Intercooler of ultra-large generating set

A generator set, super-large technology, applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of inability to make heat dissipation belts and brazing, unreasonable structure of coolers, poor heat dissipation effect, etc. Inability to make heat dissipation strips and brazing, improve heat dissipation efficiency, improve the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

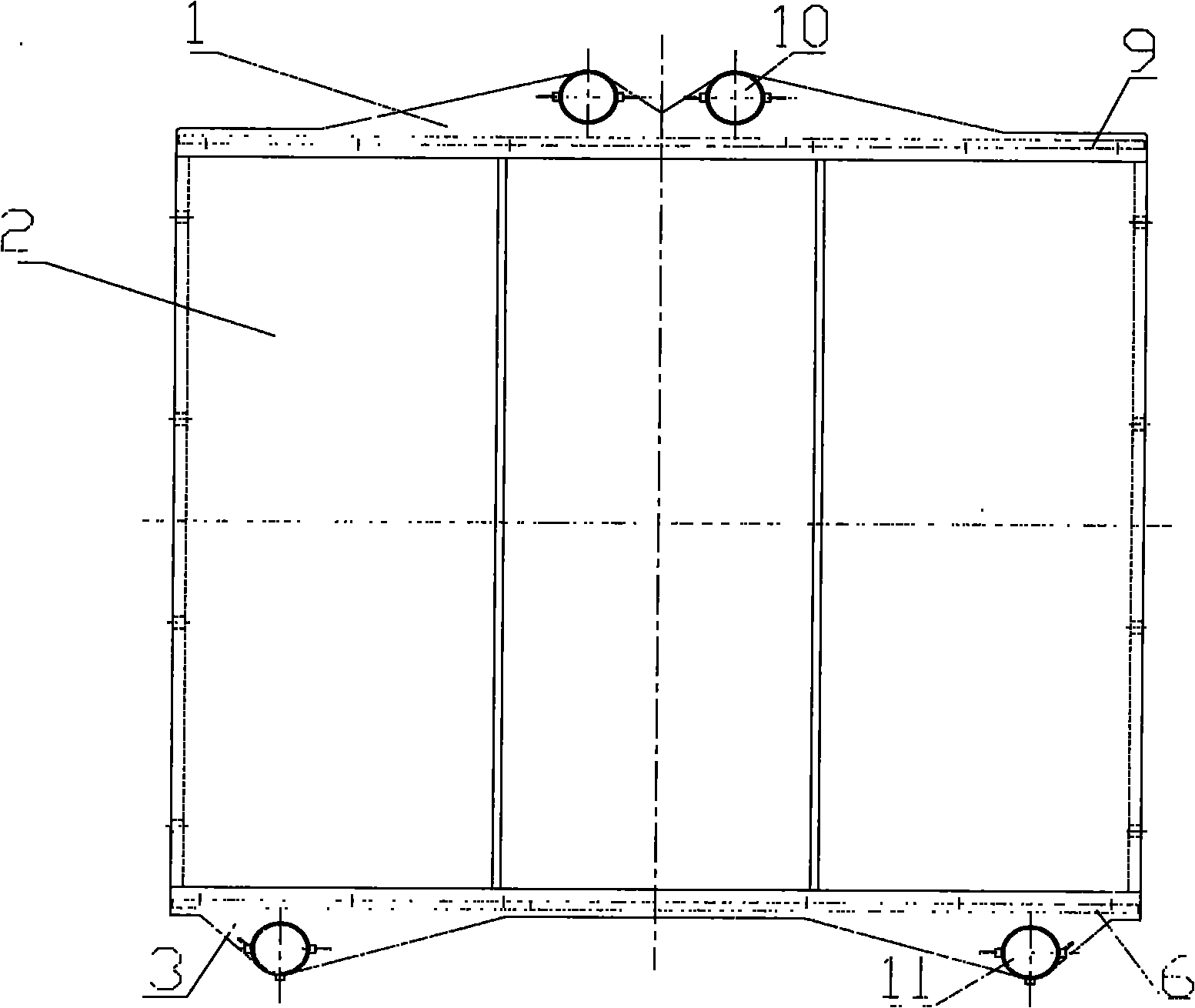

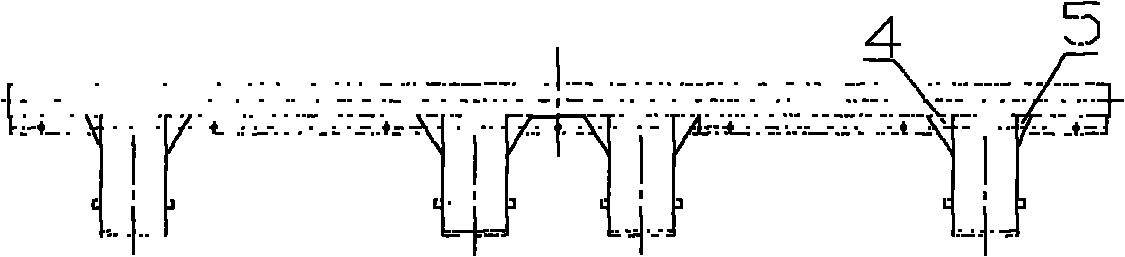

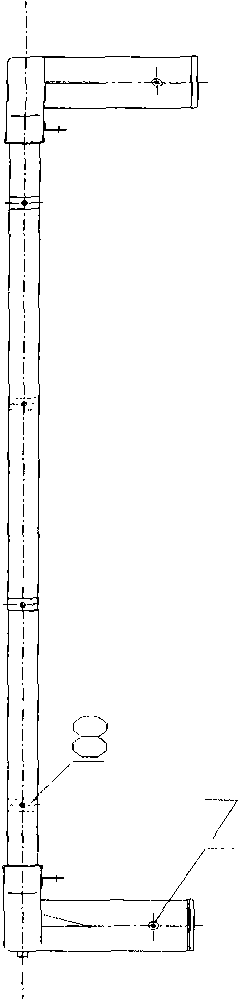

[0016] Such as figure 1 As shown, an intercooler for a super-large generator set includes an upper air chamber 1 and a lower air chamber 3, and a core body subassembly 2 is arranged between the upper air chamber 1 and the lower air chamber 3. The core subassembly 2 is composed of a main board, a side plate, a heat dissipation belt and a flat tube, the upper air chamber 1 is provided with two air inlets 10, and the lower air chamber 3 is provided with two air outlets 11, so At least three core body sub-assemblies are arranged between the upper air chamber 1 and the lower air chamber 3, and the three core body sub-assemblies ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com