Adhesive for indoor decoration and preparation method thereof

A technology for interior decoration and adhesives, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of aggravated emission, poor weather resistance, easy aging, etc., to improve the use of Good performance, good initial tack, not easy to shrink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

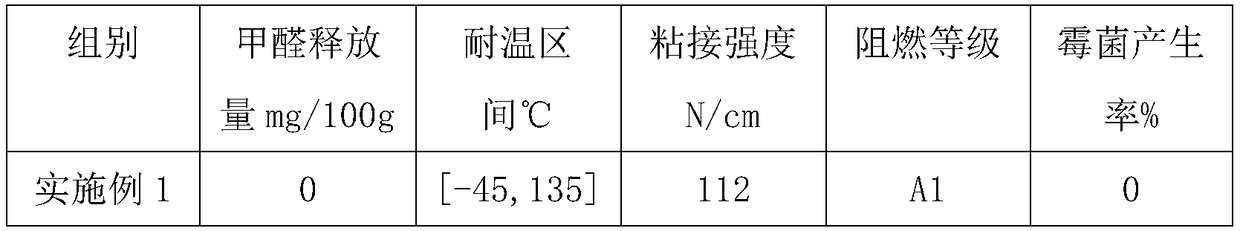

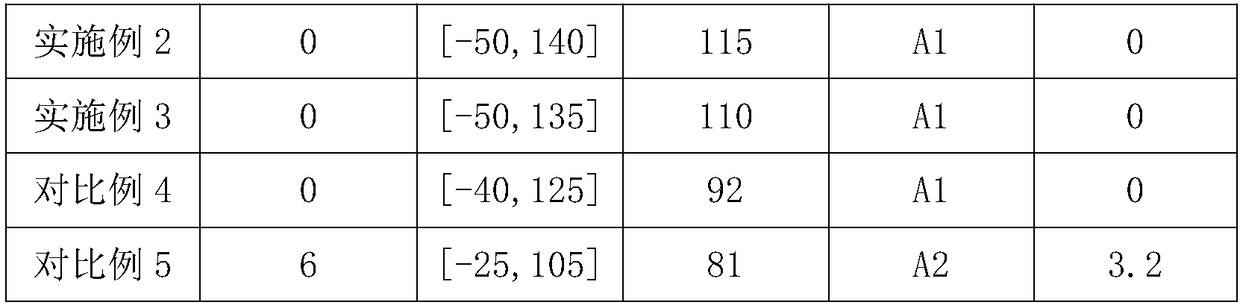

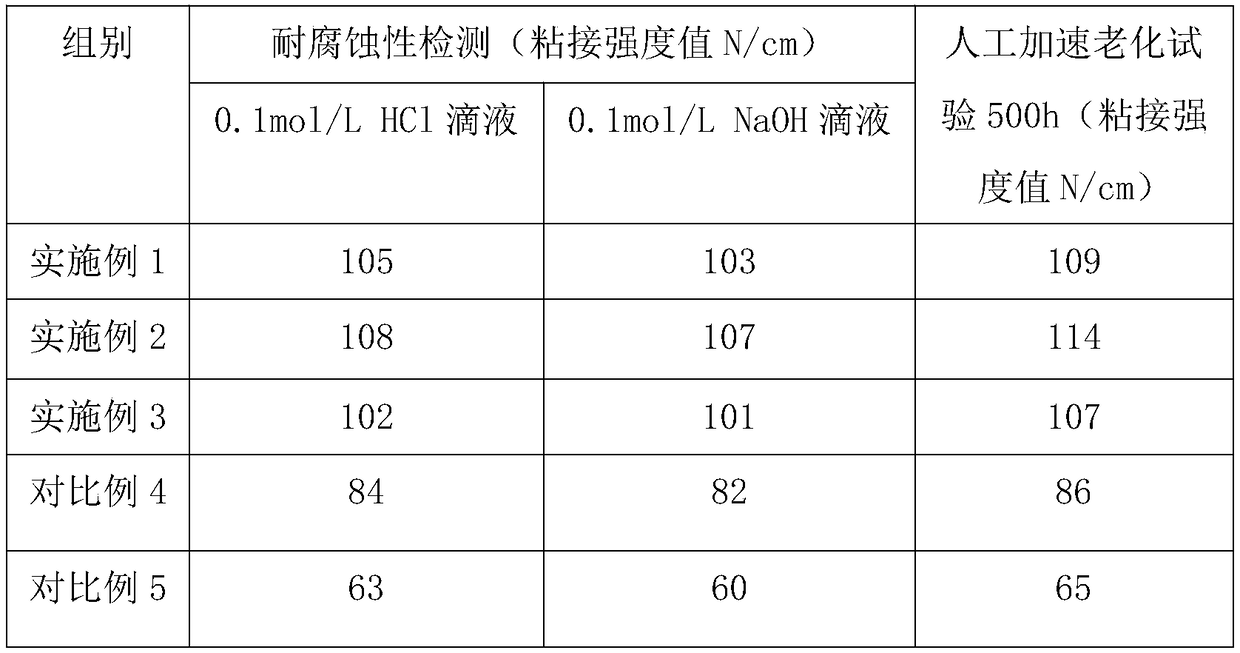

Examples

Embodiment 1

[0027] An adhesive for interior decoration, which is carried out by weighing the following raw materials: benzofuran resin 50kg, isoprene-styrene block copolymer 40kg, hide glue 15kg, glycidyl methacrylate 1kg, salicyl 1kg methyl ester, 0.8kg benzophenone, 1kg diacetone acrylamide, 0.4kg magnesium acetate tetrahydrate, 1kg hydrogenated rosin, 0.2kg 1,3-diethylthiourea, 2kg modified palm fiber, 2kg zeolite powder , kaolin 3kg, formamide 0.5kg, aluminum dihydrogen phosphate 0.2kg, antioxidant 2640.8kg, crosslinking aid: trimethylolpropane 1.5kg, plasticizer: chlorinated paraffin 1kg and titanate coupling agent 1kg ;

[0028] Above-mentioned modified palm fiber is made through the following steps:

[0029] Chopped: take 2kg of palm fiber raw material, chopped and crushed until the length is 400μm, and the aspect ratio is controlled at 100:1;

[0030] Pickling: Put the chopped palm fiber into a mixed solution of 4wt% hydrochloric acid and 10wt% glacial acetic acid and soak for 8...

Embodiment 2

[0040] An adhesive for interior decoration, which is carried out by weighing the following raw materials: benzofuran resin 55kg, isoprene-styrene block copolymer 45kg, hide glue 20kg, glycidyl methacrylate 1.5kg, water Methyl sylate 1.5kg, benzophenone 1kg, diacetone acrylamide 1.25kg, magnesium acetate tetrahydrate 0.5kg, hydrogenated rosin 1.5kg, 1,3-diethylthiourea 0.3kg, modified palm fiber 2.25kg , Zeolite powder 2.5kg, kaolin 4kg, formamide 0.7kg, aluminum dihydrogen phosphate 0.25kg, antioxidant 2640.9kg, cross-linking aid: trimethylolpropane 1.75kg, plasticizer: dioctyl phthalate 1.25kg and silane coupling agent KH5501.5kg;

[0041]Above-mentioned modified palm fiber is made through the following steps:

[0042] Chopped: Take 2.25kg of palm fiber raw material, chopped and crushed until the length is 500μm, and the aspect ratio is controlled at 100:1;

[0043] Pickling: Put the chopped palm fiber into a mixed solution of 5wt% hydrochloric acid and 11wt% glacial acetic...

Embodiment 3

[0053] An adhesive for interior decoration, which is carried out by weighing the following raw materials: benzofuran resin 60kg, isoprene-styrene block copolymer 50kg, hide glue 25kg, glycidyl methacrylate 2kg, salicylic acid 2kg methyl ester, 1.2kg benzophenone, 1.5kg diacetone acrylamide, 0.6kg magnesium acetate tetrahydrate, 2kg hydrogenated rosin, 0.4kg 1,3-diethylthiourea, 2.5kg modified palm fiber, zeolite Powder 3kg, kaolin 5kg, formamide 0.9kg, aluminum dihydrogen phosphate 0.3kg, antioxidant 2641kg, crosslinking aid: m-xylylenediamine 2kg, plasticizer: methyl pentachlorostearate 1.5kg and aluminum acid Ester coupling agent 2kg;

[0054] Above-mentioned modified palm fiber is made through the following steps:

[0055] Chopped: take 2.5kg of palm fiber raw material, chopped and crushed until the length is 600μm, and the aspect ratio is controlled at 100:1;

[0056] Pickling: Put the chopped palm fiber into a mixed solution of 6wt% hydrochloric acid and 12wt% glacial a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com