Preparation method of 1, 4 enyne compound

A compound, enyne technology, applied in the field of organic chemical synthesis, can solve problems such as poor economy and unfriendly environment, and achieve the effects of convenient operation, low preparation cost and high atom economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) In a 10mL Shrek tube, under nitrogen atmosphere, add 0.4mmol 2-(hydroxy(phenyl)meth)acrylate, 0.6mmol phenylpropylic acid, 0.015mmol tetrakis(triphenylphosphine)palladium , 0.04mmol calcium bistrifluoromethanesulfonimide, 0.04mmol cesium fluoride, add 4mL dimethyl sulfoxide, stir and react under nitrogen and 100°C, the reaction equation is:

[0031]

[0032] (2) After TLC monitors that the reaction is complete, remove the solvent with a vacuum rotary evaporator, and separate the product by thin-layer chromatography. The developing agent is petroleum ether / ethyl acetate system, and the product is yellow liquid (Z)-2-benzylidene- 5-Phenylpent-4-acid methyl ester, yield 79%.

Embodiment 2

[0034] (1) In a 10mL Shrek tube, under nitrogen atmosphere, add 0.3mmol 1-(4-methylphenyl)prop-2-en-1-ol, 0.45mmol 3-(3-methoxyphenyl ) propiolic acid, 0.02mmol tetrakis(triphenylphosphine) palladium, 0.03mmol calcium trifluoromethanesulfonate, 0.03mmol cesium fluoride, add 2mL N,N-dimethylacetamide, stir under nitrogen at 80°C reaction, the reaction equation is:

[0035]

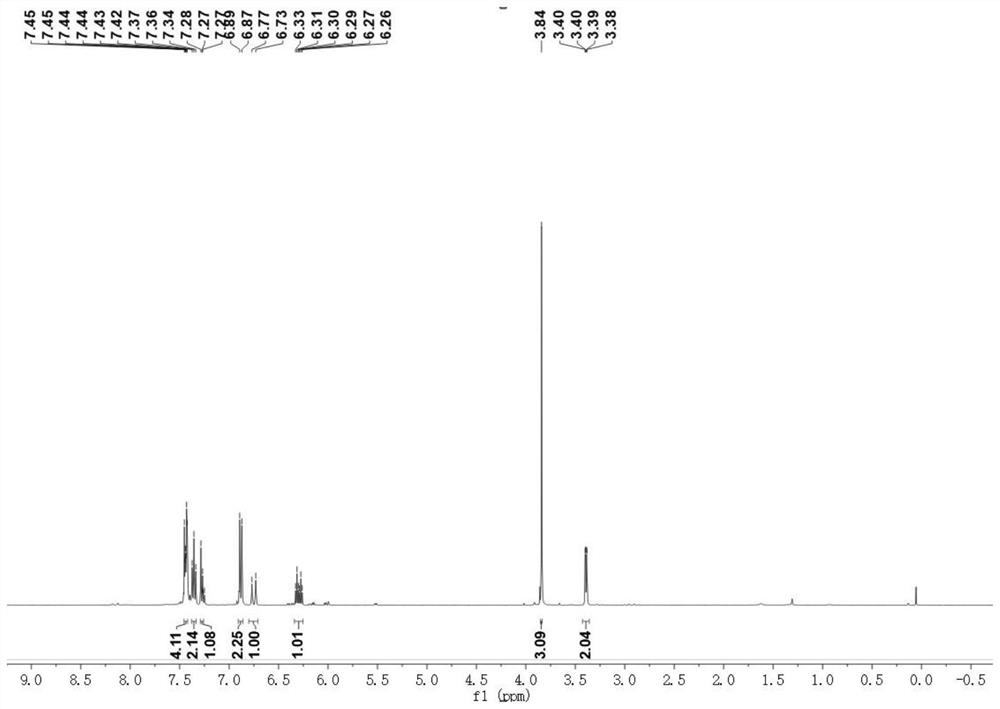

[0036] (2) After TLC monitors that the reaction is complete, remove the solvent with a vacuum rotary evaporator, and separate the product by thin-layer chromatography. The developing agent is petroleum ether / ethyl acetate system, and the product is light yellow liquid (E)-4-methylbenzene Base-5-phenyl-1-penten-4-yne, yield 67%.

Embodiment 3

[0038] (1) In a 10mL Shrek tube, under nitrogen atmosphere, add 0.35mmol cinnamyl alcohol, 0.5mmol 3-(3,4-dimethoxyphenyl) propynoic acid, 0.015mmol tetrakis(triphenylphosphine) Palladium, 0.035mmol calcium bistrifluoromethanesulfonimide, 0.035mmol cesium fluoride, add 3mL ethylene glycol dimethyl ether, stir and react under nitrogen at 90°C, the reaction equation is:

[0039]

[0040] (2) After TLC monitors that the reaction is complete, remove the solvent with a vacuum rotary evaporator, and separate the product by thin-layer chromatography. The developer is petroleum ether / ethyl acetate system, and the product is a light yellow liquid (E) 1,5-diphenyl Base-1-penten-4-yne, yield 76%.

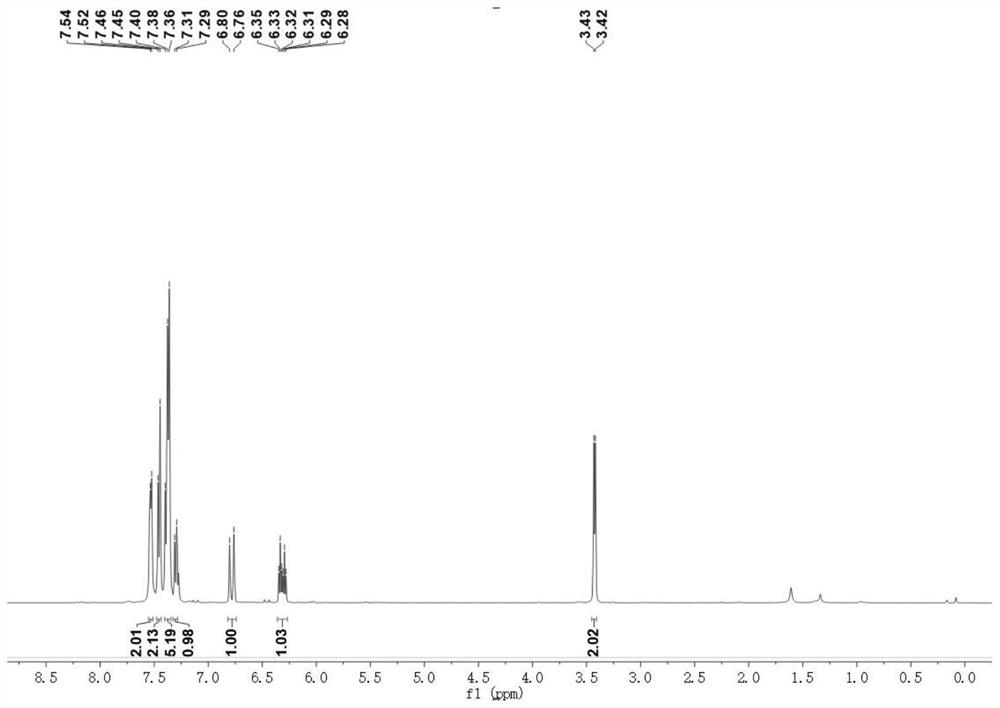

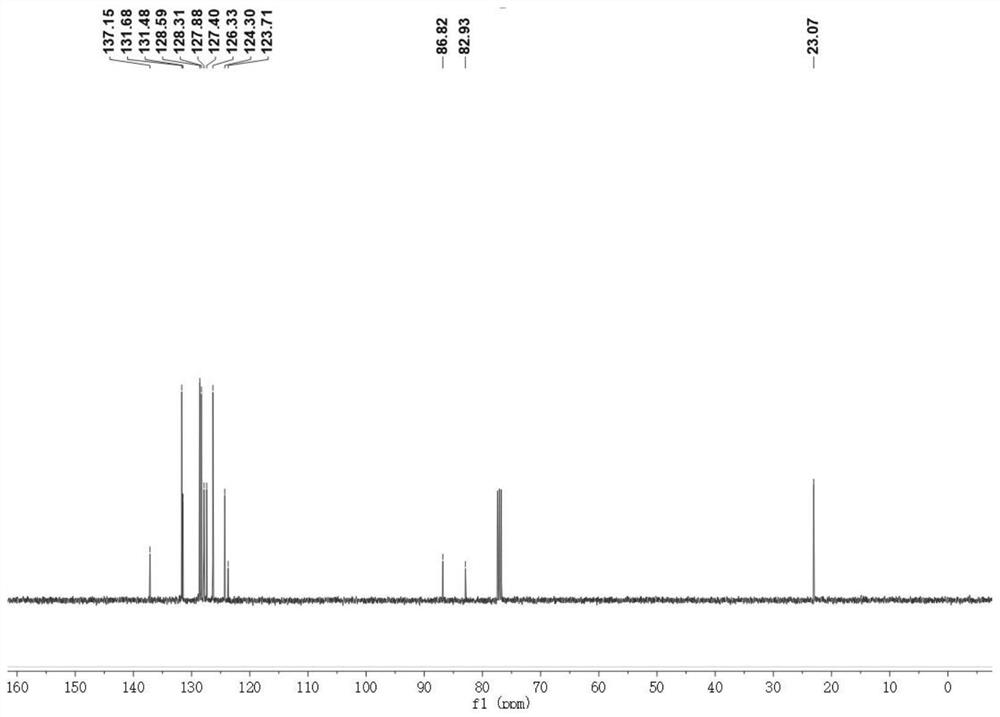

[0041] (E) 1,5-diphenyl-1-pentene-4-yne was detected by nuclear magnetic resonance, as attached Figure 1~2 shown, with figure 1 is (E) 1,5-diphenyl-1-pentene-4-yne H NMR spectrum, attached figure 2 It is the carbon nuclear magnetic resonance spectrum of (E) 1,5-diphenyl-1-penten-4-yne....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com