Patents

Literature

50results about How to "Low silver content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conductive adhesive composition and electronic element using same

ActiveCN104822789AHigh temperature and humidity resistanceLow silver contentNon-macromolecular adhesive additivesSolid electrolytic capacitorsConductive polymerElectrolytic capacitor

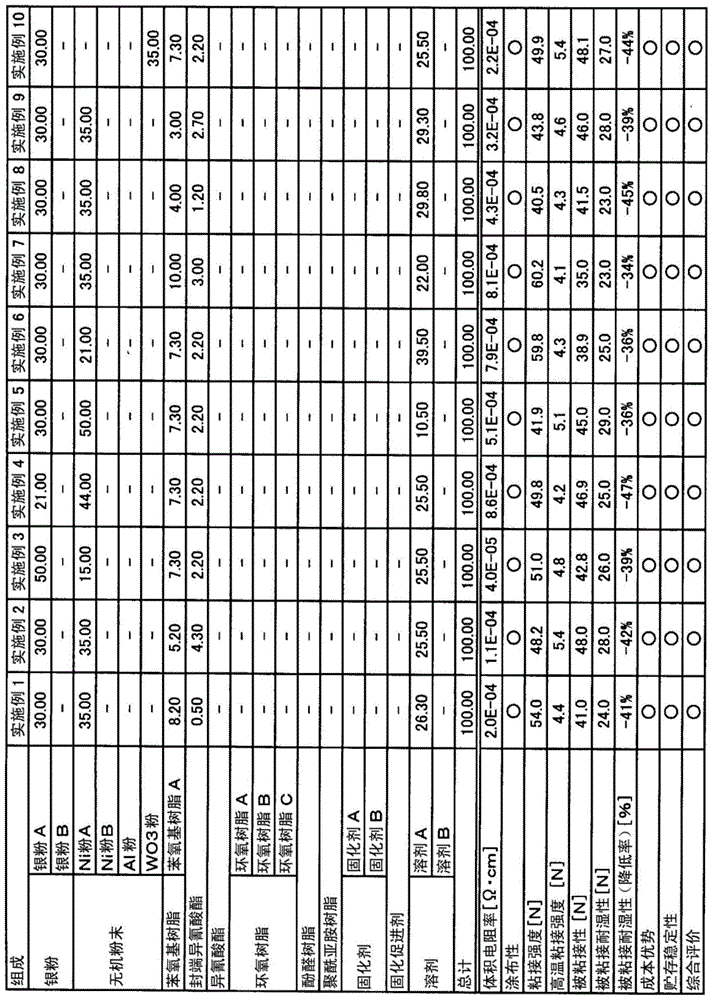

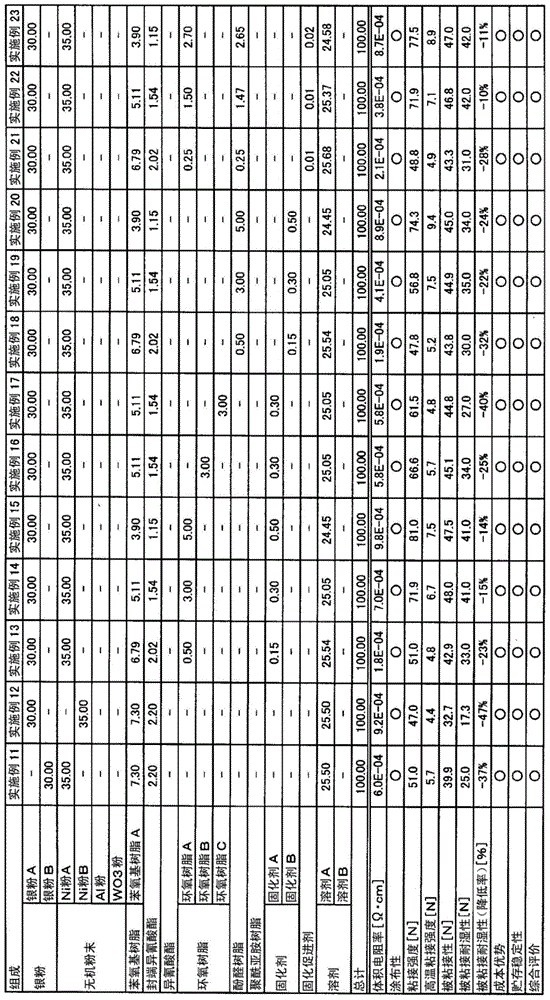

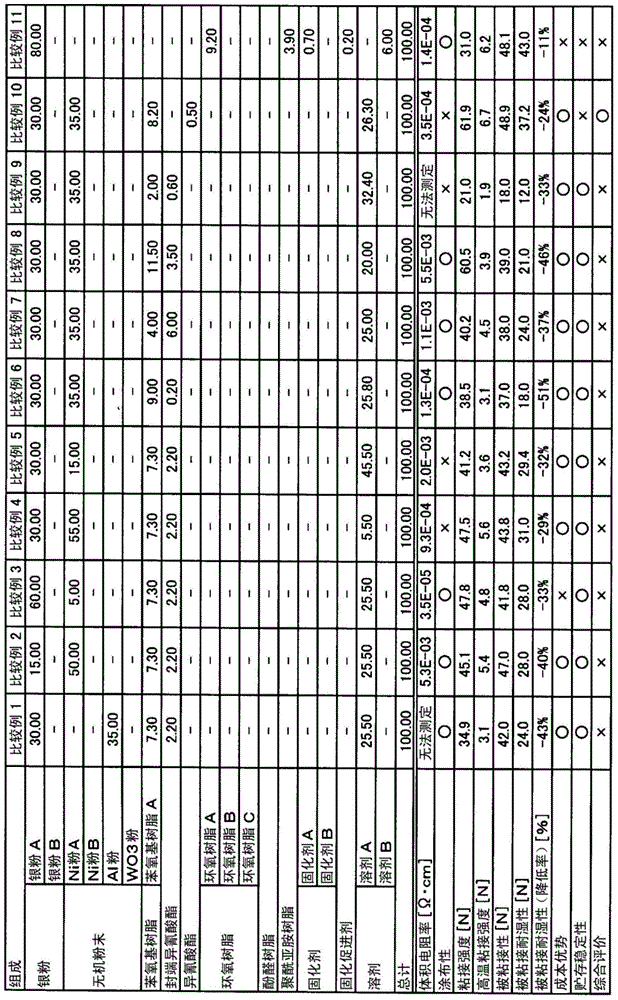

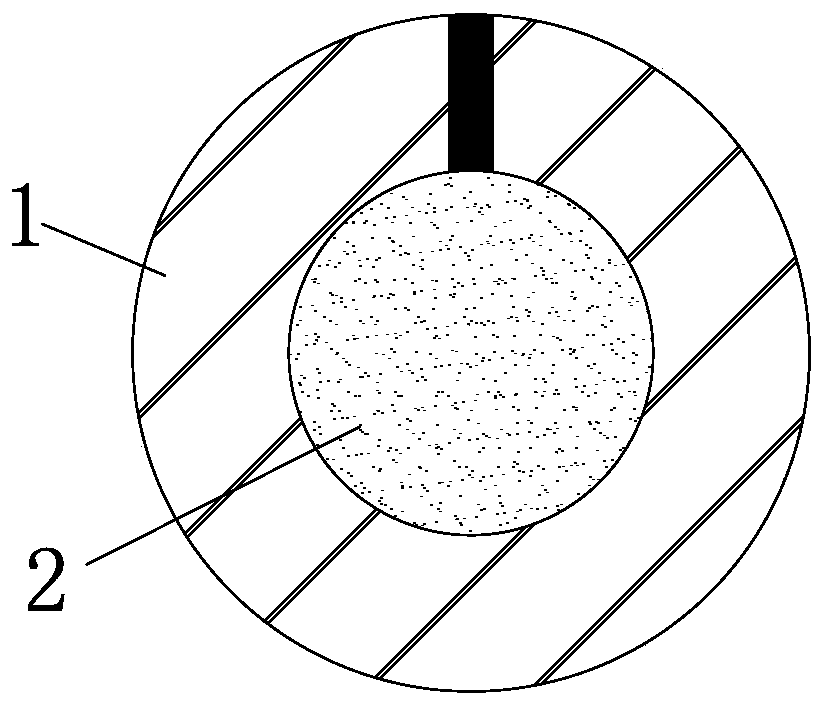

Provided are: a conductive resin paste which has a low silver content and can be cured at a lower temperature in a shorter time than conventional resin pastes, while having a low resistance, high adhesion and excellent storage stability as a material for internal electrodes of solid electrolytic capacitors, conductive aluminum solid electrolytic capacitors and the like; and an electronic element which uses this conductive resin paste. A conductive adhesive composition which contains (A) a silver powder and (B) an inorganic powder filler having a specific gravity of 4 or more as conductive powders, (C) a phenoxy resin and (D) a blocked isocyanate as binder components, and (E) a solvent. This conductive adhesive composition is characterized in that: the silver powder (A) is blended in an amount of 20-50% by weight relative to the total weight; the inorganic powder filler (B) is blended in an amount of 60% by weight or less relative to the total weight; the amount of the blocked isocyanate (D) is 5-90 parts by weight relative to 100 parts by weight of the phenoxy resin (C); and the binder components ((C) + (D)) are contained in an amount of 5-14% by weight relative to the total weight.

Owner:SUMITOMO METAL MINING CO LTD

A kind of preparation method of high energy rare earth powder alloy electric contact material

The invention relates to a method for producing an electrical contact material, particularly relates to a method for producing a high-energy rare earth powder alloy electrical contact material. According to the technical scheme provided by the invention, the method for producing a high-energy rare earth powder alloy electrical contact material is characterized by comprising the following steps of: firstly, completely mixing and stirring alumina powder, silver powder, lanthanum powder, graphite powder, molybdenum powder, yttrium powder, boron powder and nickel copper powder; secondly, using anoil press to squeeze and mold the powder, and then sintering the squeezed and molded object into a vacuum high-temperature furnace and then cooling; thirdly, burning the molded object in a high-temperature furnace, then taking out and squeezing the burnt object into a panel shape by using a die on the oil press, and then cooling with cold water, and finally using a machine tool to punch the cooled object into a contact. The invention overcomes disadvantages of the prior art and provides the method for producing an environment-friendly high-energy rare earth powder alloy electrical contact material with low silver content, impact resistance, corrosion resistance, antioxidation, low resistance and good electrical conductivity.

Owner:温州银泰合金材料有限公司

Flux-cored silver solder

PendingCN110936064ALow costLow silver contentWelding/cutting media/materialsSoldering mediaDipotassium hydrogen phosphateWire breakage

The invention discloses flux-cored silver solder, which comprises a metal wrapping layer and a soldering flux core, wherein the soldering flux core is located in the metal wrapping layer. The soldering flux core comprises the following substances in parts by mass: 36%-40% of potassium hydrogen fluoride, 16%-20% of potassium fluoride, 30%-33% of boric acid, 0.1%-0.5% of cesium fluoride, 1.0%-2.0% of potassium carbonate, 0.3%-1.2% of potassium silicate, 0.3%-1.2% of sodium silicate, 0.001%-0.01% of dipotassium hydrogen phosphate and the balance potassium fluoborate. By improving the fluidity andmoisture absorption resistance of the soldering flux in the flux core, the phenomenon of wire breakage in the drawing process is prevented, and the storage time is prolonged.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

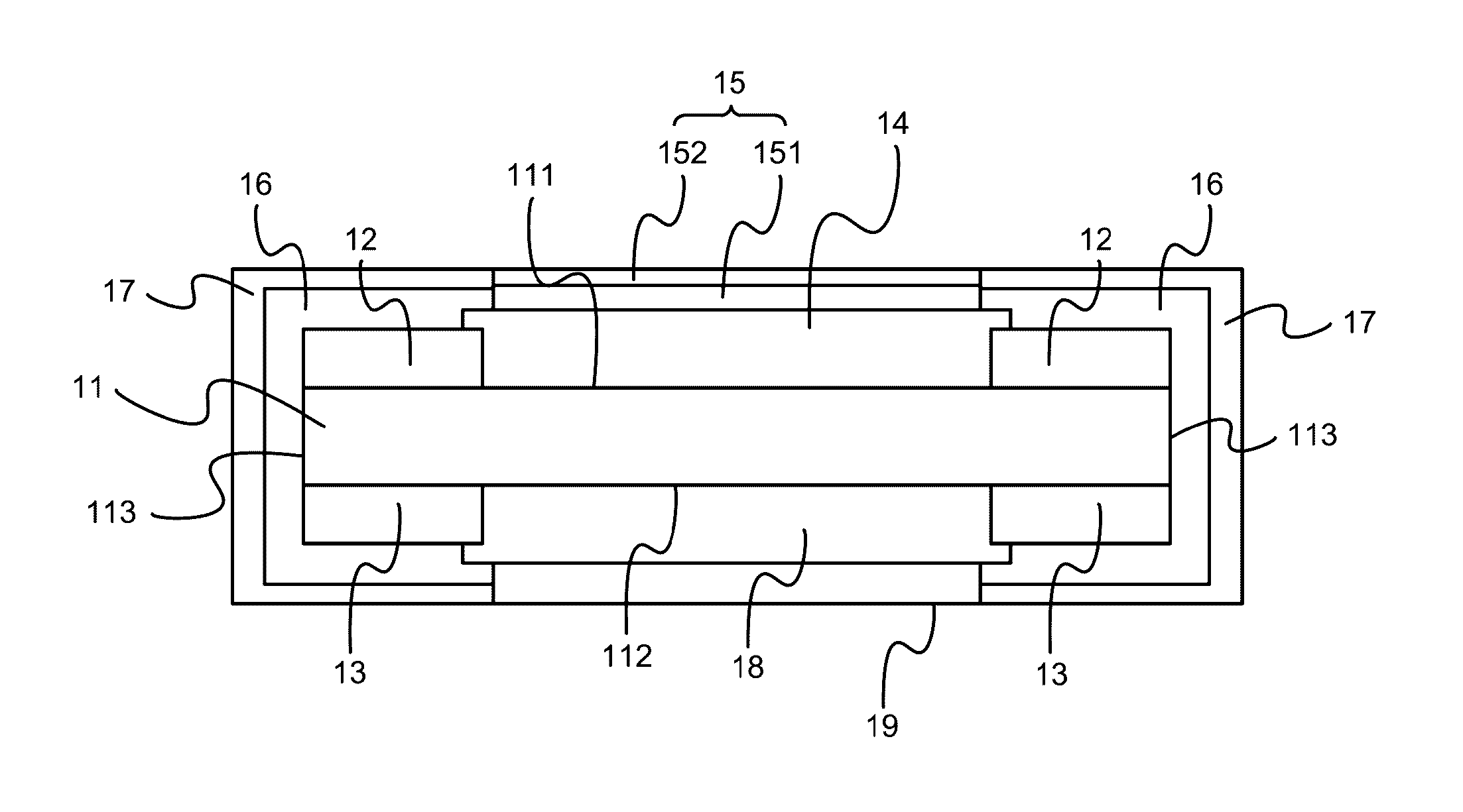

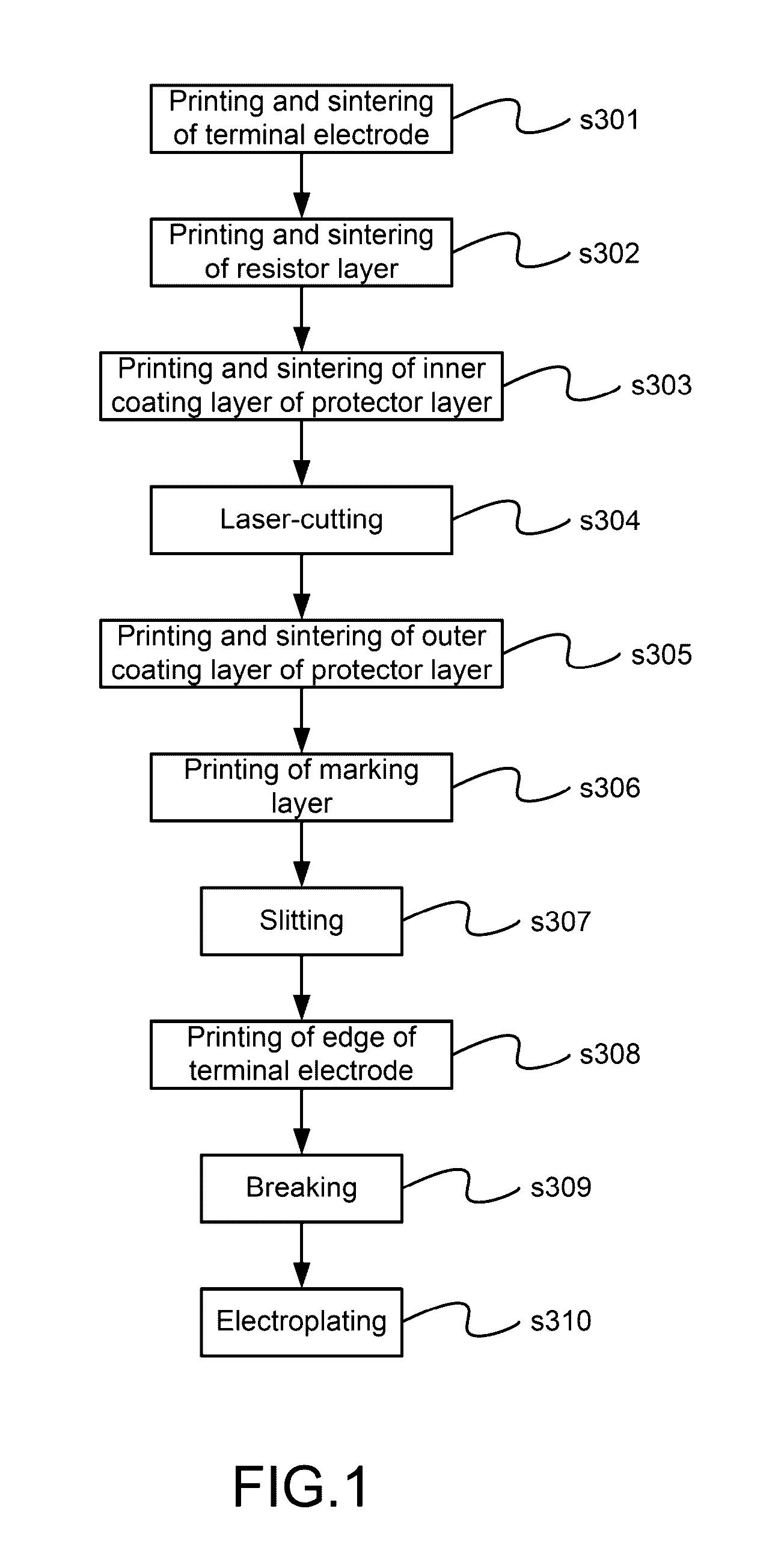

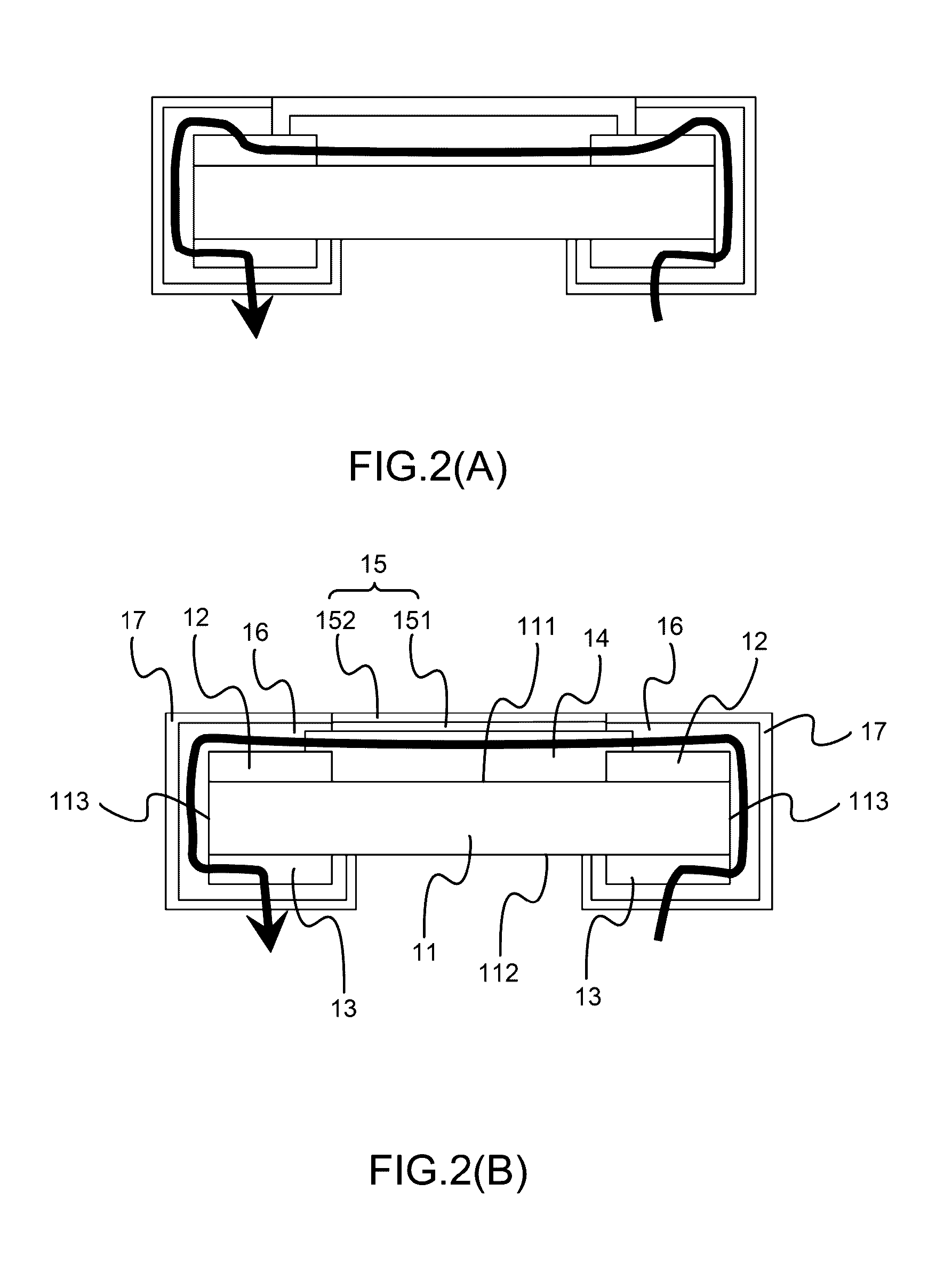

Device of Chip Resistor with Terminal Electrodes

ActiveUS20160372242A1Improve conductivityReduce parasitic effectsEnvelope/housing resistor manufactureResistor terminals/electrodesElectrical resistance and conductanceEngineering

A chip resistor having terminal electrodes is provided. In the chip resistor, a first protector layer has a size different from that of a first resistor layer. Thus, two ends of the first resistor layer are exposed to form new current conduction path. Original current conduction path having the same size of the protective layer and the resistor layer is thus replaced. Hence, resistance variation of the chip resistor is solved; yield of the chip resistor is increased; and, the material cost of the front terminal electrode is greatly reduced.

Owner:NAT CHENG KUNG UNIV

Active heatproof copper-based brazing filler metal used for aluminum bronze/stainless steel brazing and preparation method thereof

ActiveCN106077996ASolving Brazing ProblemsImprove heat resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesHeat resistanceCopper

The invention provides active heatproof copper-based brazing filler metal used for aluminum bronze / stainless steel brazing. The active heatproof copper-based brazing filler metal comprises, by weight, 20.0-23.0% of Mn, 10.0-13.0% of Ni, 21.0-25.0% of Ag, 0.5-2.0% of Zn, 0.2-0.4% of Si, 0.1-0.3% of P, 0.1-0.3% of B, 0.01-3.0% of active elements and the balance Cu; and the active elements include at least one of Zr, Li and Hf. The invention further provides a preparation method for the brazing filler metal. According to the active heatproof copper-based brazing filler metal used for aluminum bronze / stainless steel brazing and the preparation method thereof, heterogeneous brazing of aluminum bronze / stainless steel can be achieved, soldered joints are made to have good heat resistance, the brazing process performance is improved, and the cost is lowered.

Owner:SICHUAN UNIV

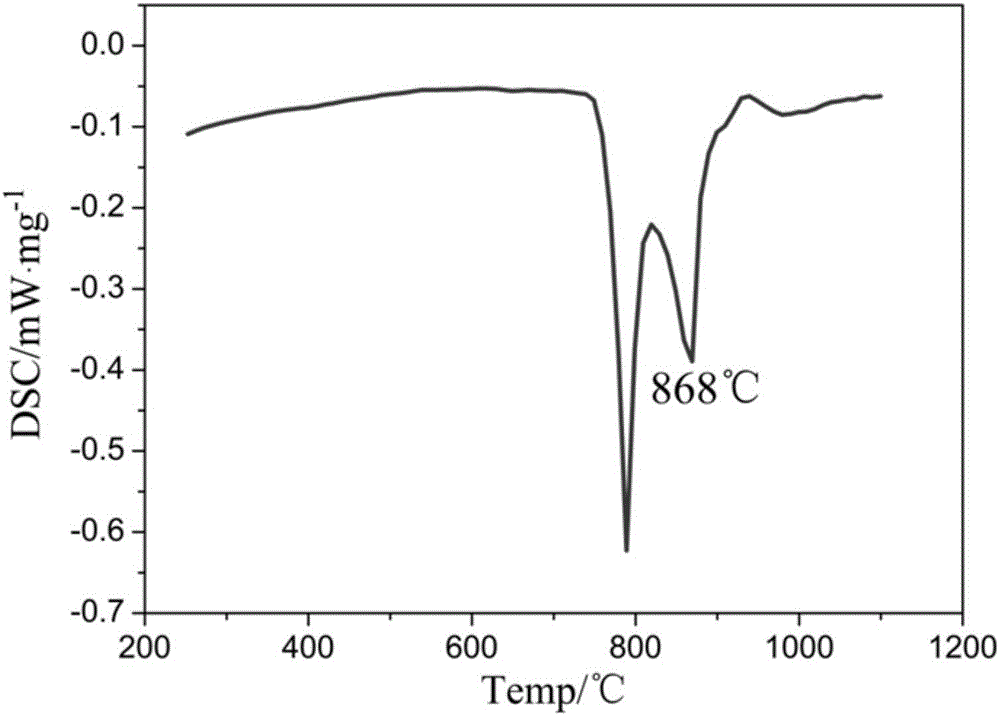

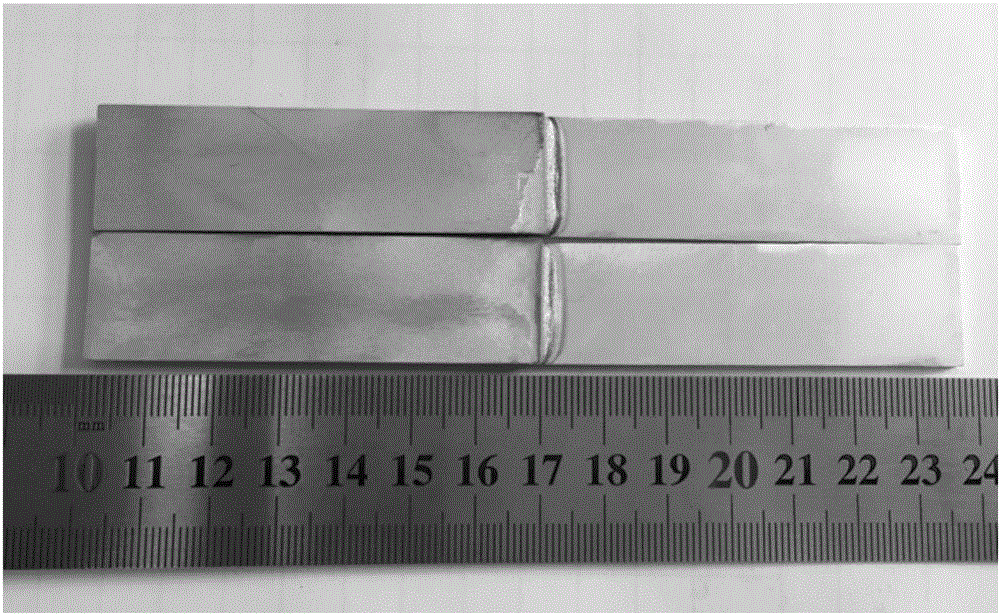

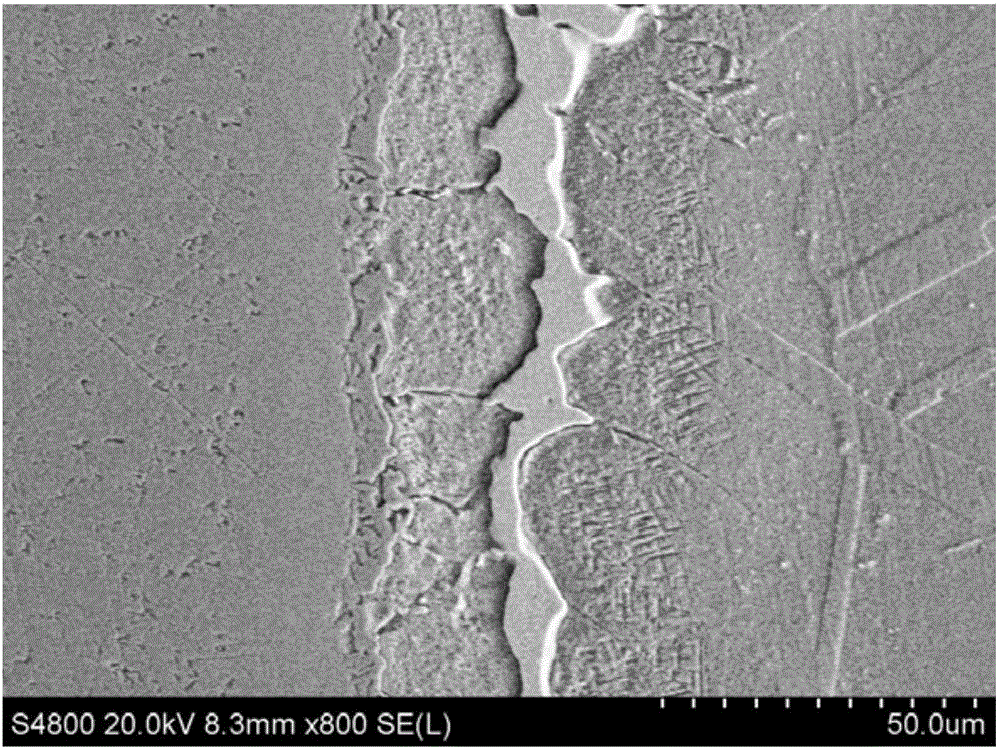

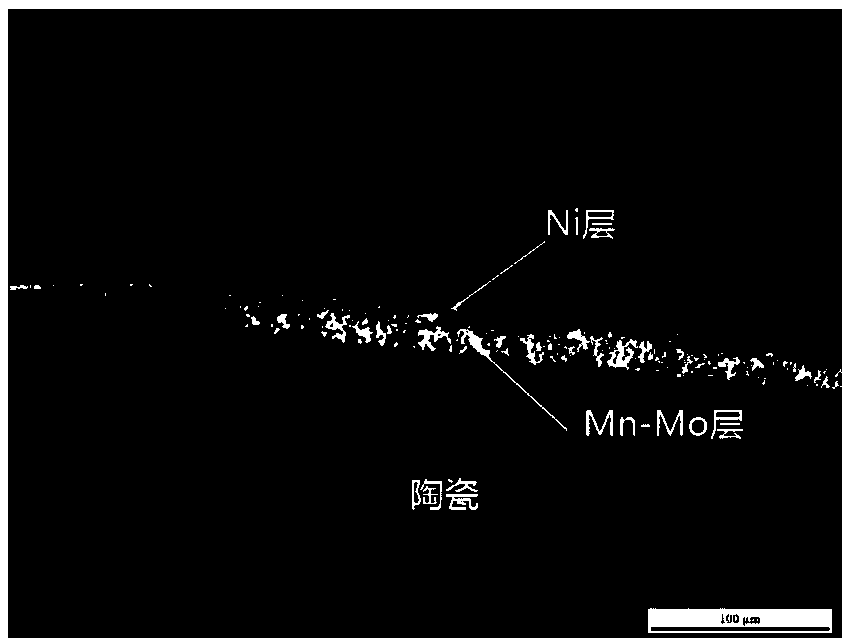

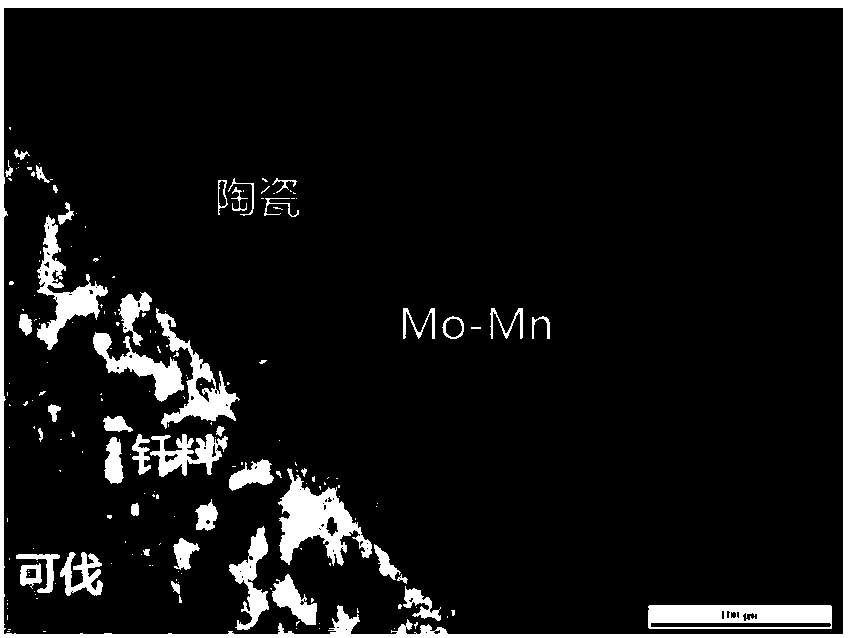

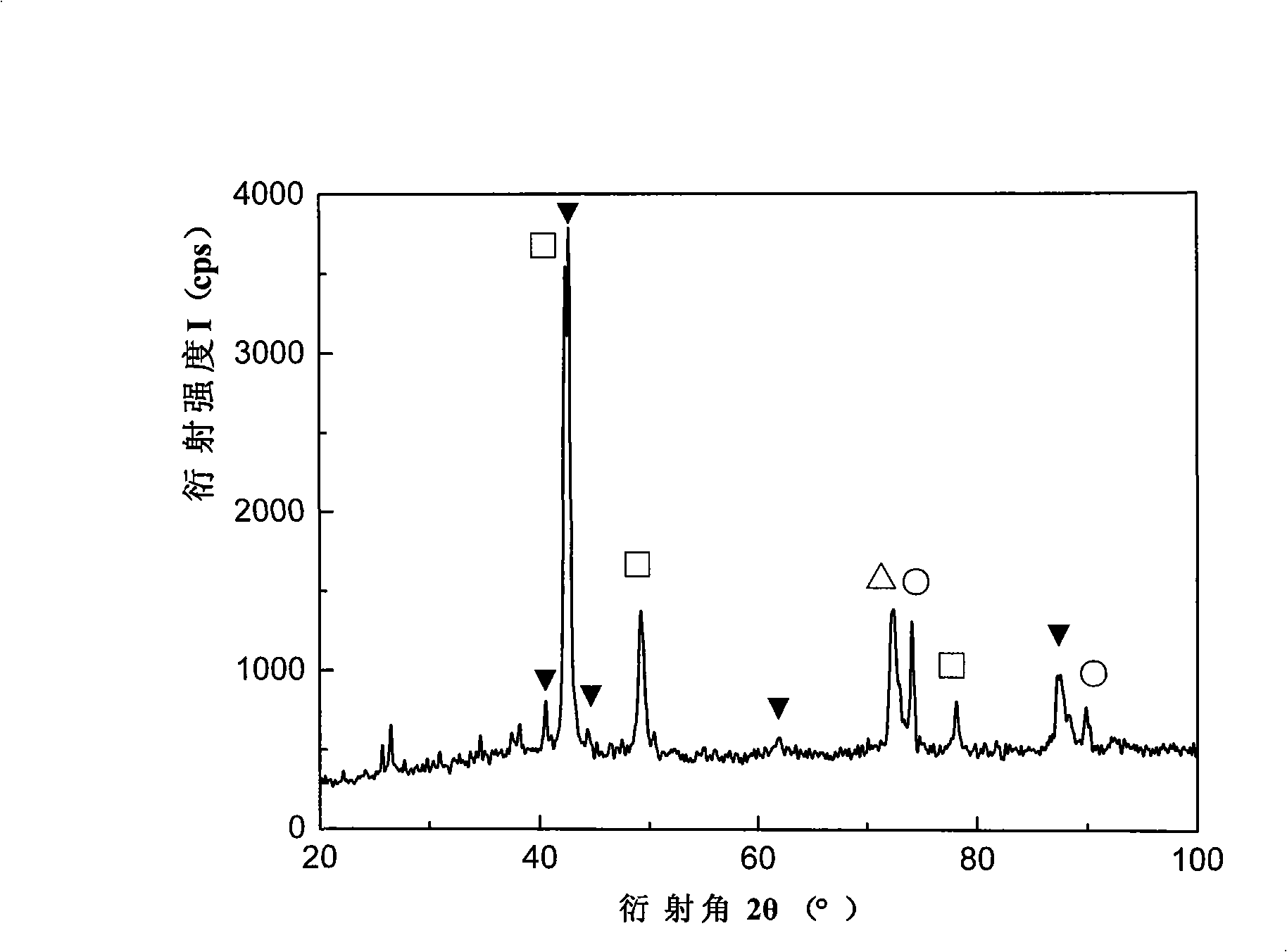

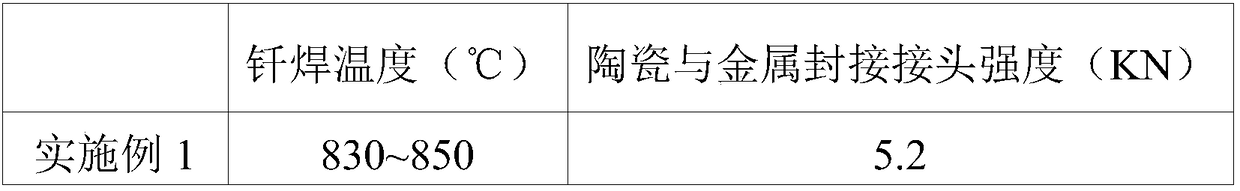

Low-silver-content silver brazing filler metal for sealing and connecting of ceramic and metal

InactiveCN107838575ALower melting temperatureExcellent cold workabilityWelding/cutting media/materialsSoldering mediaFiller metalMachinability

The invention provides low-silver-content silver brazing filler metal for sealing and connecting of ceramic and metal. The brazing filler metal includes the following metal elements comprising, by weight, 47%-58% of Ag, 39%-43% of Cu and 3%-10% of Ga. Preferably, the weight of the alloy element Cu and the weight of the alloy element Ga need to meet the condition that Cu:Ga is larger than or equalto 4.5. The silver brazing filler metal is low in silver content, and the welding temperature is equivalent to that of Ag72Cu28; the brazing filler metal machinability is good; the brazing filler metal wettability is good, and the strength of a sealing and connecting connector is high; and the low-silver-content silver brazing filler metal can be used for replacing Ag72Cu28 brazing filler metal which is widely used at present, is particularly suitable for sealing and connecting of ceramic and metal in electric vacuum devices and can also be used for vacuum brazing and gas shield brazing in other fields.

Owner:WUXI RIYUE ALLOY MATERIALS

Touch screen silver paste and preparation method thereof

InactiveCN105280266AImprove adhesionImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSolvent

The invention relates to a touch screen silver paste which comprises components in weight of 55%-65% of silver flake, 20%-45% of solvent, 8%-20% of high molecular resin and 1%-3% of additive. According to the touch screen silver paste and a preparation method thereof, the silver content is still about 60%, both the adhesive force and the electrical conductivity can be improved, the electrical conductivity of foreign silver pastes is basically realized, that is the silver content is reduced under the condition that the electrical conductivity and the adhesive force are not affected, and accordingly, the cost is saved.

Owner:TIANJIN ZHONGKE PHYSICAL & CHEM NEW MATERIAL TECH CO LTD

Preparation method for flaky rhombic silver powder slurry on back of solar cell

InactiveCN105513672AOrderly and automatic arrangementGood dispersionNon-conductive material with dispersed conductive materialPhotovoltaic energy generationFiltrationSlurry

The invention relates to a preparation method for flaky rhombic silver powder slurry on the back of a solar cell and belongs to the technical field of silver slurry preparation. The method includes the steps that firstly, anhydrous sodium carbonate and a silver nitrate solution are mixed and subjected to ultrasonic dispersion processing, after the pH value is adjusted through a sodium hydroxide solution, a hydrazine hydrate solution is dropwise added to the mixture, the mixture is subjected to suction filtration, washed with deionized water and dried, and rhombic stereoscopic super-fine silver powder is obtained; the rhombic stereoscopic super-fine silver powder is placed in a plane die, oscillates and is ground, ground flaky rhombic silver sheets are collected, and the ground flaky rhombic silver sheets, a prepared carrier solvent and other matter are ground and rolled. The prepared flaky rhombic silver powder slurry can be automatically ranked in order, the dispersion performance of the slurry is improved, and the slurry is evenly distributed. The contact resistivity is reduced, the photoelectric conversion rate is increased and ranges from 17.561% to 17.824%, the silver content is smaller than 45%, and the cost of the slurry is reduced.

Owner:CHANGZHOU QINGFA IND GAS CO LTD

Low-temperature brazing filler metal and manufacturing method thereof

InactiveCN101318268ALower requirementSimple processWelding/cutting media/materialsSoldering mediaSmelting processSolderability

The invention provides low-temperature solders and a preparation method thereof, which relates to a low-temperature solder and the preparation method thereof. The low-temperature solder and the method solves the problem that the phenomenon of active element high temperature oxidation and the melting and solidifying of solders exist in the smelting process needed by the preparation of solders, thereby influencing the weldability and the joint mechanical property of solders. The solder of the invention consists of Ag, Cu, La, Sn and Ti or TiH2. The solder of the invention consists of La, Cu, Sn and Ti or TiH2. The preparation method of the solder of the invention is as follows: the active solder raw materials are added to a planetary ball mill to be ball milled. After adopting the solder brazing prepared by the method of the invention, the shear strength of brazed joints can reach 15.37MPa.

Owner:HARBIN INST OF TECH

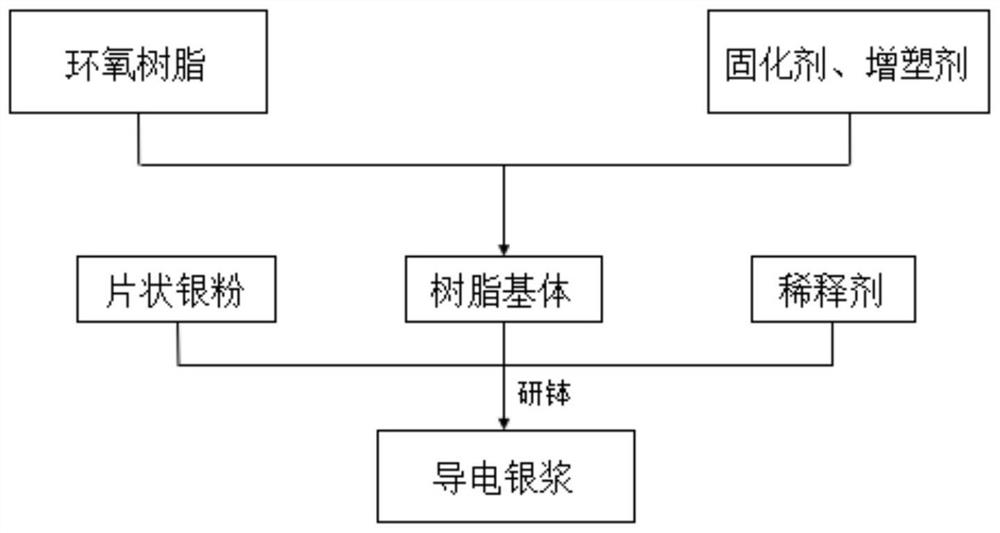

Low-silver-content ceramic filter conductive silver paste for 5G base station and preparation method and application thereof

InactiveCN111968775ALow silver contentImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePlasticizer

The invention relates to low-silver-content ceramic filter conductive silver paste for a 5G base station and a preparation method and application thereof. The silver paste is prepared from the following raw materials in parts by mass: 65-82 parts of conductive filler, 8-15 parts of epoxy resin, 3-8 parts of a curing agent, 4-12 parts of a diluent and 2-5 parts of a plasticizer. By adopting the nano silver paste for spraying, the surface metallization of a 5G dielectric ceramic filter product can be uniform, the silver consumption is low, the cost is greatly reduced, the electrical property andthe application property are excellent, and the conduction property is stable.

Owner:CHENGDU SCI & TECH DEV CENT CHINA ACAD OF ENG PHYSICS

A kind of base material containing silver ion and the preparation method of base base containing silver ion

ActiveCN102293718ALow silver contentPotential harm to human body and environment is smallImpression capsDentistry preparationsApplication securityDental Base

The invention relates to a base plate material containing silver ions, and a preparation method of base plate. The method comprises steps that: a basic base plate is manufactured by using a common base plate material containing no silver ion and dental base acrylic resin liquid; the tissue surface of the basic base plate is burnished, such that materials with a thickness of 2mm are removed. The base plate material containing silver ions and dental base acrylic resin liquid are covered on the burnished tissue surface, and compression molding and heating are carried out again, such that a base plate layer containing silver ions with a thickness of 2mm is produced. The base plate material containing silver ions is prepared from materials of, by weight: 0.05 to 1 part of an antibacterial agent, 51 to 59 parts of base plate powder, and 41 to 49 parts of the dental base acrylic resin liquid. With the technical scheme provided by the invention, application security of the material is improved, and optical property of the material is not changed.

Owner:SHANGHAI MEDICAL INSTR

Method for forming electrodes of IBC solar cell

InactiveCN103606571AReduce machine investmentLow silver contentFinal product manufacturePattern printingCell preparationAspect ratio

The invention relates to a method for forming electrodes of an IBC solar cell, and belongs to the technical field of electrodes of solar cells. The method for forming the electrodes of the IBC solar cell is mainly characterized in that primary printing and primary drying are carried out on a fine gate electrode of a positive electrode on the reverse side of the passivated IBC solar cell by using sizing agents, primary printing and primary drying are carried out on a fine gate electrode of a negative electrode on the reverse side by using sizing agents, and main gate electrodes are printed or secondary printing, secondary drying and sintering solidification are carried out on the fine gate electrode of the positive electrode and the fine gate electrode of the negative electrode at the same time when the main gate electrodes are printed. According to the method for forming the electrodes of the IBC solar cell, the machine investment of an IBC cell preparation technology is reduced, fine gates and main gates of the electrodes are separated, the sizing agents of different types are used, on the premise that the fine gate electrodes have good ohmic contact and the premise that the main gates have good weldability, the content of silver of the sizing agents of the main gates is reduced, and the cost is saved; the aspect ratio of each fine gate is increased, and on the premise that the printing sizing agents are used, it is ensured that the electric conductivity is close to or equal to the electric conductivity obtained by using an electrosilvering solution; the operation cost is reduced on the situation that the photoelectric conversion efficiency is ensured.

Owner:中电电气(扬州)光伏有限公司

Quaternary alloy brazing filler metal

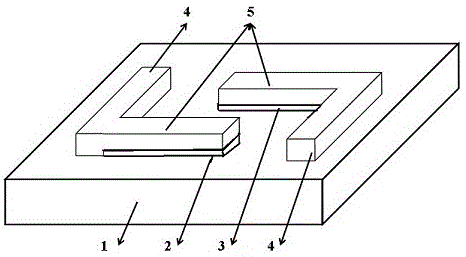

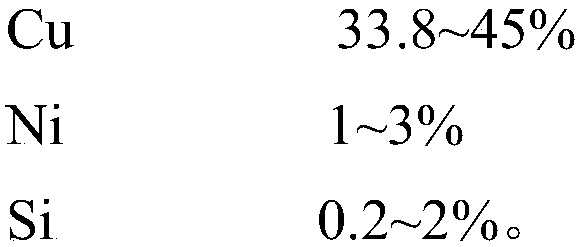

InactiveCN109175783AHigh strengthImprove wettabilityWelding/cutting media/materialsSoldering mediaOxidation resistantFiller metal

The invention discloses quaternary alloy brazing filler metal. The quaternary alloy brazing filler metal is characterized in that the brazing filler metal comprises, by mass, 50-65% of Ag, 33.8-45% ofCu, 1-3% of Ni and 0.2-2% of Si. The brazing filler metal has good machinability and wettability, high strength of a sealing joint and good oxidation resistance; Ag72Cu28 brazing filler metal which is widely used at present can be replaced by the quaternary alloy brazing filler metal, and the quaternary alloy brazing filler metal is particularly suitable for sealing of ceramics and metal in electric vacuum devices and can also be used for vacuum brazing and gas shielded brazing in other fields.

Owner:WUXI RIYUE ALLOY MATERIALS

Preparation method of brazing filler metal for lead-free tin-silver-copper brazing

PendingCN113042935ALow silver contentEasy to processWelding/cutting media/materialsSoldering mediaOxidation resistantFiller metal

The invention discloses a preparation method of brazing filler metal for lead-free tin-silver-copper brazing. The preparation method comprises the following steps that firstly, raw materials Sn, Ag, Cu, Ge, Mn, Ni and a P-Cu intermediate alloy are weighed and taken to enable that the Ni element accounts for 1%-2% of the total mass, the Ag element accounts for 2.0%-3.0% of the total mass, the Cu element accounts for 1.5%-2.5% of the total mass, the P element accounts for 0.5%-1.5% of the total mass, the Ge element accounts for 1%-2% of the total mass, the Mn element accounts for 1%-2% of the total mass, and the balance is the Sn element; the weighed raw materials are uniformly mixed, smelt in a heating furnace at the temperature of 1000 DEG C-1200 DEG C, and cast into an ingot; oxide skin and dead heads of the cast ingot are removed, and the cast ingot is made into a wire by adopting a hot extrusion forming method; and after vacuum annealing is carried out, the wire is processed into blocky brazing filler metal, rod-shaped brazing filler metal, sheet-shaped brazing filler metal or filiform brazing filler metal according to use requirements. According to the lead-free tin-silver-copper brazing filler metal prepared through the method, under the condition that good thermal performance is guaranteed, the wettability and the oxidation resistance are further improved, and the higher requirement of electronic products for the performance of welding spots is met.

Owner:江苏德誉环保设备科技有限公司

Low-melting-point lead-free solder alloy

InactiveCN106624433ALow melting pointLow costWelding/cutting media/materialsSoldering mediaSesquioxideDiiron Trioxide

The invention provides low-melting-point lead-free solder alloy. The low-melting-point lead-free solder alloy comprises, by weight, 10%-30% of bismuth, 0.6%-1.8% of silver, 0.3%-0.8% of nano iron sesquioxide particles, 0.02%-0.1% of vanadium and the balance tin. The low-melting-point lead-free solder alloy is very low in melting point, good in wetting performance and shearing resistance and low in silver content and cost.

Owner:ANHUI HUAZHONG WELDING MATERIAL CO LTD

Preparation method for back silver paste of solar cell

InactiveCN105741906AReduce contact resistivityImprove photoelectric conversion rateNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSolar cellSilicon dioxide

The invention relates to a preparation method for back silver paste of a solar cell, and belongs to the technical field of preparation of the solar cell. The preparation method comprises the following steps of firstly, mixing substances such as silicon dioxide and sodium silicate, mixing the substances with deionized water, adding substances such as silver nitrate, mixing and heating the mixture, preparing spherical silver mixed powder, and dropwise adding ammonia water into a silver nitrate solution to form a silver-ammino complex ion solution; secondly, adding a binding agent into the silver-ammino complex ion solution, stirring, heating and separating the product, mixing the collected centrifugal substance with the spherical silver mixed powder, mixing the obtained product with an urea aqueous solution, and introducing a formaldehyde gas during heating the obtained product to allow reaction; and finally, grinding and rolling the obtained product, thereby obtaining the back silver paste of the solar cell. With the back silver paste of the solar cell, prepared according to the method, the contact resistivity is reduced, the photoelectric conversion rate is improved, and moreover, the silver content is reduced and only reaches 27-35%.

Owner:JIANGSU SHIKONG COATING

Novel antioxidant multielement alloy brazing filler metal

ActiveCN109175782AHigh strengthImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaElemental compositionUltimate tensile strength

The invention discloses novel antioxidant multielement alloy brazing filler metal. The brazing filler metal comprises the following elements in percentage by weight: 49-63.8% of Ag, 34-45% of Cu, 1-2%of Ni, 0.2-1.5% of Si, 0.5-1% of Ge, 0.2-0.5% of Ce, 0.2-0.5% of Nd, and 0.1-0.5% of Hf. The brazing filler metal is excellent in machinability, wettability, sealing joint strength and oxidation resistance, can replace traditional wide-used Ag72Cu28 brazing filler metal, is particularly suitable for sealing connection of ceramic and metal in electric vacuum devices, and also can be applied to vacuum brazing and gas shielded brazing in other fields.

Owner:WUXI RIYUE ALLOY MATERIALS

Propylene direct oxidation reaction catalyst, method for preparing same, and method for preparing propylene oxide through propylene direct oxidation reaction using same

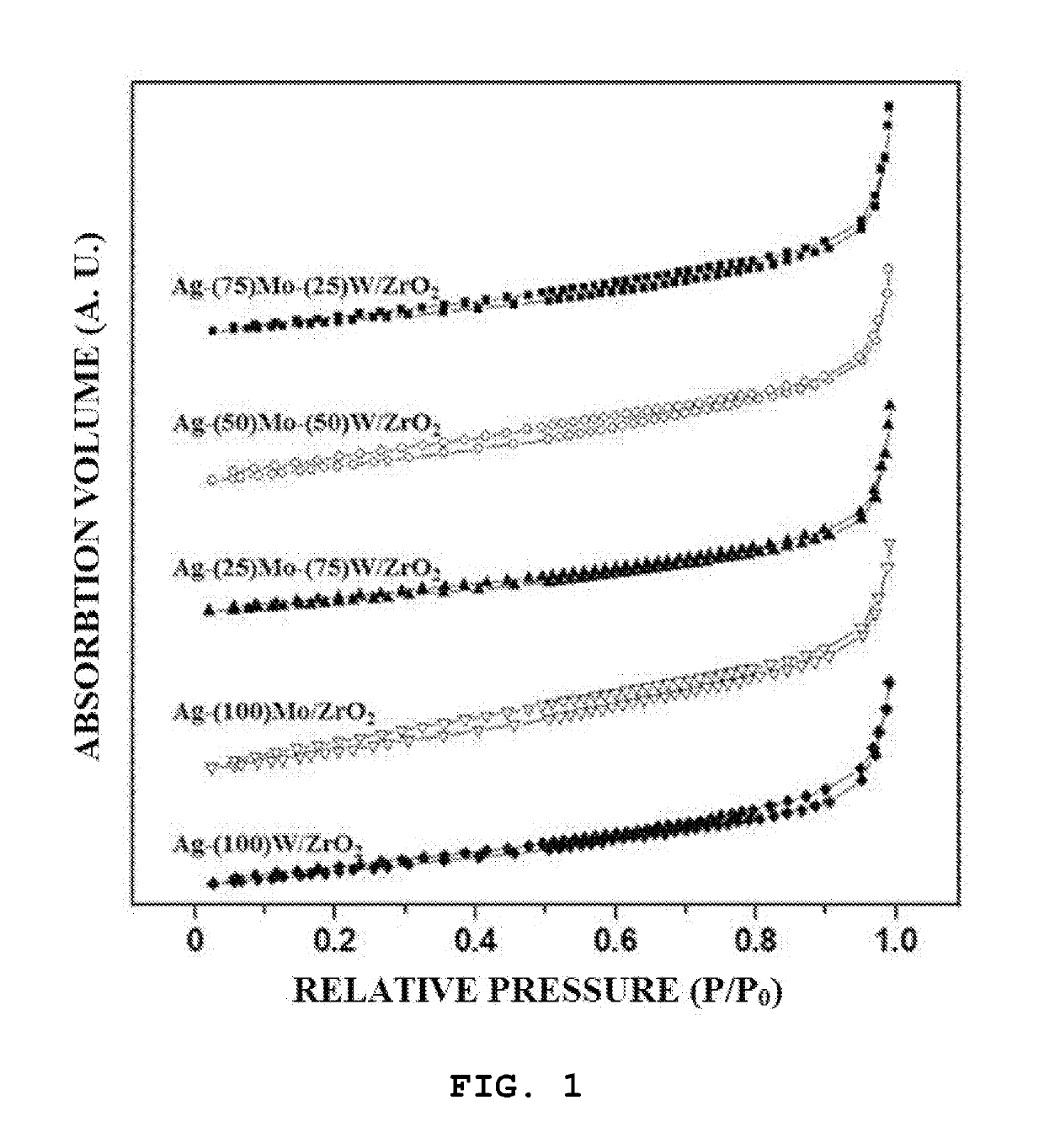

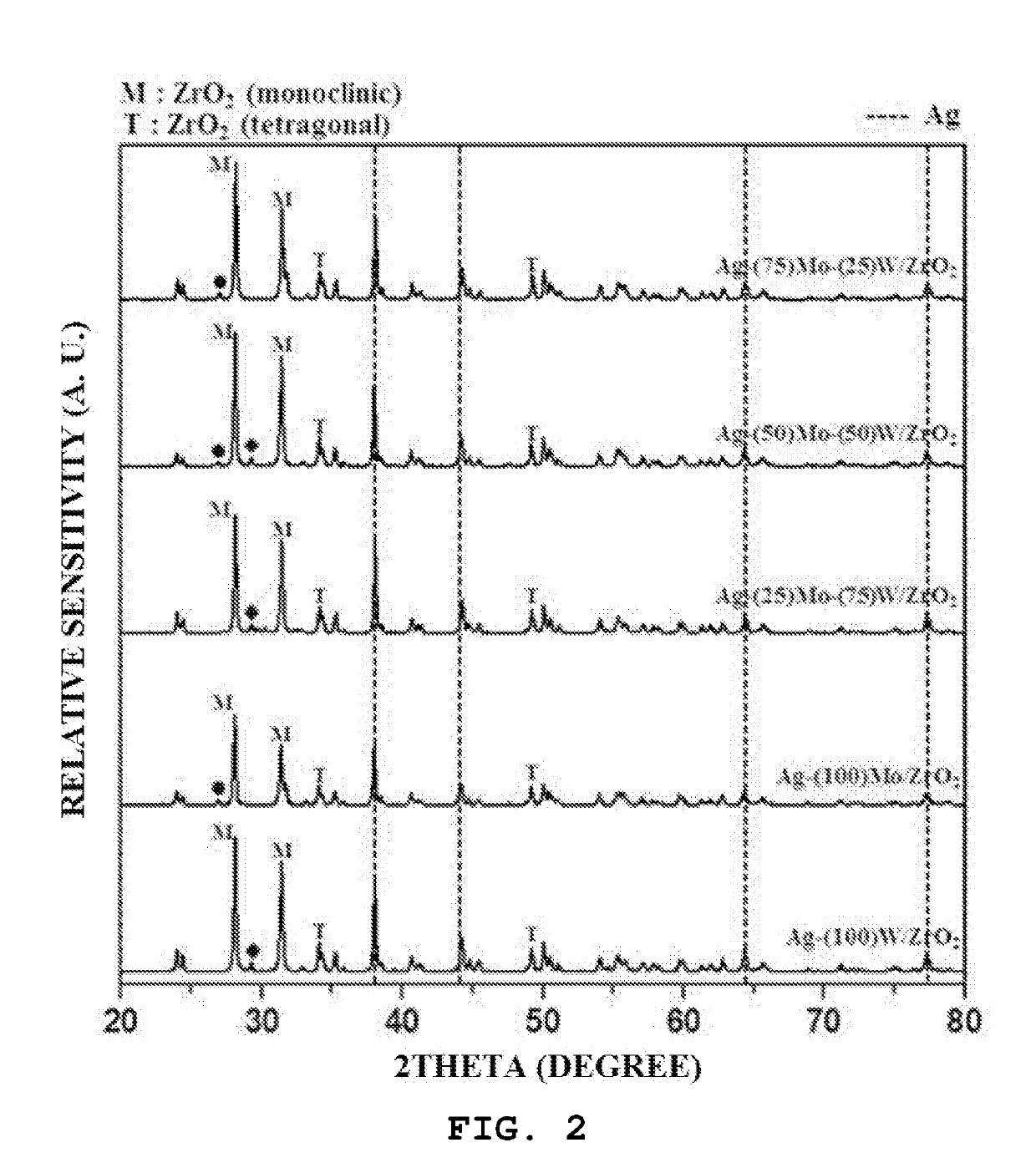

ActiveUS20190184377A1Easy to preparePosition in of economyOrganic chemistryCatalyst activation/preparationSlurryOxygen

Disclosed is a propylene direct oxidation reaction catalyst capable of preparing a propylene oxide from propylene and oxygen at a higher yield than catalysts prepared by conventional methods, by applying a specific transition metal oxide promoter in preparation of a catalyst containing silver, a transition metal oxide promoter and a carrier through a slurry process. The present invention provides a propylene direct oxidation reaction catalyst, which is a supported silver catalyst used for preparing a propylene oxide from the propylene direct oxidation reaction, the catalyst including a molybdenum oxide and a tungsten oxide as a catalyst promoter.

Owner:LOTTE CHEM CORP +1

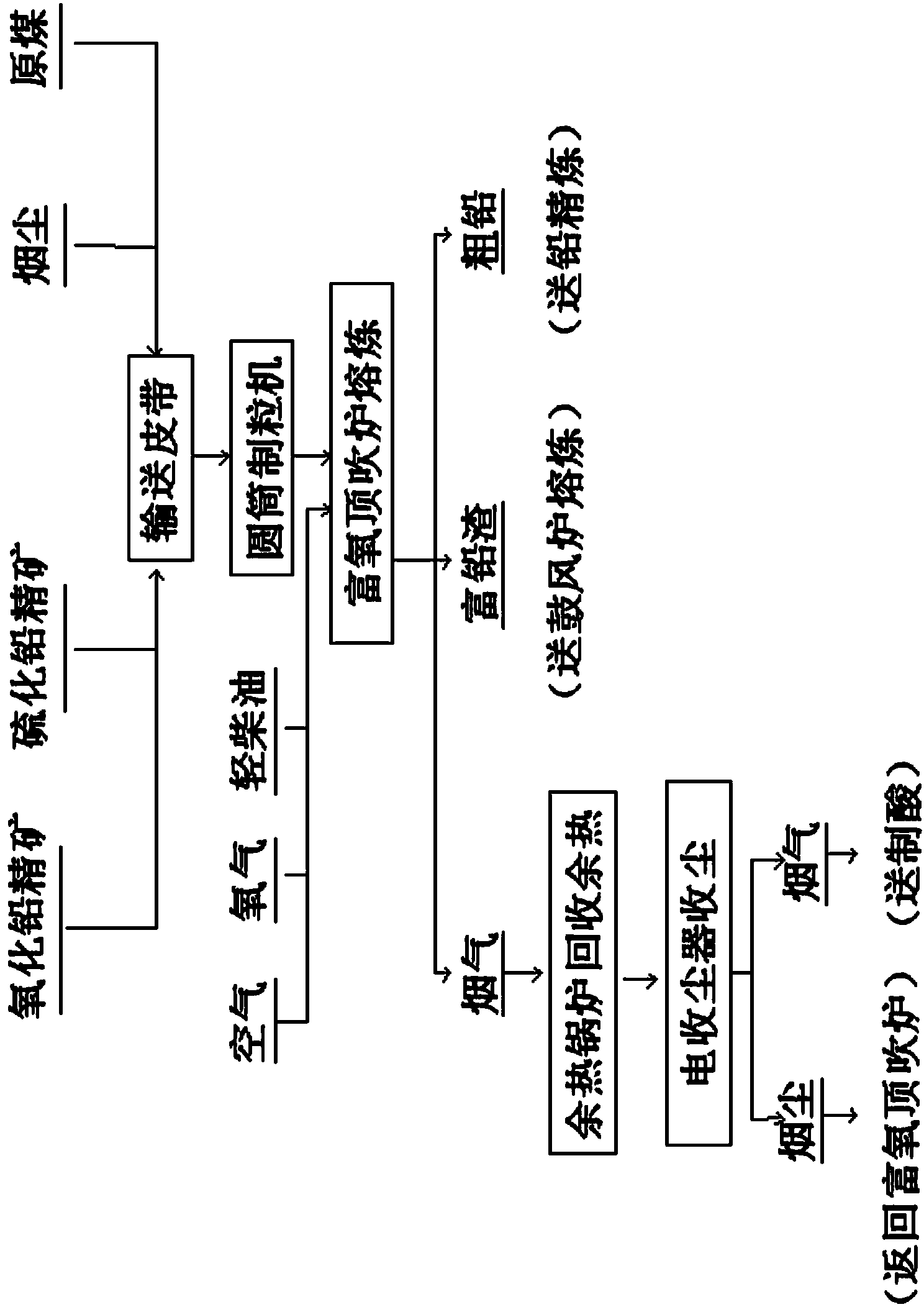

Method for processing lead oxide ore concentrate by using rich oxygen top-blowing furnace

The invention relates to a method for processing lead oxide ore concentrate by using a rich oxygen top-blowing furnace, and belongs to the technical field of thermometallurgy. The method comprises the following steps: 1) burdening lead oxide ore concentrate, lead sulfide ore concentrate, smoke dust and raw coal according to a certain ratio, and continuously adding to the inside of a rich oxygen top-blowing furnace to smelt; 2) controlling the furnace atmosphere and the temperature of a molten bath by adjusting the oxygen-enriched air, the enriched oxygen concentration and the coal supply amount, and continuously smelting the lead oxide ore concentrate; 3) smelting at the temperature of 700-850 DEG C for 1-2 hours, finishing lead carbonate decomposition and interaction of lead oxide and lead sulfide, heating to 900-1050 DEG C and then smelting for 2-3 hours, so as to obtain metal lead; 4) reducing the coal quantity to 0.5-0.8t / h, carrying out clarifying treatment for 0.5-1 hour, stopping coal feeding, discharging the lead-enriched slag from a slag hole, continuing to smelt for 0.5-1.5 hours and then discharging crude lead from a lead outlet, and feeding the smoke to prepare an aid after waste heat recovery and dust collection. The method has the characteristics of being simple in process, low in production cost, good in environment-friendly effect, and the like, and continuously treatment can be carried out.

Owner:YUNNAN CHIHONG ZINC & GERMANIUM

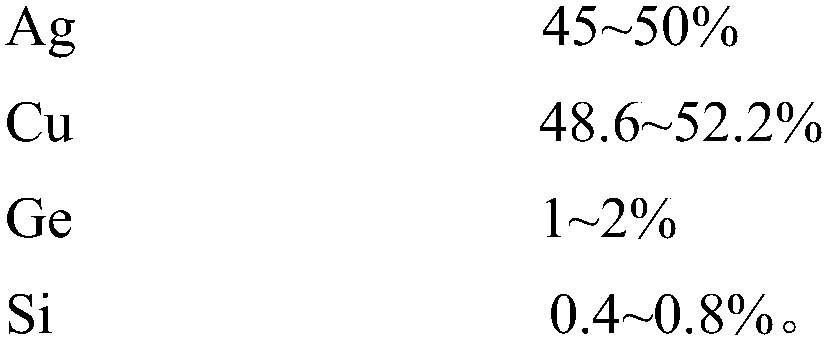

Novel oxidation-resistant quarternary alloy solder

InactiveCN109175784AGuaranteed tensile strengthImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaElemental compositionAlloy

The invention discloses a novel oxidation-resistant quarternary alloy solder. The solder is prepared from the following elements in percentage by weight: 45-50% of Ag, 48.6-52.2% of Cu, 1-2% of Ge and0.4-0.8% of Si. The oxidation-resistant low-silver alloy solder is high in machinability, high in wettability, high in sealing joint strength and high in oxidation resistance, can replace Ag72Cu28 solder which is widely used at present, and is especially applied to sealing of ceramics and metals in electrical vacuum devices.

Owner:WUXI RIYUE ALLOY MATERIALS

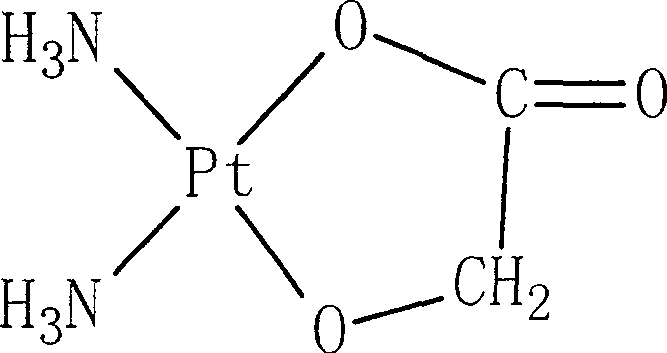

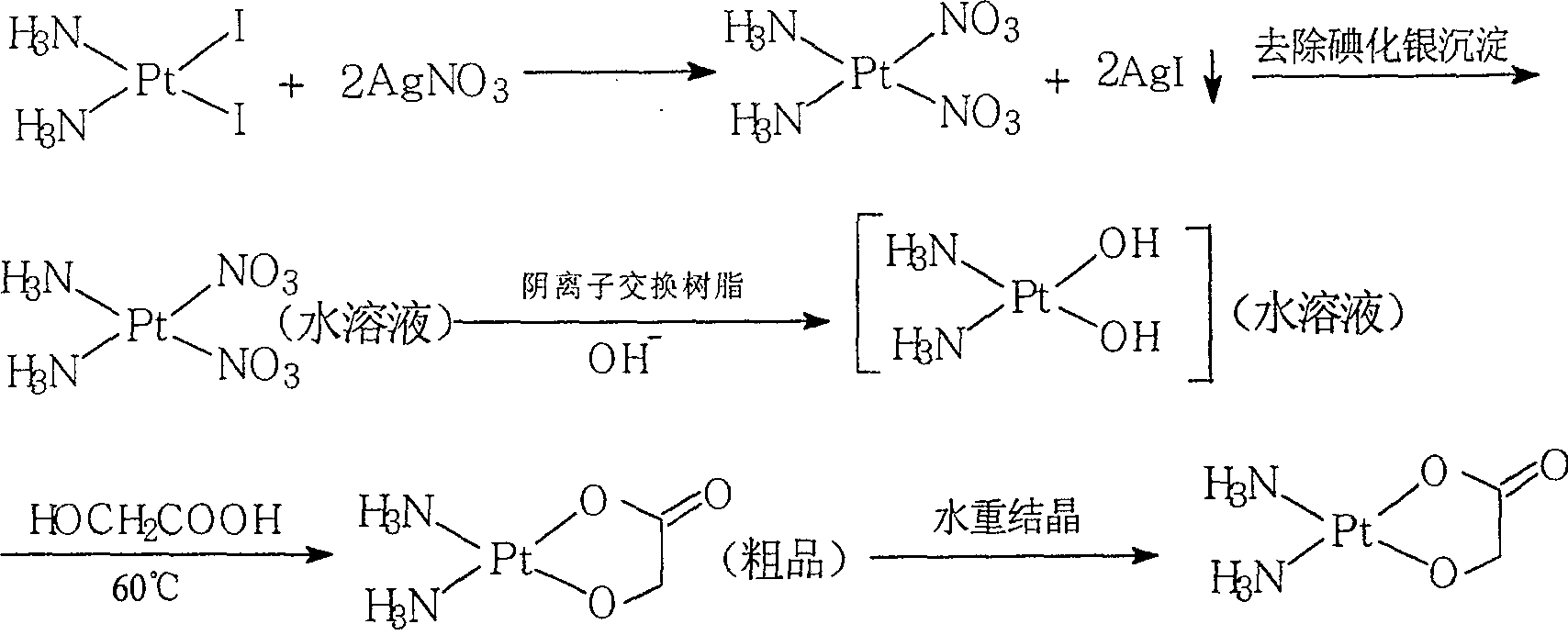

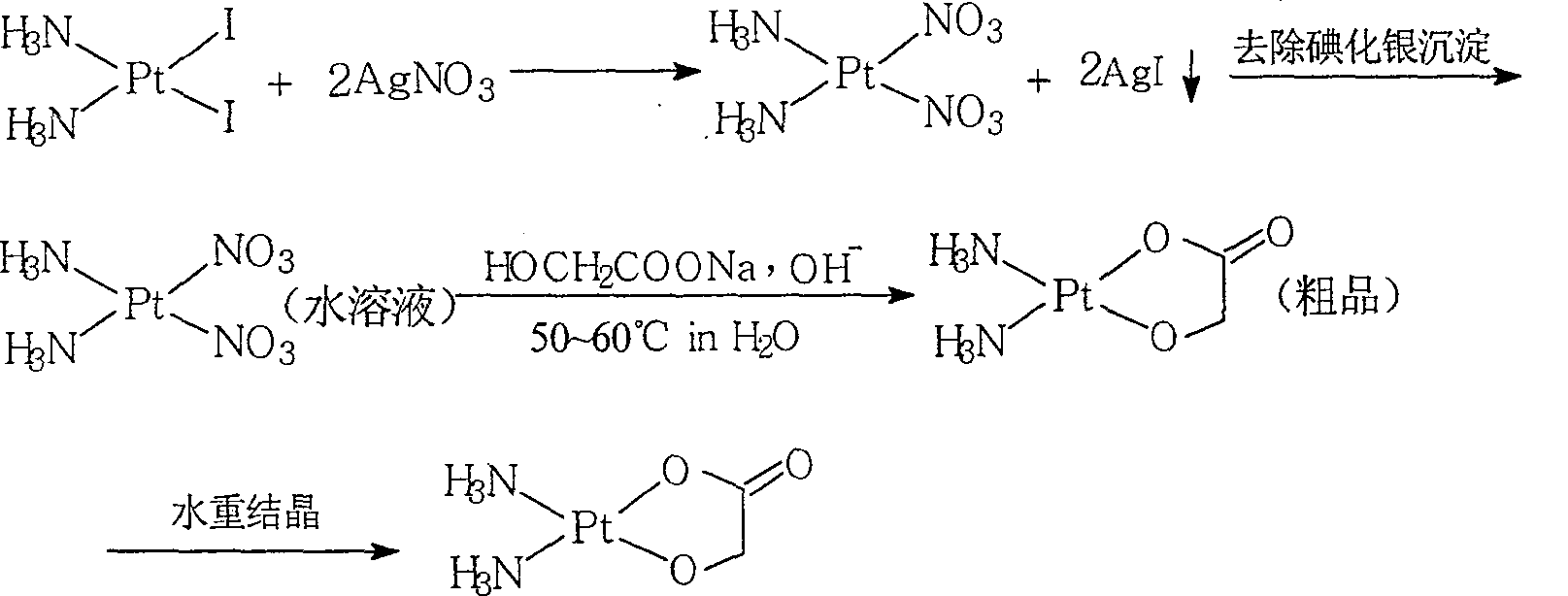

Method of preparing nedaplatin with ultra-low content of silver

ActiveCN100500681CLow silver contentQuality improvementGroup 8/9/10/18 element organic compoundsPlatinumCis-platinum

The invention discloses a making method of naiad platinum with low-silver content, which comprises the following steps: reacting cis-platinum diiododiamide and silver nitrate with molar rate at 1: 2 for 3-8 h under 10-30 deg.c; filtering; adding halogenate MX [M is Na, K, Ca, Ba, NH4 or M is (CnH2n+1) 4N (n=1-4), X=Cl, Br, I] in the filtrate to remove trace silver; reacting for 0.5-1h under 10-30 deg.c; filtering; adding sodium glycolate in the solution; adjusting pH value to neutral to react for 3-10 h under 50-60 deg.c; decompressing; condensing; filtering; drying; obtaining the product; setting the molar rate of cis-platinum diiododiamide and sodium glycolate at 1: 1 and the molar rate of halogenate MX and silver nitrate at 0.1-0.01:1.

Owner:NANJING HAIRUN PHARM CO LTD

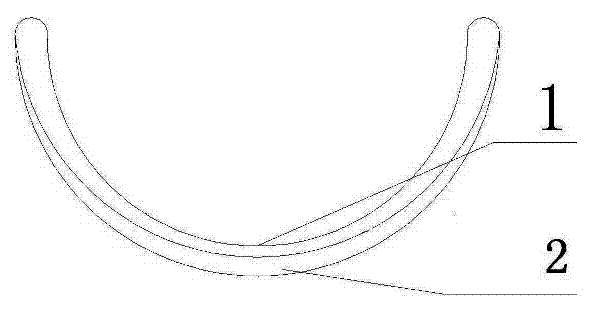

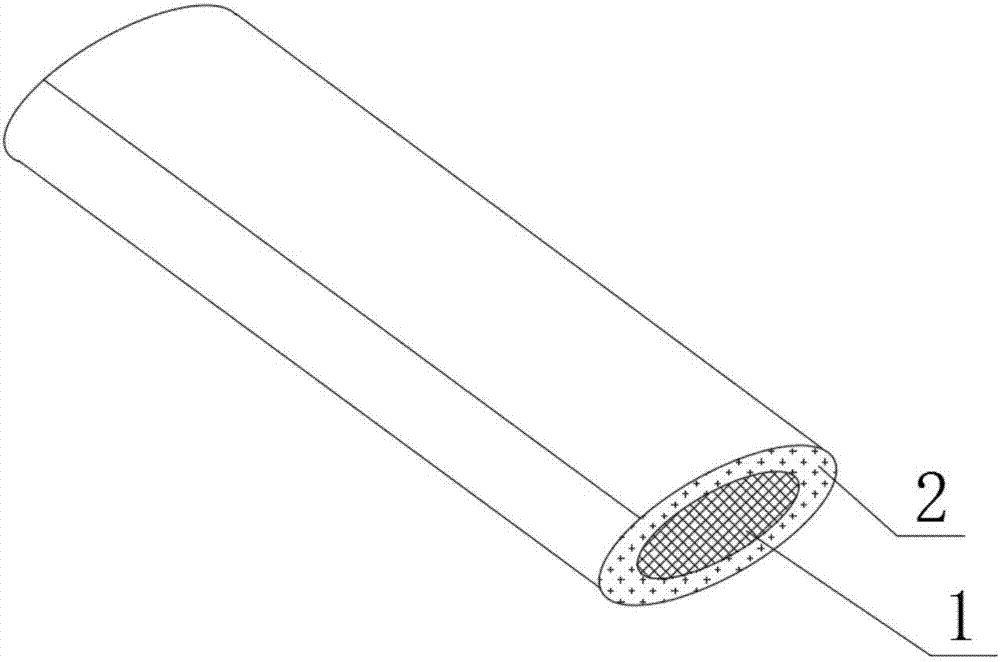

Composite soldering strip

PendingCN107146826ALow costReduce bending deformationPhotovoltaic energy generationSemiconductor devicesSilver pasteSoldering

The invention provides a composite soldering strip. The composite soldering strip comprises a substrate and an interconnected paste layer covering the surface of the substrate, and the interconnected paste layer is formed by combination of silver powder, bonding phase, and solvent. According to the composite soldering strip, compared with the prior art, the composite soldering strip and a cell can be directly welded so that the usage of silver paste on the cell is cancelled, and the cost of the cell is reduced; the usage of a tin-lead solder is replaced by the interconnected paste so that the harm to the environment is reduced; and by employing the interconnected paste, the welding temperature can be effectively reduced, bending deformation and fragmentation of the cells brought by thermal stress are reduced, and the quality stability of a photovoltaic module is improved.

Owner:SUZHOU YOURBEST NEW TYPE MATERIALS

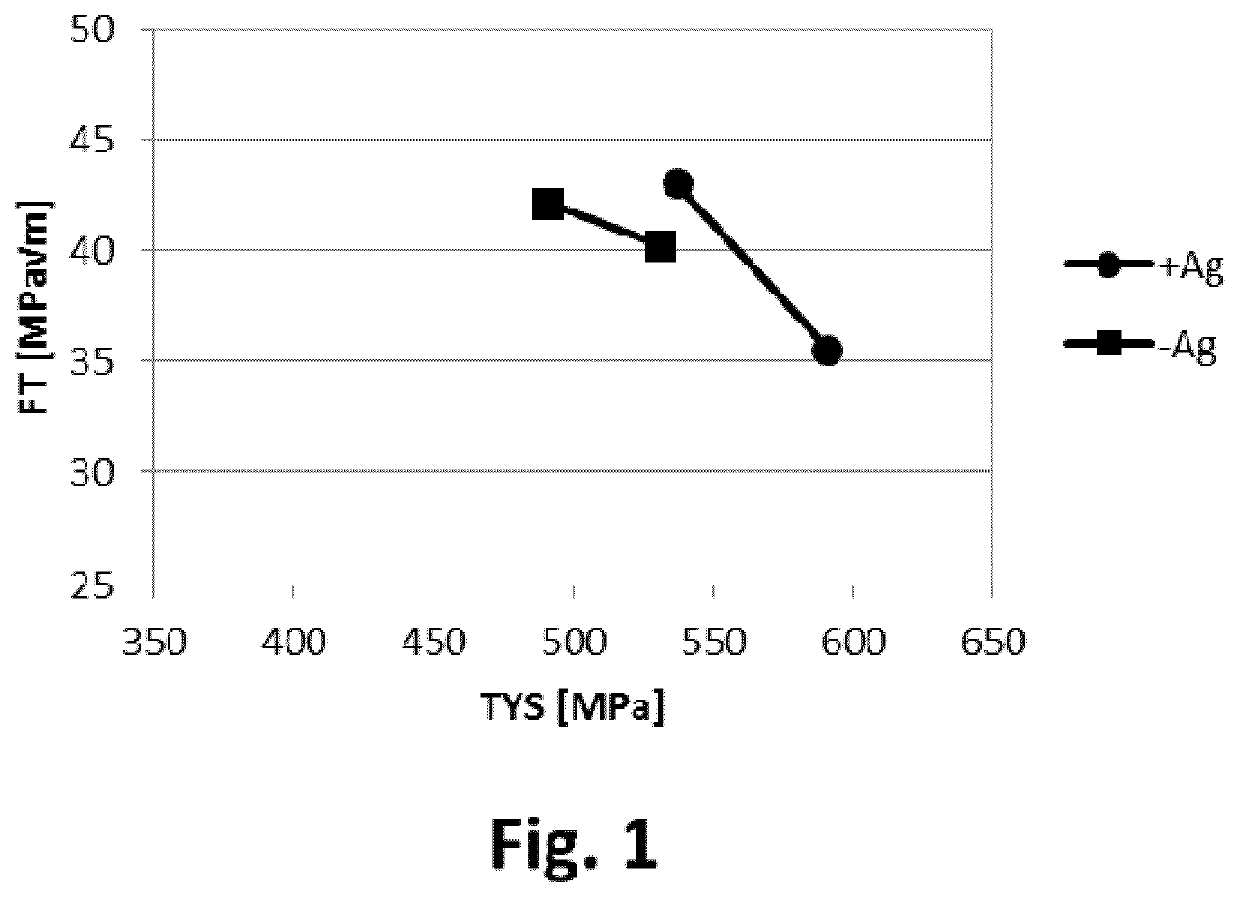

Al-Cu-Li-Mg-Mn-Zn ALLOY WROUGHT PRODUCT

An aluminium alloy wrought product for structural members having a chemical composition of, in wt. %: Cu 3.2% to 4.4%, Li 0.8% to 1.4%, Mg 0.20% to 0.90%, Mn 0.10% to 0.8%, Zn 0.20% to 0.80%, one or more elements selected from the group of: (Zr 0.05% to 0.25%, Cr 0.05% to 0.30%, Ti 0.01% to 0.25%, Sc 0.05% to 0.4%, Hf 0.05% to 0.4%), Ag<0.08%, Fe<0.15%, Si<0.15%, unavoidable impurities and balance aluminium.

Owner:NOVELIS KOBLENZ GMBH

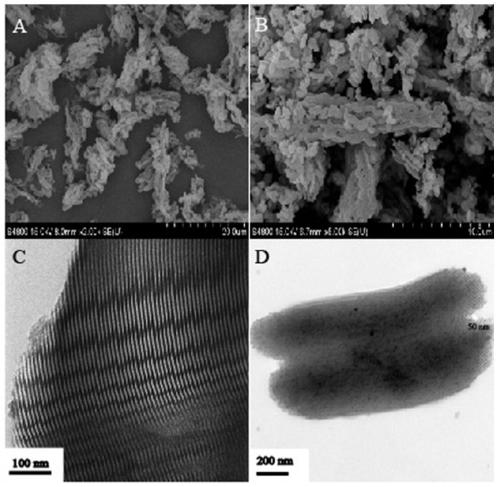

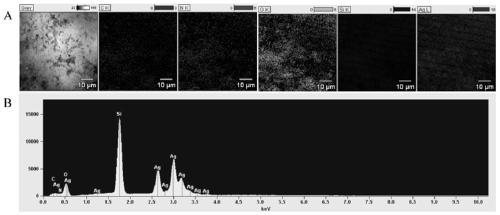

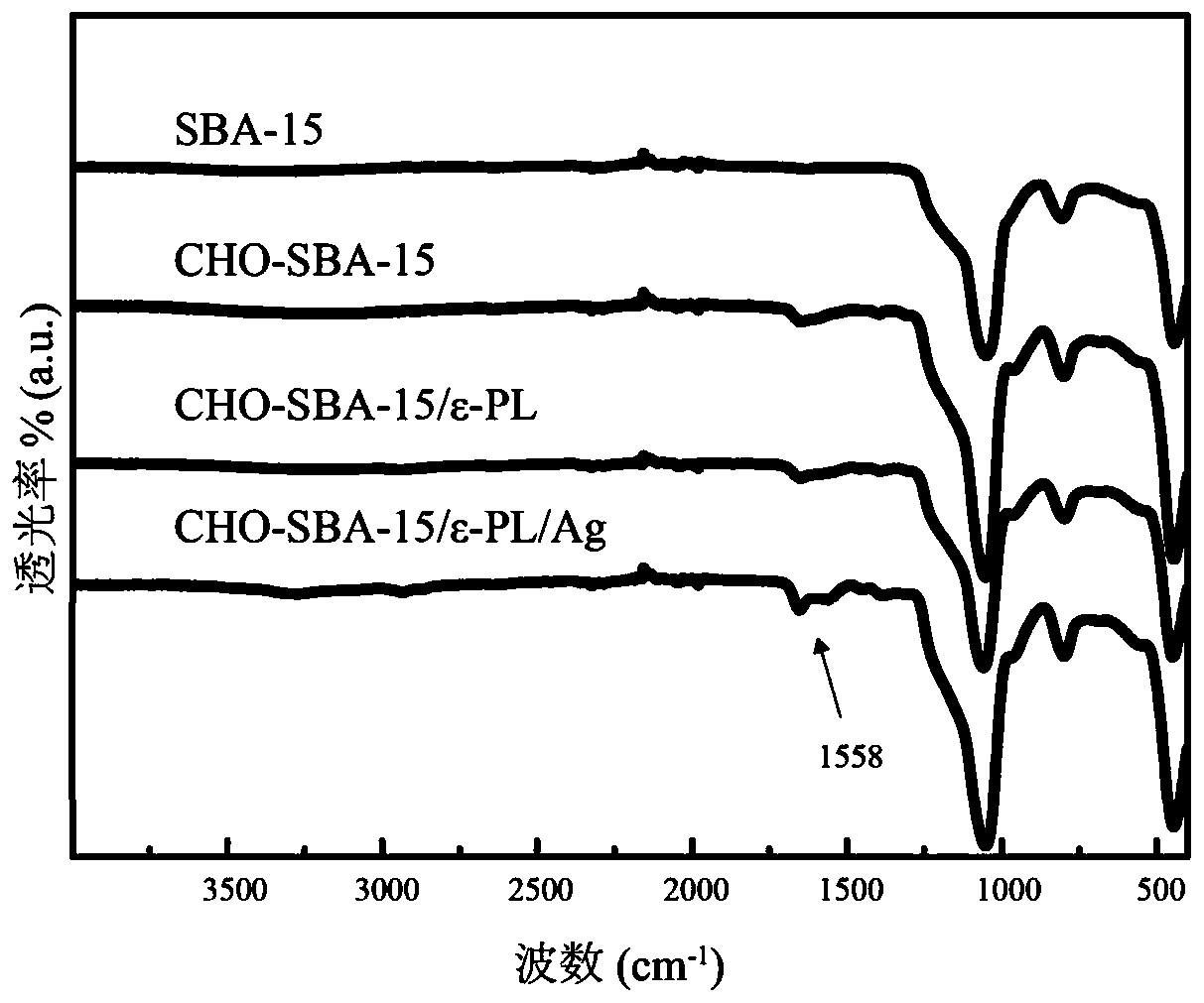

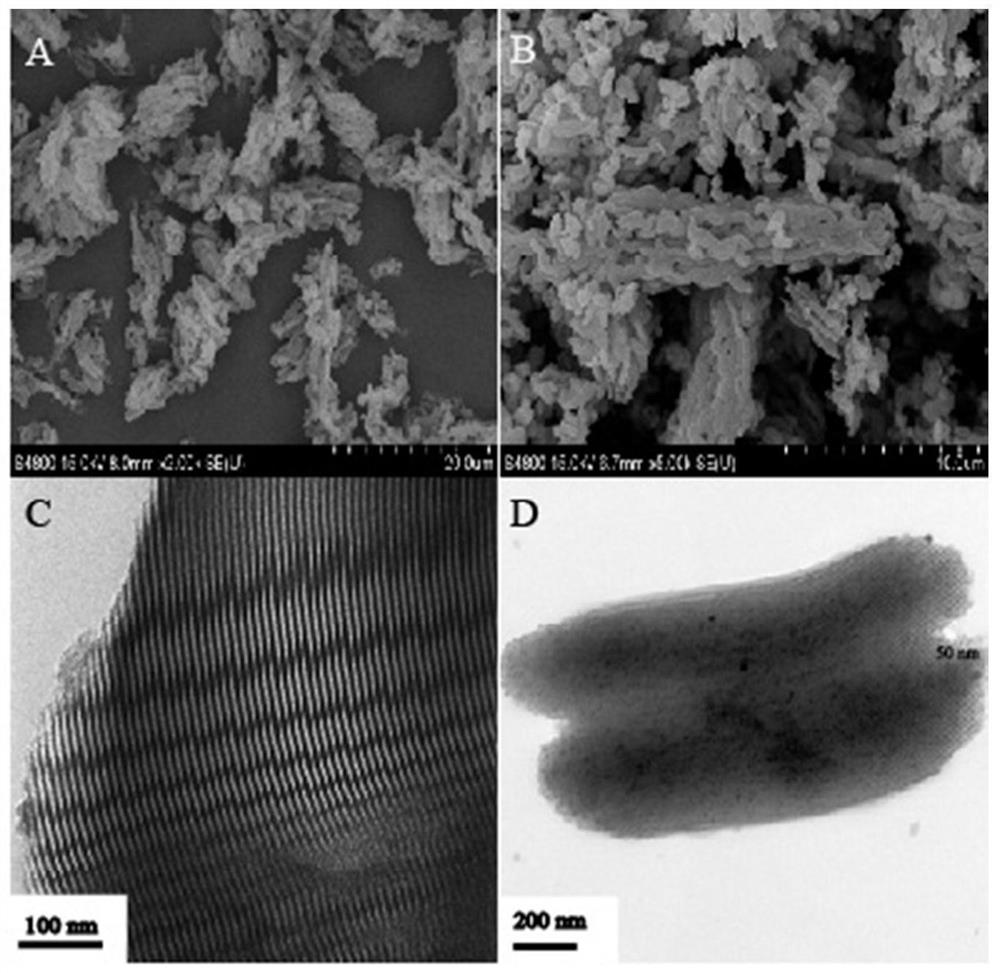

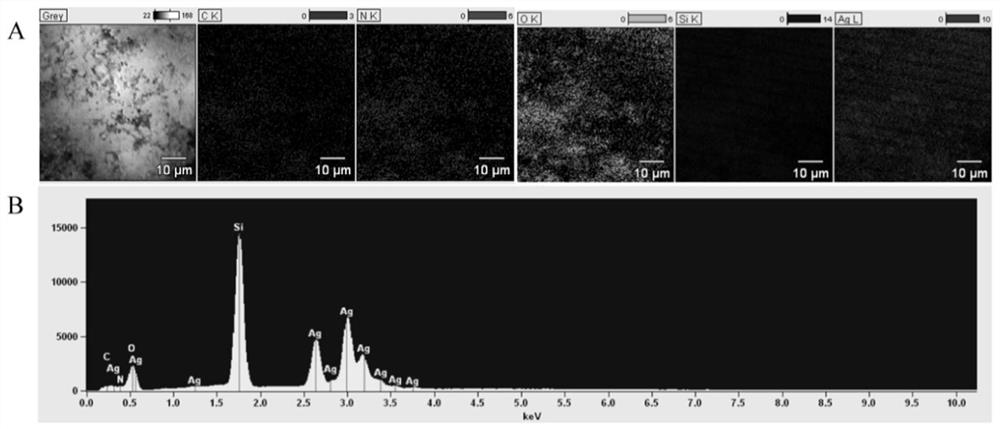

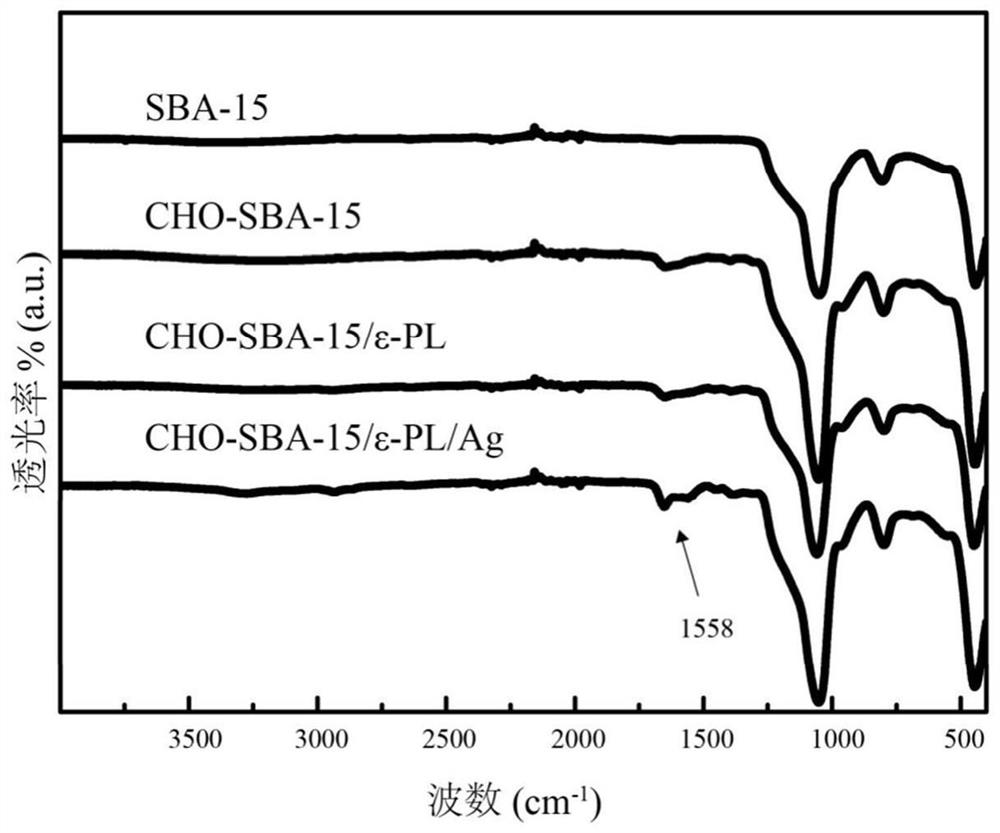

Broad-spectrum antimicrobial mesoporous silica Schiff base silver complex nanomaterial and preparation method thereof

ActiveCN111574723ALow silver contentAvoid it happening againAntibacterial agentsBiocideMicroorganismMesoporous silica

The invention relates to a broad-spectrum antimicrobial mesoporous silica Schiff base silver complex nanomaterial and a preparation method thereof. The preparation method comprises the following steps: preparing aminated mesoporous silica, preparing aldehyde mesoporous silica, and preparing a finished mesoporous silica Schiff base silver complex nanomaterial. The nanomaterial has a killing effecton various bacteria and fungi, can achieve the effects of broad spectrum, high efficiency and continuous sterilization, and can prevent the generation of drug-resistant strains while resisting bacteria.

Owner:NANJING MEDICAL UNIV +1

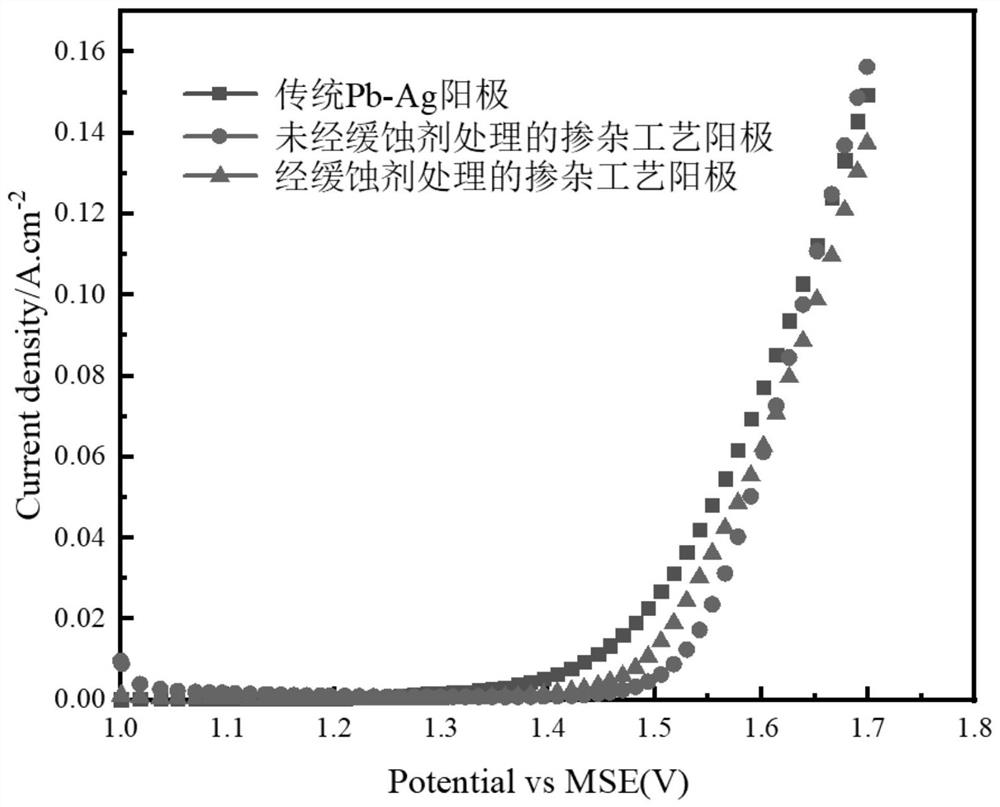

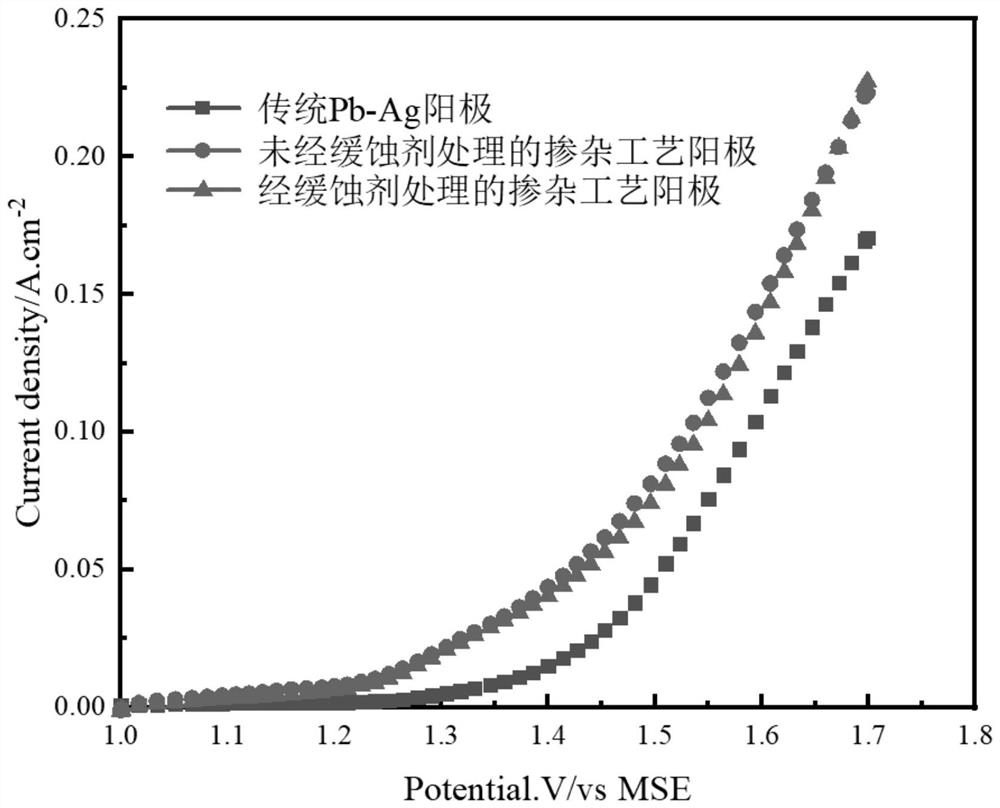

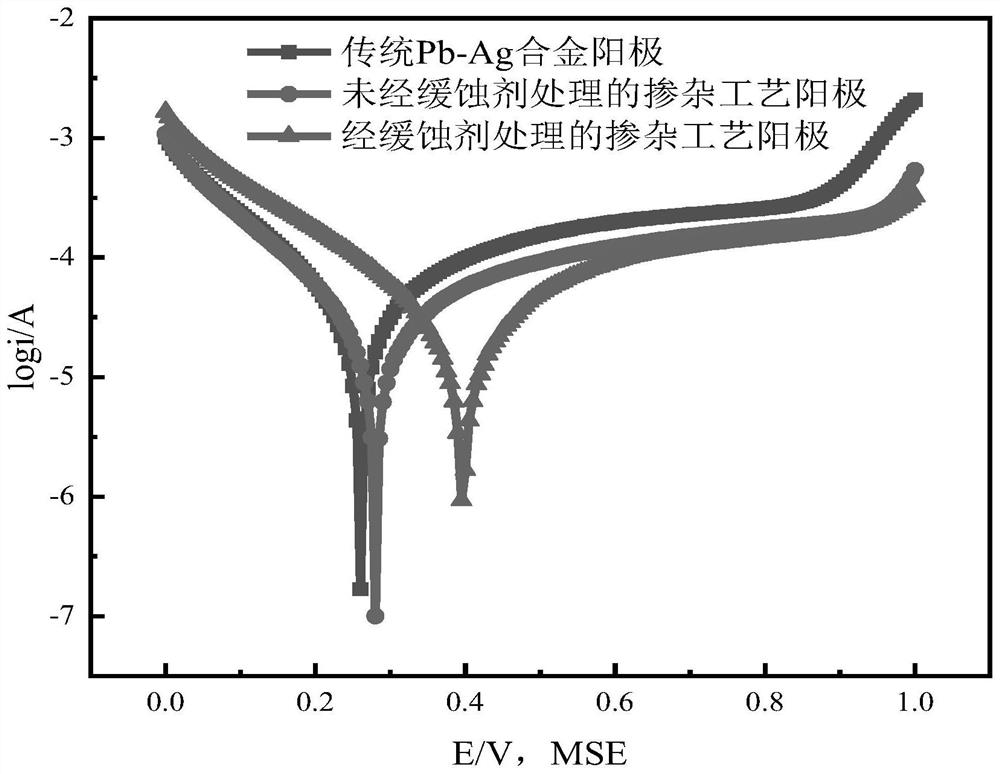

Zinc electrodeposition system suitable for high current density

PendingCN114134538ALow silver contentImprove corrosion resistancePhotography auxillary processesElectrodesElectrolytic agentHigh current density

The invention relates to a zinc electrodeposition system suitable for high current density, and belongs to the technical field of zinc hydrometallurgy. A zinc electrodeposition anode suitable for a high-current-density zinc electrodeposition system is subjected to doping modification and corrosion inhibition surface treatment, an additive capable of improving the zinc electrodeposition current efficiency under the high current density is added into electrolyte, and the additive is one or more of lauryl sodium sulfate, strontium carbonate and hexadecyl trimethyl ammonium bromide. The lead-silver alloy anode obtained through the doping technology has the advantages of being low in silver content, high in corrosion resistance and good in oxygen evolution activity, the lead-silver anode can be effectively protected through corrosion inhibition surface treatment, the low corrosion rate is shown in an accelerated corrosion experiment, meanwhile, the electrochemical performance is excellent, and the anode oxygen evolution potential is low; the additive is added into the electrolyte, so that the zinc electrodeposition current efficiency can be effectively improved, and the electrolyte is suitable for high-current-density zinc electrodeposition.

Owner:KUNMING HENDERA SCI & TECH +1

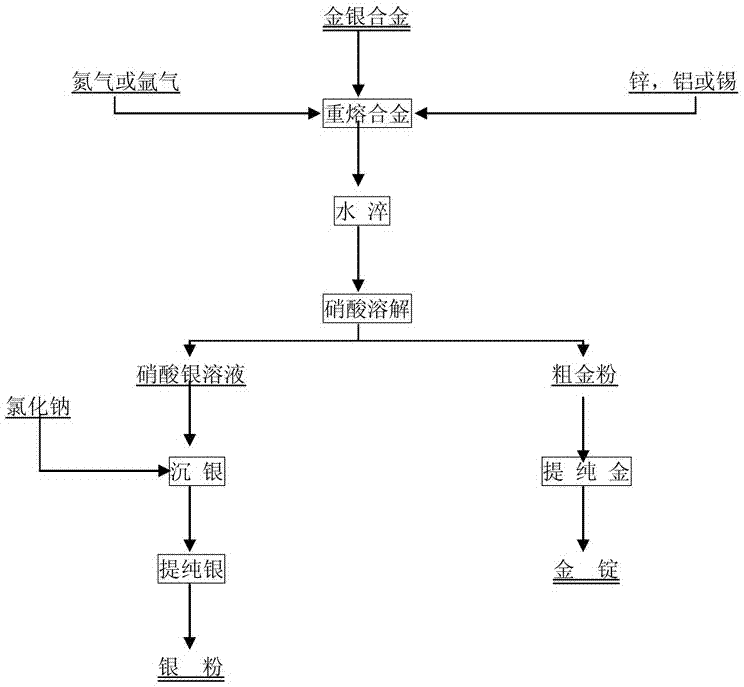

A kind of gold-silver alloy separation and purification process

The invention relates to a gold-silver alloy separation and purification technique, belonging to the technical field of metallurgy. The technique comprises the following steps: 1) remelting the alloy; 2) quenching with water; 3) dissolving silver and impure metals with nitric acid; 4) depositing silver; 5) purifying the silver; and 6) purifying the gold. The base metals are introduced to change the composition of the gold-silver alloy, thereby solving the problem of mutual wrapping in the alloy dissolution process.

Owner:HUNAN JINWANG BISMUTH

Broad-spectrum antimicrobial mesoporous silica Schiff base silver complex nanomaterial and preparation method thereof

ActiveCN111574723BLow silver contentAvoid it happening againAntibacterial agentsBiocideMicroorganismMesoporous silica

The invention relates to a broad-spectrum antimicrobial mesoporous silicon oxide Schiff base silver complex nanomaterial and a preparation method thereof. The preparation method comprises: preparing aminated mesoporous silicon oxide, preparing aldylated mesoporous silicon oxide, and preparing a finished product of mesoporous silicon oxide Schiff base silver complex nanometer material. The nanomaterial has a killing effect on a variety of bacteria and fungi, can achieve broad-spectrum, high-efficiency, and continuous sterilization effects, and can prevent the generation of drug-resistant strains while antibacterial.

Owner:NANJING MEDICAL UNIV +1

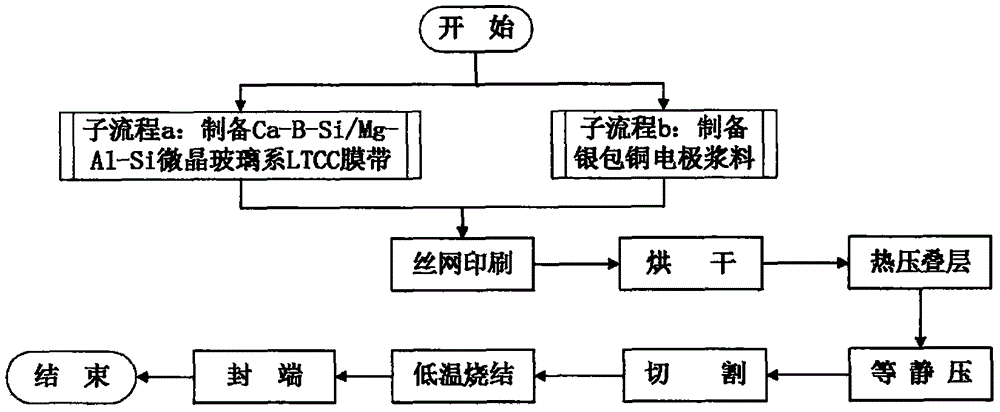

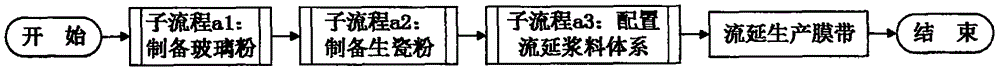

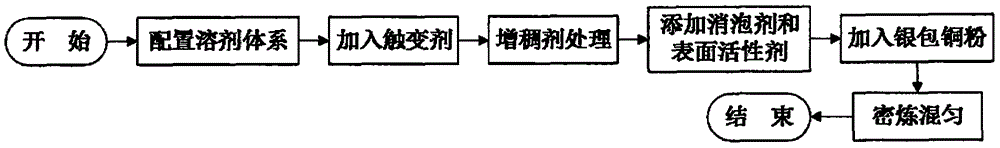

Solving scheme for customized matching of silver-coated copper electrode slurry and LTCC membrane band

ActiveCN106205855AReduced feasibilityReduce negative impactCeramicsNon-conductive material with dispersed conductive materialRadio frequencyAerospace

The invention provides a solving scheme for customized matching of silver-coated copper electrode slurry and an LTCC membrane band, namely a similar all-side parameters-based customized matching scheme for membrane band casting slurry and silver-coated copper electrode slurry in an LTCC technology. A solving scheme for fundamentally and comprehensively solving the problem of poor tolerance of the LTCC technology is provided mainly for the problem of matching of porcelain and the electrode slurry. The adopted electrode slurry is prepared from silver-coated copper powder, so that the economic applicability of the solving scheme is also improved. The solving scheme provided by the invention has the characteristics of ordinary and easy-to-purchase materials, good process tolerance and the like, meets the green and energy-saving environmental protection requirements, has a good industrial application prospect, provides a solid foundation for high-speed development of LTCC industrialization of our country, and is expected to be applied on a large scale in multiple fields of wireless communication, aerospace and military, microwave-radio frequency device application, automotive electronic devices and the like.

Owner:YUNNAN INFINE NEO MATERIAL

Method for producing high-energy rare earth powder alloy electrical contact material

The invention relates to a method for producing an electrical contact material, particularly relates to a method for producing a high-energy rare earth powder alloy electrical contact material. According to the technical scheme provided by the invention, the method for producing a high-energy rare earth powder alloy electrical contact material is characterized by comprising the following steps of: firstly, completely mixing and stirring alumina powder, silver powder, lanthanum powder, graphite powder, molybdenum powder, yttrium powder, boron powder and nickel copper powder; secondly, using anoil press to squeeze and mold the powder, and then sintering the squeezed and molded object into a vacuum high-temperature furnace and then cooling; thirdly, burning the molded object in a high-temperature furnace, then taking out and squeezing the burnt object into a panel shape by using a die on the oil press, and then cooling with cold water, and finally using a machine tool to punch the cooled object into a contact. The invention overcomes disadvantages of the prior art and provides the method for producing an environment-friendly high-energy rare earth powder alloy electrical contact material with low silver content, impact resistance, corrosion resistance, antioxidation, low resistance and good electrical conductivity.

Owner:温州银泰合金材料有限公司

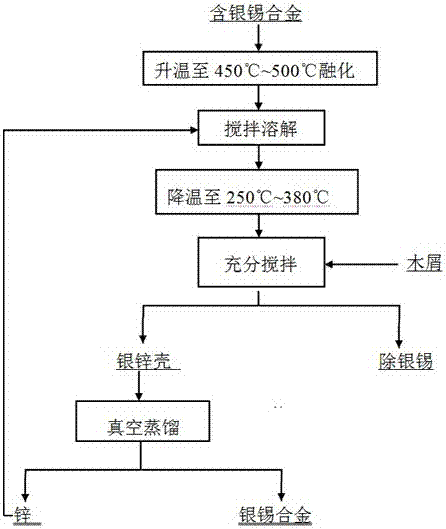

A method for adding sawdust to remove silver from silver-containing tin alloy

ActiveCN104928491BImprove universalityWide range of silver contentProcess efficiency improvementNonferrous metalLiquid state

The invention relates to a method for adding wood bits into silver-containing tin alloy to remove silver and belongs to the technical field of nonferrous metal pyrogenic process smelting. First, silver-containing tin alloy is subjected to high-temperature full fusion, then, crude zinc is added into the molten silver-containing tin alloy, full stirring and dissolution are carried out, when temperature is lowered to 250-380 DEG C, wood bits with the weight five times of that of silver in the crude zinc are added, full stirring is carried out, residue dragging is carried out, and repeated working is carried out. When observed floating objects are black carbon granules, residue dragging is stopped, finally, liquid-state tin containing small amount of silver and a silver-zinc shell containing the carbon granules are obtained, and after the liquid-state tin is cooled, desilverization tin is obtained. The method is simple in technology, the process is safe and reliable, operation is convenient, cost is low, raw material universality is high, equipment is simple, and the tin alloy silver-containing range which can be processed is wide.

Owner:KUNMING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com