Active heatproof copper-based brazing filler metal used for aluminum bronze/stainless steel brazing and preparation method thereof

A stainless steel and aluminum bronze technology, applied in welding equipment, welding/welding/cutting items, welding/cutting media/materials, etc., can solve the problem of unsuitable aluminum bronze/stainless steel brazing, poor surface wettability of aluminum bronze, and unsatisfactory Heat strength requirements and other issues to achieve the effect of avoiding adverse effects, low silver content, and improving brazing process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] In the present embodiment, the steps of the preparation method of the active heat-resistant copper-based solder for aluminum bronze / stainless steel brazing are as follows:

[0035] (1) Ingredients

[0036]Cathode copper with brand Cu-CATH-1, electrolytic manganese with brand DJMnD99.8, electrolytic nickel with brand Ni9999, silver with brand IC-Ag99.90, zinc ingot with brand Zn99.99, and Si with brand -1 industrial silicon, zirconium grade Zr-1, copper-phosphorus master alloy with a P content of about 14wt%, and a nickel-boron master alloy with a B content of about 16wt% as raw materials, according to the following components and percentages Content ingredients: Mn 21.0wt%, Ni 11.5wt%, Ag 23.0wt%, Zn 1.0wt%, Si 0.3wt%, P 0.2wt%, B 0.2wt%, Zr 1.5wt%, the balance is Cu; The total amount is 10.0kg.

[0037] (2) Melting

[0038] Put the raw materials prepared in step (1) except the active element zirconium into the crucible, put the crucible into a vacuum induction melti...

Embodiment 2

[0047] In the present embodiment, the steps of the preparation method of the active heat-resistant copper-based solder for aluminum bronze / stainless steel brazing are as follows:

[0048] (1) Ingredients

[0049] Cathode copper with brand Cu-CATH-1, electrolytic manganese with brand DJMnD99.8, electrolytic nickel with brand Ni9999, silver with brand IC-Ag99.90, zinc ingot with brand Zn99.99, and Si with brand -1 industrial silicon, lithium brand Li-3, copper-phosphorus master alloy with a P content of about 14wt%, and a nickel-boron master alloy with a B content of about 16wt% are used as raw materials, according to the following components and their percentages Content ingredients: Mn 21.0wt%, Ni 12.0wt%, Ag 22.0wt%, Zn 1.5wt%, Si 0.2wt%, P 0.1wt%, B 0.2wt%, Li 0.5wt%, the balance is Cu; The total amount is 9.9kg.

[0050] (2) Melting

[0051] Put the raw materials prepared in step (1) except the active element lithium into the crucible, put the crucible into a vacuum indu...

Embodiment 3

[0059] In the present embodiment, the steps of the preparation method of the active heat-resistant copper-based solder for aluminum bronze / stainless steel brazing are as follows:

[0060] (1) Ingredients

[0061] Cathode copper with brand Cu-CATH-1, electrolytic manganese with brand DJMnD99.8, electrolytic nickel with brand Ni9999, silver with brand IC-Ag99.90, zinc ingot with brand Zn99.99, and Si with brand -1 industrial silicon, zirconium with grade Zr-1, hafnium with grade HHf-1, copper-phosphorus master alloy with P content of about 14wt%, nickel-boron master alloy with B content of about 16wt% as raw materials, according to the following Components and their percentage ingredients: Mn 21.0wt%, Ni 13.0wt%, Ag25.0wt%, Zn 2.0wt%, Si 0.4wt%, P 0.3wt%, B 0.3wt%, Zr 1.0wt% , Hf 0.05wt%, the balance is Cu; the total amount of raw materials is 10.3kg.

[0062] (2) Melting

[0063] Put the raw materials prepared in step (1) except the active elements zirconium and hafnium into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

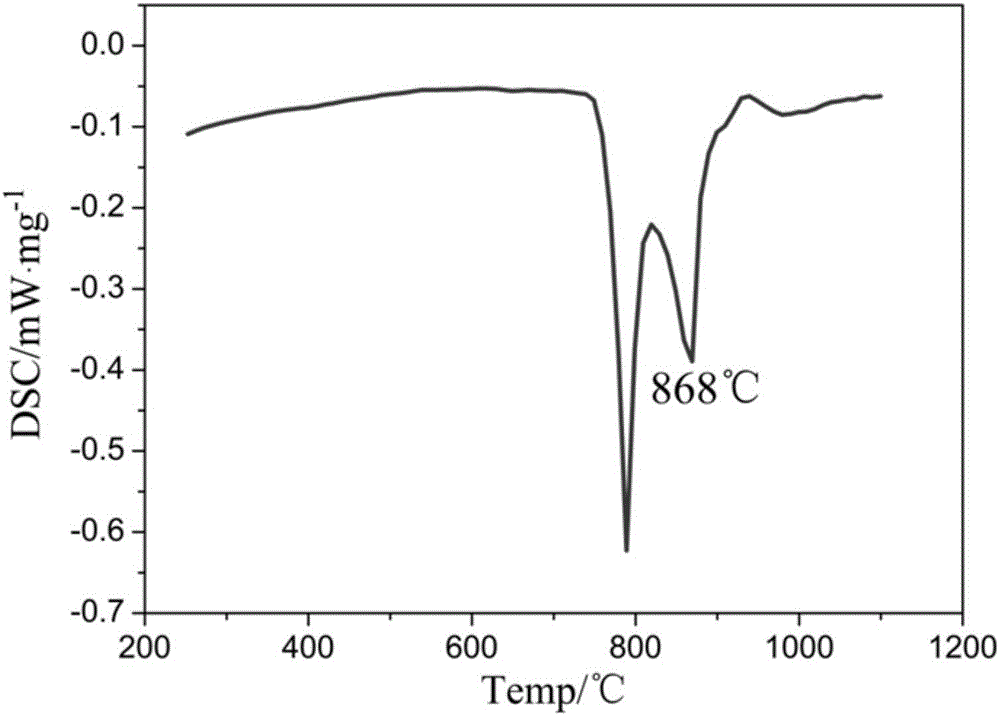

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com