Patents

Literature

45 results about "Caesium fluoride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Caesium fluoride or cesium fluoride is an inorganic compound usually encountered as a hygroscopic white solid. It is used in organic synthesis as a source of the fluoride anion. Caesium has the highest electropositivity of all non-radioactive elements and fluorine has the highest electronegativity of all elements.

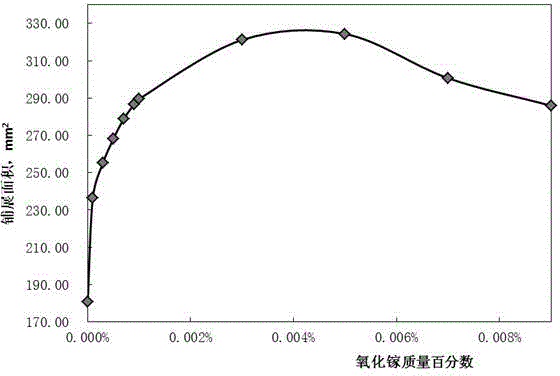

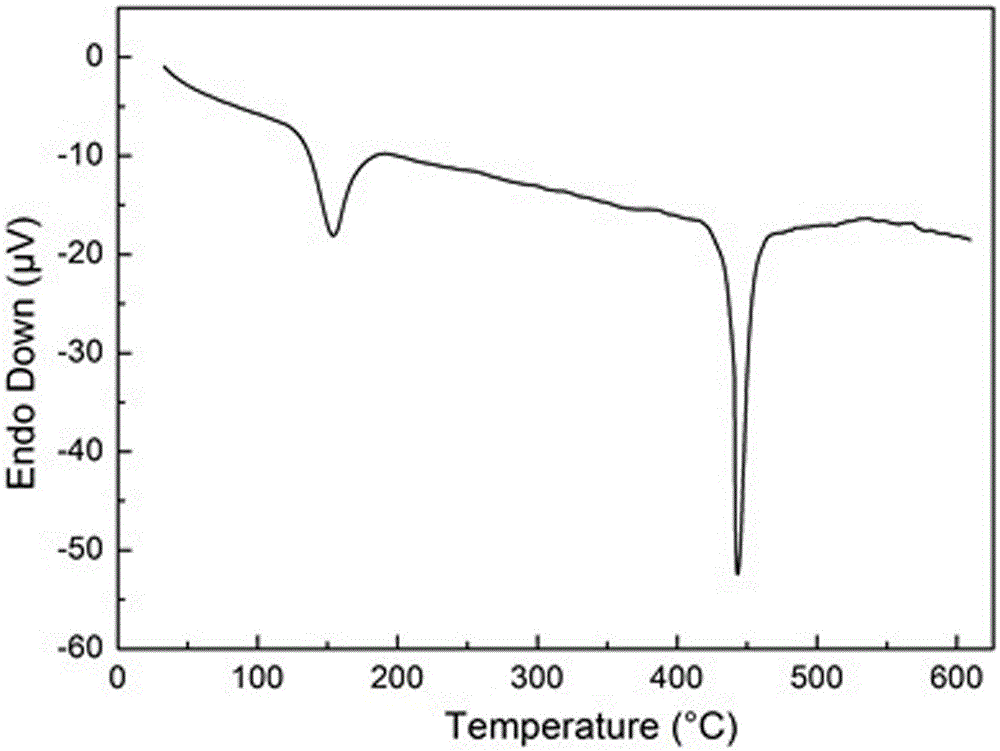

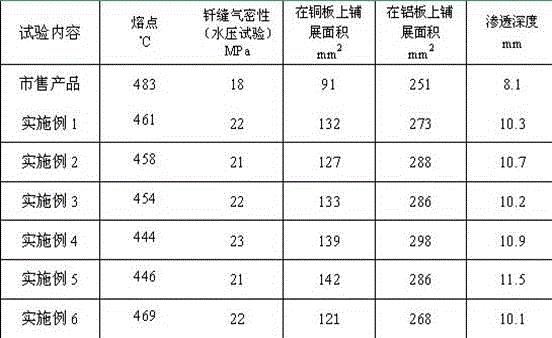

Brazing aluminum steel and cesium and rubidium containing brazing flux thereof

ActiveCN103909359ALow costImprove reliabilityWelding/cutting media/materialsSoldering mediaAluminum fluorideRubidium

The invention relates to brazing aluminum steel and a cesium and rubidium containing brazing flux thereof and belongs to the field of brazing materials in non-metal materials. The brazing flux comprises, by a mole ratio, 0.01 mol to 0.56 mol of rubidium fluoride (RbF), 0.15 mol to 0.58 mol of cesium fluoride (CsF), 0.001 mol to 0.25 mol of aluminum oxide (Al2O3), 0.001 mol to 0.2 mol of potassium fluoride (KF), 0.002 mol to 0.05 mol of gallium fluoride (GaF3), 0.001 mol to 0.025 mol of lithium fluoride (LiF), 0.001 mol to 0.025 mol of boron fluoride (BF3), and the balance aluminum fluoride (AlF3). According to the brazing aluminum steel and a cesium and rubidium containing brazing flux thereof, brazing technical requirements of aluminum to aluminum, aluminum to copper, and aluminum to steel can be simultaneously met, and the high-activity novel soldering flux is achieved.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

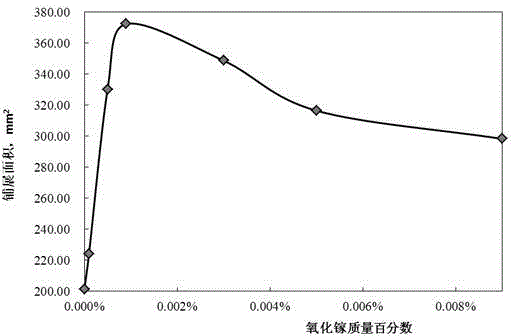

Caesium rubidium soldering flux containing gallium oxide

ActiveCN104551450ASatisfy brazing requirementsGood spreadabilityWelding/cutting media/materialsSoldering mediaRubidiumAluminium fluoride

The invention discloses a caesium rubidium soldering flux containing gallium oxide, belonging to the brazing material field of non-metallic materials. The caesium rubidium soldering flux containing gallium oxide is characterized in that the caesium rubidium soldering flux containing gallium oxide comprises the following components in proportion in mole number: 0.12-0.5 mole of rubidium fluoride (RbF), 0.12-0.5 mole of cesium fluoride (CsF), 0.001-0.2 mole of aluminium oxide (Al2O3), 0.001-0.02 mole of potassium fluoride (KF), 0.0001-0.02 mole of gallium oxide (Ga2O3), and 0.159-0.479 mole of aluminium fluoride (AlF3). According to the caesium rubidium soldering flux containing the gallium oxide, the requirement on brazing the aluminium-copper, the aluminium-steel and the aluminium-aluminium can be satisfied simultaneously and the caesium rubidium soldering flux containing gallium oxide has high activity.

Owner:ZHEJIANG YONGWANG WELDING MATERIALS CO LTD

Self-brazing material for welding aluminum-copper member

ActiveCN102935558ALow melting pointHigh melting pointWelding/cutting media/materialsSoldering mediaYarnPotassium fluoride

The invention discloses a self-brazing material for welding an aluminum-copper member. The self-brazing material comprises the following components: 12-15 percent of fluoride (30-80 percent of aluminum fluoride, 5-35 percent of caesium fluoride and the balance of potassium fluoride), 0.01-0.3 percent of hafnium, 0.01-0.8 percent of germanium, 0.05-2 percent of nickel, 0.8-3 percent of copper, 5-17 percent of silicon and the balance of aluminum. The self-brazing material is prepared through the following steps of: smelting and atomizing the raw materials of hafnium, the germanium, the nickel, the copper, the silicon and the aluminum in a vacuum furnace into fine powder; and then uniformly mixing with the fluoride, pressing into a composite ingot, directly extruding the composite ingot into a yarn or pipe, and winding the yarn into a coil or cutting the pipe into a ring to obtain the self-brazing material. The self-brazing material disclosed by the invention has the advantages that trace elements of Ge and Hf are introduced on the basis of the traditional Al-Si-Cu-Ni alloy system brazing material, so that the brazing material smelting temperature is lowered, the burning loss of an aluminum base material during welding is favorably avoided, the strength and plasticity of the brazing material are improved, the mechanical property of a brazing joint is favorably improved, and the improvement of the plasticity of the brazing material can ensure that the production efficiency is increased.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

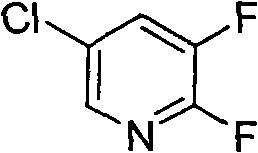

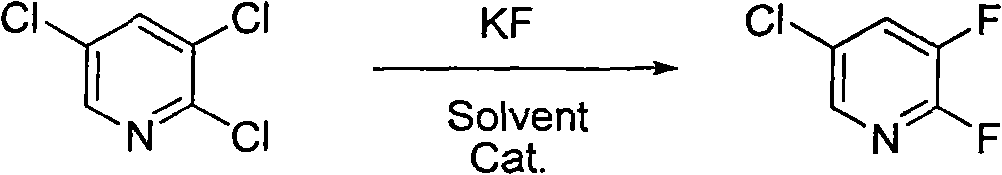

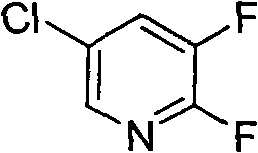

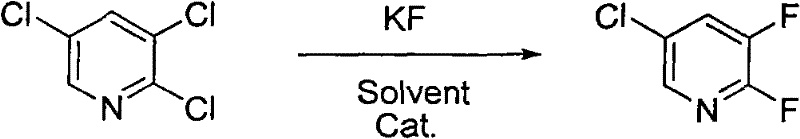

Synthesis method of 2,3-difluoro-5-chloropyridine

InactiveCN101648904AReduce usageSolve the shortcomings of low yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsOrganic solventPotassium fluoride

The invention discloses a synthesis method of 2,3-difluoro-5-chloropyridine, and the method comprises the following steps: in organic solvent, adopting 2,3,5-trichlopyridine and potassium fluoride asraw materials and tetraphenylphosphonium bromide or tetrabutylphosphonium bromide as phase transfer catalyst, keeping temperature at 180-190 DEG C for 5-10h under the protection of inert gas and keeping temperature at 200-210 DEG C for 10-15h to prepare 2,3-difluoro-5-chloropyridine. The synthesis method of 2,3-difluoro-5-chloropyridine of the invention adopts cheap and accessible potassium fluoride as fluorinating agent and adds phase transfer catalyst and controls the reaction temperature to prepare high yield 2,3-difluoro-5-chloropyridine, thus avoiding to use more expensive fluorinating agent such as caesium fluoride and the like and solving the defect that the yield of the reaction that potassium fluoride is directly used to perform fluorination is low. The method of the invention hassimple operation and is applicable to the large-scale production of 2,3-difluoro-5-chloropyridine.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

Fluoride brazing flux for copper-aluminum dissimilar metal and preparation method for fluoride brazing flux

ActiveCN103769776AReduce the temperatureLow melting pointWelding/cutting media/materialsSoldering mediaPotassium fluorideCopper fluoride

The invention relates to the field of brazing materials, in particular to fluoride brazing flux for copper-aluminum dissimilar metal and a preparation method for the fluoride brazing flux. The fluoride brazing flux consists of cesium fluoride, aluminum trifluorid, potassium fluoride, copper difluoride and assistant. The preparation method comprises the following steps: mixing the cesium fluoride, the aluminum trifluorid, the potassium fluoride, the copper difluoride, zinc difluoride and lithium fluoride powder with zinc powder or ZnAl alloyed powder in proportion, adding a proper amount of deionized water and grinding in a mortar to form paste, and then, drying and grinding.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

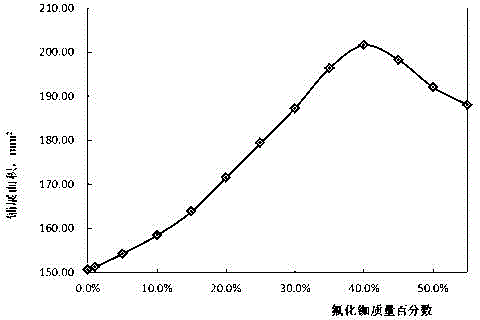

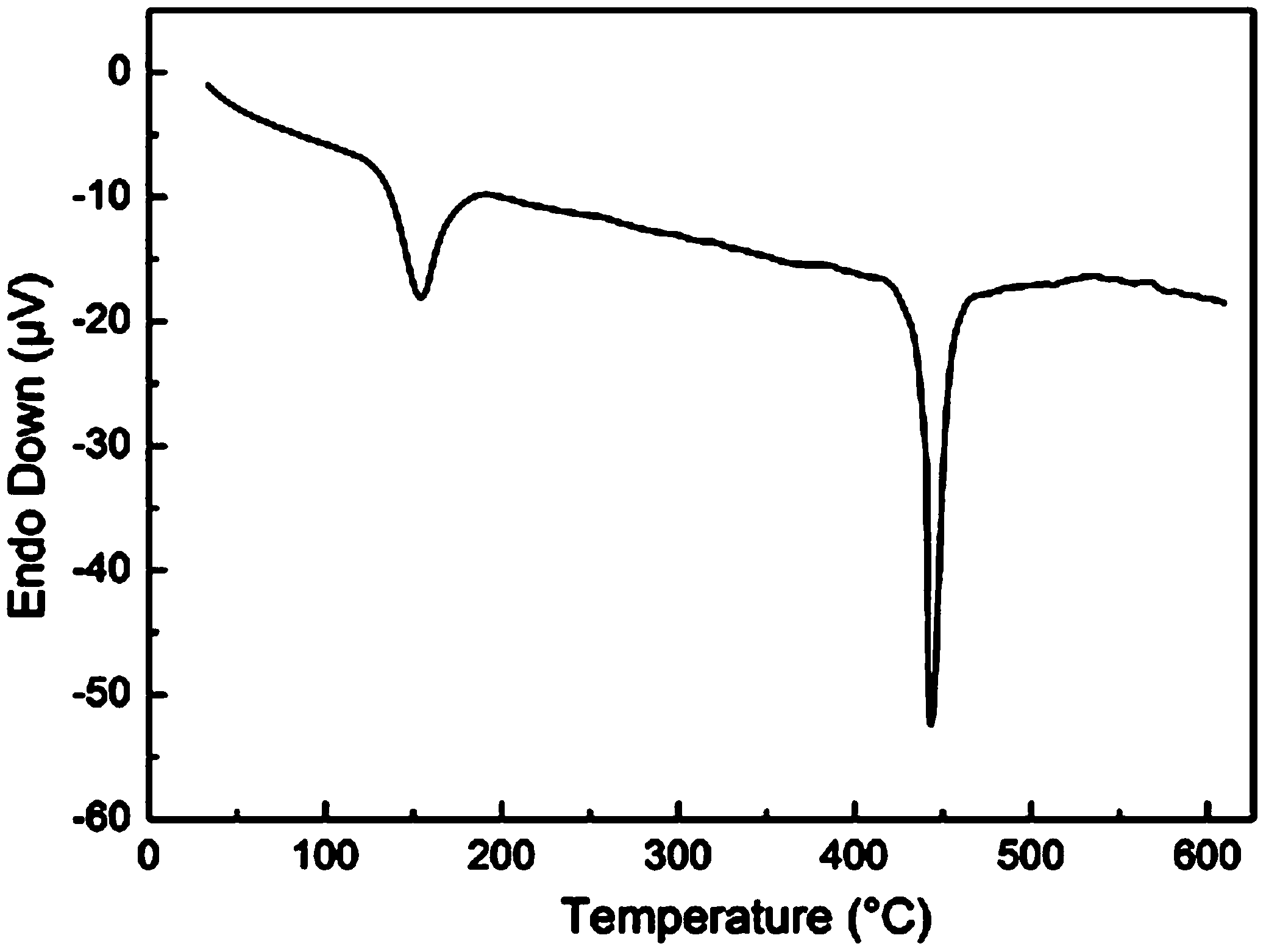

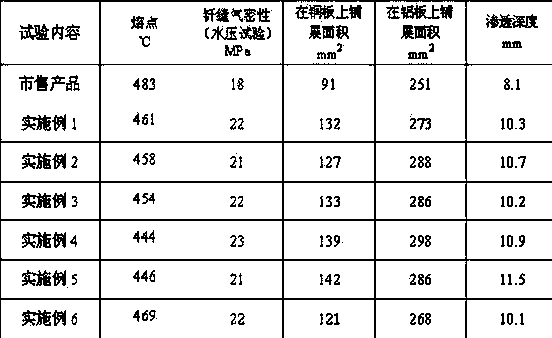

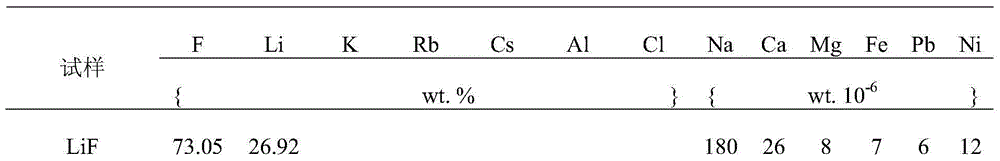

Medium-temperature type anti-corrosion fluoroaluminate soldering flux and preparation method thereof

ActiveCN104816107AIncrease moistureImprove ductilityWelding/cutting media/materialsSoldering mediaRubidiumLepidolite

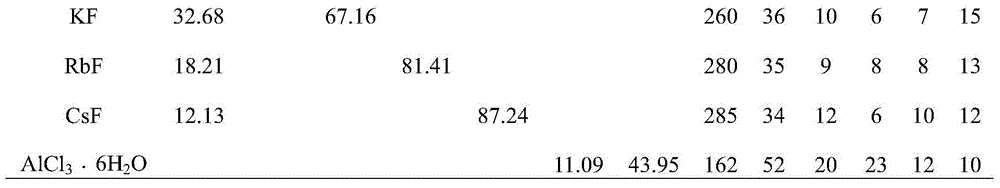

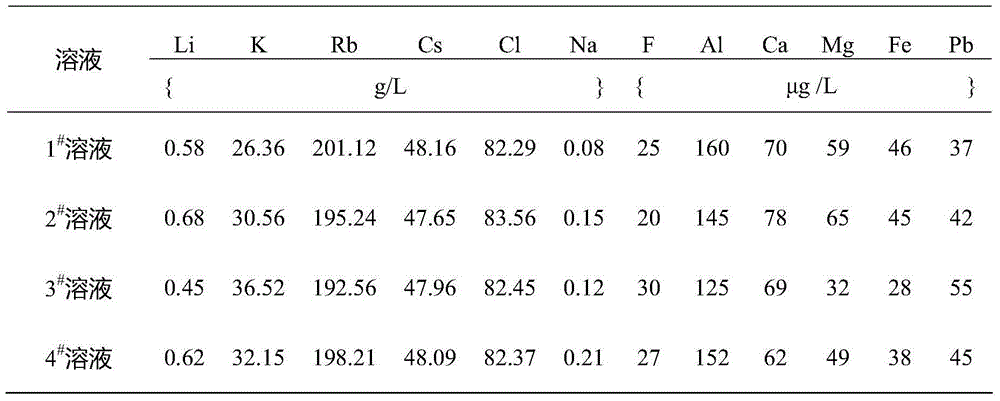

The invention relates to medium-temperature type anti-corrosion fluoroaluminate soldering flux and a preparation method thereof. The soldering flux takes lithium-settling mother liquor obtained by extracting lithium from Jiangxi lepidolite as a base solution; the base solution is subjected to impurity removal to obtain a solution rich in k, Rb and Cs as a raw material solution; one or more of aluminum fluoride, potassium fluoride, rubidium fluoride and cesium fluoride are dosed and added to prepare mixed type soldering flux; the added metal salts can be extracted from the lepidolite. The lepidolite is rich in rubidium and cesium, so that the production cost of the novel soldering flux is greatly reduced, and the Jiangxi lepidolite realizes resource maximum utilization. The medium-temperature type anti-corrosion fluoroaluminate soldering flux is suitable for welding aluminum alloy and high-magnesium alloy, and has special activity on alloy with high magnesium content.

Owner:JIANGXI HZONE LITHIUM TECH

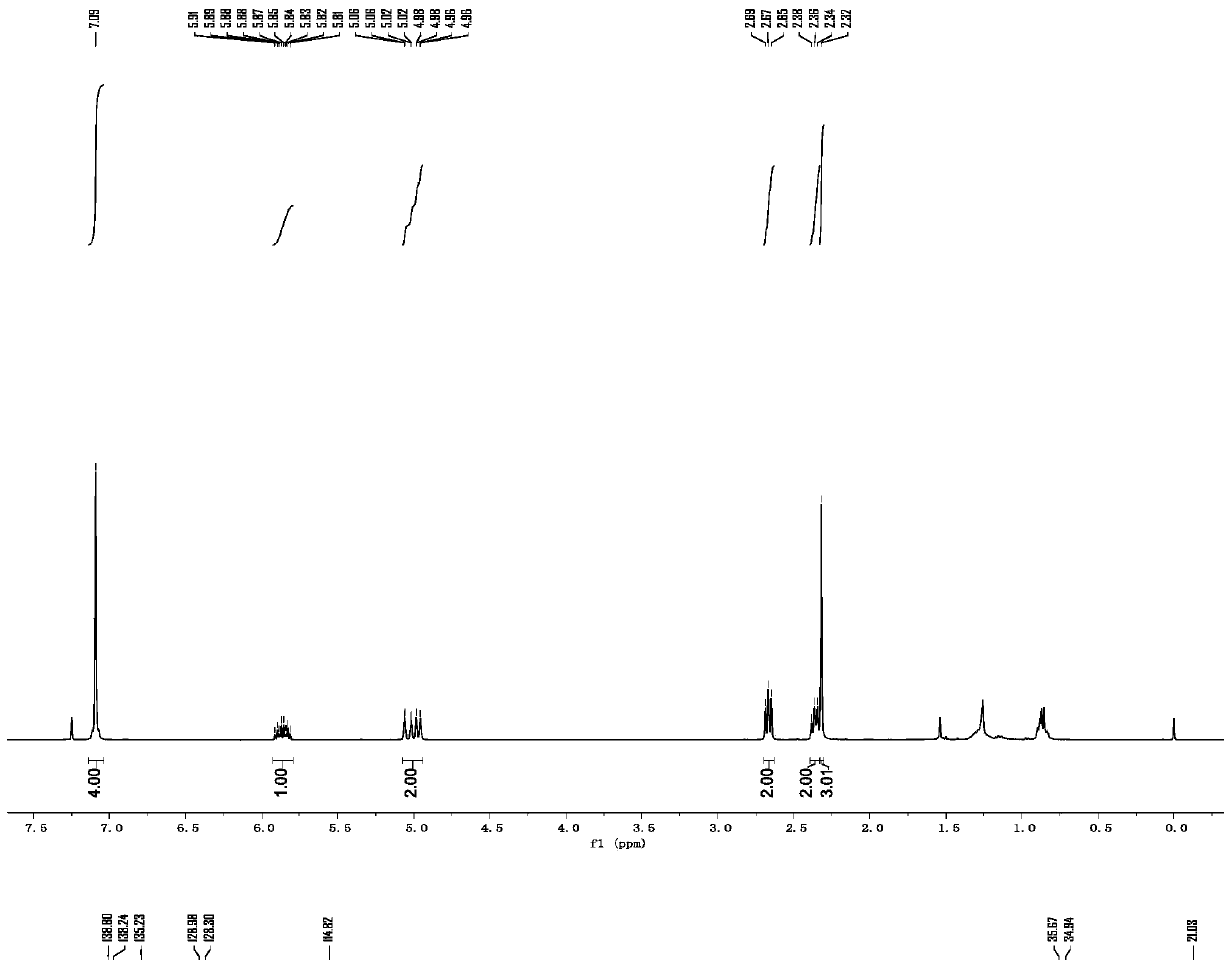

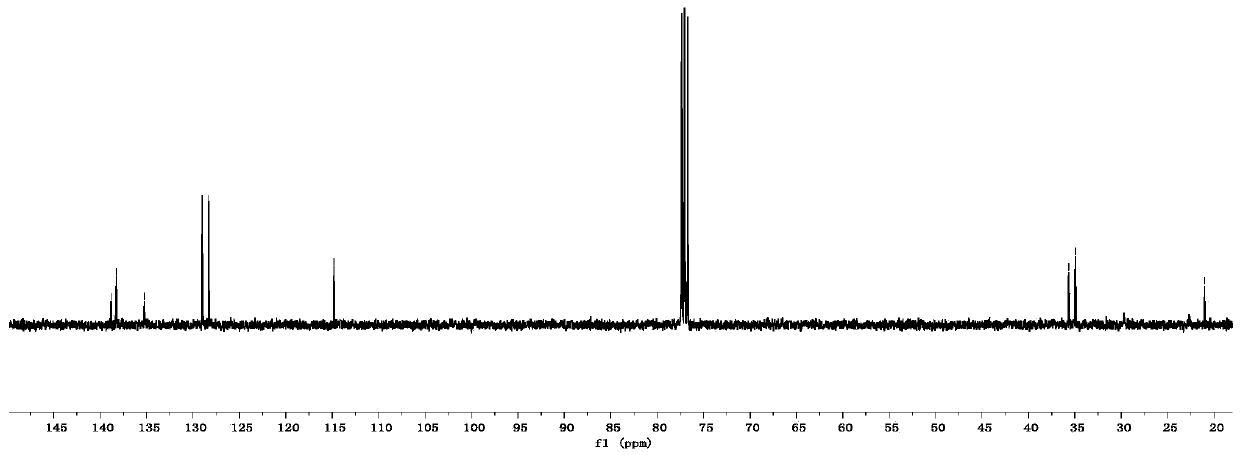

Efficient preparation method of 1-aryl-4-butene compound

ActiveCN111116285AHigh selectivityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationPtru catalystPalladium catalyst

The invention belongs to the technical field of fine chemicals and related chemistry, and provides an efficient preparation method of a 1-aryl-4-butene compound. The 1-aryl-4-butene compound can be obtained by taking halogen-containing methyl aromatic hydrocarbon and derivatives thereof as raw materials, taking cesium fluoride as an alkali in the presence of a palladium catalyst and a ligand and reacting with allyl boronic acid pinacol ester for 12 hours at the temperature of 80-100 DEG C under the condition of an anhydrous organic solvent. The method has the beneficial effects that the selectivity is high, the reaction conditions are mild, the operation is simple and convenient, the possibility of industrialization is realized, and the 1-aryl-4-butene compound is obtained at a relativelyhigh yield; the 1-aryl-4-butene compound synthesized by the method can be further functionalized to obtain various compounds, and is applied to development and research of natural products, functionalmaterials and fine chemicals.

Owner:DALIAN UNIV OF TECH

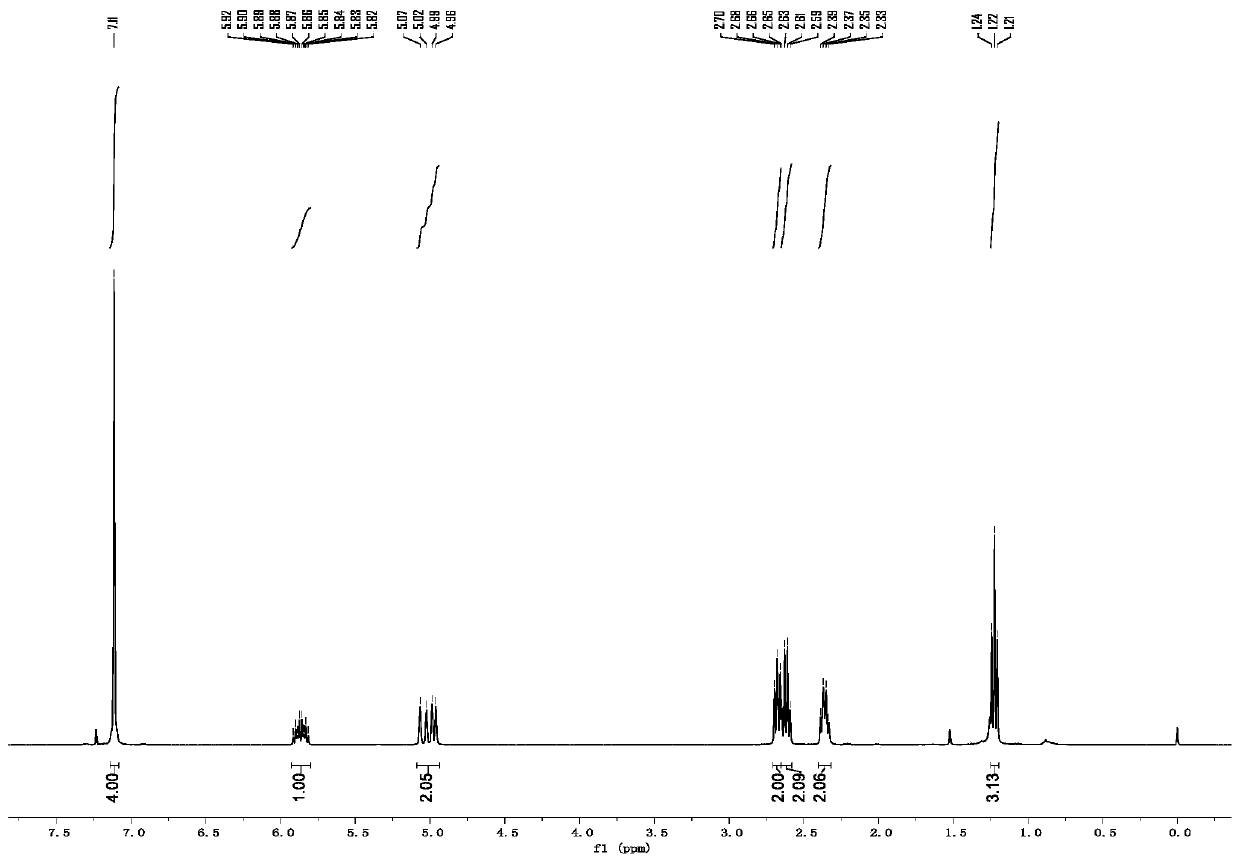

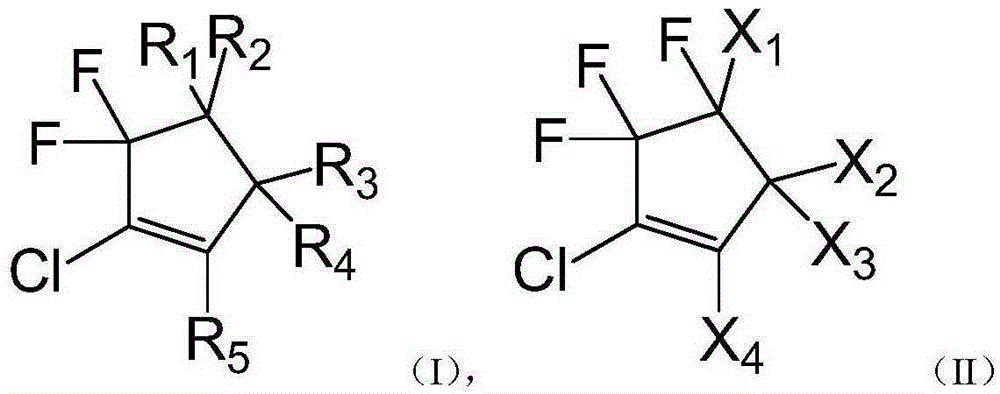

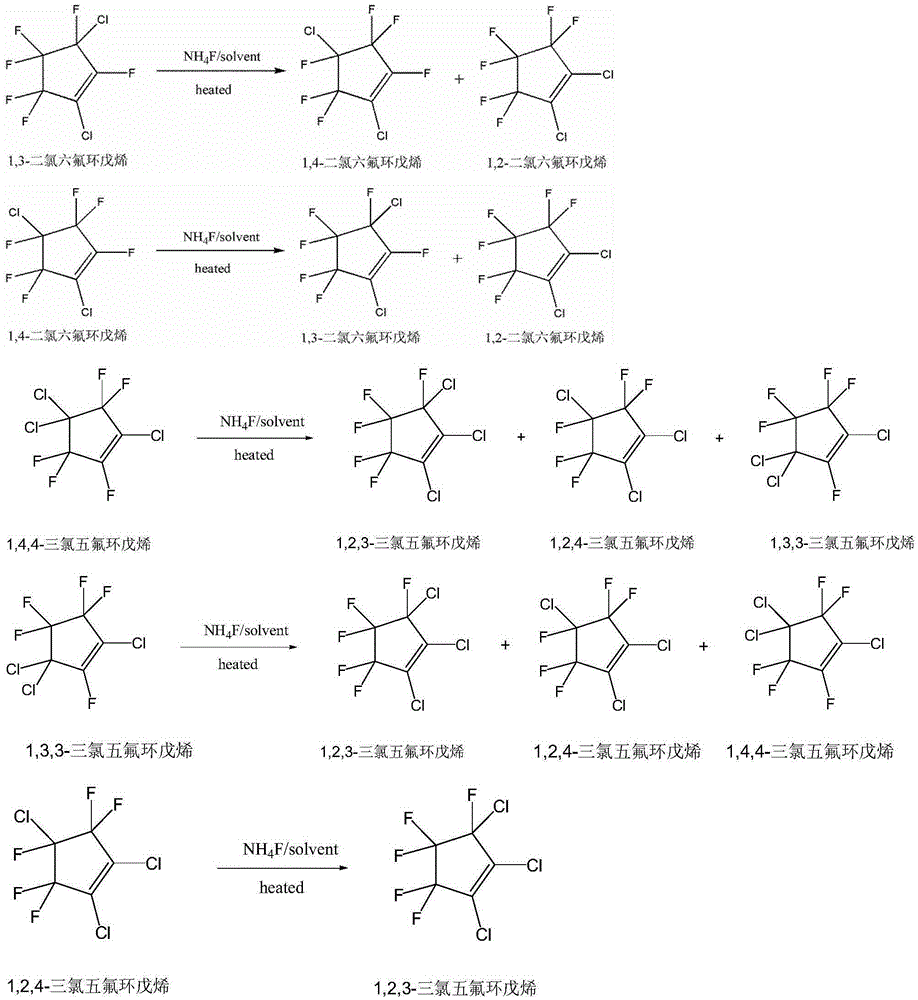

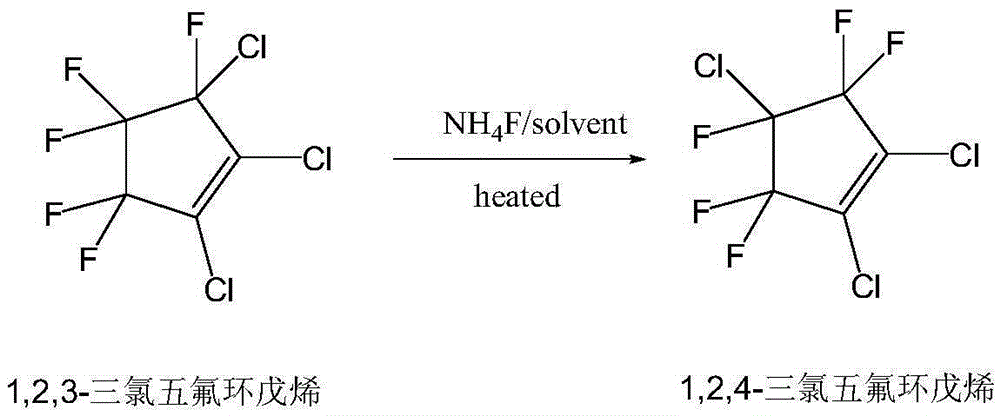

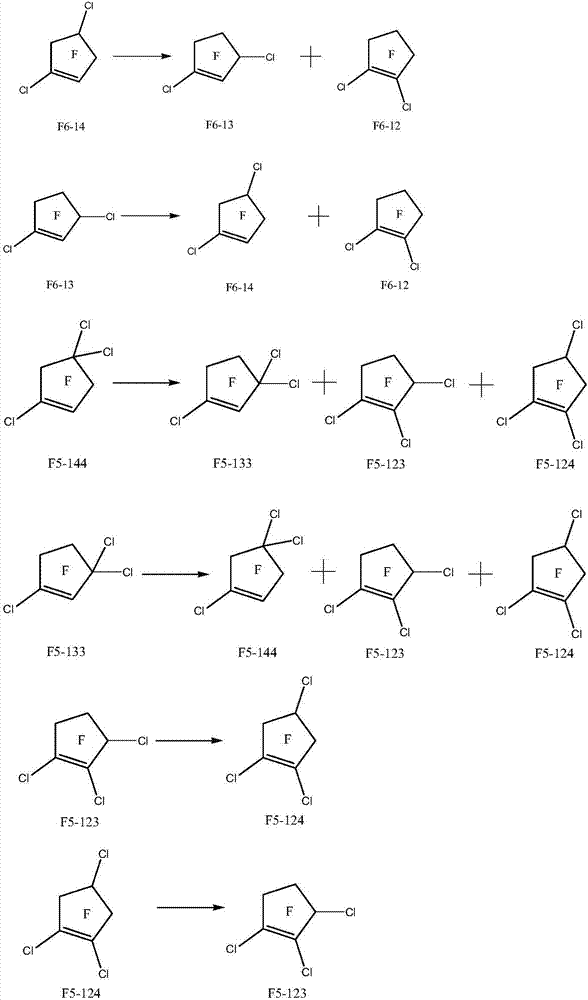

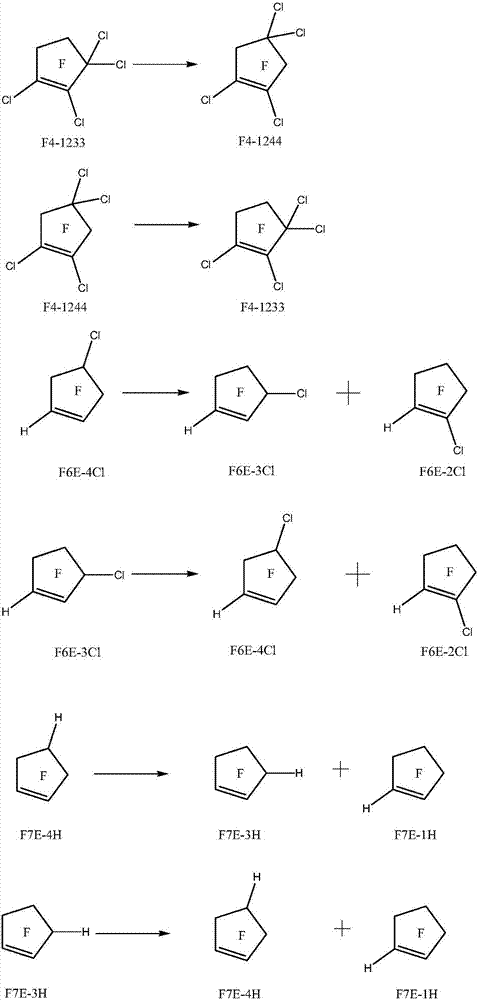

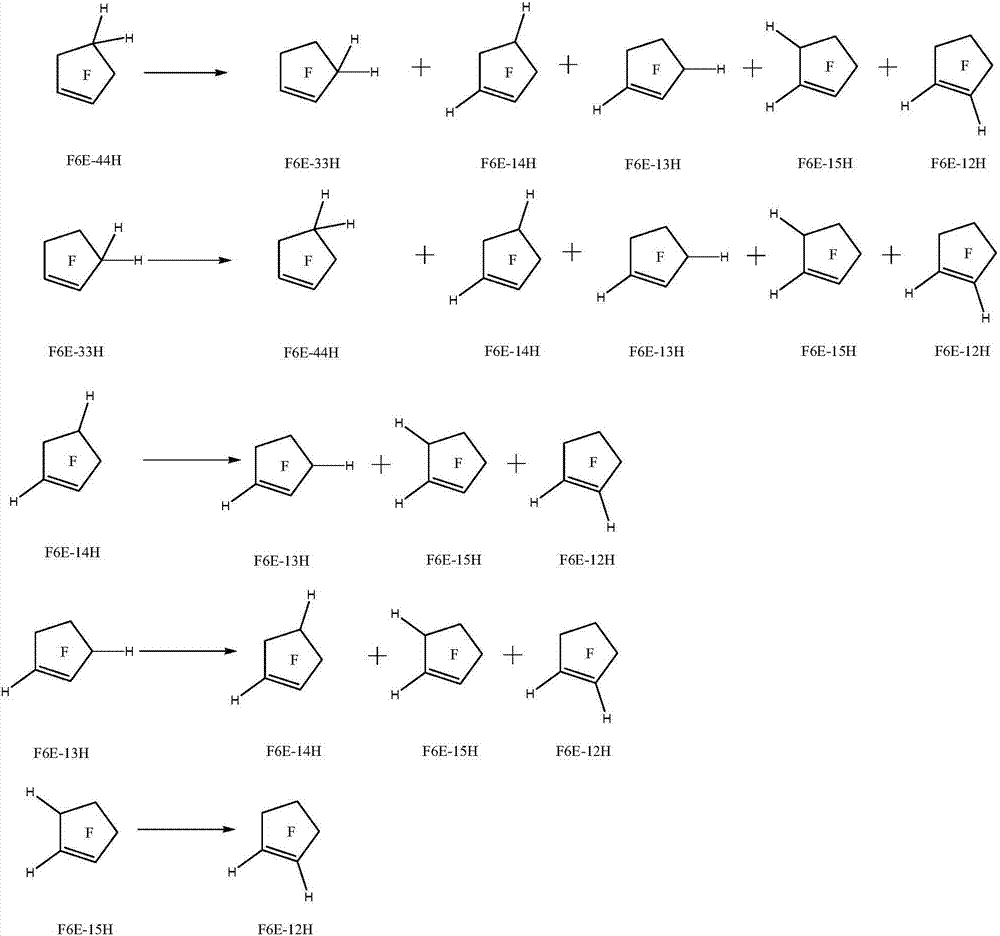

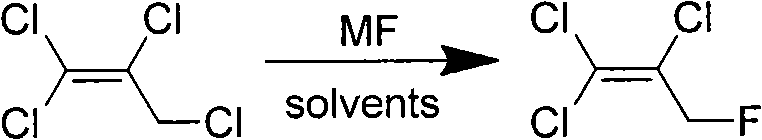

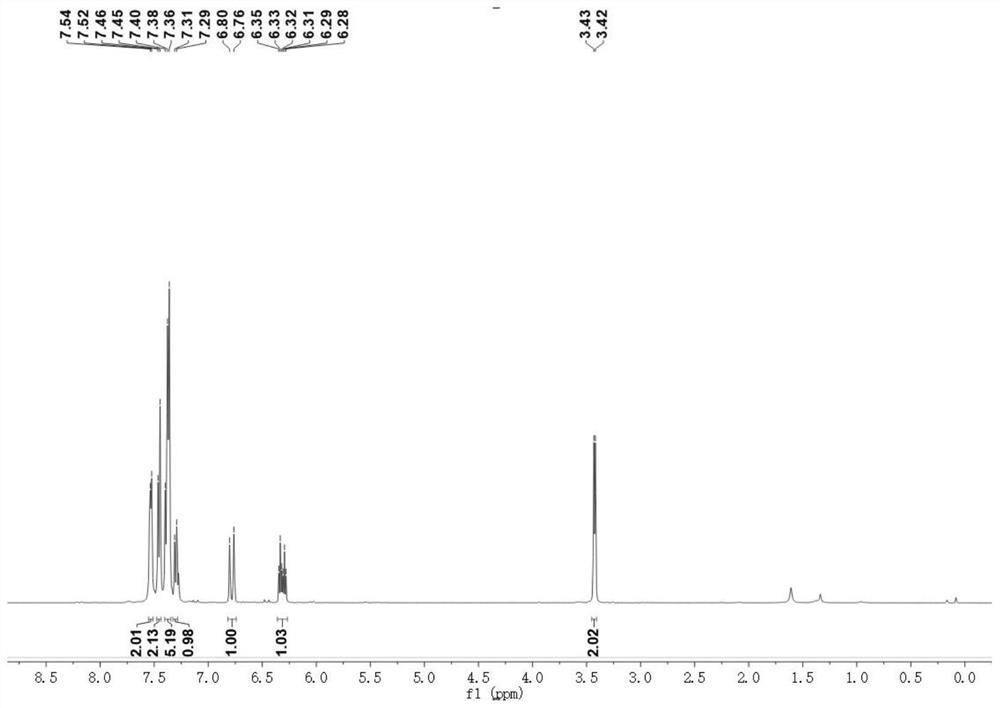

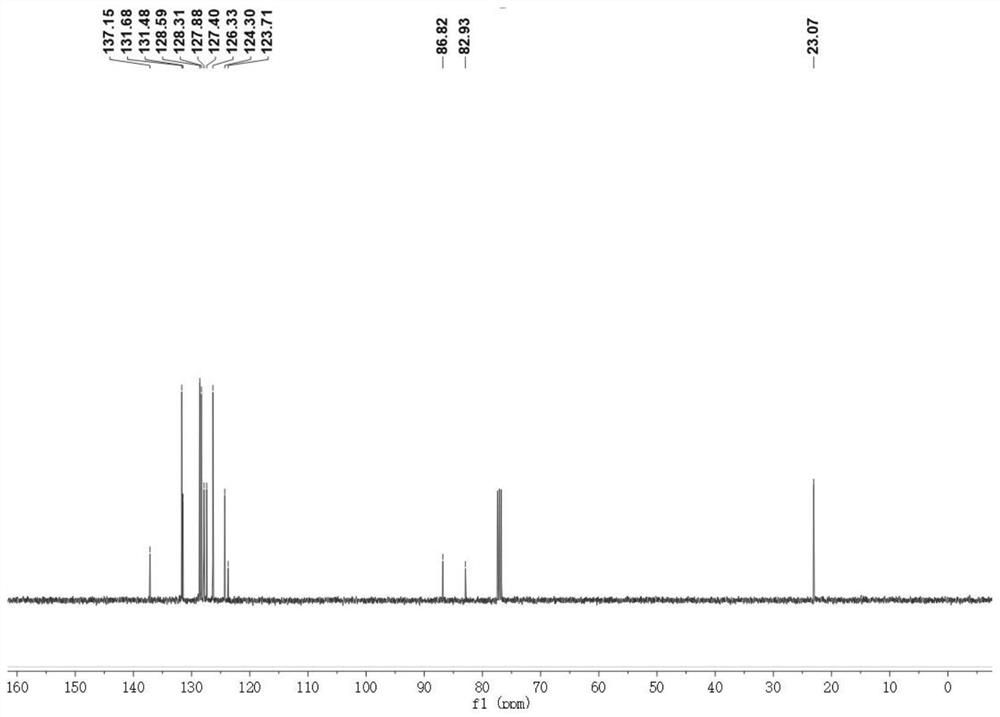

Method for preparing chlorine fluorine cyclopentene isomeride

The invention relates to a method for preparing chlorine fluorine cyclopentene isomeride in the formula (II) (please see the formula in the specification). The chlorine fluorine cyclopentene isomeride is obtained with chlorine fluorine cyclopentene in the formula (I) (please see the formula in the specification) as the raw material in solvent dimethylformamide, dimethyl sulfoxide or sulfolane by conducting an isomerization reaction in catalysts ammonium fluoride, ammonium bifluoride, potassium fluoride, lithium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride. The technological method is little in raw material toxicity and mild in reaction conditions, the reaction is easy to control, the isomeride yield of chlorine fluorine cyclopentene is high, and industrialization is easy.

Owner:BEIJING YUJI SCI & TECH +1

Method for preparing halogenated pentacyclic olefin by gas-phase isomerization reaction

ActiveCN107445794ARaw materials are easy to getPhysical/chemical process catalystsHalogenated hydrocarbon preparationIsomerizationGas phase

The invention relates to a method for preparing halogenated pentacyclic olefin by gas-phase isomerization reaction. The method comprises the following steps of: by adopting the halogenated pentacyclic olefin C5HxFyClz as a material, under the existence of an isomerization catalyst, generating the gas-phase isomerization reaction to obtain isomers of the halogenated pentacyclic olefin, wherein X is an integer from 0 to 2, Y is an integer from 4 to 7, Z is an integer from 0 to 4, the sum of X and Y and Z is 8, and the isomerization catalyst is prepared by adopting at least one of lithium fluoride, potassium fluoride, sodium fluoride, rubidium fluoride or cesium fluoride as an active component and loading the active component on at least one of carriers such as aluminium fluoride, magnesium fluoride, iron fluoride, chromium fluoride and zinc fluoride. The method has the advantages that the material is easy to obtain, the isomerization catalyst is low in price, the yield of the isomer is higher, and the method is applicable to large-scale preparation of the isomers of the halogenated pentacyclic olefin by gas-phase reaction.

Owner:BEIJING YUJI SCI & TECH

Brazing flux without corrosion for aluminum and aluminum alloy brazing

InactiveCN101439449BLow melting pointExcellent brazeabilityWelding/cutting media/materialsSoldering mediaPotassium fluorideAluminium fluoride

The invention relates to a corrosion-free soldering flux used for braze welding aluminium and aluminium alloy. Counted by weight percentage, the soldering flux used for braze welding the aluminium and aluminium alloy comprises the following components: 32.0-34.0 percent of cesium fluoride, 44.0-46.5 percent of aluminium fluoride, 20.5-23.5 percent of potassium fluoride, 0.5-2.5 percent of one, two or three materials selected from tin fluoride, zinc fluoride and lithium fluoride. The corrosion-free soldering flux of the invention has low melting point and better soldering performance.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

Synthesis method of 2,3-difluoro-5-chloropyridine

InactiveCN101648904BReduce usageSolve the shortcomings of low yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPotassium fluorideSynthesis methods

The invention discloses a synthesis method of 2,3-difluoro-5-chloropyridine, and the method comprises the following steps: in organic solvent, adopting 2,3,5-trichlopyridine and potassium fluoride as raw materials and tetraphenylphosphonium bromide or tetrabutylphosphonium bromide as phase transfer catalyst, keeping temperature at 180-190 DEG C for 5-10h under the protection of inert gas and keeping temperature at 200-210 DEG C for 10-15h to prepare 2,3-difluoro-5-chloropyridine. The synthesis method of 2,3-difluoro-5-chloropyridine of the invention adopts cheap and accessible potassium fluoride as fluorinating agent and adds phase transfer catalyst and controls the reaction temperature to prepare high yield 2,3-difluoro-5-chloropyridine, thus avoiding to use more expensive fluorinating agent such as caesium fluoride and the like and solving the defect that the yield of the reaction that potassium fluoride is directly used to perform fluorination is low. The method of the invention has simple operation and is applicable to the large-scale production of 2,3-difluoro-5-chloropyridine.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

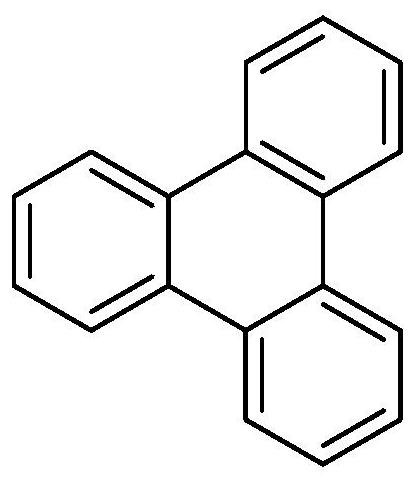

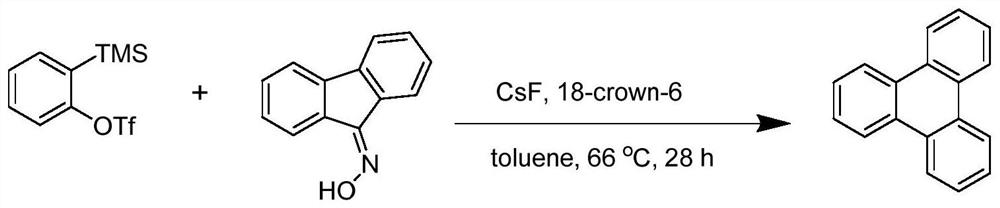

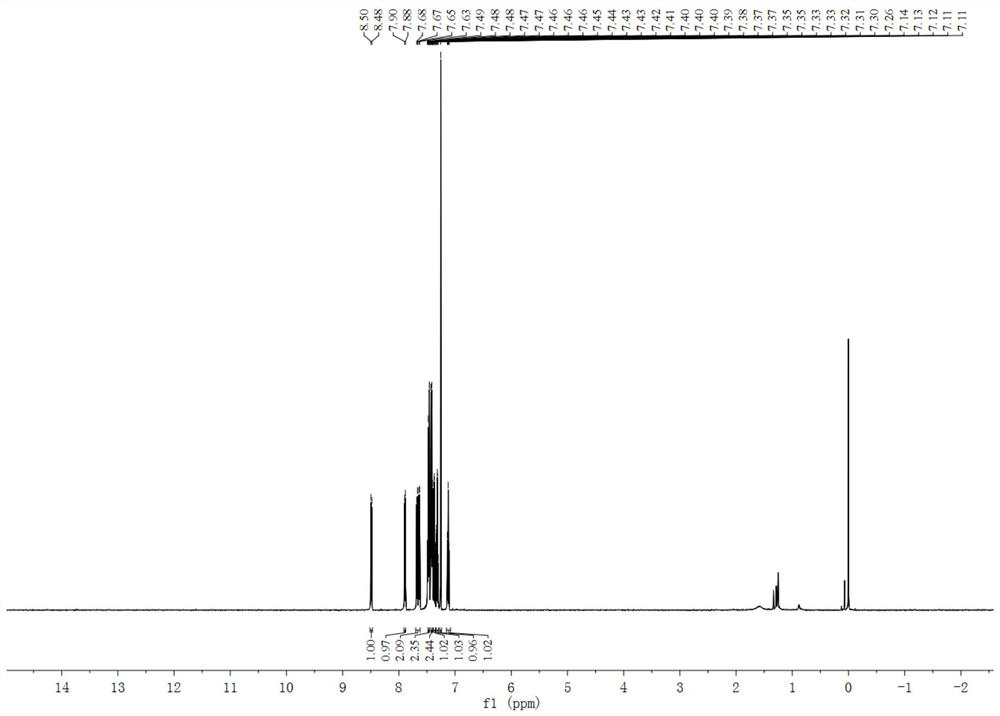

Synthesis method of triphenylene compound

ActiveCN111675591AMild reaction conditionsEasy to implementHydrocarbonsHydrocarbon preparationPtru catalystBenzo(c)phenanthrene

The invention provides a synthesis method of a triphenylene compound. By taking 2-(trimethylsilyl)phenyl trifluoromethane sulfonate as a benzyne precursor, cesium fluoride as an alkali and 18-crown-6-ether as a phase transfer catalyst, a reaction of the precursor with 9-fluorenone oxime under the condition of no additional metal catalyst is realized through a one-pot process reaction. The reactioncondition is mild and easy to realize, the reaction overcomes the defect that transition metal or noble metal catalysts are required to be added in the previous reaction, and a brand-new way is provided for developing the triphenylene compound.

Owner:ANHUI NORMAL UNIV

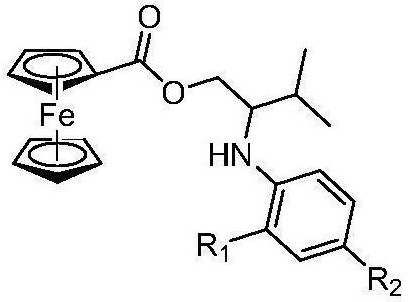

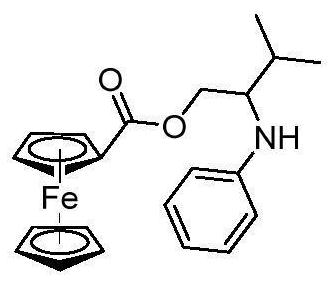

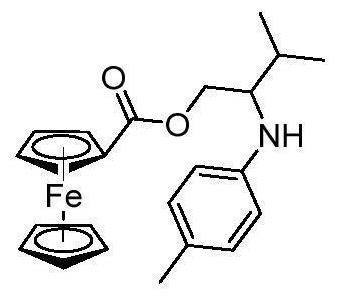

Ferrocenyl-containing arylamine compound and synthesis method thereof

ActiveCN111662339AAtom economy is highOvercome the substrateChemical recyclingMetallocenesPtru catalystTriflic acid

The invention provides a ferrocenyl-containing arylamine compound and a synthesis method thereof. A trifluoromethanesulfonic acid-2-(trimethylsilyl) phenyl ester compound is used as a benzyne precursor, cesium fluoride is used as an alkali, 18-crown-6-ether is used as a phase transfer catalyst, and a ferrocenyl arylamine structural unit is efficiently constructed through a one-pot reaction under the condition of no additional metal catalyst. The reaction overcomes the defects that a transition metal or noble metal catalyst needs to be added in the conventional reaction, the requirements on a substrate and reaction conditions are harsh and the like, the reaction is simple in substrate synthesis, reagents are easy to obtain, target molecules are obtained simply and quickly with high atom economy, and a brand-new way is provided for developing the ferrocenyl-containing arylamine compound.

Owner:ANHUI NORMAL UNIV

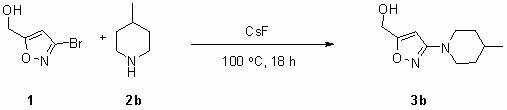

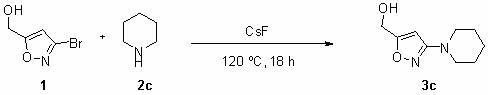

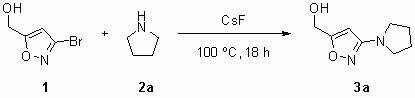

Synthesizing method for N, N-double substitution-3-amino isoxazole-5-methanol compound

ActiveCN102558083AReduce usageMild reaction conditionsOrganic chemistryCombinatorial chemistryPyrrolidine

The invention relates to a synthesizing method for an N, N-double substitution-3-amino isoxazole-5-methanol compound, and mainly solves the technical problems of long procedure, rigorous reaction conditions, toxic reagent using and the like in the conventional synthesis method. The synthesizing method for N, N-double substitution-3-amino isoxazole-5-methanol compound in the invention comprises the steps as follows: under the action of cesium fluoride, 3-bromine isoxazole-5-methenol 1 and an amine compound 2 are directly subjected to substitution reaction on a solvent-free condition to generate the N, N-double substitution-3-amino isoxazole-5-methanol compound 3. The reaction formula is as follows: the amine compound in one of pyrrolidine, piperidine and 4-methylpiperidine.

Owner:WUXI BIOLOGICS CO LTD +1

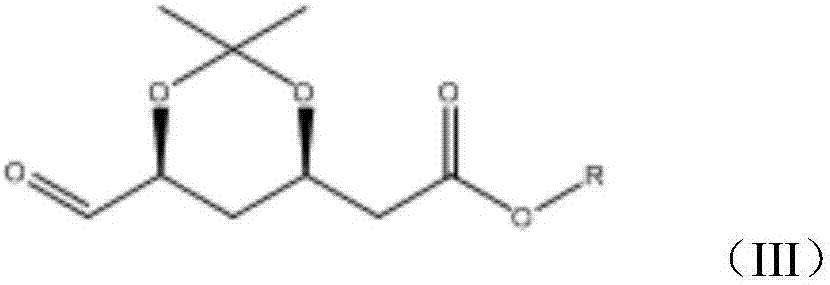

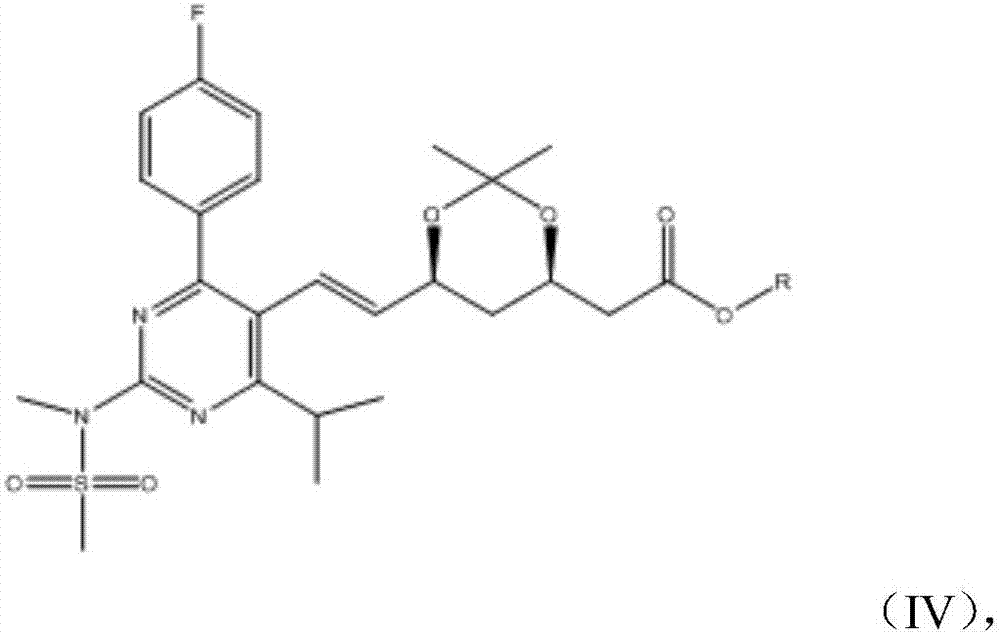

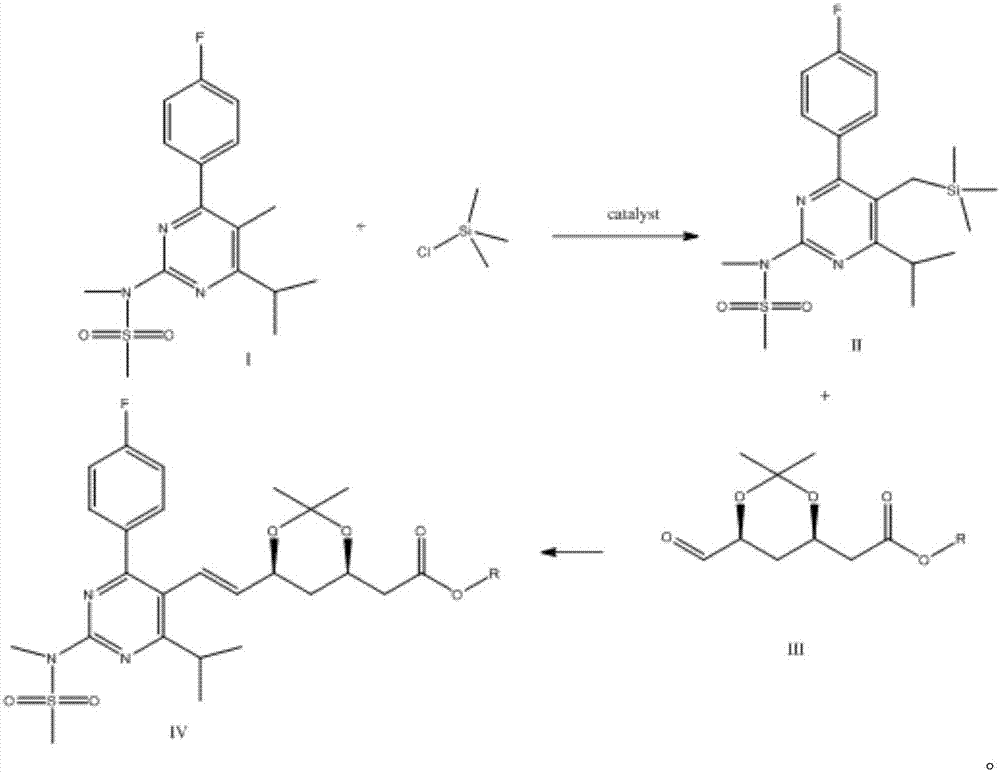

A kind of synthesis technique of the intermediate of synthetic rosuvastatin

The present invention discloses a synthesis process of (4R,6S,E)-2-{6-[2-[4-(4-fluorophenyl)-6-isopropyl-2-(N-methyl (methylsulfonyl) amino) pyrimidin-5-yl] ethenyl]-2,2-dimethyl-1,3-epoxyhexane-4-yl} acetate alkyl ester. With an aprotic polar solvent as solvent, 4-(4-fluorophenyl)-6-isopropyl-2-(N-methyl-N-methanesulfonyl amino)-5-pyrimidine methyl, n-butyl lithium, 2,2,6,6-tetramethyl piperidine or LDA react with trimethyl silicon chloride; and then the reaction products react with (4R-cis)-6-[(acetyloxy) methyl]-2,2-dimethyl-1,3-dioxo hexane-4-alkyl acetate under catalysis of cesium fluoride in an aprotic polar solvent to produce the target product. The process uses trimethyl silicon as a condensation agent, and does not use alkali; the cesium fluoride is directly used as a catalyst; and the usage amount and three wastes are less. Z type condensation ethylenic bond is less than 10%, which is much less than the triphenylphosphine process. The reaction process does not need low temperature, is easy to realize industrialization and has the advantages of easily available raw materials and low cost.

Owner:乐普制药科技有限公司

Fluoride brazing flux for copper-aluminum dissimilar metals and preparation method thereof

ActiveCN103769776BReduce the temperatureLow melting pointWelding/cutting media/materialsSoldering mediaPotassium fluorideCopper fluoride

The invention relates to the field of brazing materials, in particular to a fluoride flux for copper-aluminum dissimilar metals and a preparation method thereof, which consists of cesium fluoride, aluminum trifluoride, potassium fluoride, copper difluoride and additives; Cesium fluoride, aluminum trifluoride, potassium fluoride, copper difluoride, zinc difluoride, lithium fluoride powder and zinc powder or ZnAl alloy powder are mixed in proportion, and an appropriate amount of deionized water is added and ground in a mortar until Paste, then dried and ground.

Owner:ZHEJIANG XINRUI WELDING MATERIAL

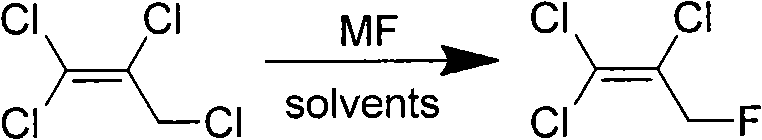

Synthesis method of 1,1,2-trichloro-3-fluoropropylene

ActiveCN102603463AMild reaction conditionsImprove conversion rateHalogenated hydrocarbon preparationPotassium fluorideButanediol

The invention provides a synthesis method of 1,1,2-trichloro-3-fluoropropylene, comprising the following step: in the presence of a polyalcohol solvent, carrying out a reaction on 1,1,2,3-tetrachloropropene and an alkali metal fluoride at 90-120 DEG C for 1.0-10h to obtain 1,1,2-trichloro-3-fluoropropylene. The molar ratio of the alkali metal fluoride to 1,1,2,3-tetrachloropropene is (1-5):1, wherein the alkali metal fluoride is sodium fluoride, potassium fluoride or cesium fluoride; and the polyalcohol is glycol, 1,2-propanediol, 1,3-propanediol, 2,3-butanediol, diethylene glycol, triethylene glycol, tetraethylene glycol or glycerol. The synthesis method provided by the invention is mainly applied to preparing 1,1,2-trichloro-3-fluoropropylene.

Owner:山东华安近代环保科技有限公司

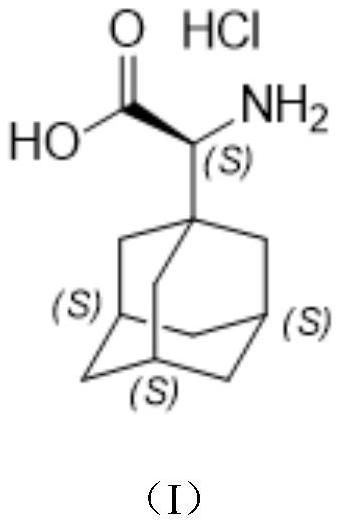

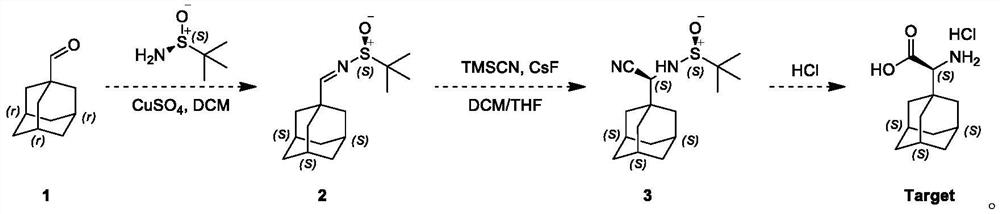

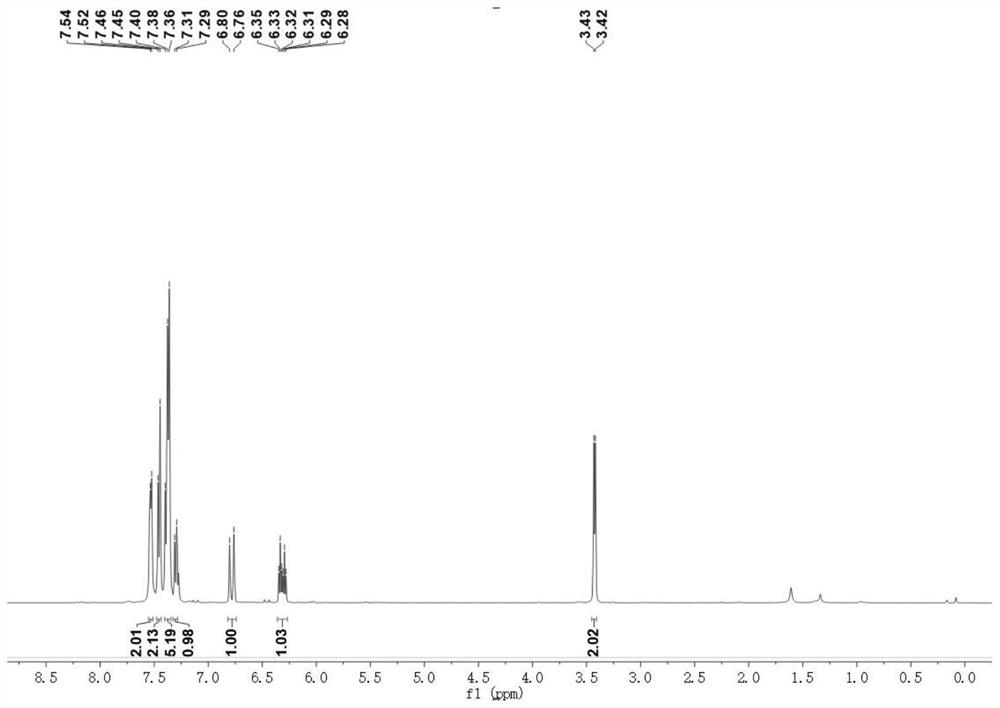

A kind of preparation method of (s)-2-(adamantan-1-yl)-2-aminoacetic acid hydrochloride

ActiveCN112679369BMethod route shortEasy to operateOrganic compound preparationAmino-carboxyl compound preparationCyanide compoundTert butyl

The invention discloses a preparation method of (S)-2-(adamantane-1-yl)-2-aminoacetic acid hydrochloride, wherein, comprising the following steps: firstly, 1-adamantanecarboxaldehyde and (S) ‑(‑)‑tert-butyl sulfinamide was dissolved in methylene chloride, then slowly adding dehydrating agent and pyridine p-toluenesulfonate, and reacted for 16 hours at a temperature of 20 ° C to obtain tert-butyl sulfinyl imide ; tert-butyl sulfenimide is dissolved in dichloromethane and tetrahydrofuran, trimethylnitrile silane and cesium fluoride are added, and the reaction is carried out at a temperature of 20 ° C for 16 hours to obtain cyanide; use a hydrolysis reagent to hydrolyze cyanide, First react for 6 hours at a temperature of 15°C, and then react at a temperature of 110°C for 16 hours to obtain the final compound, namely (S)-2-(adamantan-1-yl)-2-aminoacetic acid hydrochloride Salt, mainly to solve the technical problem that there is no suitable industrial synthesis method at present.

Owner:南通药明康德医药科技有限公司

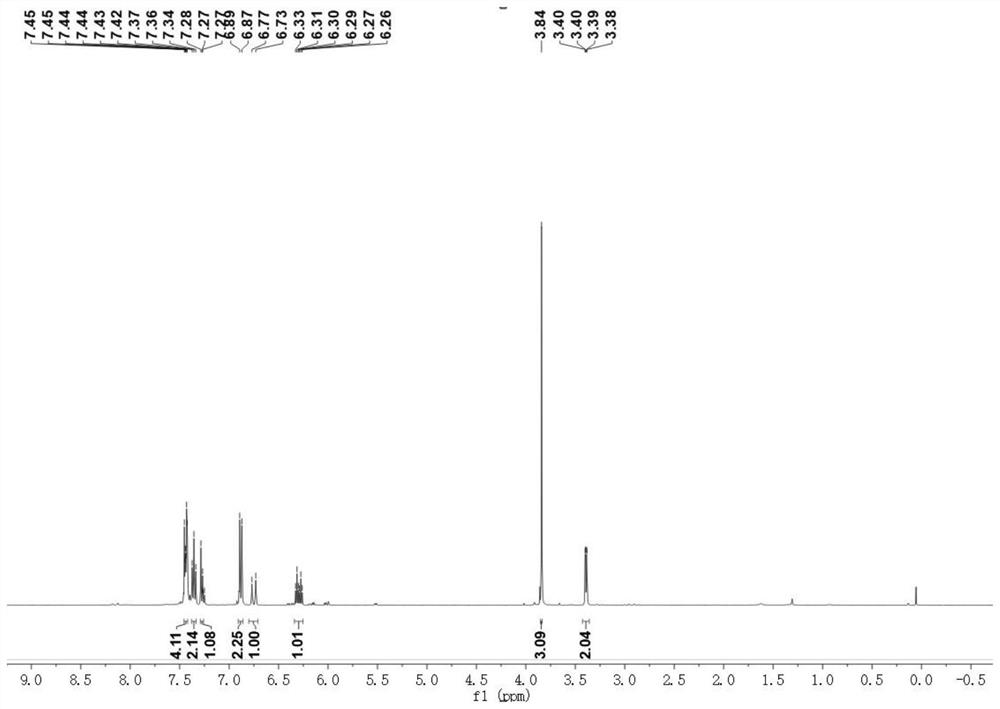

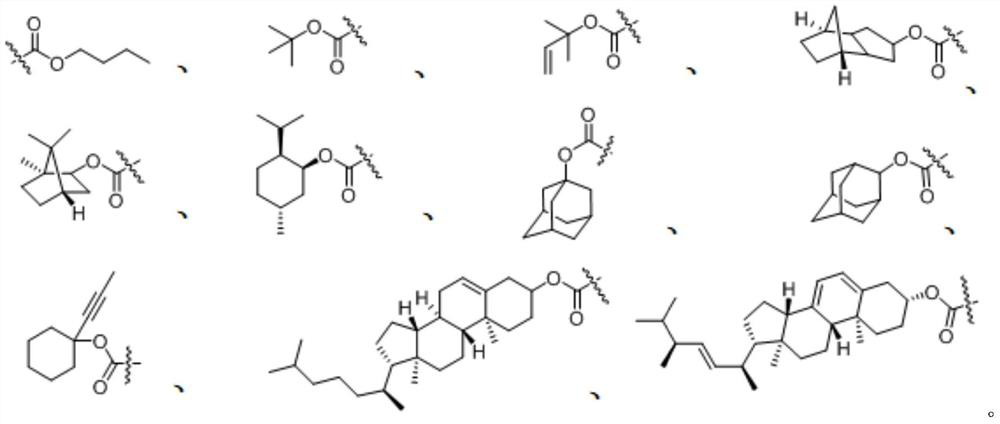

Preparation method of 1, 4 enyne compound

ActiveCN113548965AEasy to prepareEasy to operateOrganic compound preparationCarboxylic acid esters preparationPtru catalystEthyl acetate

The invention discloses a preparation method of a 1, 4 enyne compound, which comprises the following steps of in an inert gas atmosphere, adding allyl alcohol, acetylenic acid and a combined catalyst into an organic solvent, and stirring and reacting for 12-24 hours at the temperature of 80-100 DEG C to obtain a reaction solution, wherein the combined catalyst is prepared from organic palladium, villiaumite and cesium fluoride, and the villiaumite is bis (trifluoromethanesulfonimide) salt or bis (trifluoromethanesulfonate), and extracting the reaction solution by using water and ethyl acetate to remove part of the reaction solvent, drying and concentrating an organic phase, and purifying by using a petroleum ether / ethyl acetate developing solvent system through thin layer chromatography to obtain the 1, 4-eneyne compound. The preparation method is simple and convenient to operate, the obtained by-products only comprise water and carbon dioxide, and the method has the advantages of being high in atom economy and environmentally friendly; in addition, the preparation method is low in raw material price and wide in applicable substrate range.

Owner:NANJING UNIV OF TECH

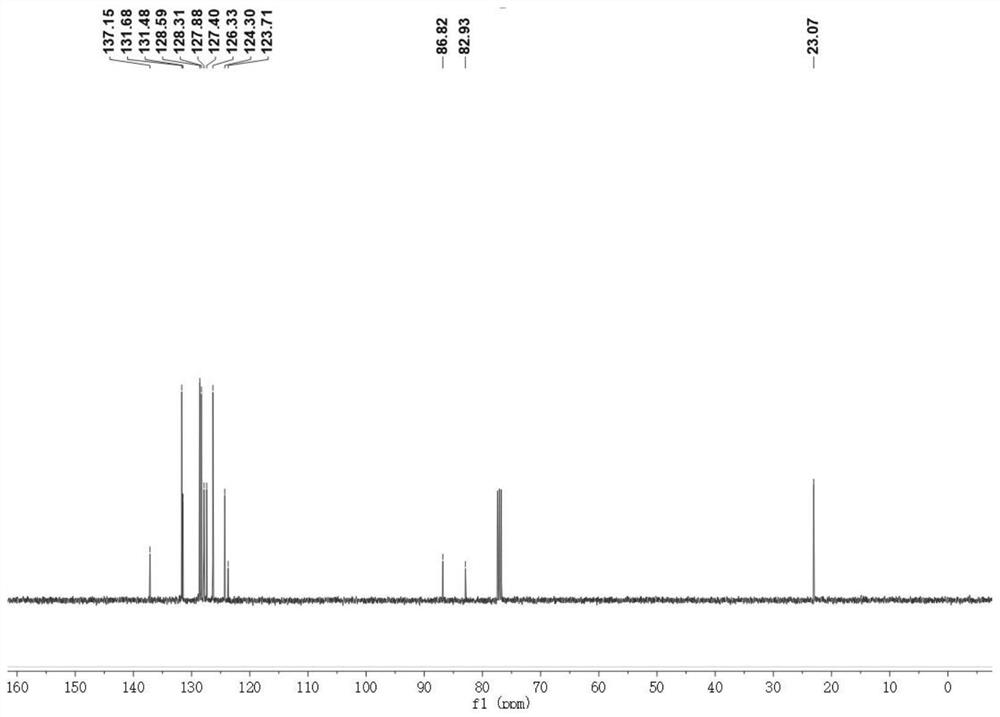

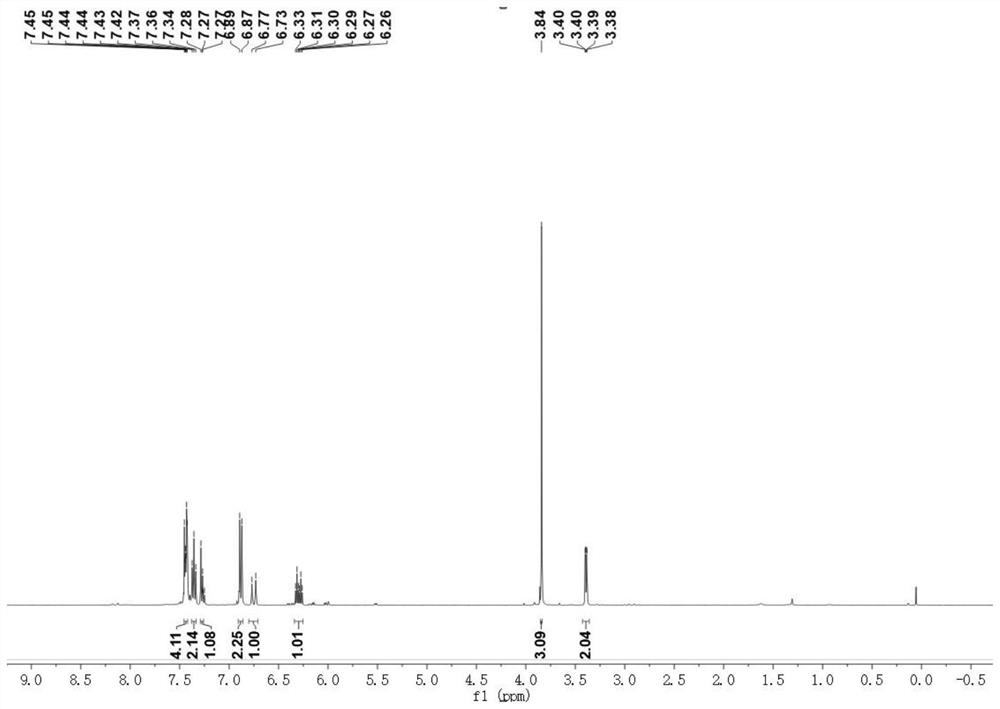

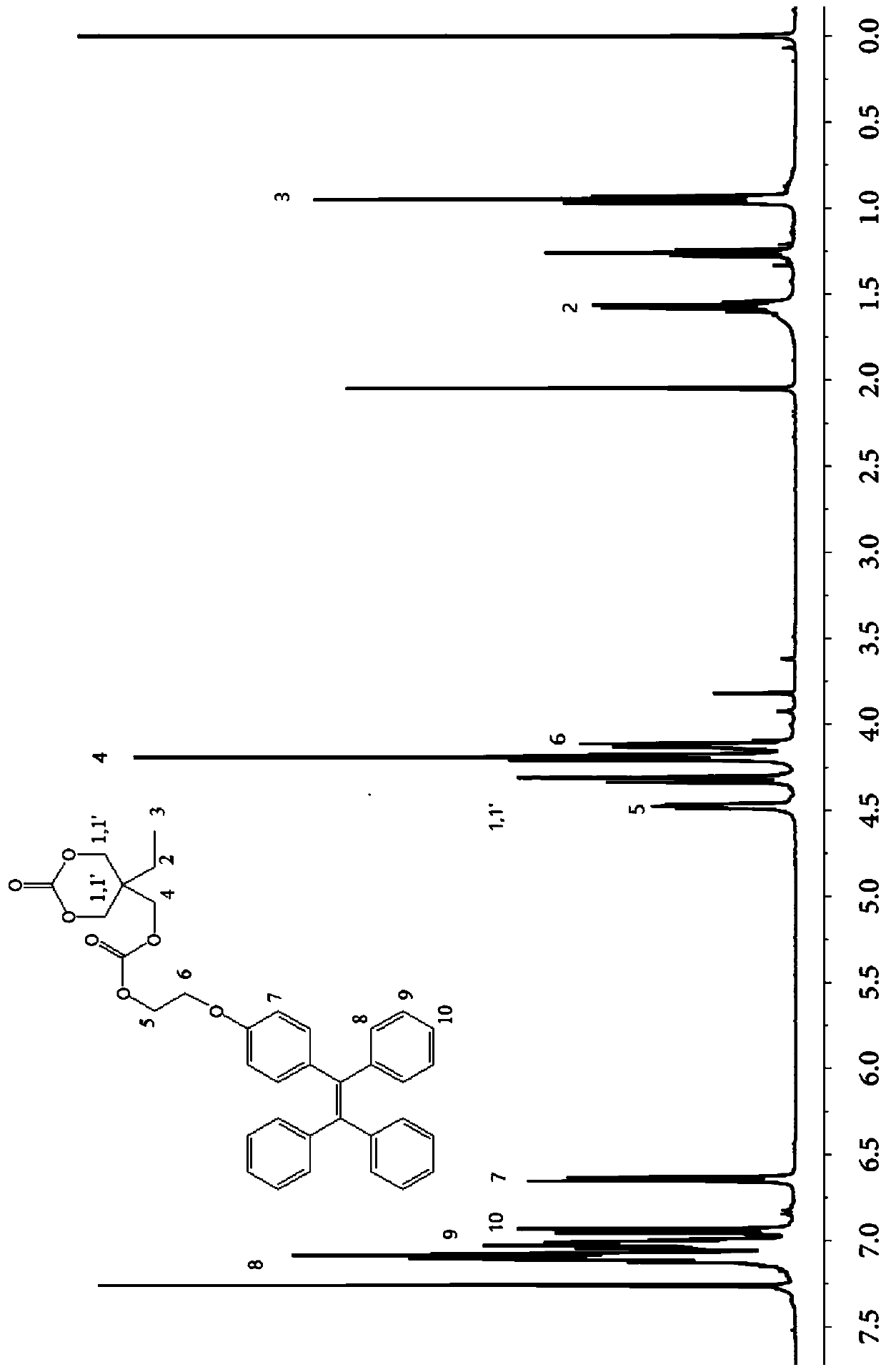

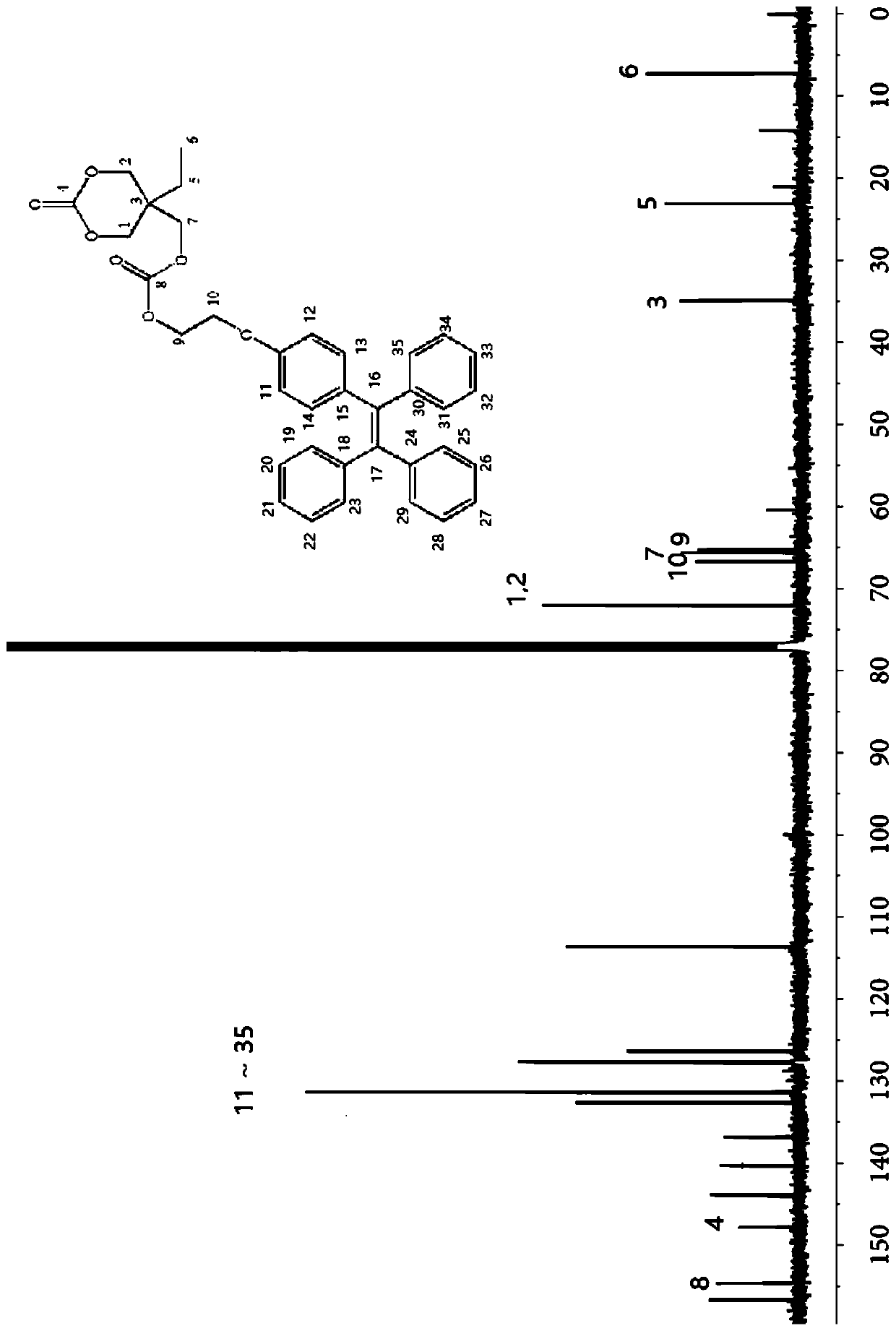

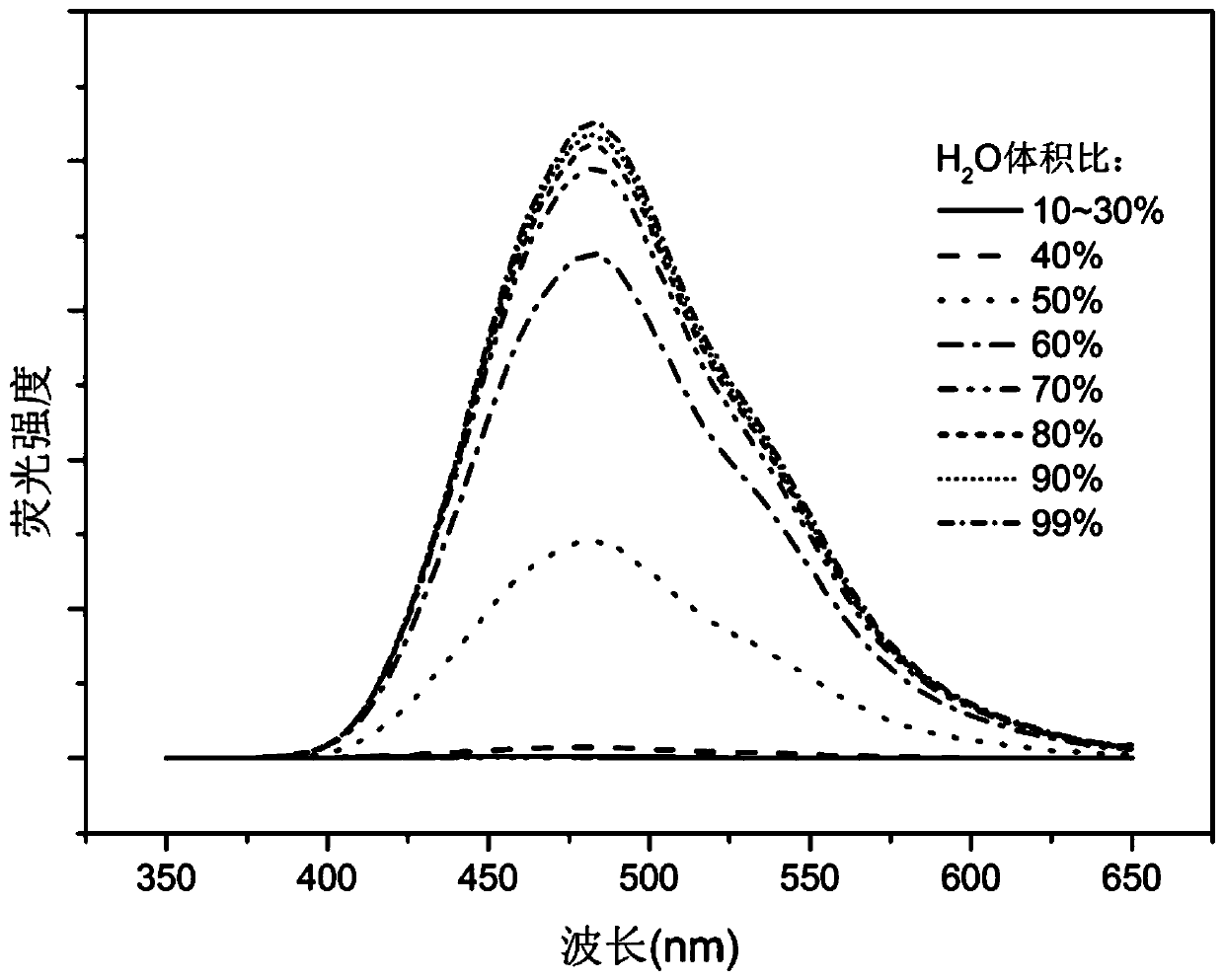

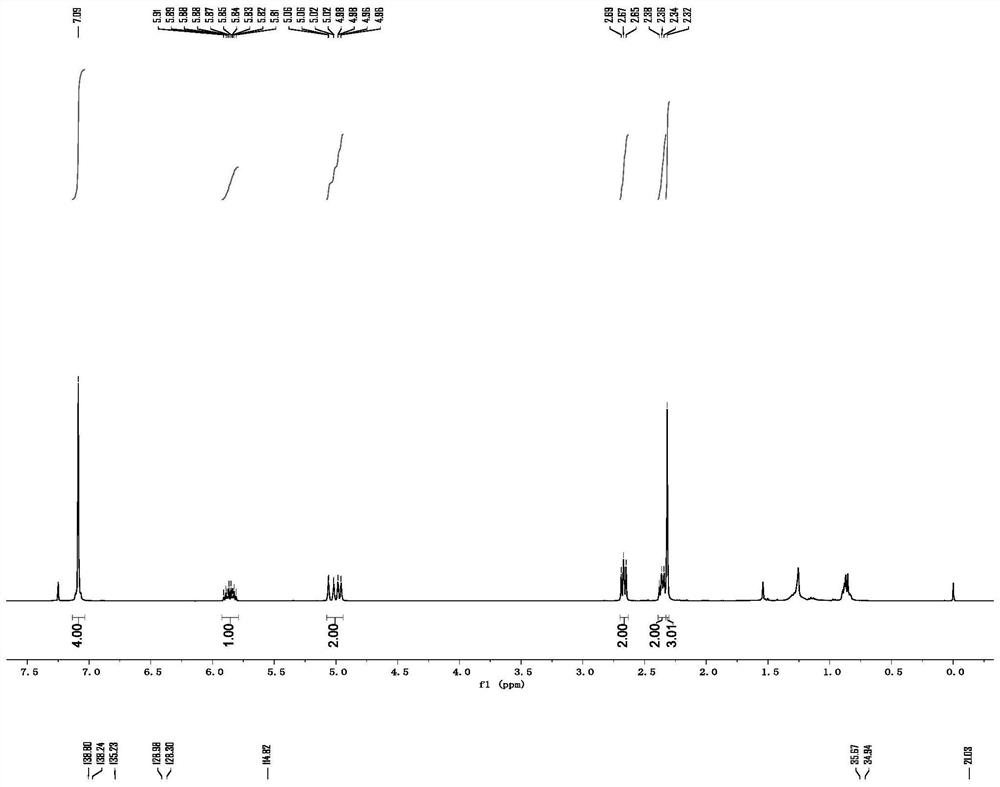

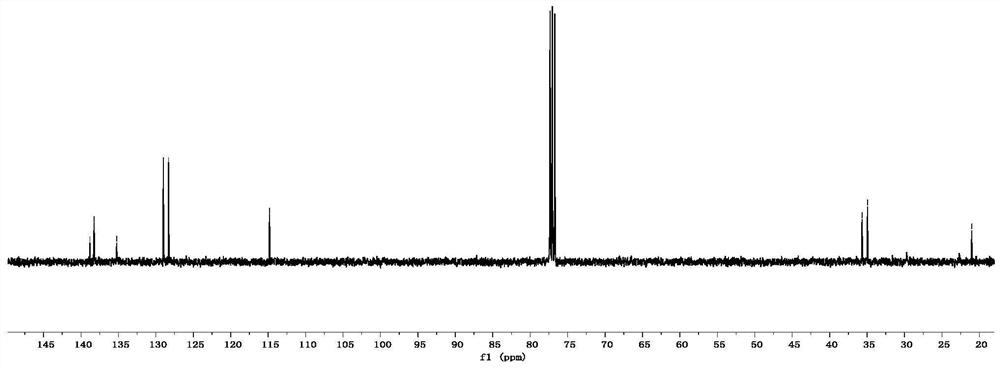

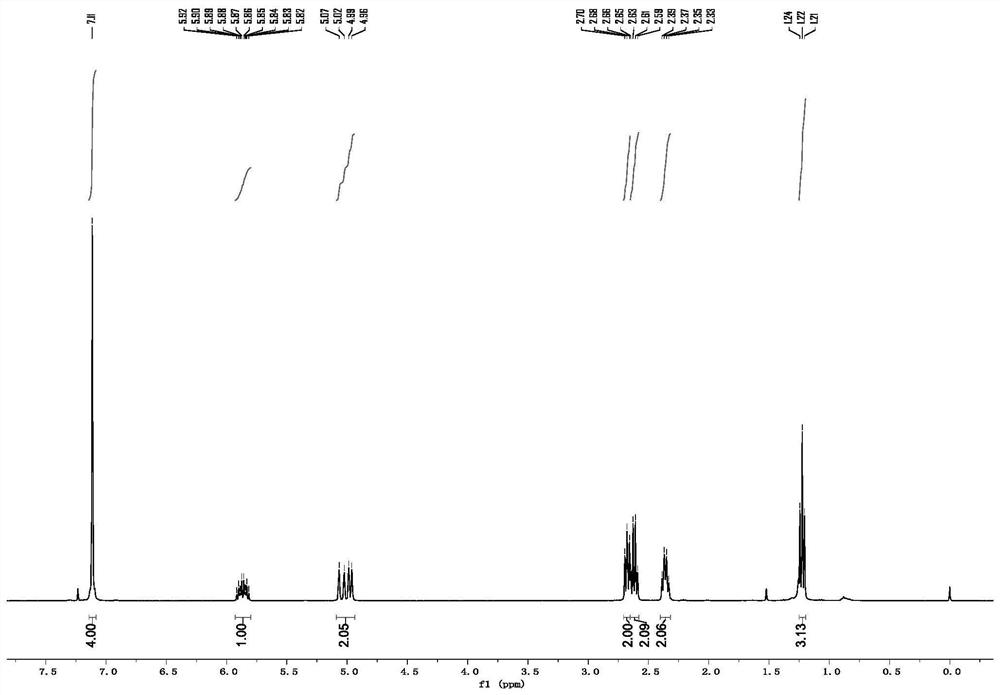

A fluorescent functionalized carbonate, its preparation method and application, and fluorescent polycarbonate prepared therefrom

InactiveCN107459505BGood biocompatibilityPromote degradationOrganic chemistryLuminescent compositionsFluorescenceCatalytic effect

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of preparation method of efficient 1-aryl-4-butene compound

ActiveCN111116285BHigh selectivityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationPalladium catalystBoronic acid

The invention belongs to the field of fine chemicals and related chemical technologies, and provides a highly efficient preparation method of 1-aryl-4-butene compounds. Using halogen-containing methyl aromatic hydrocarbons and their derivatives as raw materials, in the presence of palladium catalysts and ligands, cesium fluoride as a base, under the condition of anhydrous organic solvents, and allylboronic acid pinacol ester at 80 ° C ~ 1-aryl-4-butene compound can be obtained by reacting at 100°C for 12 hours. The invention has the beneficial effects of high selectivity, mild reaction conditions, easy and convenient operation, the possibility of realizing industrialization, and obtaining 1-aryl-4-butene compounds in a relatively high yield; the 1-aryl-4-butene compound synthesized by the method is Aryl-4-butene compounds can be further functionalized to obtain various compounds, which are applied in the development and research of natural products, functional materials and fine chemicals.

Owner:DALIAN UNIV OF TECH

A kind of preparation method of 1,4 enyne compounds

ActiveCN113548965BEasy to prepareEasy to operateOrganic compound preparationCarboxylic acid esters preparationPtru catalystOrganosolv

The invention discloses a method for preparing 1,4 enyne compounds. In an inert gas atmosphere, allyl alcohol, alkynoic acid and a combined catalyst are added into an organic solvent, and the reaction is stirred at a temperature of 80-100° C. for 12-12 24h, a reaction solution was obtained; the combined catalyst was composed of organic palladium, fluoride salt and cesium fluoride, and the fluoride salt was bis-trifluoromethanesulfonimide salt or bis-trifluoromethanesulfonate; then the reaction solution was passed through water Extraction with ethyl acetate to remove part of the reaction solvent, drying and concentrating the organic phase, and purification by thin layer chromatography with petroleum ether / ethyl acetate developing solvent system to obtain 1,4-enyne compounds. The preparation method of the present invention is simple, the operation is convenient, the obtained by-products are only water and carbon dioxide, and has the characteristics of high atom economy and environmental protection; in addition, the preparation method of the present invention has low price of raw materials and a wide range of applicable substrates.

Owner:NANJING TECH UNIV

Synthesis method of 1,1,2-trichloro-3-fluoropropylene

ActiveCN102603463BMild reaction conditionsImprove conversion rateHalogenated hydrocarbon preparationPotassium fluorideButanediol

The invention provides a synthesis method of 1,1,2-trichloro-3-fluoropropylene, comprising the following step: in the presence of a polyalcohol solvent, carrying out a reaction on 1,1,2,3-tetrachloropropene and an alkali metal fluoride at 90-120 DEG C for 1.0-10h to obtain 1,1,2-trichloro-3-fluoropropylene. The molar ratio of the alkali metal fluoride to 1,1,2,3-tetrachloropropene is (1-5):1, wherein the alkali metal fluoride is sodium fluoride, potassium fluoride or cesium fluoride; and the polyalcohol is glycol, 1,2-propanediol, 1,3-propanediol, 2,3-butanediol, diethylene glycol, triethylene glycol, tetraethylene glycol or glycerol. The synthesis method provided by the invention is mainly applied to preparing 1,1,2-trichloro-3-fluoropropylene.

Owner:山东华安近代环保科技有限公司

Method for brazing aluminium parts on the carbon steel part surface and aluminizing anti-rust on the non brazing surface

ActiveCN100446918CReduce manufacturing costVacuum evaporation coatingSputtering coatingNitrogenNitrogen gas

The invention relates to the rust resistant method for aluminum coating of carbon steel part, aluminum soldering part and non aluminum soldering part, then installing aluminum part on the surface of the carbon steel part. Sending the assembled part into 200 deg.C-250deg.C drying oven, drying the compound soldering agent sufficiently, then taking into the controllable atmosphere oven for soldering and plating under the protection of the nitrogen, controlling the temperature within 570-615deg.C, soldering aluminum part on the surface of the carbon steel part, with the rest of the surface plated with aluminum, to finish the soldering and plating at one time, with the compound soldering material made of 30%-50% soldering material, 20%-40% soldering agent with the rest being ethandiol solution and the soldering material being Al. 85%-94%,Si: 15%-6%, the rest being microelement, the soldering material being aluminun fluoride 40-75%, and caesium fluoride 25-60%. It can be used to reduce the manufacturing cost.

Owner:SHUANGLIANG ECO ENERGY SYST CO LTD

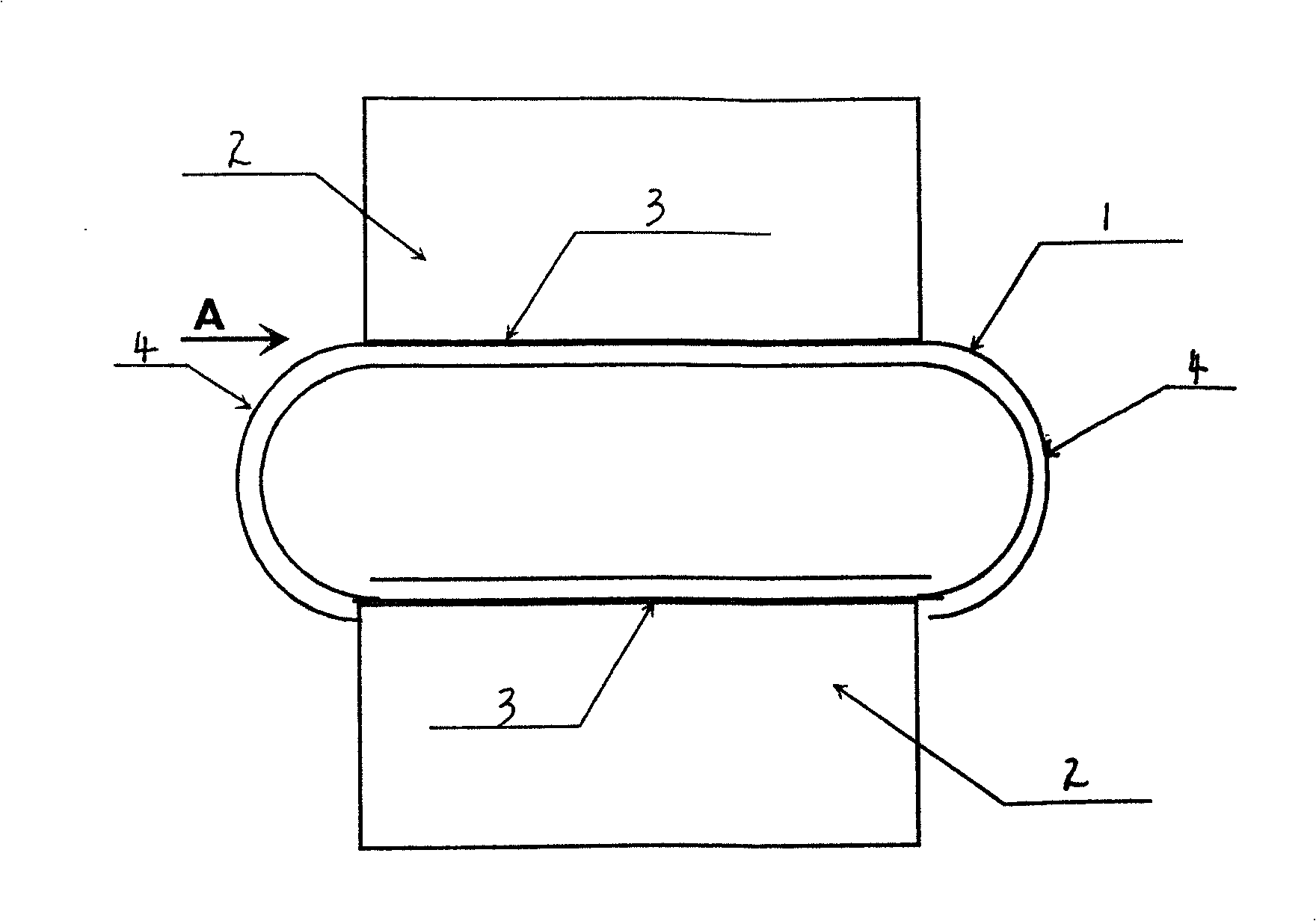

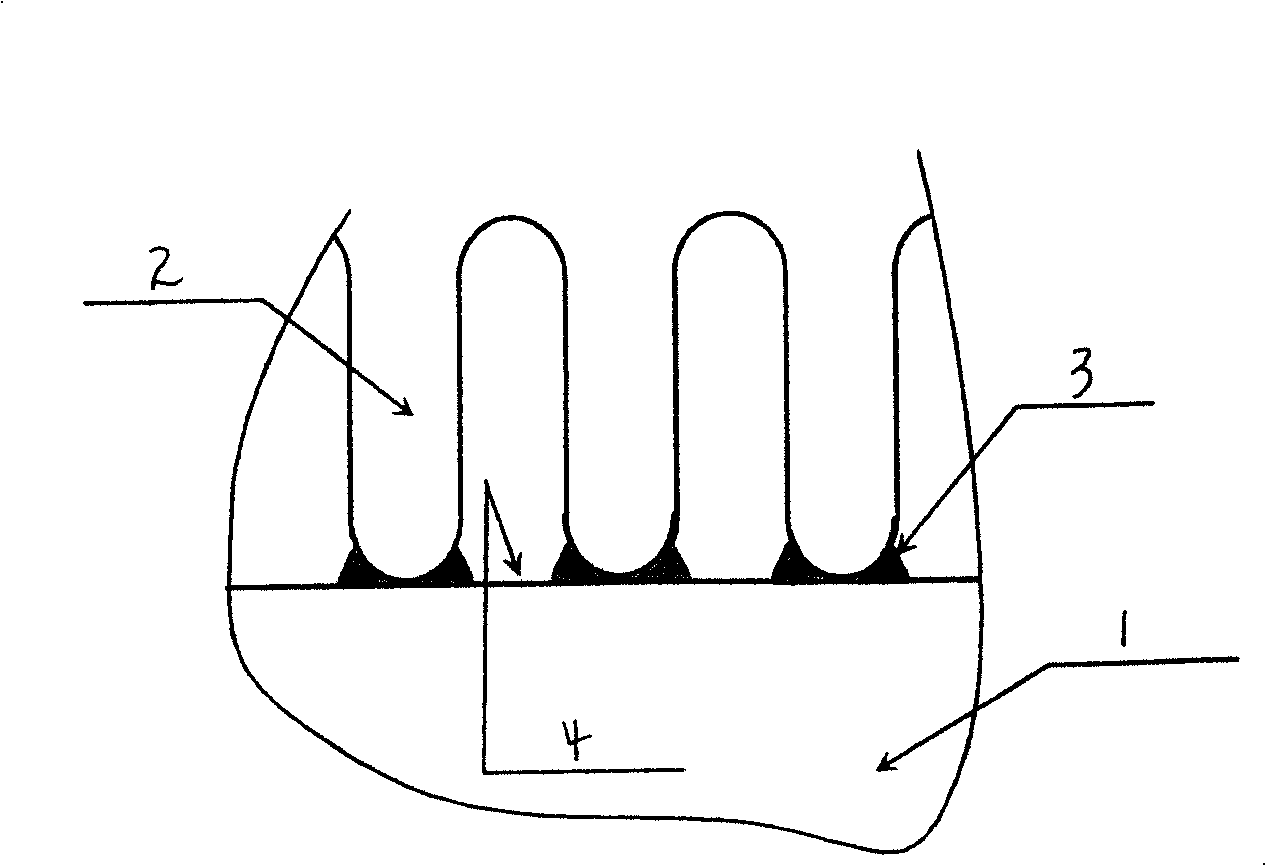

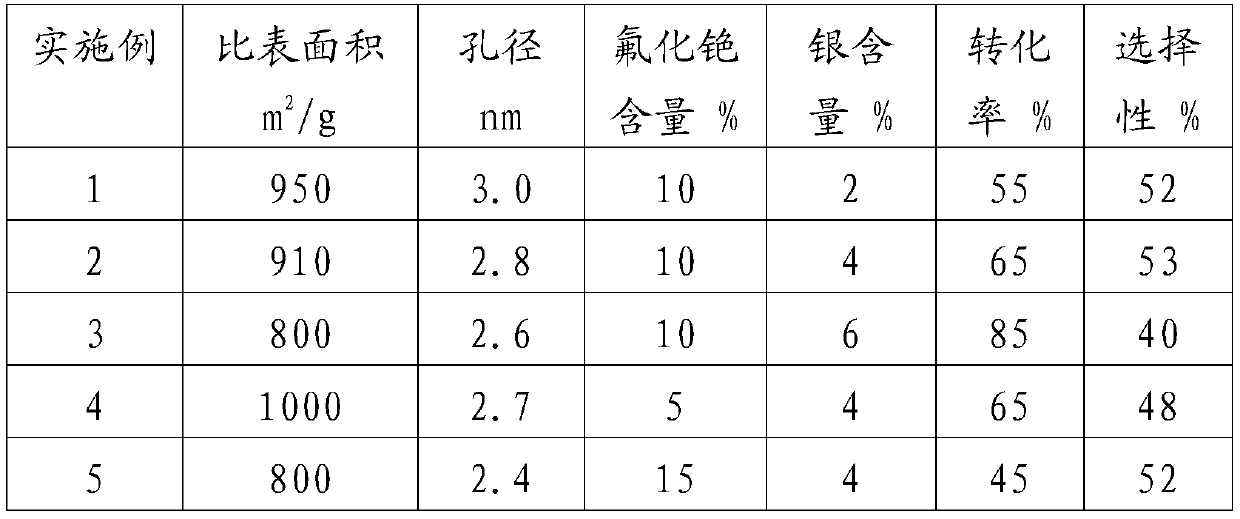

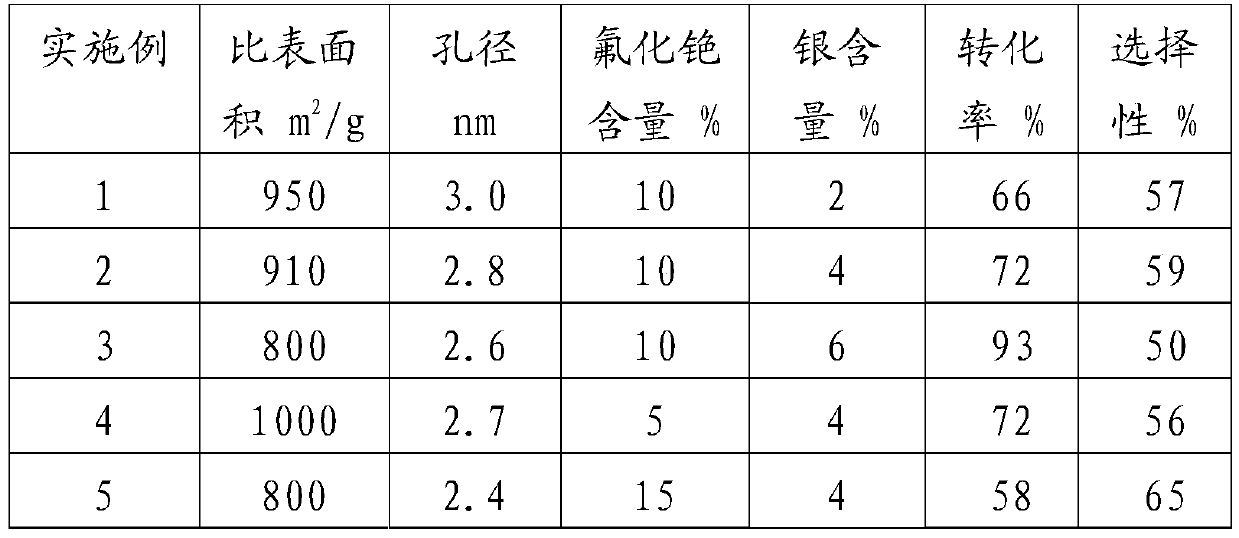

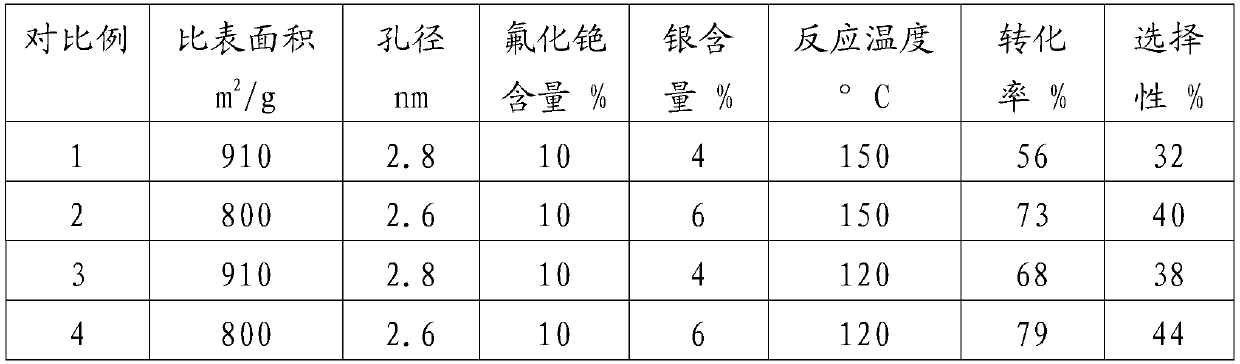

Modified silicon dioxide mesoporous catalyst and preparation method thereof

ActiveCN111514923AImprove performanceThe synthesis process is simpleOrganic chemistryMolecular sieve catalystsPtru catalystSilicic acid

The invention belongs to the field of catalysts, and particularly relates to a modified silicon dioxide mesoporous catalyst and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving cetyl trimethyl ammonium bromide (CTAB) in distilled water, stirring for 30 minutes at room temperature, and then sequentially adding ammonia water and tetraethoxysilane (TEOS) to obtain a post-mixed solution; 2) adding a cesium fluoride solution and a silver nitrate solution into the mixed solution obtained in the step 1); stirring at room temperature; and 3) adding themixture obtained in the step 2) into a reaction kettle containing a polytetrafluoroethylene lining, crystallizing, taking out the sample, carrying out suction filtration, washing and drying, and carrying out high-temperature roasting in a muffle furnace. In the preparation process of the modified silicon dioxide mesoporous catalyst, due to the fact that one-step synthesis is adopted, cesium fluoride and silver oxide directly enter the skeleton structure of the catalyst carrier, and uniform distribution of cesium fluoride and silver oxide components is guaranteed.

Owner:TIANJIN CHANGLU CHEM NEW MATERIAL CO LTD

A kind of photocurable polysilazane and preparation method thereof, SICN ceramics and preparation method thereof

The invention belongs to the technical field of ceramic materials, and in particular relates to a photocurable polysilazane and a preparation method thereof, SiCN ceramics and a preparation method thereof. In the present invention, by using 3-(trimethyloxysilyl)propyl methacrylate as a modifying agent, tetrabutylammonium fluoride, potassium fluoride and / or cesium fluoride are used as catalysts to Silazane is modified to activate the Si-H and N-H bonds of the branch chain under the condition of ensuring the polysilazane main chain is continuous, and then react with the modifier to introduce a photocurable group to obtain a photocurable polysilazane. Curing polysilazane, the photocurable polysilazane of the present invention can be combined with 3D photocuring molding to prepare complex shape embryos, and SiCN ceramics can be prepared after sintering.

Owner:GUANGDONG UNIV OF TECH

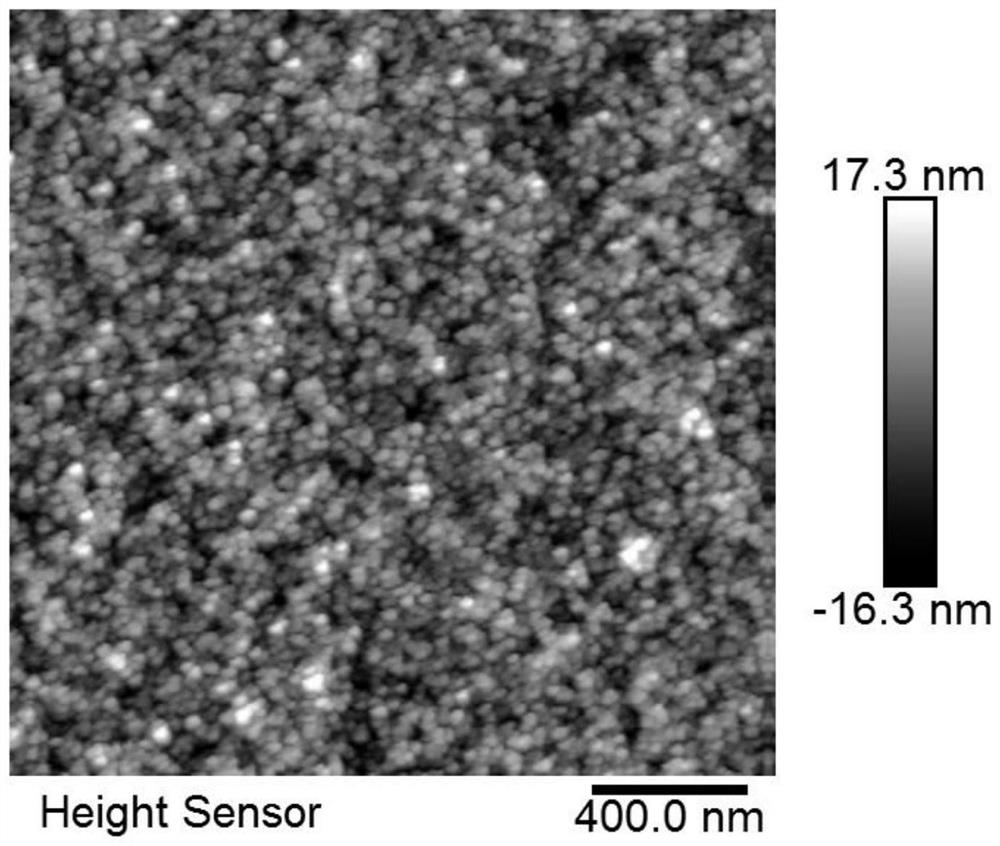

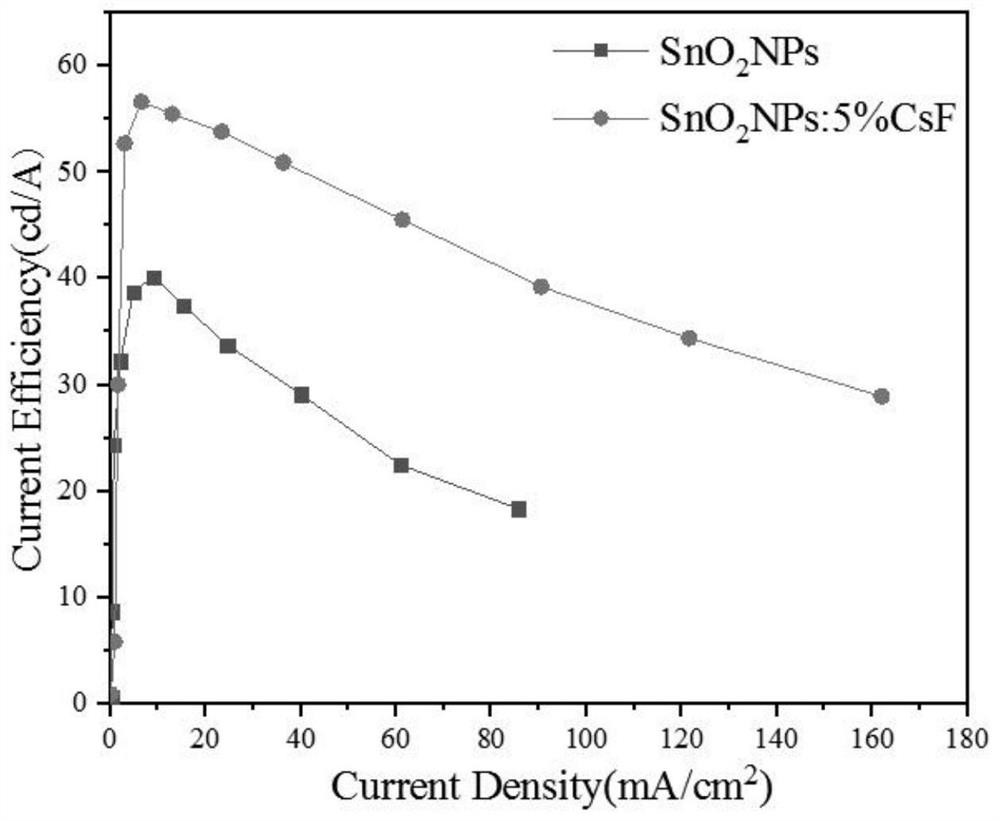

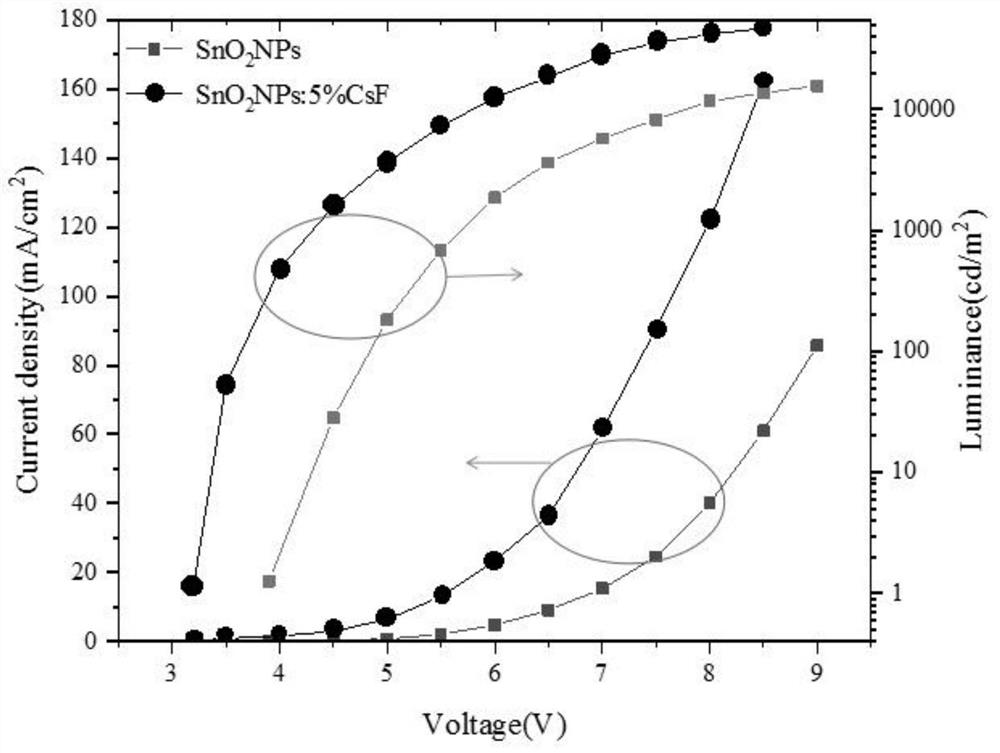

Inverted organic light-emitting diode device and preparation method thereof

ActiveCN112397665AImprove injection abilityHigh electron mobilitySolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionMaterials science

The invention discloses an inverted organic light-emitting diode device and a preparation method thereof. The performance of the inverted organic light-emitting diode device is improved by enhancing electron injection. The inverted organic light-emitting diode device structure comprises an ITO substrate, a doped electron injection layer, an energy level matching layer, a hole blocking layer, a light-emitting layer, a hole transport layer, a hole injection layer and an anode layer; according to the preparation method, a methanol solution of cesium fluoride is used for treating a stannic oxide solution through a solution process, and the electron mobility of the prepared cesium fluoride doped stannic oxide nanoparticle film is improved compared with that of an untreated stannic oxide film. The stannic oxide film is used as an electron injection layer of an inverted organic light-emitting diode device, so that compared with a device in which an untreated stannic oxide film is used as theelectron injection layer, the electronic current of the device is increased, and the driving voltage is reduced. The doped electron injection layer is prepared by a solution method with a simple process, and an effective scheme is provided for realizing inverted solution processing of an OLED device with low driving voltage and high efficiency.

Owner:SHANGHAI UNIV

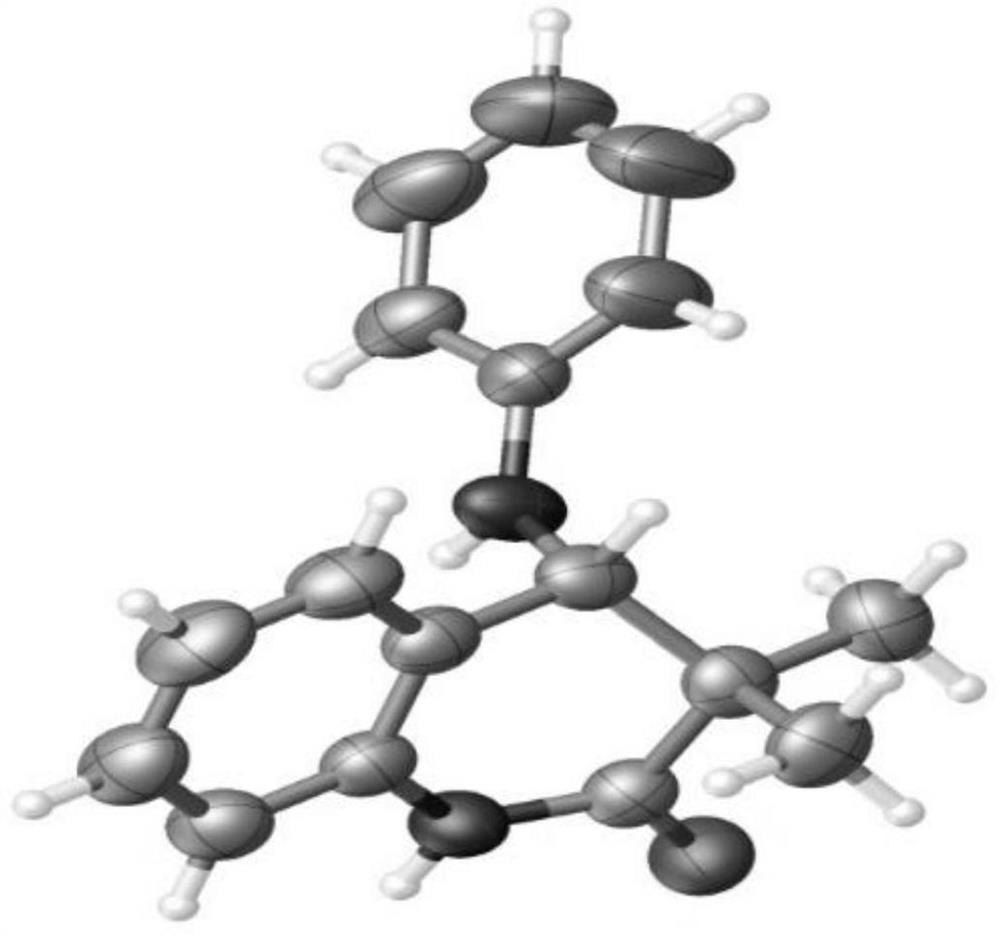

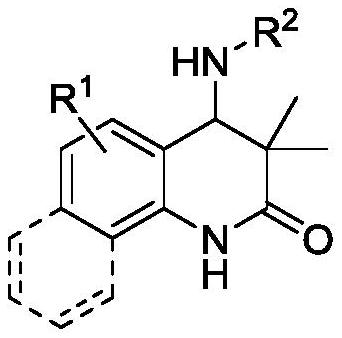

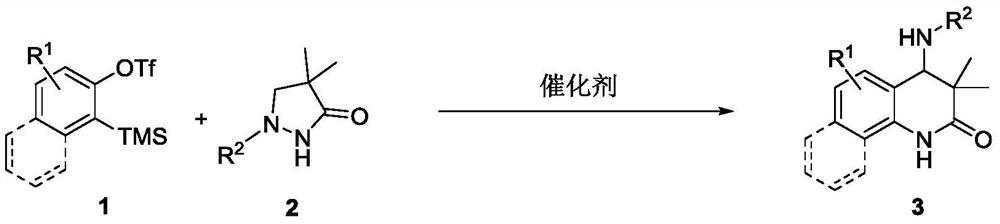

Synthetic method and anticancer activity of 4-amino dihydroquinolinone compound

ActiveCN113754584AHigh anticancer activityImprove toleranceOrganic chemistryAntineoplastic agentsCancer cellOrganic synthesis

The invention discloses a synthesis method and anticancer activity of a 4-amino dihydroquinolinone compound, which belongs to the technical field of organic synthesis and drug discovery. 2-(trimethylsilyl) aryl trifluoromethanesulfonate 1 and a 1-substituted pyrazolidinone compound 2 are used as raw materials and react in an organic solvent in the presence of a catalyst and cesium fluoride to obtain the 4-amino dihydroquinolinone compound 3, and the compound shows remarkable anti-proliferative activity on cancer cells such as REC-1 and Ramos. The synthesis method disclosed by the invention has the advantages of wide substrate range, mild reaction conditions, good functional group tolerance and the like, and the obtained product has potential medicinal value.

Owner:HENAN NORMAL UNIV

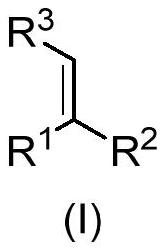

Gamma-amino acid analogue and synthesis method thereof

ActiveCN112321475ASelectiveLow toxicityOrganic chemistry methodsPeptide preparation methodsMolecular sievePhotosensitizer

The method discloses a gamma-amino acid analogue and a synthesis method thereof. The method comprises the following steps of adding a photosensitizer, alkali and carboxylic acid into a dry reaction tube, adding a solvent and a reaction substrate under the atmosphere of protective gas, reacting under the irradiation of visible light, carrying out acidification quenching treatment on the mixture obtained by the reaction after the reaction of the raw materials is finished, and separating and purifying to obtain a product gamma-amino acid analogue. The photosensitizer comprises Ir[dF(CF3)(ppy)]2(dtbbpy).PF6, Ir(ppy)2(dbbpy).PF6, 4CzIPN, and the alkali is cesium fluoride, cesium carbonate or potassium fluoride; the additive is a molecular sieve; and the reaction substrate is an alkene compound.The gamma-amino acid analogue is efficiently and highly selectively synthesized under the atmosphere of visible light induction and protective gas. According to the scheme, reaction conditions are mild, reaction substrate selectivity is wide, and the reaction substrate selectivity is amplified to the gram-level scale.

Owner:SICHUAN UNIV

Preparation method of self-brazing material for welding aluminum-copper member

ActiveCN102935558BLow melting pointHigh melting pointWelding/cutting media/materialsSoldering mediaYarnPotassium fluoride

The invention discloses a self-brazing material for welding an aluminum-copper member. The self-brazing material comprises the following components: 12-15 percent of fluoride (30-80 percent of aluminum fluoride, 5-35 percent of caesium fluoride and the balance of potassium fluoride), 0.01-0.3 percent of hafnium, 0.01-0.8 percent of germanium, 0.05-2 percent of nickel, 0.8-3 percent of copper, 5-17 percent of silicon and the balance of aluminum. The self-brazing material is prepared through the following steps of: smelting and atomizing the raw materials of hafnium, the germanium, the nickel, the copper, the silicon and the aluminum in a vacuum furnace into fine powder; and then uniformly mixing with the fluoride, pressing into a composite ingot, directly extruding the composite ingot into a yarn or pipe, and winding the yarn into a coil or cutting the pipe into a ring to obtain the self-brazing material. The self-brazing material disclosed by the invention has the advantages that trace elements of Ge and Hf are introduced on the basis of the traditional Al-Si-Cu-Ni alloy system brazing material, so that the brazing material smelting temperature is lowered, the burning loss of an aluminum base material during welding is favorably avoided, the strength and plasticity of the brazing material are improved, the mechanical property of a brazing joint is favorably improved, and the improvement of the plasticity of the brazing material can ensure that the production efficiency is increased.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com