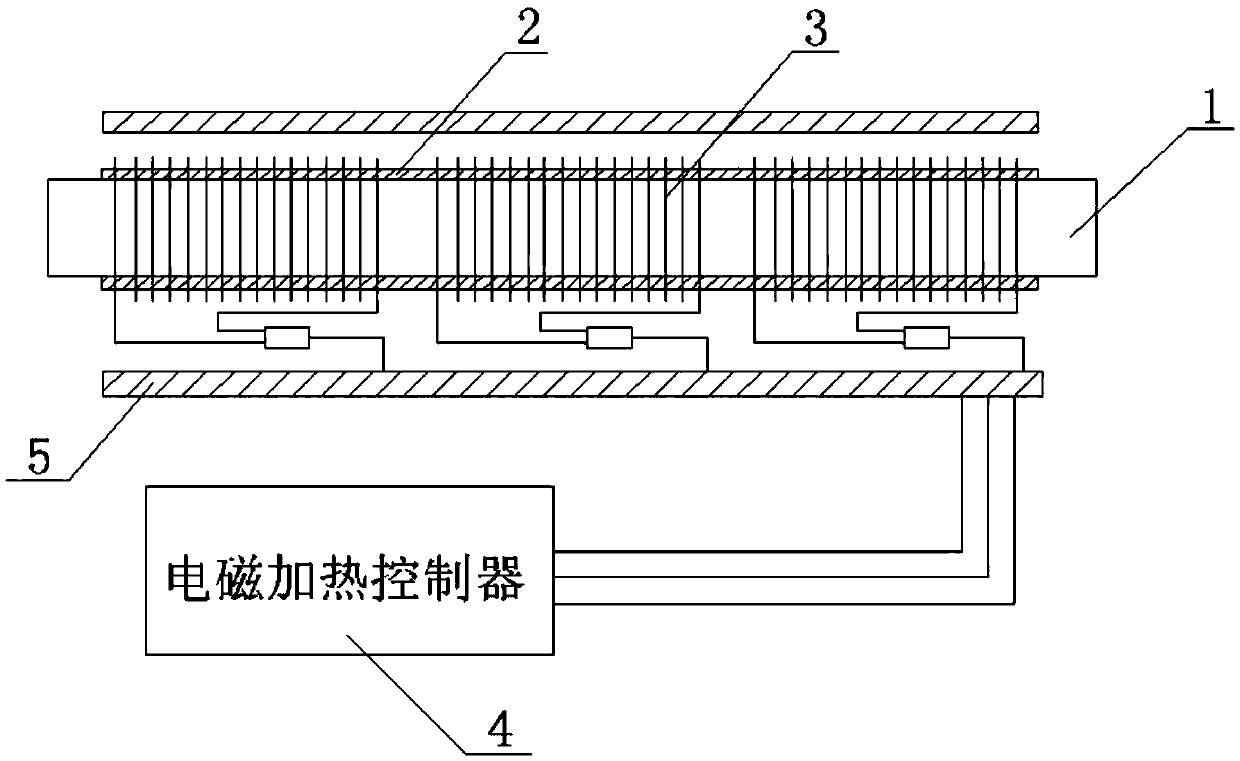

[0014] Such as figure 1 As shown, an electromagnetic induction heating system for an injection molding machine includes an electromagnetic heating cylinder and an electromagnetic heating controller 4, wherein the electromagnetic heating cylinder is composed of three layers, including the innermost barrel 1, and the middle layer is used to prevent the innermost layer of the barrel 1 The thermal insulation cotton 2 that dissipates heat and the electromagnetic induction coil 3 wound on the outermost layer, the electromagnetic induction coil 3 is connected with the electromagnetic heating controller 4 and controlled by the electromagnetic heating controller 4 . The electromagnetic induction coil 3 is also covered with a protective cover 5 for protecting the electromagnetic heating cylinder from damage.

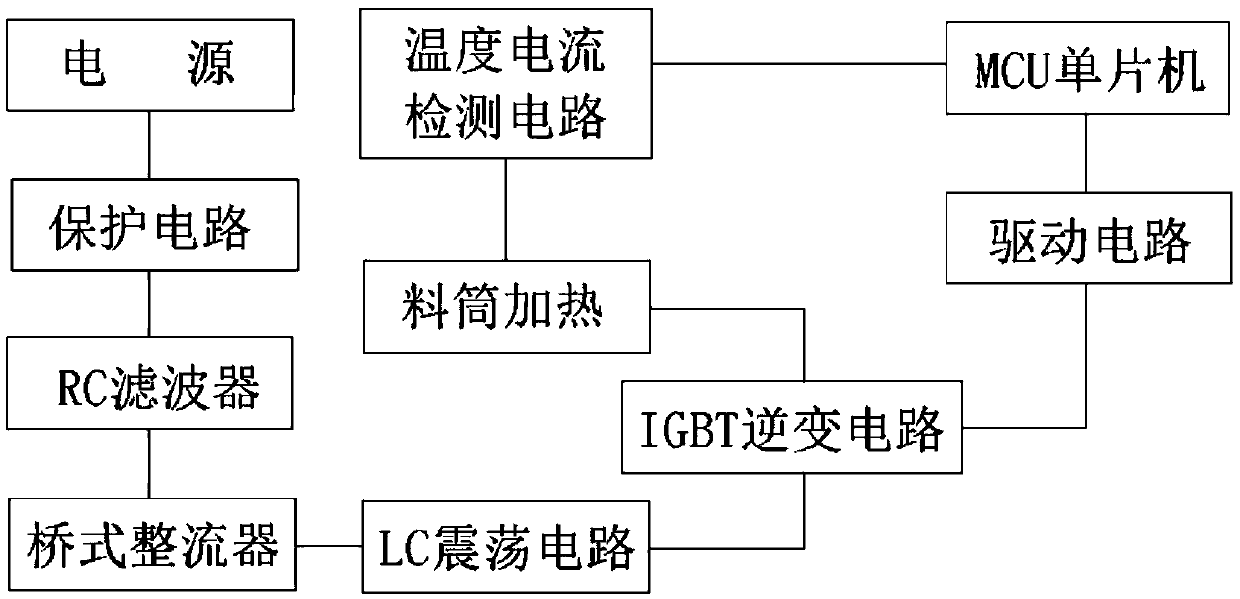

[0015] The electromagnetic heating controller 4 includes a protection circuit connected to the power supply. The protection circuit is used to protect the internal circuit of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com