Solving scheme for customized matching of silver-coated copper electrode slurry and LTCC membrane band

A technology of electrode paste and solutions, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve problems such as low feasibility, restricting the development of a complete set of LTCC processes, and difficulty in jumping out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

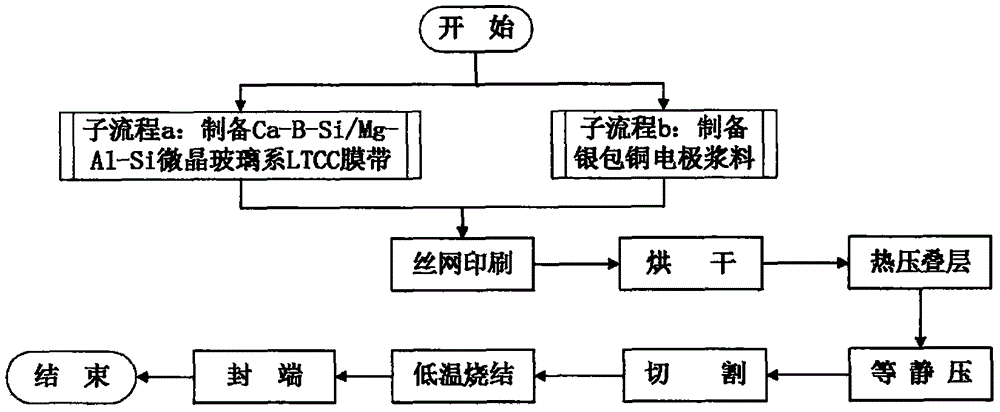

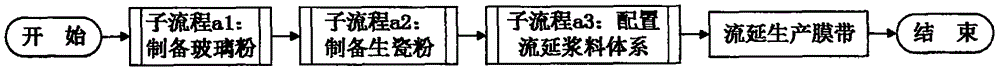

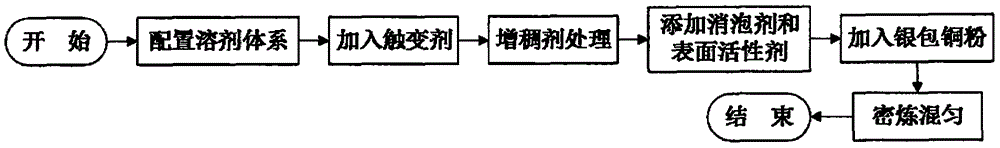

Method used

Image

Examples

Embodiment 1~5

[0076] Examples 1 to 5 investigate the relationship between the formula of compound porcelain powder and the index of cast slurry

Embodiment 1

[0078] Preparation of glass powder: Weigh the glass powder precursor raw material Ca(OH) according to the glass powder configuration 2 3675.8g, weighed H 3 BO 3 5226.8g, weighed SiO 2 4312.7g, weighed Mg(OH) 2 975.6g, weighed ZnO 1075.8g, weighed ZrO 2 4507.7g, weighed 29661.6g of absolute ethanol, weighed 59323.2g of zirconia balls (Φ5) (i.e. material: absolute ethanol: zirconia balls = 1:1.5:3), mixed the above materials, separated the zirconia after ball milling for 15h The balls were dried at 80°C, put into a glass frit furnace to melt, the melting temperature was 1450°C, crushed, weighed 24442.2g of absolute ethanol, weighed 48884.4g of zirconia balls (Φ3), (i.e. material: absolute alcohol : zirconia balls=1:1.5:3) separate the zirconia balls after ball milling for 24h, dry at 90°C, pass through a 350-mesh sieve to obtain glass powder for later use, and weigh 16295g.

[0079] Preparation of green porcelain powder: weigh Al according to the following table 2 o 3 Add...

Embodiment 2-5

[0083] Examples 2-5 The preparation of green porcelain powder compounded porcelain powder and the parameters of the casting slurry system are shown in the table below. The preparation of glass powder and the parts not mentioned are the same as in Example 1:

[0084]

[0085]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com