Method for processing lead oxide ore concentrate by using rich oxygen top-blowing furnace

A technology of lead oxide concentrate and oxygen-enriched top blowing, which is applied in the field of pyrometallurgy, can solve the problems of high environmental protection hazards and high energy consumption, and achieve the effects of promoting development, low energy consumption, and relieving the tension of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

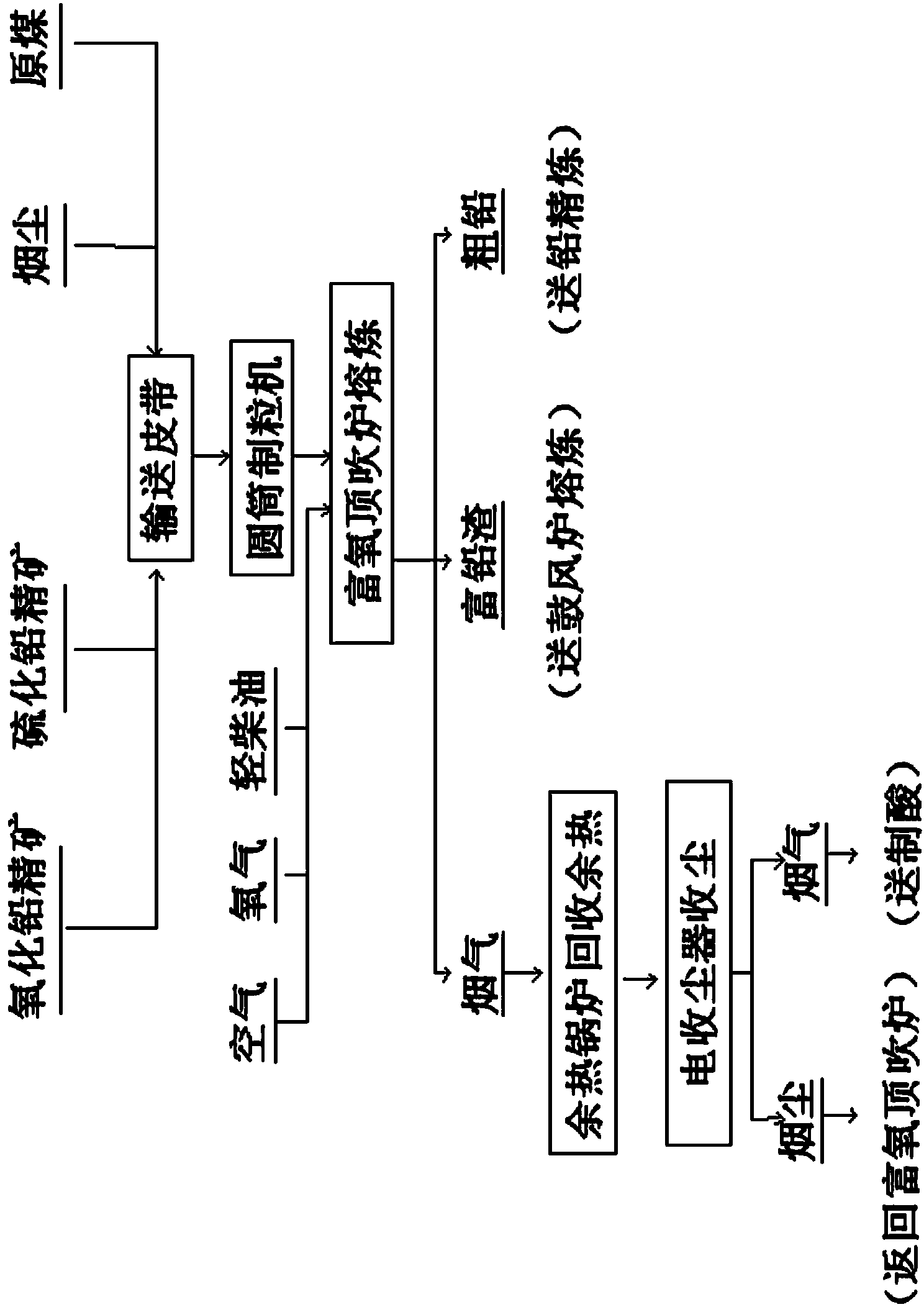

Image

Examples

Embodiment 1

[0020] Example 1 : Taking the processing of 50 tons of lead oxide concentrate raw materials as an example, its composition is shown in Table 1.

[0021] Table 1 Composition of lead oxide concentrate (%)

[0022] name Pb SiO 2 S Zn Ag (g / t) Cd As Lead Oxide Concentrate 65 14 1.5 0.12 50 0.03 0.04

[0023] 1) Set 5t / h of lead oxide concentrate, 8t / h of lead sulfide concentrate, 18t / h of soot and lead concentrate mixture, and 1.2t / h of raw coal on the DCS, and continuously add oxygen-enriched top blowing after mixing and granulating Melting in the furnace.

[0024] 2) Strictly control the air volume at 2.5-4.5 Nm during the smelting process 3 / s, the enriched oxygen concentration is controlled within the range of 25-35%.

[0025] 3) Smelting at 700-850°C for 2 hours to decompose lead carbonate, lead oxide and lead sulfide to interact with each other, then raise the temperature to 900-1050°C for 3 hours, and adjust the amount of materia...

Embodiment 2

[0033] Example 2 : Taking the processing of 80 tons of lead oxide concentrate raw materials as an example, its composition is shown in Table 3.

[0034] Table 3 Composition of lead oxide concentrate (%)

[0035] name Pb SiO 2 S Zn Ag (g / t) Cd As Lead Oxide Concentrate 68 16 2.3 0.08 30 0.02 0.05

[0036] 1) Set 6t / h of lead oxide concentrate, 10t / h of lead sulfide concentrate, 16 t / h of soot and lead sulfide concentrate mixture, and 1.5t / h of raw coal on the DCS, and add oxygen-enriched top continuously after mixing and granulating Melting in a blowing furnace.

[0037] 2) Strictly control the air volume at 2.5-4.5 Nm during the smelting process 3 / s, the enriched oxygen concentration is controlled within the range of 25-35%.

[0038] 3) Smelting at a temperature of 700-850°C for 2 hours to decompose lead carbonate, lead oxide and lead sulfide to interact with each other, then raise the temperature to 900-1050°C for another 2.5 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com