Modified silicon dioxide mesoporous catalyst and preparation method thereof

A technology of silica and mesoporous silica, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, molecular sieve catalyst, etc. The specific surface area is small, and the synthesis process is simplified, the method is simple, and the catalytic performance is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

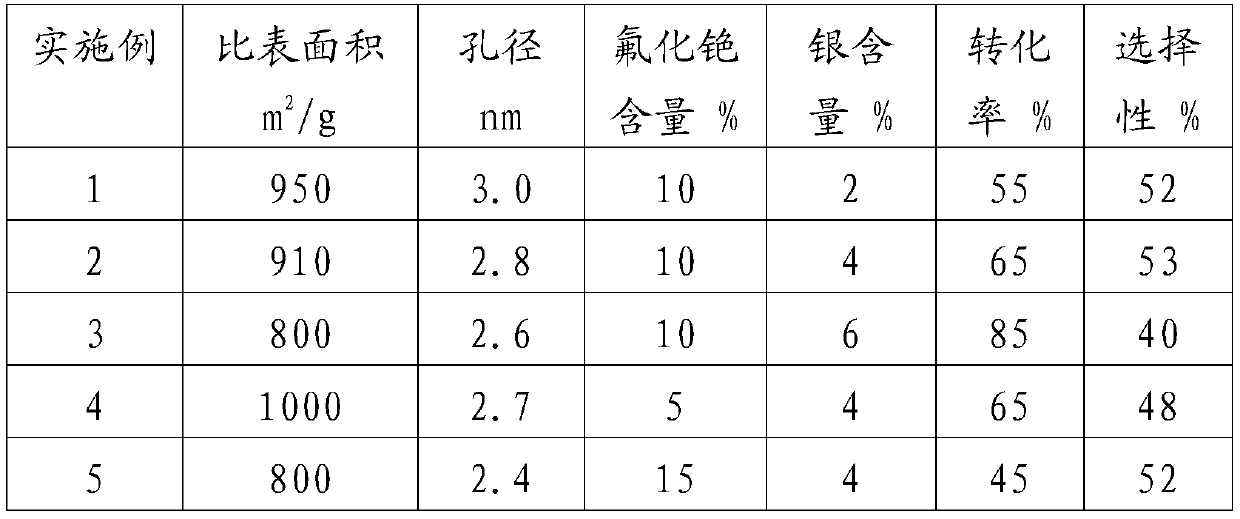

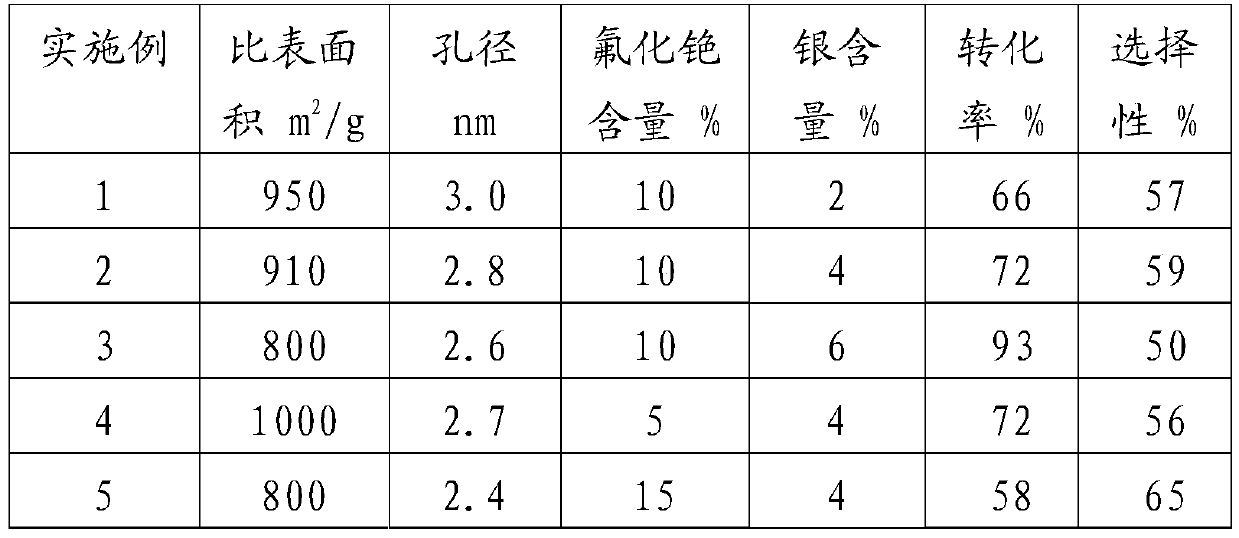

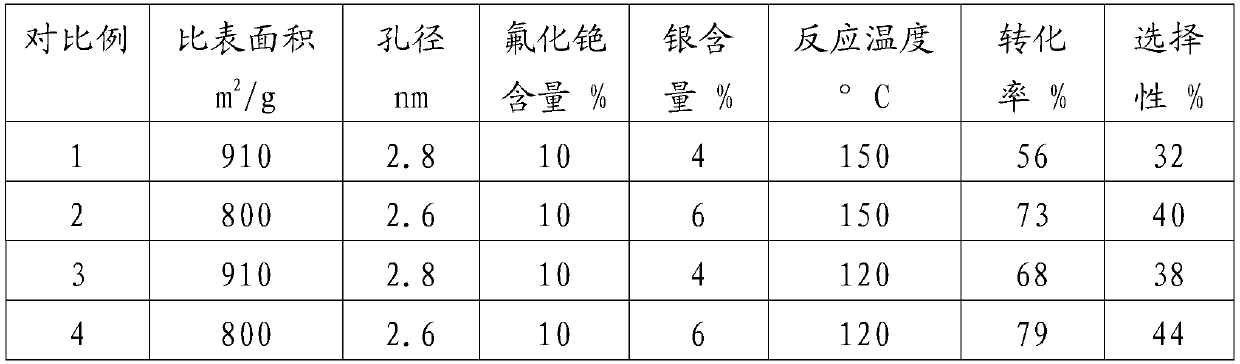

[0022] Dissolve a certain amount of cetyltrimethylammonium bromide (CTAB) in a certain amount of distilled water, stir at room temperature for 30 minutes, then add a certain amount of ammonia water, and then add tetraethyl orthosilicate (TEOS), The molar ratio of each component in the solution is: TEOS:CTAB:NH3:H2O=1:0.15:0.68:43. The above solution was stirred again at room temperature for 1 hour, and then different cesium fluoride solutions and silver nitrate solutions were added thereto, and different catalysts were prepared by adding different amounts of cesium fluoride and silver nitrate (see Table 1). Stir again at room temperature for 1 hour, then put it into a reaction kettle with a polytetrafluoroethylene liner, and crystallize at 120 °C for 48 hours. The sample was taken out again, then washed by suction filtration, dried, and then roasted in a muffle furnace at 400 degrees Celsius for 6 hours.

[0023] Tablet granulation: Press the calcined powder catalyst with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com