Al-Cu-Li-Mg-Mn-Zn ALLOY WROUGHT PRODUCT

a technology of wrought alloys and cu-li, which is applied in the field of cu-li wrought alloy products, can solve the problems of insufficient combined strength and fracture toughness of such alloys, and the difficult casting of conventional alloys containing relatively high amounts of lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

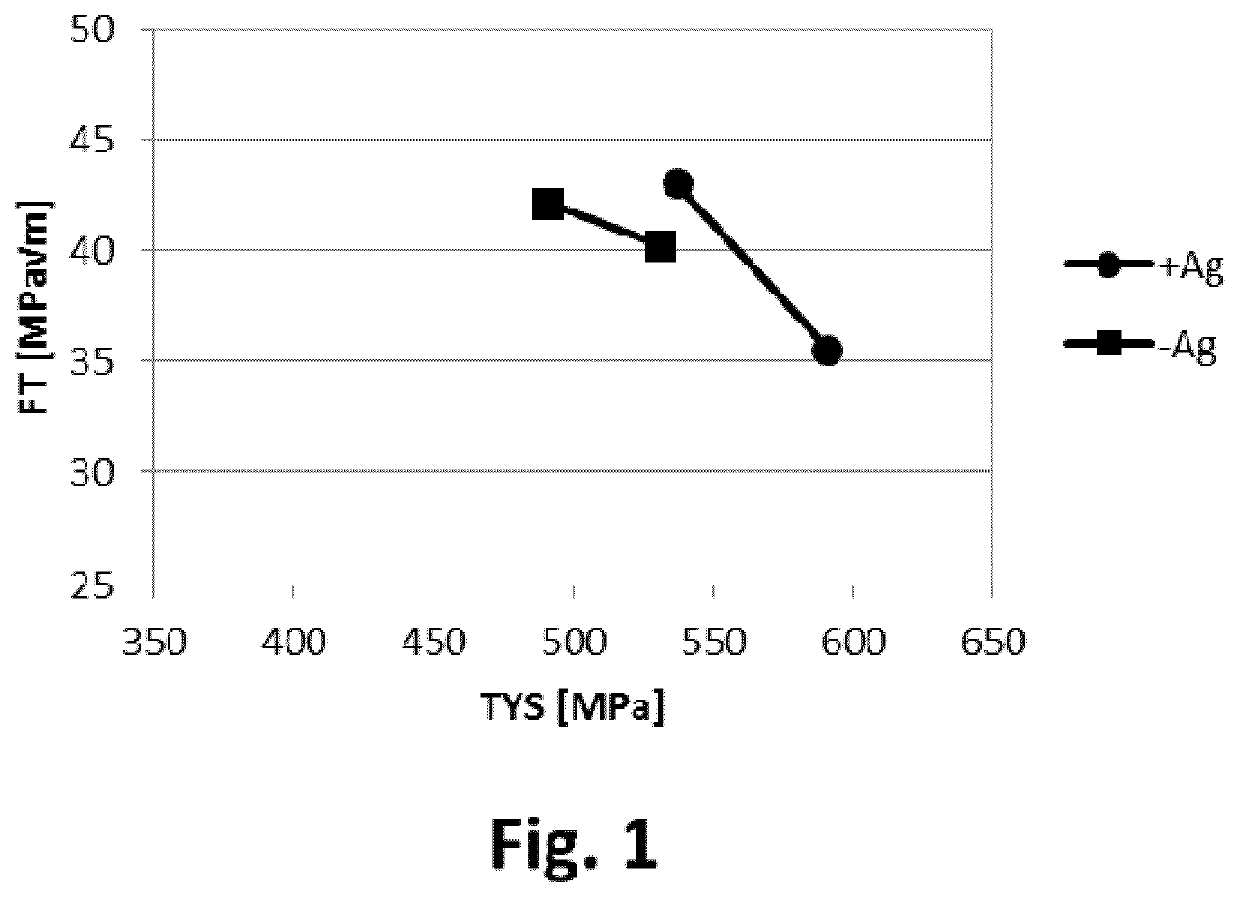

[0057]On a laboratory scale 2 alloys have been cast and machined into rolling blocks of 260×200×80 mm. The alloy compositions are given in Table 1. These were homogenised for 5 h@500° C. followed by 10 h@510° C. After pre-heating to 480° C. the rolling blocks were hot rolled from 80 mm to a gauge of 30 mm. Then solution heat-treated for 30 min@500° C. followed by a cold water quench and within 30 minutes thereafter stretched by 2%.

TABLE 1Alloy composition (in wt. %) of the alloys processed.Balance is made by aluminium and unavoidableimpurities and with 0.03% Fe and 0.02% Si.Alloying elementAlloyCuLiMgMnZnZrTiAgA3.91.10.40.40.40.110.020.35B3.91.10.40.40.40.110.020.0

[0058]In order to bring the alloy to a T84 temper the Ag-free alloy was aged for 16 h@150° C. and the Ag containing alloy for 10.5 h@150° C. The difference in ageing time to arrive at the T84 temper is due to the difference in silver-content which has an effect on the ageing response.

[0059]In order to test the thermal stab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com