Preparation method of carbon fiber reinforced polyimide fiber metal laminate

A polyimide matrix and fiber metal laminate technology is applied in the preparation of carbon fiber reinforced polyimide matrix fiber metal laminates and fiber metal laminates, and can solve the impact resistance and fatigue resistance of finished fiber metal laminates. Poor, low applicable temperature of fiber metal laminates, cumbersome preparation process, etc., to achieve the effects of excellent high temperature resistance and fatigue resistance, low production cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

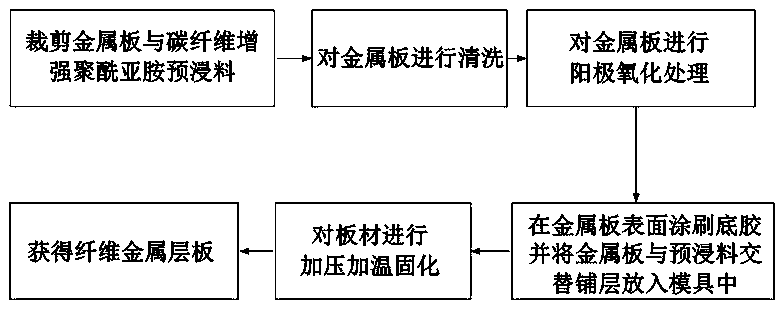

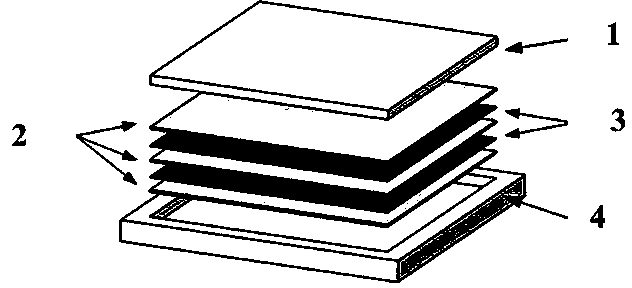

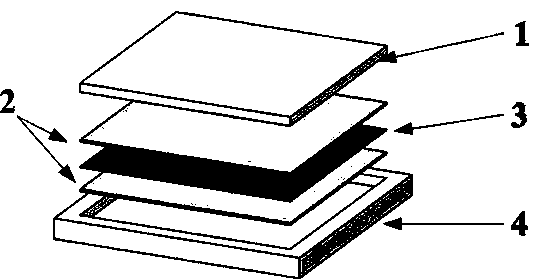

[0035] Such as figure 1 , 2 Shown, the preparation method of carbon fiber reinforced polyimide matrix fiber metal laminate of the present invention is as follows:

[0036] The first step: the 0.3mm thick TA 2 2 The sheet and the carbon fiber reinforced polyimide prepreg 3 are cut into a size of 300mm×300mm;

[0037] Step 2: Remove TA by ultrasonic cleaning 2 2 Surface impurities, scrub with acetone to remove surface oil and impurities, immerse the metal plate in NaOH (sodium hydroxide) with a concentration of 25-30g / L and NaOH with a concentration of 25-30g / L 2 CO 3 (sodium carbonate) in lye, wash for 0.5-1min, temperature 50-60℃, then rinse with water for 2-5min, put TA2 in HNO3 (nitric acid) with a concentration of 300-500g / L and soak for 2-5min , and then rinse with water for 2-5 minutes;

[0038] The third step: the TA 2 2 Connect the positive pole of the power supply, and the stainless steel sheet is used as the counter electrode to connect the negative pole of the...

Embodiment 2

[0043] Such as figure 1 , 2 Shown, the preparation method of carbon fiber reinforced polyimide matrix fiber metal laminate of the present invention is as follows:

[0044] The first step: the 0.4mm thick TA 1 2 Plate and carbon fiber reinforced polyimide prepreg 3 Cut into 300mm×300mm size;

[0045] Step 2: Remove TA by ultrasonic cleaning 12 Surface impurities, scrub with acetone to remove surface oil and impurities, immerse the metal plate in NaOH (sodium hydroxide) with a concentration of 25-30g / L and NaOH with a concentration of 25-30g / L 2 CO 3 (sodium carbonate) in lye, wash for 0.5-1min, temperature 50-60℃, then rinse with water for 2-5min, put TA2 in HNO3 (nitric acid) with a concentration of 300-500g / L and soak for 2-5min , and then rinse with water for 2-5 minutes;

[0046] The third step: the TA 1 1 Connect the positive pole of the power supply, and the stainless steel sheet is used as the counter electrode to connect the negative pole of the power supply. NaO...

Embodiment 3

[0051] Such as figure 1 , 2 Shown, the preparation method of carbon fiber reinforced polyimide matrix fiber metal laminate of the present invention is as follows:

[0052] The first step: the 0.2mm thick TC 4 2 Plate and carbon fiber reinforced polyimide prepreg 3 Cut into 100mm×100mm size;

[0053] Step 2: Remove TC with ultrasonic cleaning 4 2 Surface impurities, scrub with acetone to remove surface oil and impurities, immerse the metal plate in NaOH (sodium hydroxide) with a concentration of 25-30g / L and NaOH with a concentration of 25-30g / L 2 CO 3 (sodium carbonate) in the lye, wash 0.5-1min, temperature 50-60℃, then rinse with water for 2-5min, put TC4 into HNO3 (nitric acid) with a concentration of 300-500g / L and soak for 2-5min , and then rinse with water for 2-5 minutes;

[0054] The third step: the TC 4 2 Connect the positive pole of the power supply, and the stainless steel sheet is used as the counter electrode to connect the negative pole of the power sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com