Constant-pressure variable radial-plunger pump

A constant pressure variable, radial column technology, applied in the direction of pumps, multi-cylinder pumps, liquid variable capacity machinery, etc., can solve the problems of bulky, short service life, difficult to promote, etc., to achieve simple variable operation and long service life Long-lasting, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

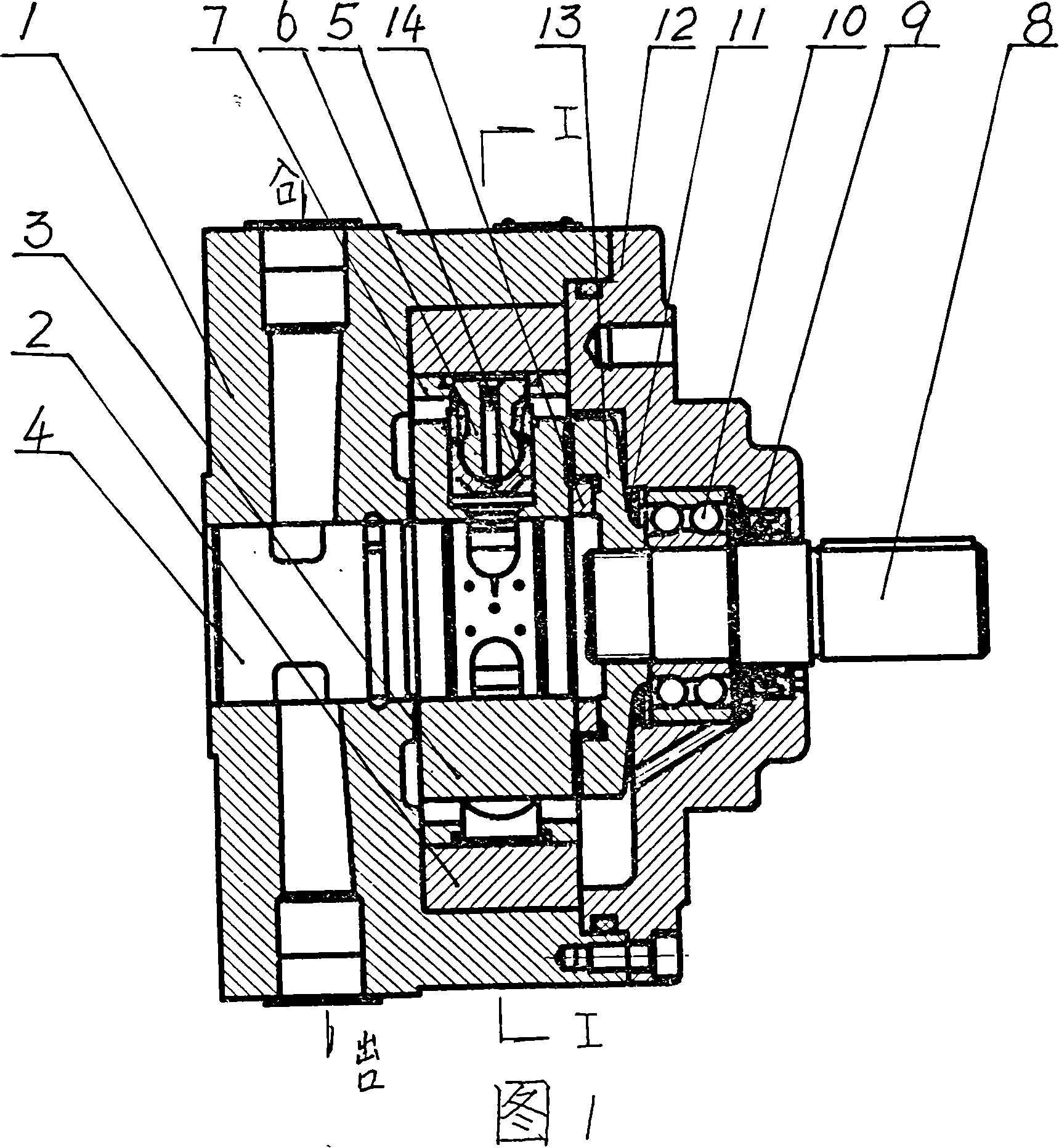

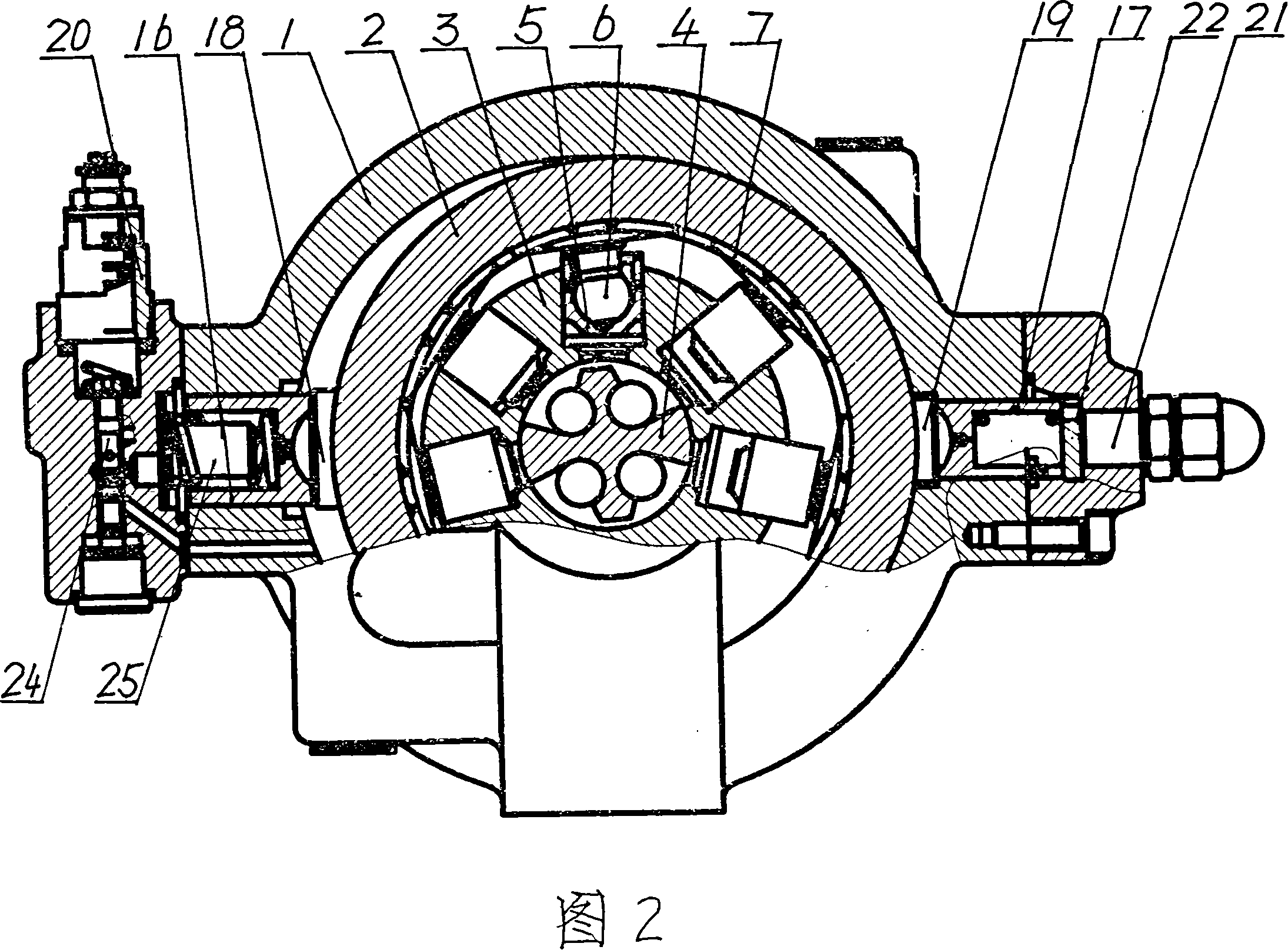

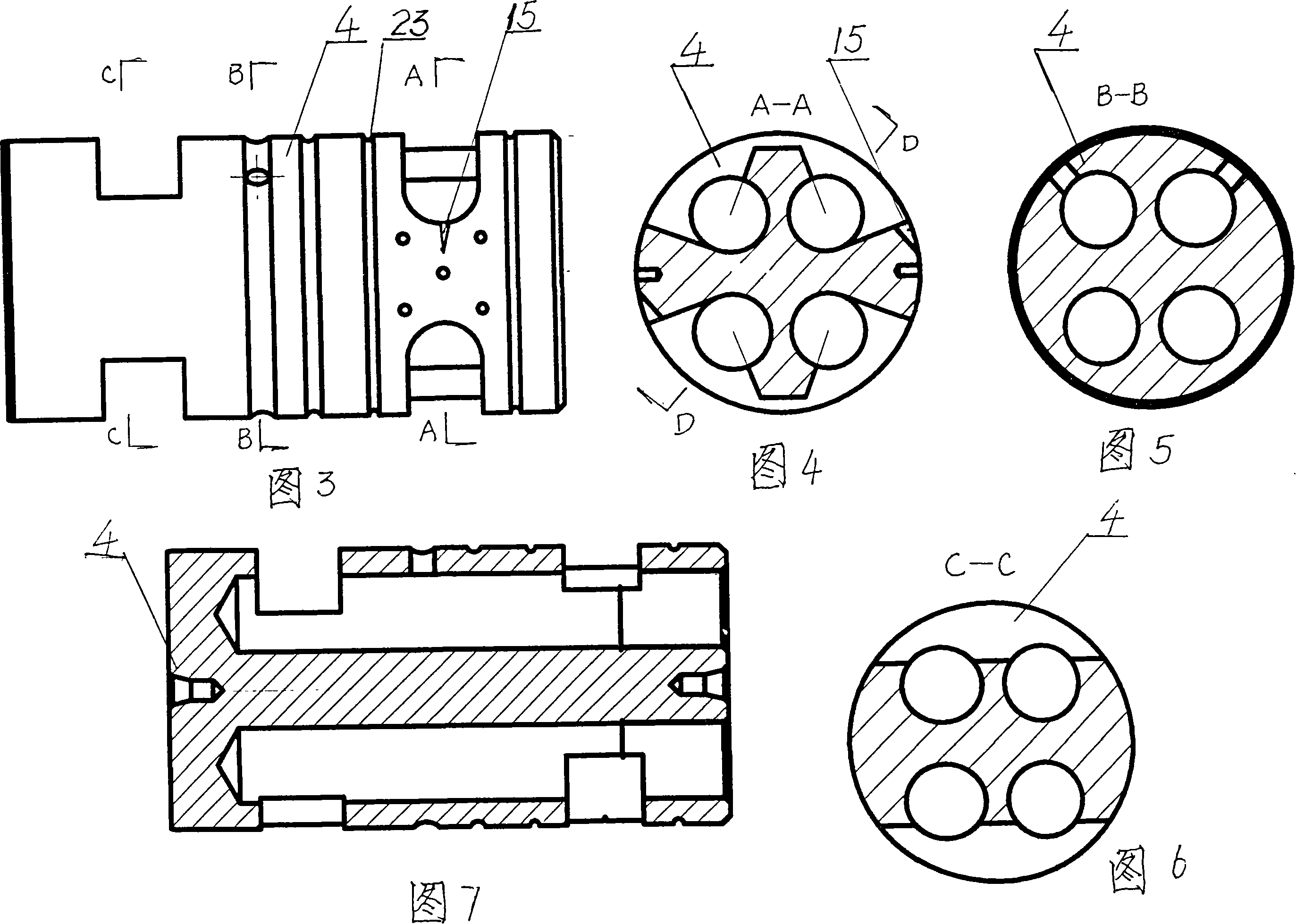

[0033] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are exemplified, and detailed descriptions are given below with reference to the accompanying drawings. Please refer to FIGS. 1-19 .

[0034] As shown in Figure 1 and Figure 2: the present invention consists of a pump casing 1, a stator 2, a rotor 3, a distribution shaft 4, a plunger 5, a rod 6, a return ring 7, a transmission shaft 8, a pump cover 12, a coupling 13, Cross slider 14, large control column 16, small control plunger 17, slide blocks 18 and 19, manual constant pressure variable valve 20 form.

[0035] ①. As shown in Figure 1 and Figure 2: the shape of the inner hole of the pump casing 1 is oblong, that is, the circle of the inner hole is cut in half from the center line and then pulled apart, and then two straight lines and arcs are used to form The tangent lines are connected together to ensure that the stator 2 can have space ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com