Flux-cored silver solder

A technology of silver solder and flux core, applied in welding/cutting medium/material, welding medium, metal processing equipment, etc., can solve problems such as fracture of flux cored silver solder, broken wire phenomenon, plastic matching of silver solder, etc. Achieve the effect of improving market competitiveness, reducing material costs, and stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

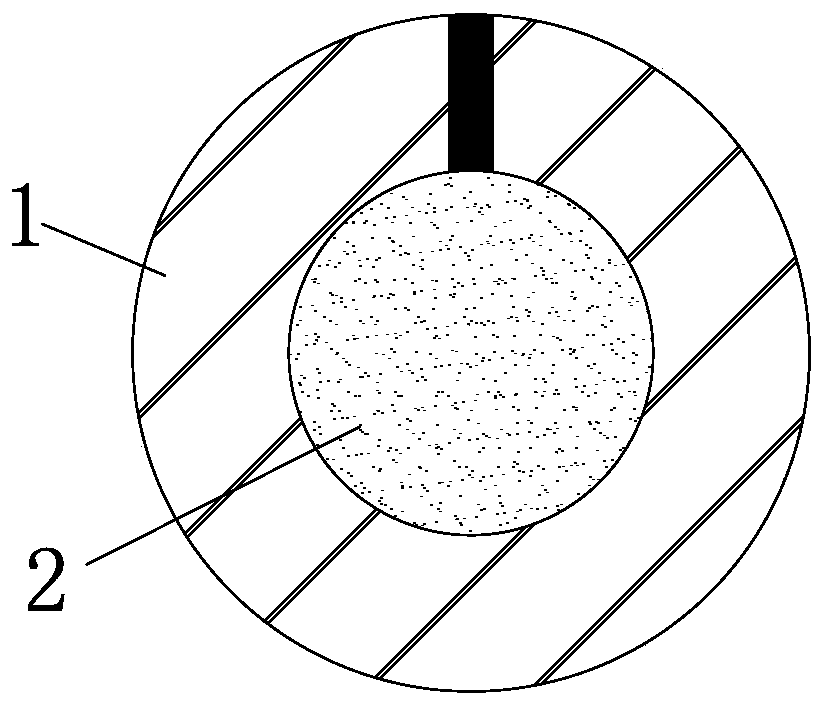

[0048] This embodiment discloses a kind of flux cored silver solder, such as figure 1 As shown, it includes a metal cladding layer 1 and a flux core 2, and the flux core 2 is inside the metal cladding layer 1;

[0049] The metal cladding layer 1 is a BAg18CuZnSn silver solder strip, which includes the following substances in terms of mass fraction: 17.0% Ag, 44.0% Cu, 2.0% Sn, and the balance is Zn.

[0050] The flux core 2 includes the following substances according to the mass fraction: Potassium Hydrogen Fluoride (KHF 2 ) is 36%, potassium fluoride is 20%, boric acid is 33%, cesium fluoride is 0.1%, potassium carbonate is 2.0%, potassium silicate is 0.3%, sodium silicate is 0.3%, dipotassium hydrogen phosphate is 0.001 %, the balance is potassium fluoroborate (KBF 4 ).

[0051] The ratio of potassium silicate to sodium silicate is 1:1.

[0052] The mass of flux powder accounts for 18% of the mass of the whole low-silver cored silver solder.

[0053] The preparation met...

Embodiment 2

[0060] This embodiment discloses a kind of flux cored silver solder, such as figure 1 As shown, it includes a metal cladding layer 1 and a flux core 2, and the flux core 2 is inside the metal cladding layer 1;

[0061] The metal cladding layer 1 is a BAg18CuZnSn silver solder strip, which includes the following substances in terms of mass fraction: 19.0% Ag, 38.0% Cu, 2.5% Sn, and the balance is Zn.

[0062] The flux core 2 includes the following substances according to the mass fraction: Potassium Hydrogen Fluoride (KHF 2 ) is 40%, potassium fluoride is 16%, boric acid is 30%, cesium fluoride is 0.5%, potassium carbonate is 1.0%, potassium silicate is 1.2%, sodium silicate is 1.2%, dipotassium hydrogen phosphate is 0.01 %, the balance is potassium fluoroborate (KBF 4 ).

[0063] The ratio of potassium silicate to sodium silicate is 1:1.

[0064] The mass of flux powder accounts for 32% of the mass of the whole low-silver cored silver solder.

[0065] Using BAg18CuZnSn si...

Embodiment 3

[0069] This embodiment discloses a kind of flux cored silver solder, such as figure 1 As shown, it includes a metal cladding layer 1 and a flux core 2, and the flux core 2 is inside the metal cladding layer 1;

[0070] The metal cladding layer 1 is a BAg18CuZnSn silver solder strip, which includes the following substances in terms of mass fraction: 18.0% Ag, 41.0% Cu, 2.2% Sn, and the balance is Zn.

[0071] The flux core 2 includes the following substances according to the mass fraction: Potassium Hydrogen Fluoride (KHF 2 ) is 38%, potassium fluoride is 18%, boric acid is 31%, cesium fluoride is 0.2%, potassium carbonate is 1.5%, potassium silicate is 1.0%, sodium silicate is 1.0%, dipotassium hydrogen phosphate is 0.005 %, the balance is potassium fluoroborate (KBF 4 ).

[0072] The ratio of potassium silicate to sodium silicate is 1:1.

[0073] The mass of flux powder accounts for 22% of the mass of the whole low-silver cored silver solder.

[0074] Using 6mm wide and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

| Wire diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com