Cushion material formed of spring-structured resin-molded product, manufacturing method thereof, and mold used therefor

A resin molding, elastic structure technology, applied in the field of buffer materials, can solve the problems of unresolved, burning, troublesome manufacturing methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

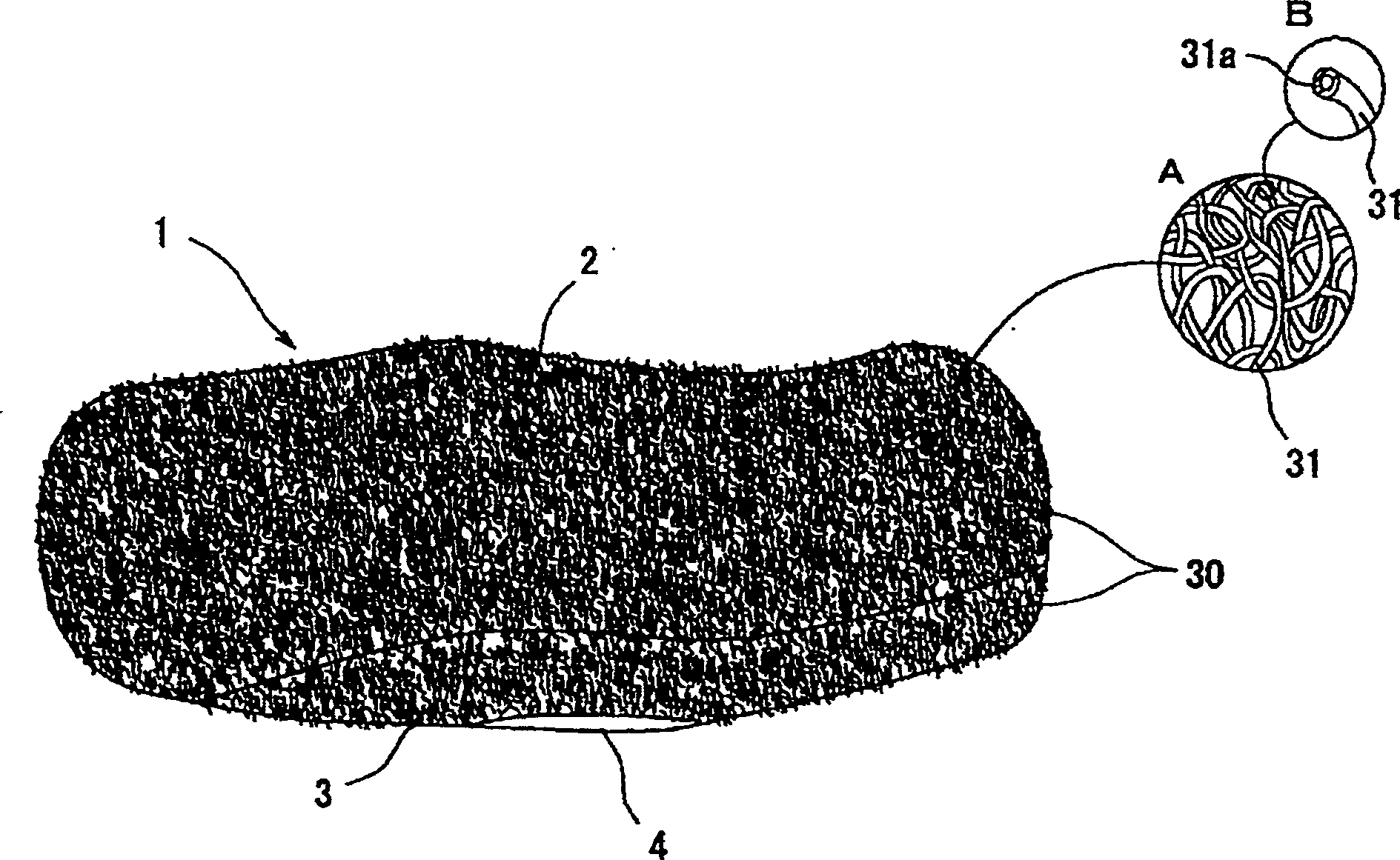

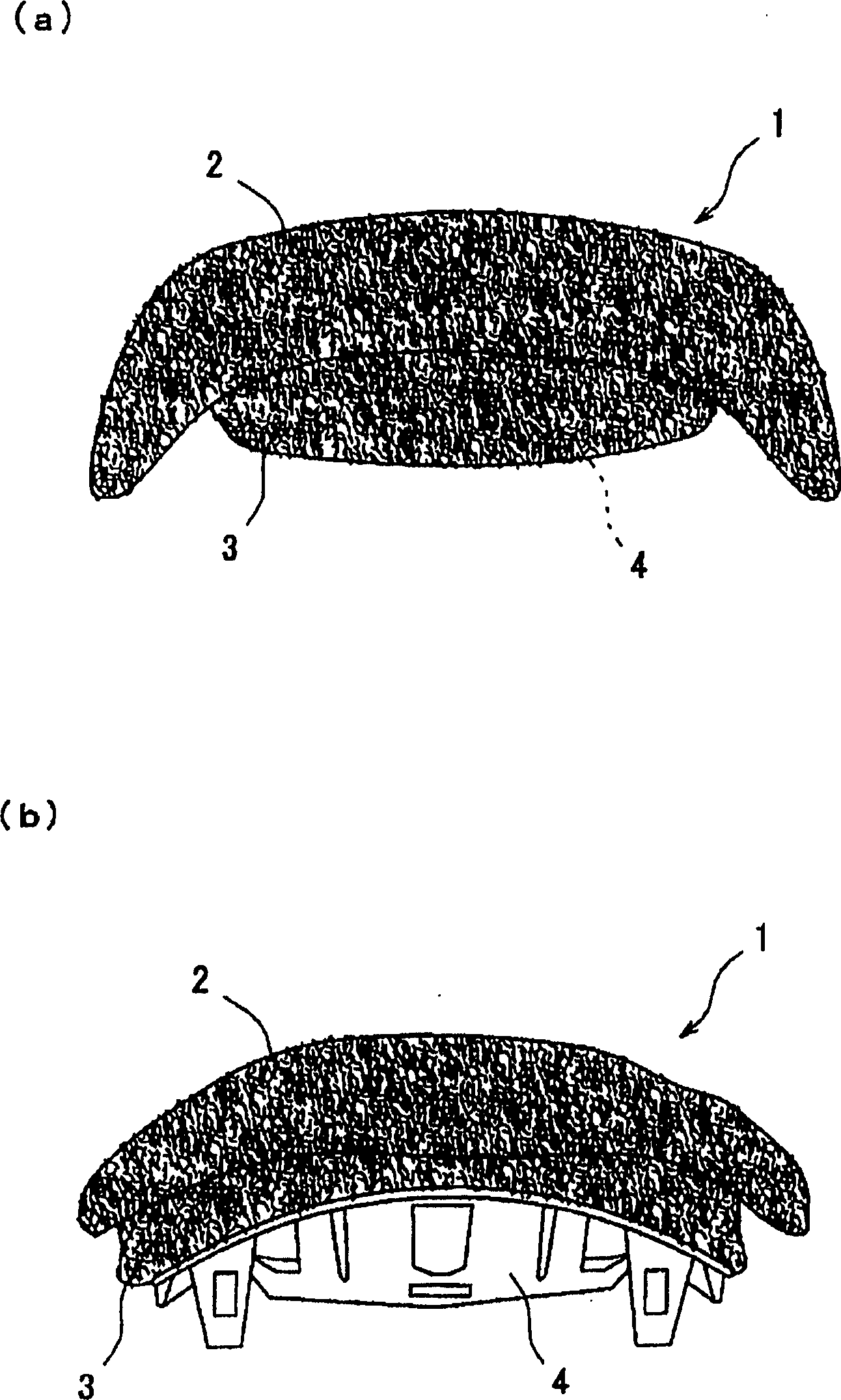

[0040] The method for producing a cushioning material composed of an elastic structural resin molded product of the present invention is characterized in that a three-dimensional structure having voids having a predetermined bulk density is formed, and the voids are composed of solid and / or hollow continuous filaments composed of thermoplastic resin and / or random annular or coiled adjacent filaments of short filaments, formed by contacting each other, polymerizing and concentrating, under the temperature conditions necessary to soften the three-dimensional structure, heating the above-mentioned female mold and / or the above-mentioned For the three-dimensional structure, the above-mentioned three-dimensional structure is clamped by the above-mentioned female mold and the male mold, and the above-mentioned three-dimensional structure is hardened by cooling.

[0041] Furthermore, it is preferable to profile the end of the three-dimensional structure protruding from the gap betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com