Low-silver-content ceramic filter conductive silver paste for 5G base station and preparation method and application thereof

A technology of ceramic filter and conductive silver paste, which is applied in the direction of waveguide devices, cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of high cost and high silver consumption, and achieve high Conductivity, surface smoothing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

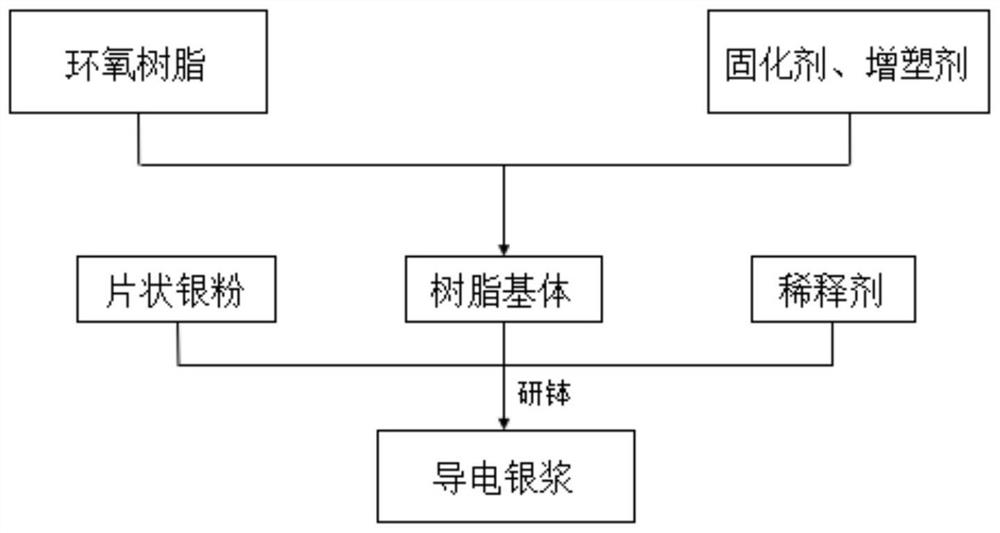

Method used

Image

Examples

Embodiment 1

[0022] Among the present invention, 5G base station is used ceramic filter conductive silver paste, and the selection of material is:

[0023] Conductive filler selects flaky rate 87.5%, particle size is micron and uniform flaky silver powder, the mass fraction of flaky silver powder is 70 parts;

[0024] The resin material is bisphenol A type epoxy resin with at least two reactive epoxy groups in the molecule, which has strong adhesion to metals and strong chemical corrosion resistance. It can be cured in a wide temperature range and has a volume of Shrinkage is small, and the mass fraction of bisphenol A type epoxy resin is 14 parts;

[0025] The curing agent is an acid anhydride curing agent. This example uses phthalic anhydride (PA), a white crystal with a melting point of 128 ° C. The mass fraction of phthalic anhydride (PA) is 5 parts; the diluent is reactive diluent 692 (benzyl glycidyl ether) and non-reactive diluent butyl acetate, the mass parts are respectively 2 pa...

Embodiment 2

[0032] Among the present invention, 5G base station is used ceramic filter conductive silver paste, and the selection of material is:

[0033] The conductive filler is selected from flake silver powder with high flaky rate, large particle width-thickness ratio, and uniform particle size of micron, and the mass fraction of the silver powder is 66 parts.

[0034] The resin material is bisphenol A type epoxy resin with at least two reactive epoxy groups in the molecule, which has strong adhesion to metals and strong chemical corrosion resistance. It can be cured in a wide temperature range and has a volume of Shrinkage is small, and the mass fraction of bisphenol A type epoxy resin is 15 parts.

[0035] The curing agent is acid anhydride curing agent. In this example, bisacid anhydride (MA) is selected as white crystal. The curing condition is 160-200° C., and the mass fraction of bisacid anhydride (MA) is 6 parts.

[0036] The diluents are reactive diluent 692 (benzyl glycidyl ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com