Zinc electrodeposition system suitable for high current density

A high current density, zinc electrowinning technology, applied in the direction of electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of anode corrosion intensification, achieve the effect of improving catalytic activity, improving corrosion resistance, and low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

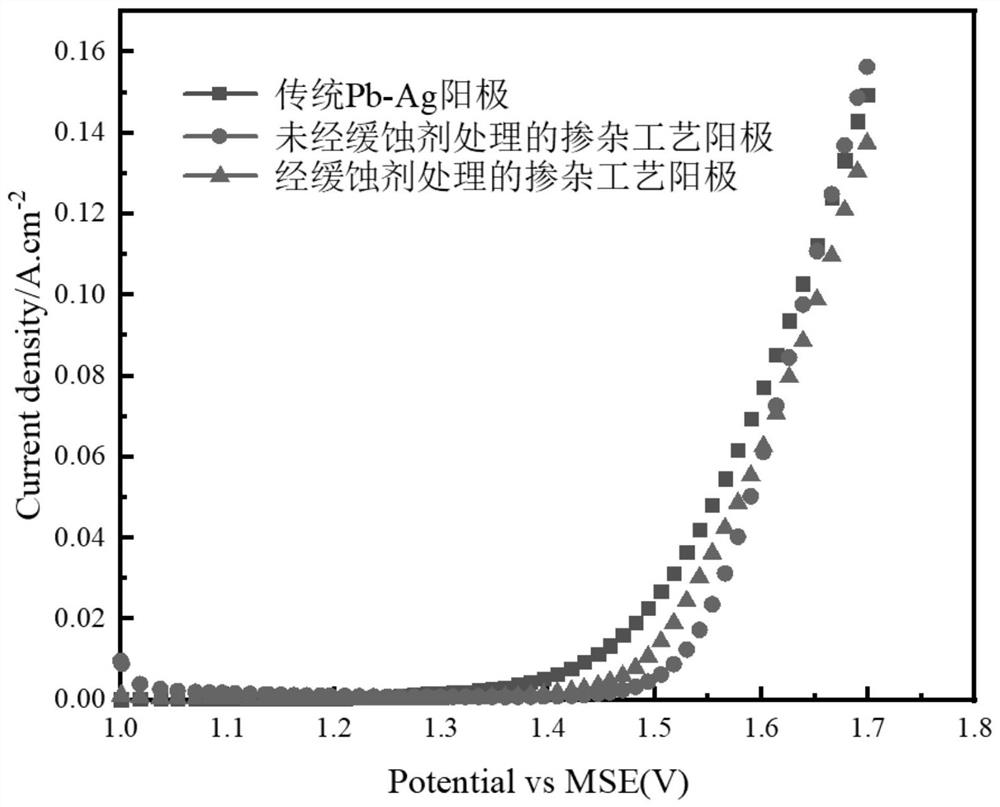

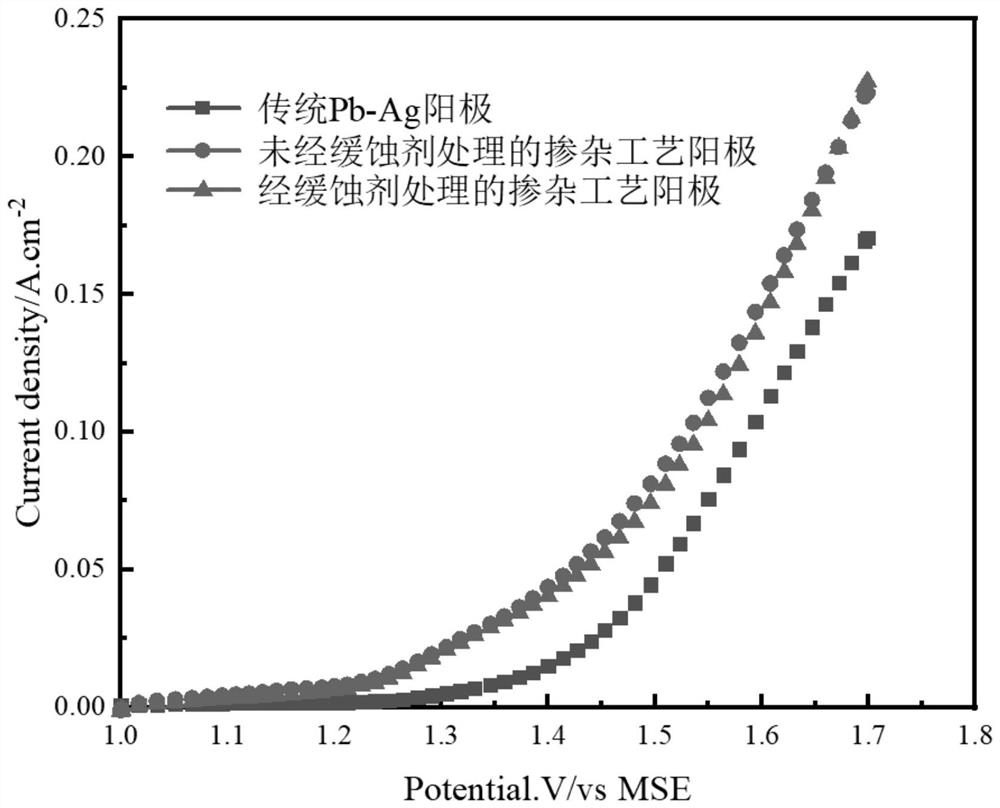

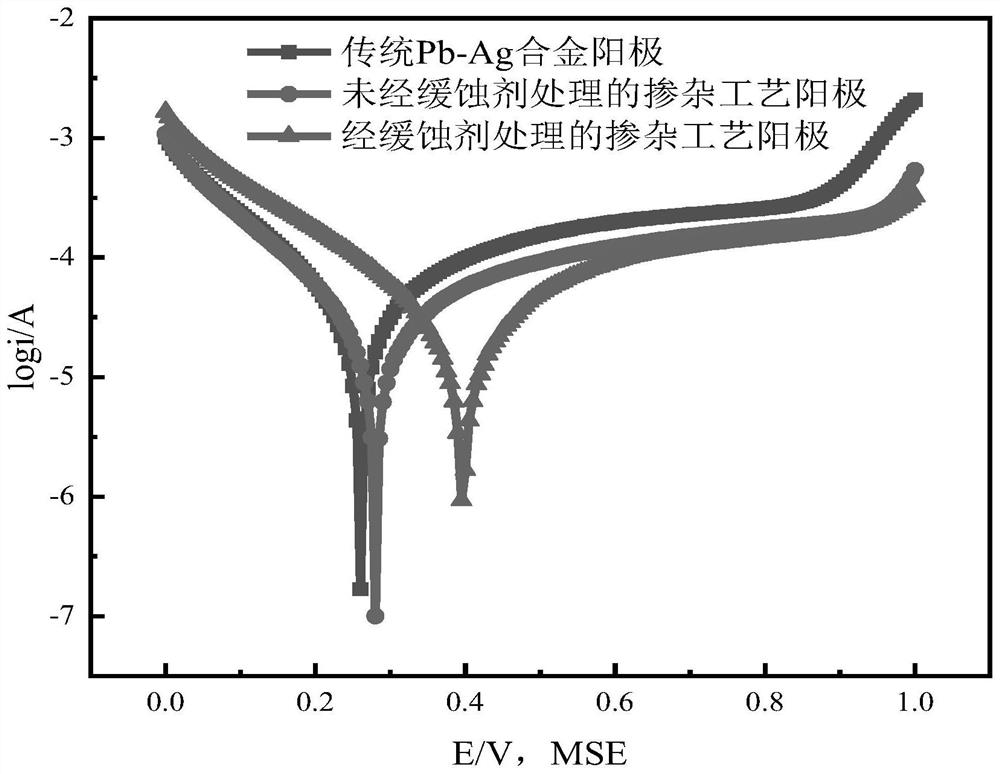

[0041] Example 1: Zinc electrodeposition system suitable for high current density, zinc electrodeposition anode is modified by doping and anti-corrosion surface treatment, additives are added to the electrolyte to improve the current efficiency of zinc electrodeposition under high current density, wherein the additive is Sodium lauryl sulfate, the additive amount of sodium lauryl sulfate in the electrolyte is 0.7mg / L, and the zinc electrowinning electrolyte also contains Zn 2+ 50g / L, H 2 SO 4 150g / L, Mn 2+ 5g / L;

[0042] The specific steps of doping modification are as follows:

[0043] 1) heating and melting lead metal to form lead liquid, adding silver to the lead liquid and smelting at a temperature of 550-560°C to obtain lead-silver alloy melt;

[0044] 2) adding the dopant to the lead-silver alloy melt and melting at a temperature of 550-560°C, adding a refining agent to continue refining at a temperature of 550-560°C, removing scum, and casting to obtain a lead-silv...

Embodiment 2

[0076] Example 2: Zinc electrodeposition system suitable for high current density, zinc electrodeposition anode is modified by doping and anti-corrosion surface treatment, additives that can improve the current efficiency of zinc electrodeposition under high current density are added to the electrolyte, wherein the additive is Hexadecyltrimethylammonium bromide, the additive amount of hexadecyltrimethylammonium bromide in the electrolyte is 0.7mg / L, and the zinc electrowinning electrolyte also contains Zn 2+ 50g / L, H 2 SO 4 150g / L, Mn 2+ 5g / L;

[0077] The specific steps of doping modification are as follows:

[0078] 1) heating and melting lead metal to form lead liquid, adding silver into the lead liquid and smelting at a temperature of 600-650°C to obtain a lead-silver alloy melt;

[0079] 2) adding the dopant to the lead-silver alloy melt and melting at a temperature of 620-660°C, adding a refining agent to continue refining at a temperature of 620-660°C, removing scu...

Embodiment 3

[0105] Example 3: Zinc electrowinning system suitable for high current density, zinc electrowinning anode is modified by doping and corrosion-inhibiting surface treatment, and an additive that improves the current efficiency of zinc electrowinning at high current density is added to the electrolyte, wherein the additive is Strontium carbonate, the additive (strontium carbonate) in the electrolyte is added in an amount of 0.7mg / L, and the zinc electrowinning electrolyte also contains Zn 2+ 50g / L, H 2 SO 4 150g / L, Mn 2+ 5g / L;

[0106] The specific steps of doping modification are as follows:

[0107] 1) heating and melting lead metal to form lead liquid, adding silver to the lead liquid and smelting at a temperature of 500-550°C to obtain a lead-silver alloy melt;

[0108] 2) adding the dopant to the lead-silver alloy melt and melting at a temperature of 520-560°C, adding a refining agent to continue refining at a temperature of 520-560°C, removing scum, and casting to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com