Passive refrigeration crystal, passive refrigeration coating as well as preparation method and application thereof

A passive refrigeration and crystal technology, applied in the direction of coating, crystal growth, chemical instruments and methods, etc., can solve the problems of non-corrosion or aging of materials, high manufacturing cost, difficult manufacturing and application, etc., to achieve low cost, reduce surface The effect of temperature and performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

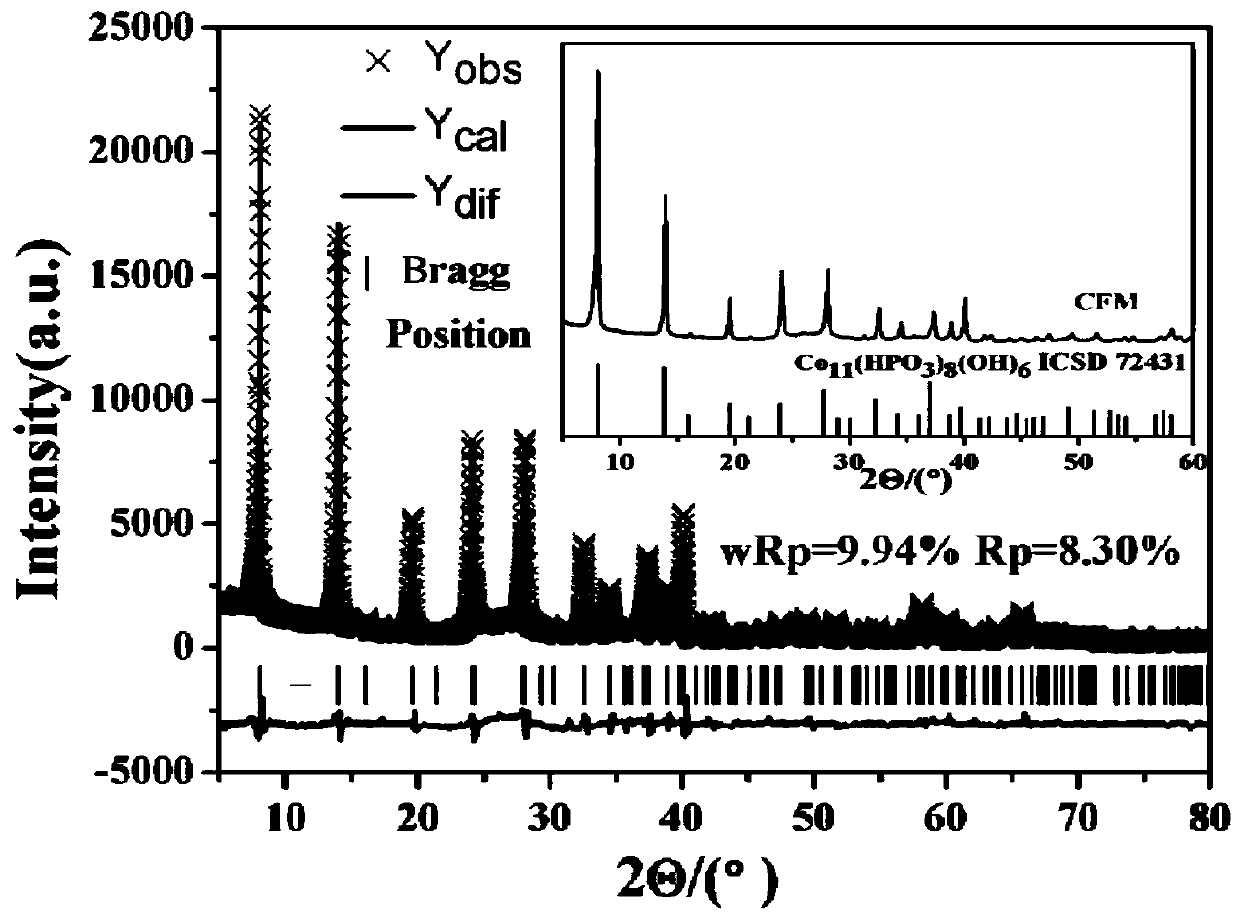

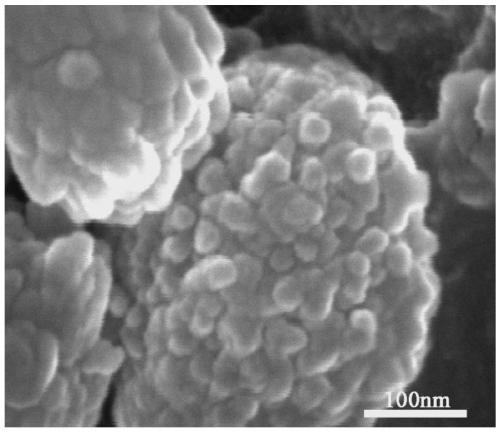

[0057] Preparation of Passively Cooled Crystals

[0058] According to the synthesis of 0.02 / 11mol target product Ca y Mg 11-y (HPO 3 ) 8 (OH) 6-x f x (x=3, y=0.5) Calculate the corresponding required mass of each reactant.

[0059] (1) Accurately weigh 4.094g of magnesium acetate tetrahydrate and 0.160g of calcium acetate monohydrate, mix the two into a beaker, dissolve with 20-30g of water and stir until it becomes a transparent colorless liquid.

[0060] (2) Take by weighing 1.64g phosphorous acid solid and 0.229g sodium fluoride solid powder, phosphorous acid and sodium fluoride are dissolved in deionized water respectively, obtain the phosphorous acid aqueous solution that concentration is 0.082g / ml and concentration is 0.0114g / ml ml of sodium fluoride solution.

[0061] (3) Mix all the solutions prepared in steps (1) and (2) to obtain a mixed solution, add a magnetic stirrer, adjust the rotating speed to 300r / min, place the mixed solution on a magnetic stirrer and ...

Embodiment 2

[0079] According to the synthesis of 0.02 / 11mol target product Ca y Mg 11-y (HPO 3 ) 8 (OH) 6-x f x (x=2, y=0.5), the required mass of each reactant can be calculated according to the stoichiometric ratio. The synthesis route of the target product and the preparation method of the passive refrigeration coating are the same as those in Example 1, and will not be repeated here.

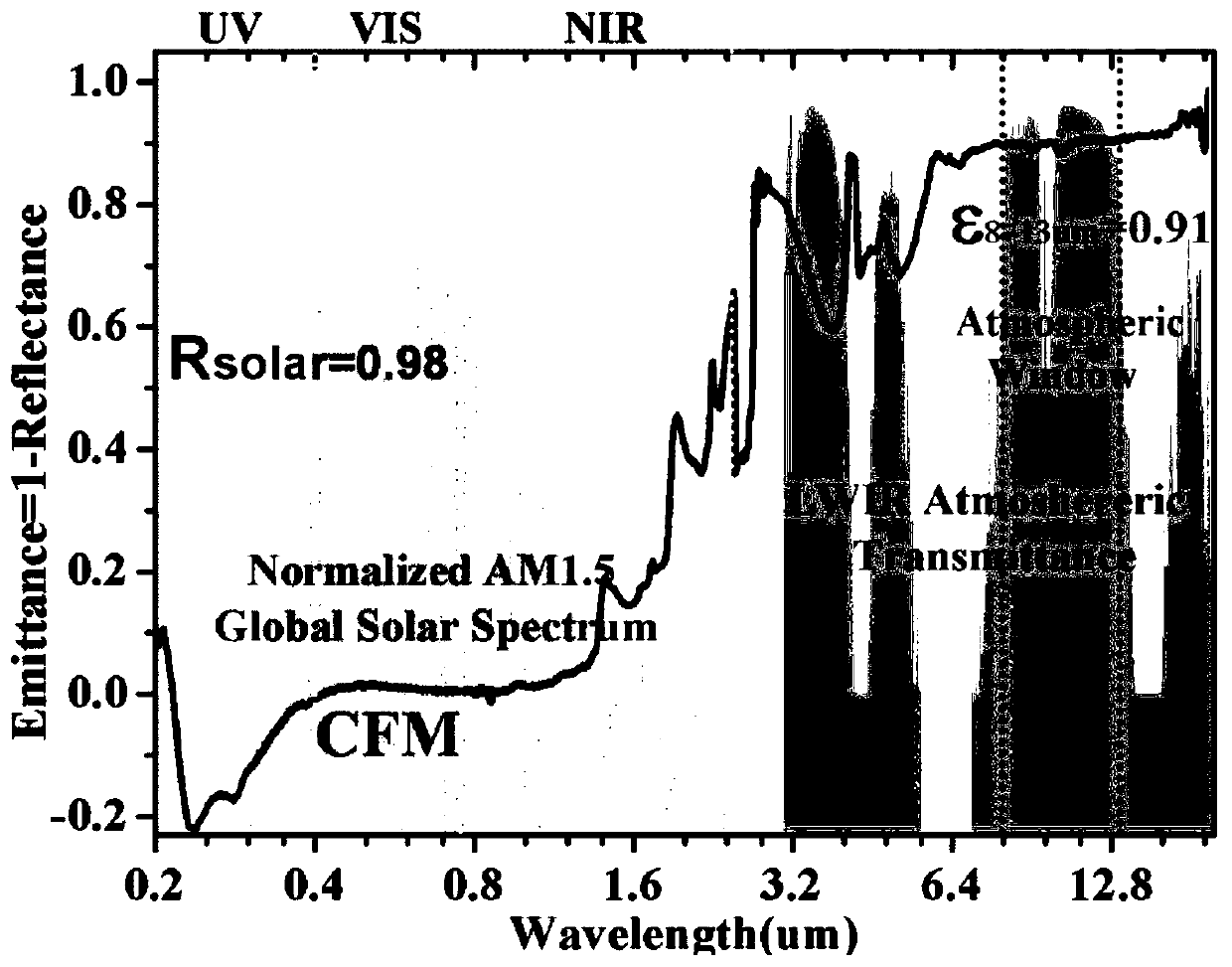

[0080] The passive refrigeration crystal prepared in Example 2 has a reflectivity of 0.96 in the ultraviolet-visible-near-infrared band (0.2-2.5um), and an emissivity of 0.91 at the transparent window of the atmosphere (8-13um), and exhibits excellent performance in the infrared long-wave range. A certain emission selectivity.

[0081] The refrigeration test results of the passive refrigeration coating prepared in this example are similar to those in Example 1, and will not be repeated here.

Embodiment 3

[0083] According to the synthesis of 0.02 / 11mol target product Ca y Mg 11-y (HPO 3 ) 8 (OH) 6-x f x (x=3, y=1), the required mass of each reactant can be calculated according to the stoichiometric ratio. The synthesis route of the target product and the preparation method of the passive refrigeration coating are the same as those in Example 1, and will not be repeated here.

[0084] The passive refrigeration crystal prepared in Example 3 has a reflectivity of 0.97 in the ultraviolet-visible-near-infrared band (0.2-2.5um), and an emissivity of 0.90 at the transparent window of the atmosphere (8-13um), and exhibits excellent performance in the infrared long-wave range. A certain emission selectivity.

[0085] The refrigeration test results of the passive refrigeration coating prepared in this example are similar to those in Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com