Birdcage type vehicle body skeleton structure

A skeleton structure, birdcage-type technology, applied in load-bearing body structure, superstructure, vehicle parts, etc., can solve problems such as the weak connection between the roof assembly and the side panel assembly, and the poor impact resistance of the body frame. Achieve the effect of strong impact resistance, firm back wall frame and firm structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

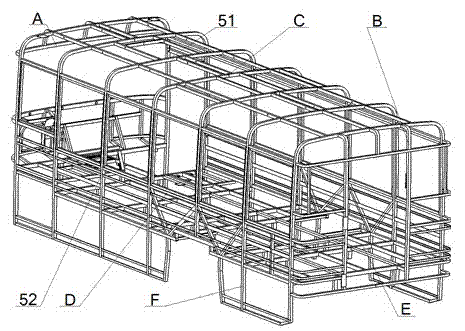

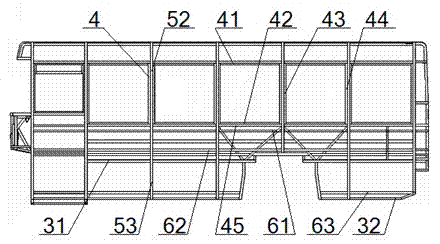

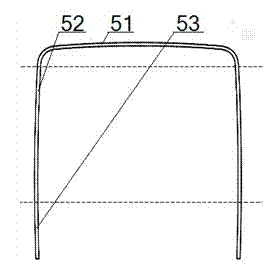

[0055] see figure 1 – Figure 4 , a birdcage body frame structure, comprising a front wall assembly A, a rear wall assembly B and a top cover assembly C, the two ends of the top cover assembly C are connected to the front wall assembly A, the rear wall assembly The upper end of B is connected, the lower ends of the front wall assembly A and the rear wall assembly B are connected with the bottom frame assembly E, and the side part of the bottom frame assembly E is connected with the top cover assembly C through the side wall assembly D. The top cover assembly C includes a plurality of parallel top beams 51, and the side wall assembly D includes a plurality of side wall vertical beams 52 parallel to each other; connected, the bottom of the side girder 52 is fixedly connected with the skirt assembly F, and the top beam 51 and the side girder 52 are integrated; the vehicle body skeleton structure also includes a plurality of rectangular side window frames 4, each Rectangular sid...

Embodiment 2

[0057] see Figure 5 – Figure 9 , embodiment 2 is basically the same as embodiment 1, its difference is:

[0058] The side wall assembly D is provided with under-window reinforcing stringers 71 and middle reinforcing stringers 72, the upper side of the under-window reinforcing stringers 71 is fixedly connected with the side window lower stringers 45, and the under-window reinforcing stringers 71 The lower side of the lower side of the window is fixedly connected with the embedded stringer 61 under the window, and the upper side and the lower side of the middle reinforced stringer 72 are respectively fixedly connected with the two middle embedded stringers 62; the skirt assembly F is provided with The skirt reinforcement stringer 73, the upper side of the skirt reinforcement stringer 73 is fixedly connected with the skirt embedded stringer 63, and the lower side of the skirt reinforcement stringer 73 is fixedly connected with the skirt connection stringer 32; The rear wall a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com