Patents

Literature

102 results about "Combinatorial catalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Monolithic catalyst for catalyzing combustion of volatile organic compounds and preparation method of catalyst

InactiveCN105964254AEasy to manufactureImprove production efficiencyIncinerator apparatusMetal/metal-oxides/metal-hydroxide catalystsCordieriteManganese oxide

The invention belongs to the technical field of catalysis, and particularly discloses a monolithic catalyst for catalyzing combustion of volatile organic compounds and a preparation method of the catalyst. According to the catalyst, cordierite honeycomb ceramic serves as a carrier, and the carrier is coated with a coating containing a metal active component and an auxiliary, wherein the catalyst active component is selected from any one or a combination of noble metals of Pt and Pd, and the catalyst auxiliary is selected from one or a combination of metal oxides such as aluminum oxide, titanium oxide, chromic oxide, cobaltous oxide and manganese oxide. The preparation method of the catalyst is simple, and the catalyst has the advantages that the coating is not prone to disengagement, the initiation temperature is low, the activity is good, the high-temperature-resistant property is good, and the noble metal content is low; the catalyst can be widely used for purification treatment of organic waste gas.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

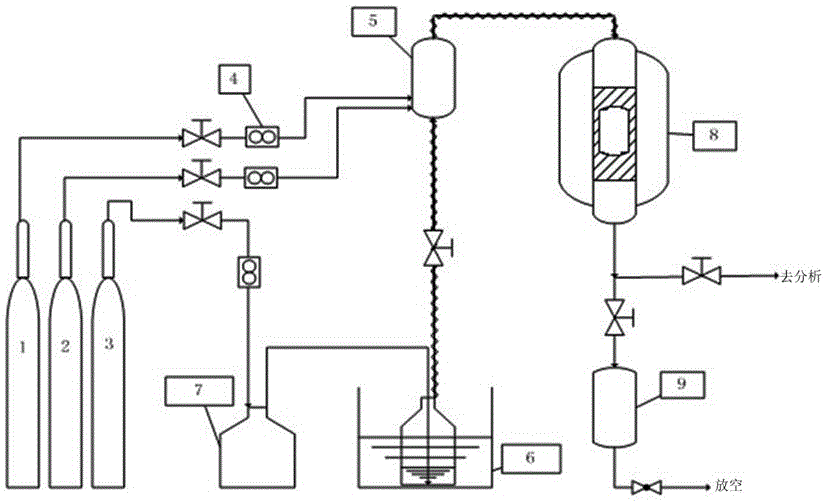

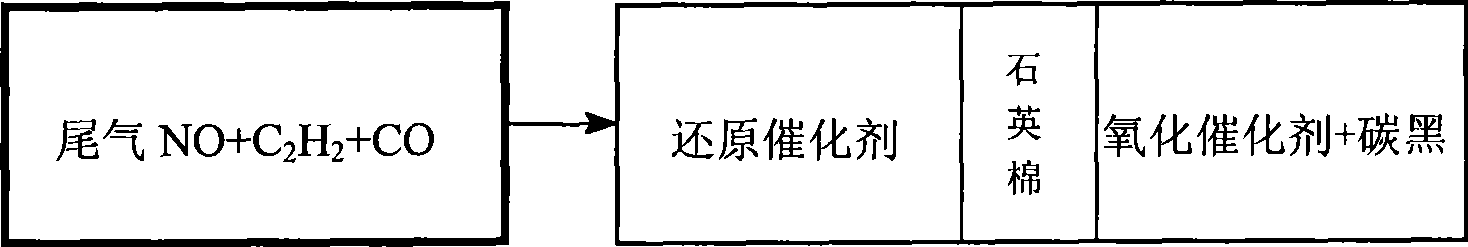

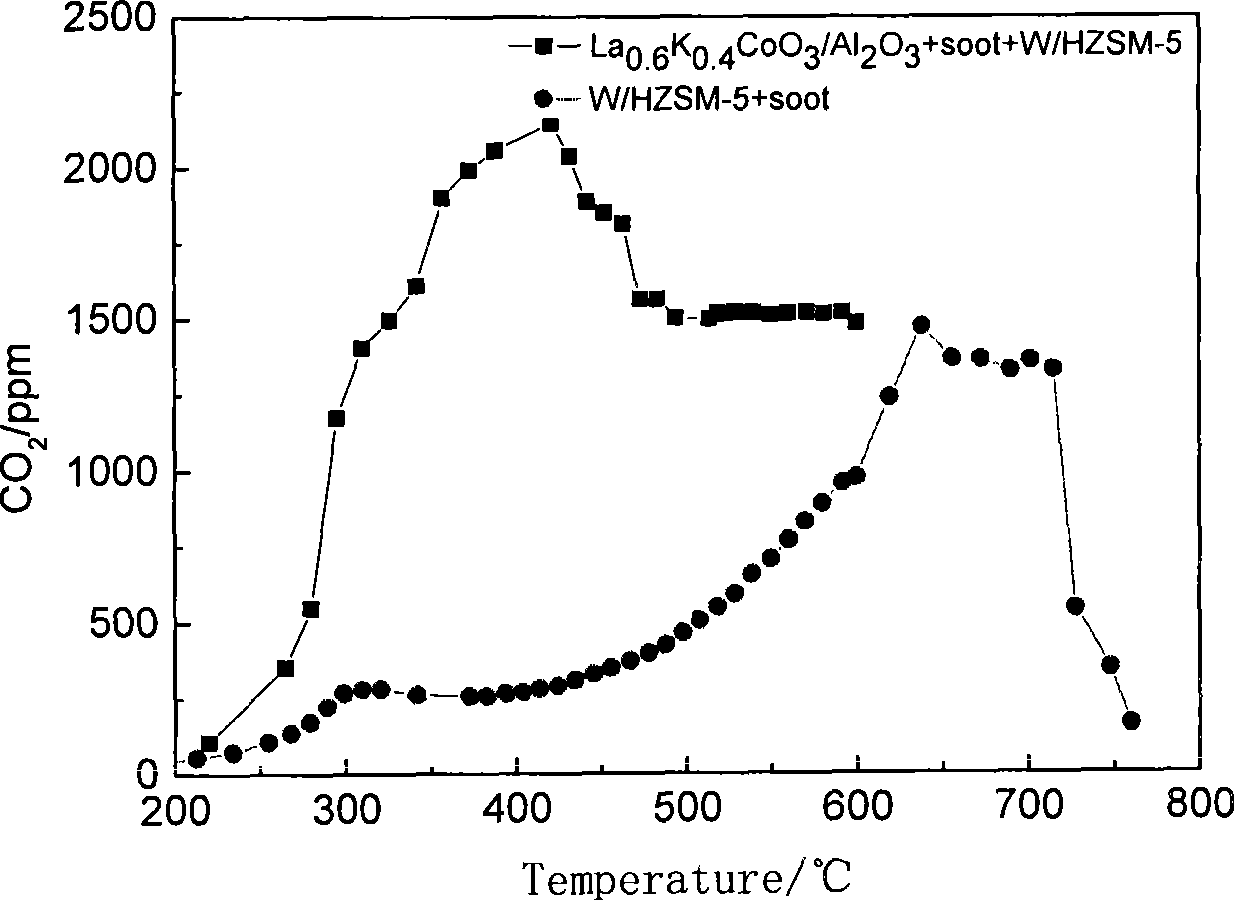

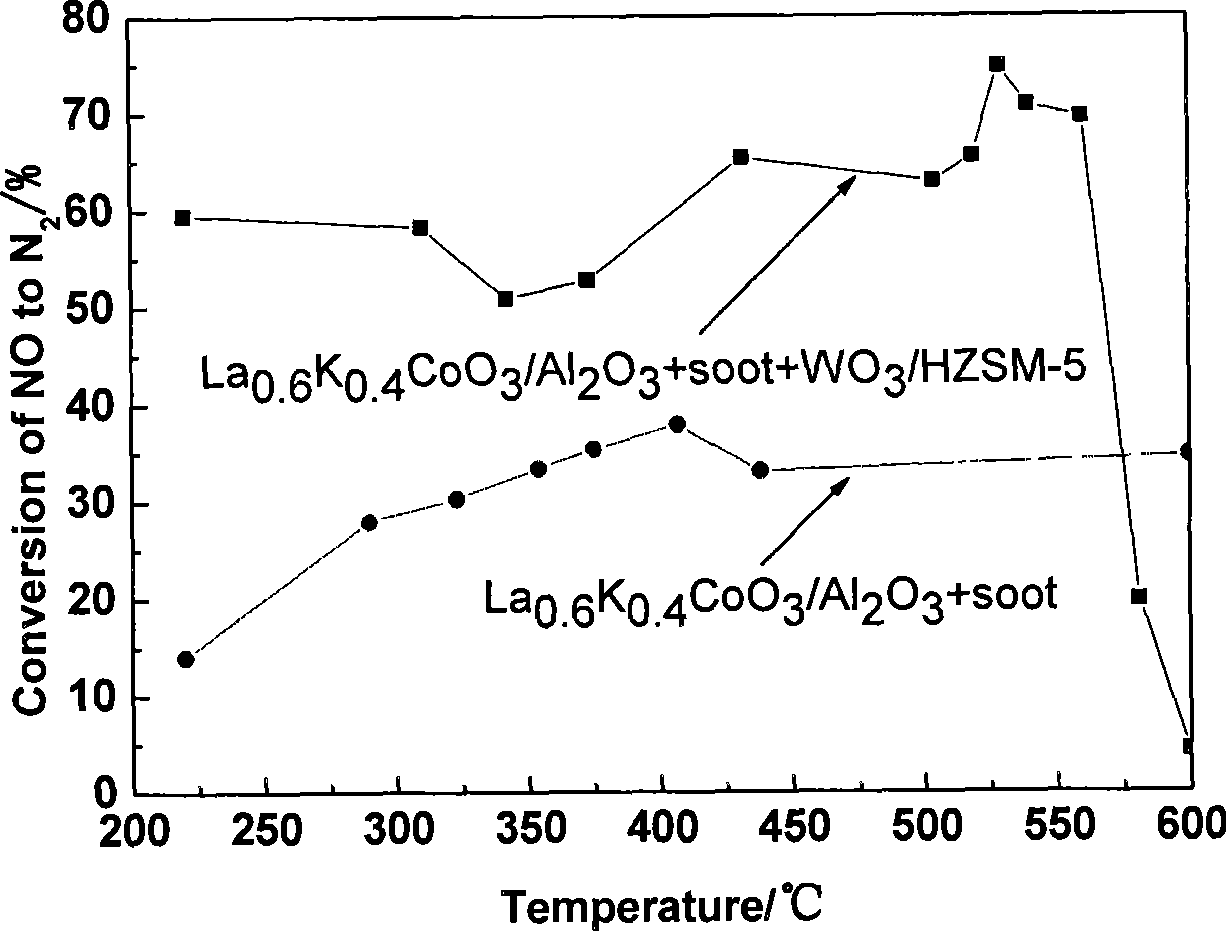

Combined catalyst for simultaneously eliminating four kinds of pollutants from diesel exhaust and purification method

InactiveCN101468295AAchieve simultaneous removalMild reactivityMolecular sieve catalystsDispersed particle separationParticulatesPurification methods

The invention relates to a composite catalyst capable of eliminating four main pollutants in diesel engine tail gas simultaneously and a method for purifying the diesel engine tail gas. The composite catalyst consists of an oxidation catalyst and a reduction catalyst, wherein the active components of the oxidation catalyst are selected from perovskite or similar perovskite composite oxides, and the reduction catalyst is an HZSM-5 molecular sieve modified by a transition metal oxide. The composite catalyst is filled into two catalyst bed layers in a constant temperature section of a reactor so that the diesel engine tail gas passes through the reduction catalyst bed layer and the oxidation catalyst bed layer and is warmed up to perform reaction, thus the aim of eliminating the pollutants of carbon particles, hydrocarbons, carbon monoxide, nitrogen oxide and the like simultaneously can be achieved. Because of the high efficiency oxidizing property and high efficiency reducing property, the used composite catalyst can purify the diesel engine tail gas under a comparatively mild condition.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

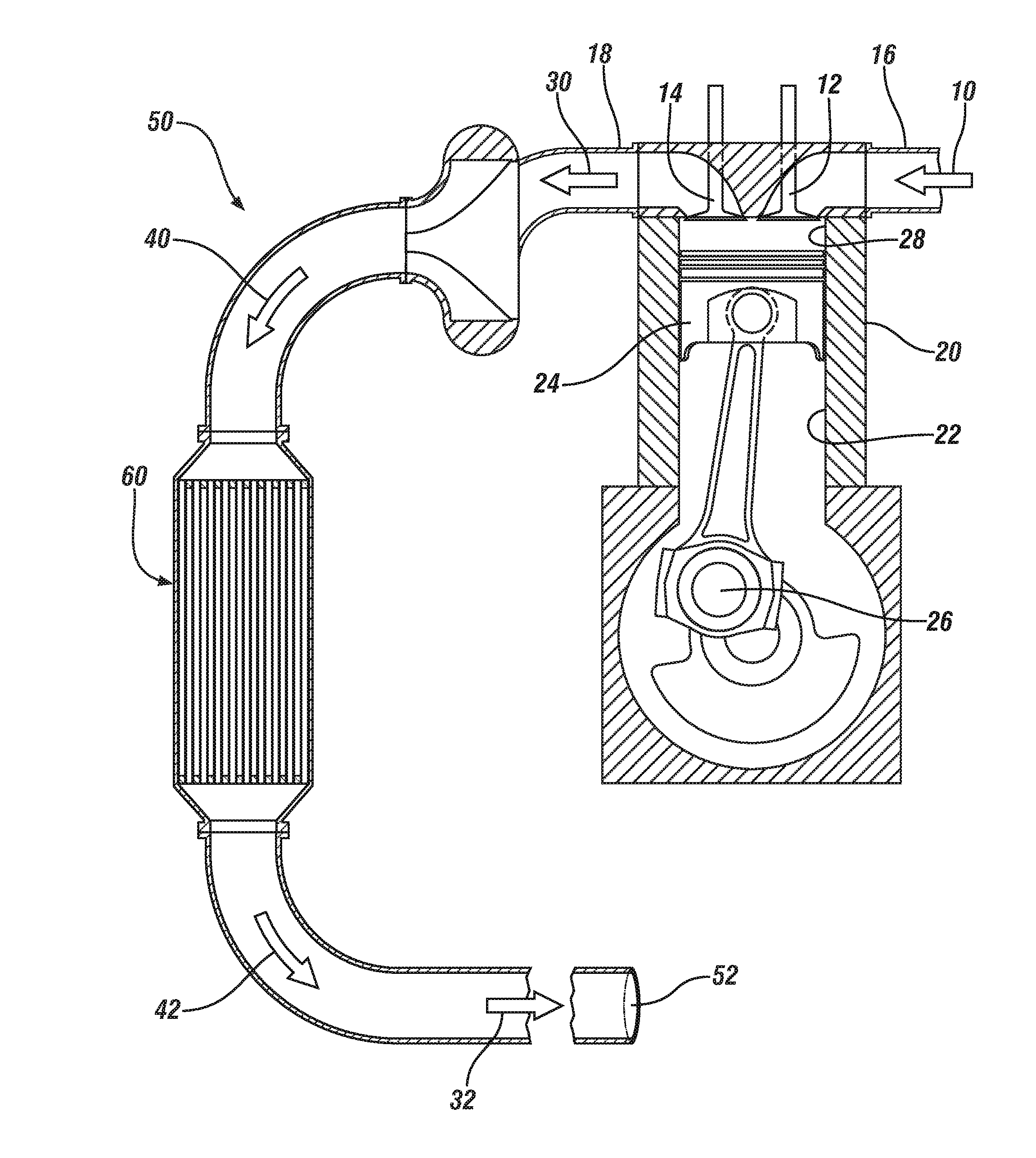

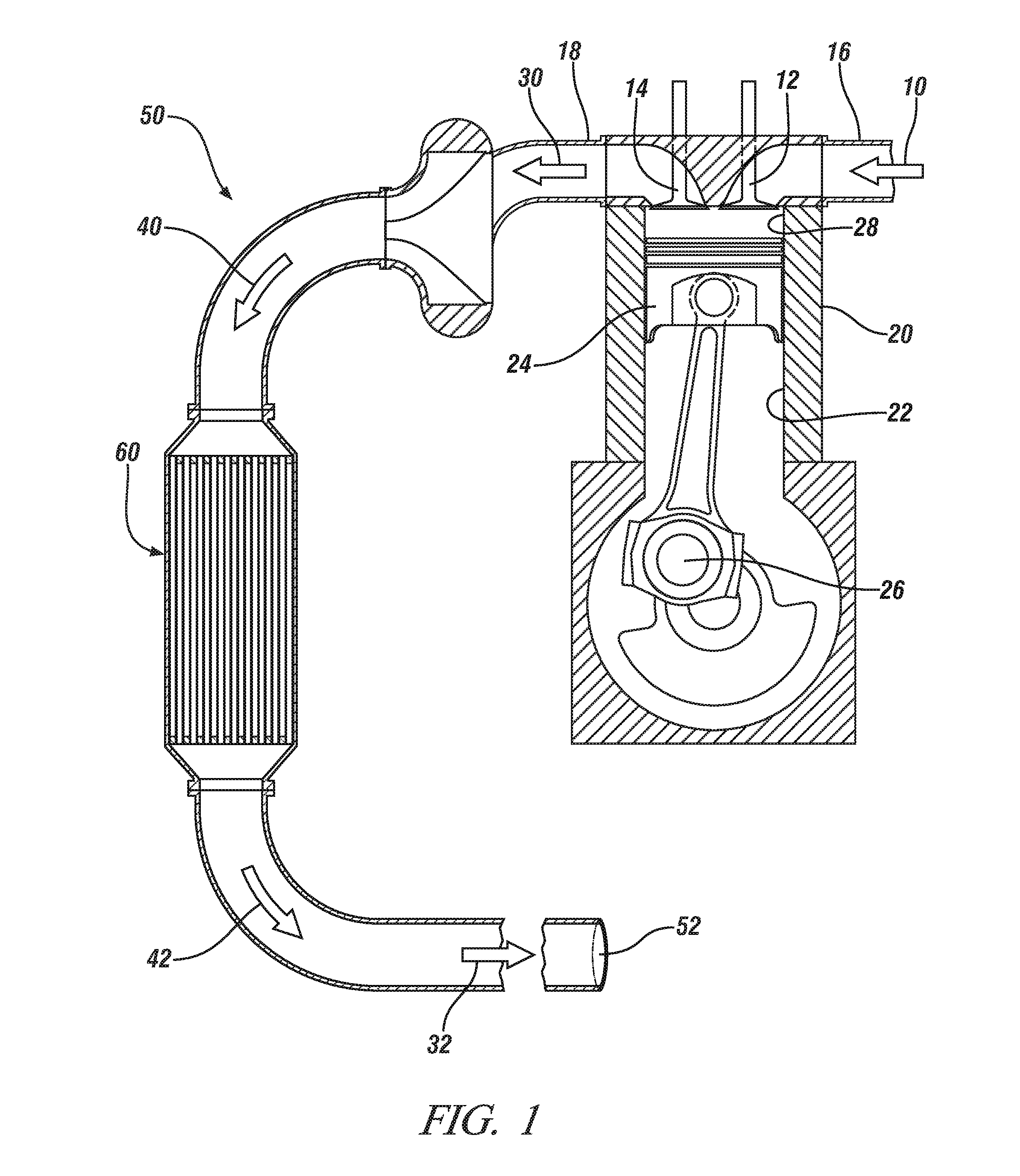

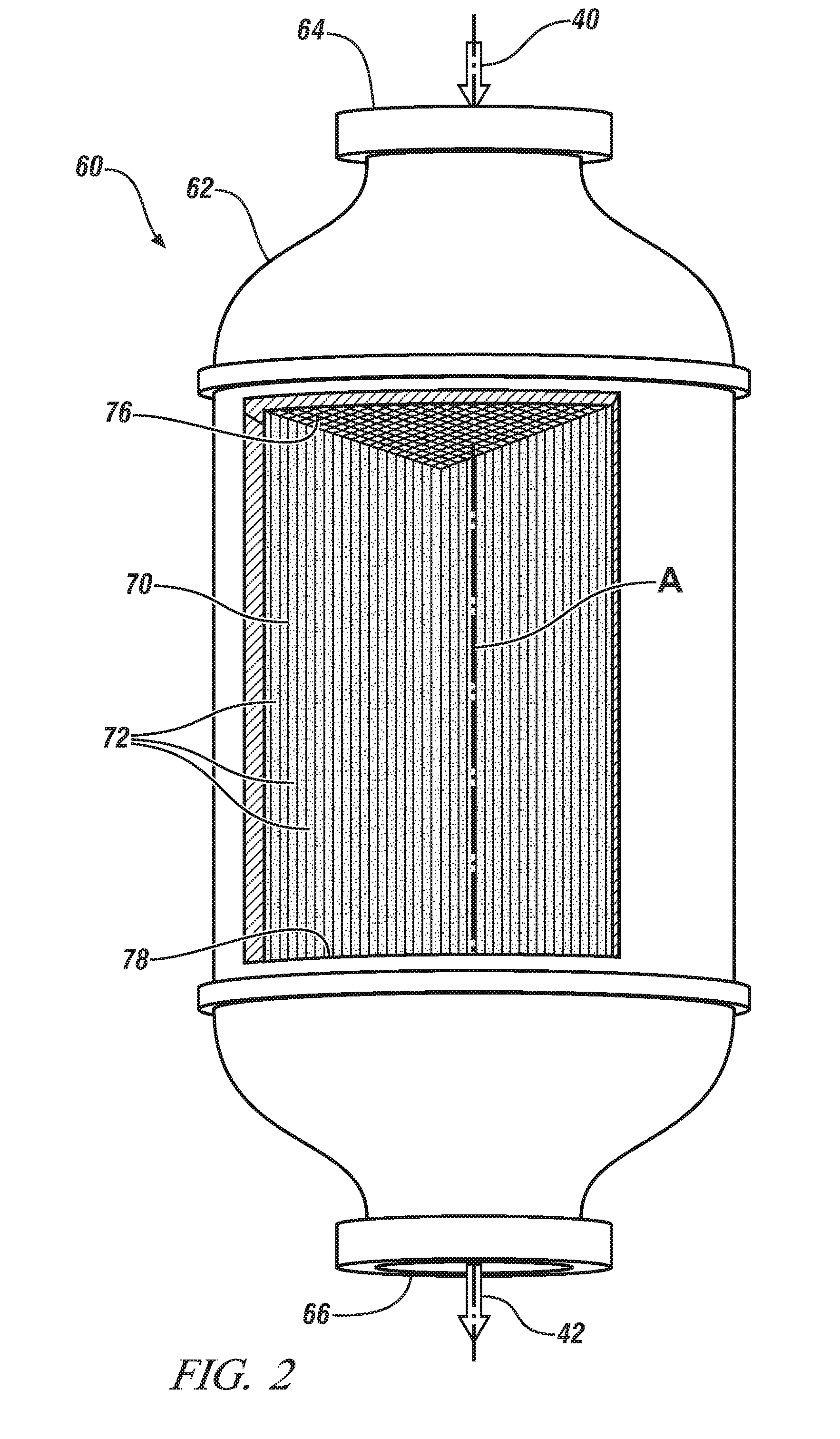

Oxidation catalysts for engines producing low temperature exhaust streams

ActiveUS20120291420A1Low temperatureEfficiently oxidizedCombination devicesHeterogenous catalyst chemical elementsDiesel engineAluminium oxide

The oxidation of carbon monoxide (CO) and hydrocarbons (HC) in an oxygen-containing gas stream, such as the exhaust stream from a diesel engine, or other lean-burn engine, may be catalyzed using a combination of mixed oxide particles of cerium, zirconium and copper, and discrete particles of an alumina-supported platinum group metal catalyst. The catalyzed oxidation of CO and HC by this combination of oxidation catalyst particles is effective at temperatures below 300° C.

Owner:GM GLOBAL TECH OPERATIONS LLC

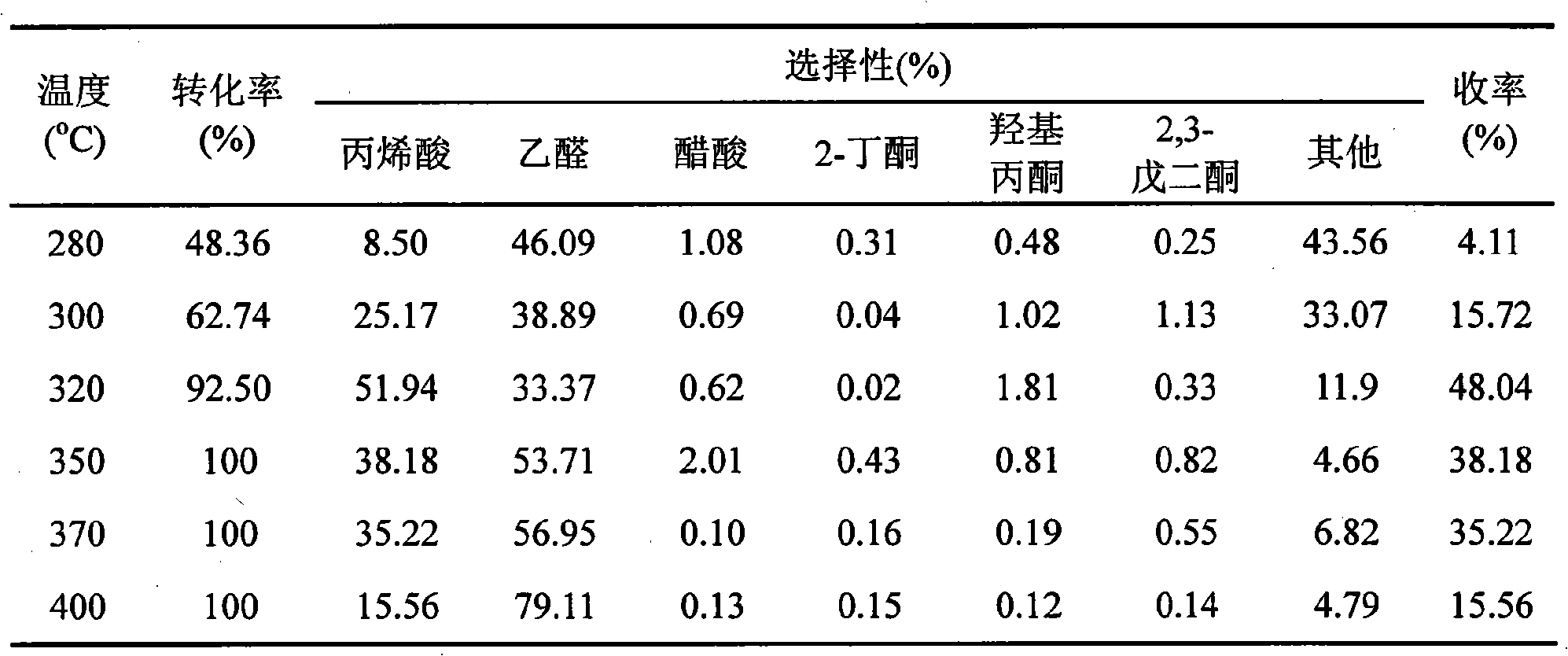

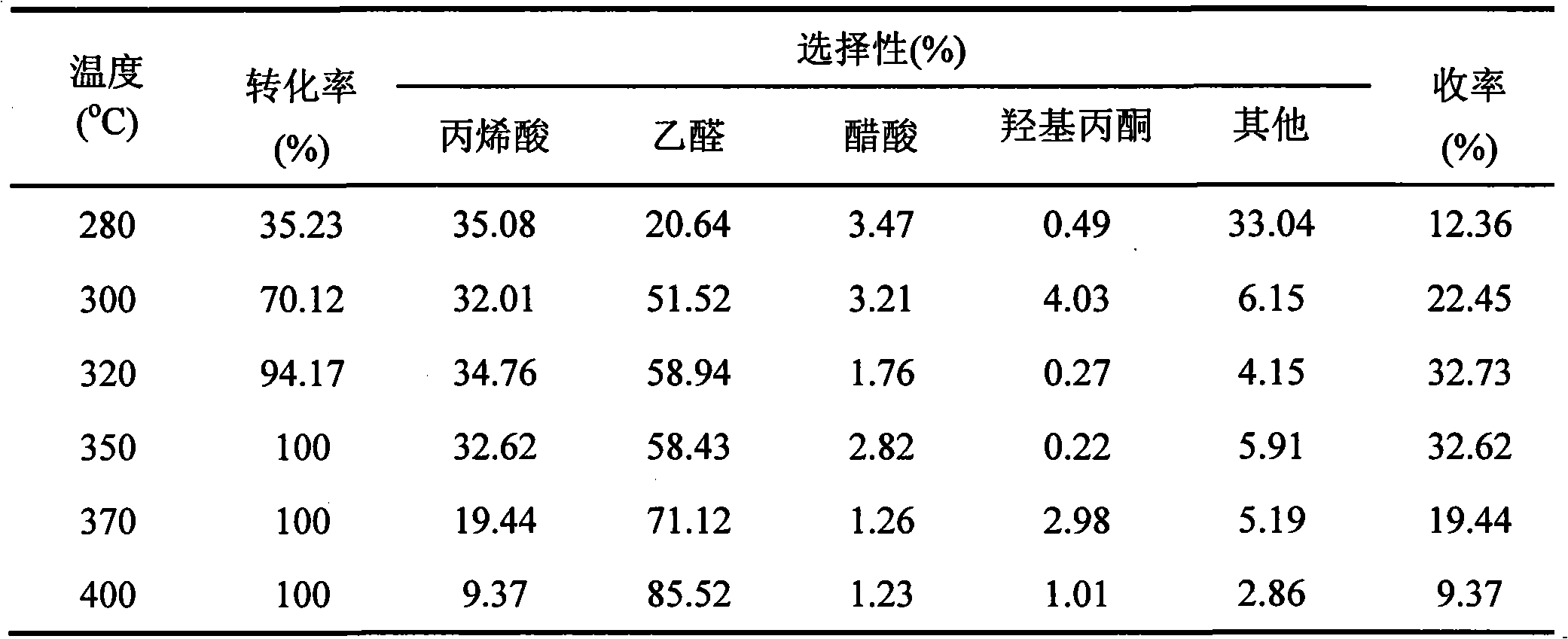

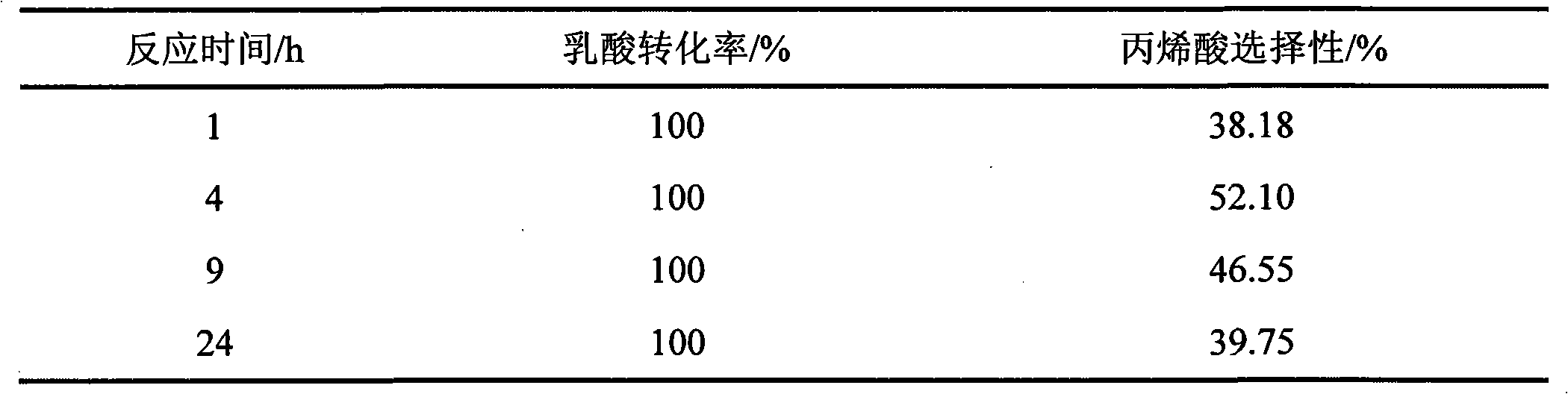

Catalyst for producing acroleic acid by lactic acid dewatering and reaction technique

InactiveCN101352688AEasy to makeImprove performanceMolecular sieve catalystsOrganic compound preparationRare-earth elementMolecular sieve

The invention relates to a catalyst for preparing acrylic acid from lactic acid dehydration and a reaction technology thereof. The catalyst comprises an inorganic porous material vector and an active metal component with 1wt% to 50wt% (calculated in the form of oxide), wherein, the inorganic porous material vector is one of silica-aluminum molecular sieve, phosphorous-aluminum molecular sieve, silica-phosphorous-aluminum molecular sieve and mesoporous material, and the active metal component is one of or a plurality of materials combined according to the random ratio such as IA, IIA, IIB, VIB, VIIB, VIIIB and rare earth elements. The catalyst is prepared in a way that the inorganic porous material vector is impregnated and loaded into the solution of soluble salt or hydroxide which contains active metal. The reaction of preparing acrylic acid from lactic acid dehydration is carried out in a fixed-bed flow-typed reactor which is filled with the catalyst; lactic acid which has 10-100% of concentration is directly put into the reactor to carry out catalytic dehydration at 280 DEG C to 400 DEG C without preheating gasification, so as to obtain 100% of lactic acid conversion rate and over 63% of acrylic acid selectivity.

Owner:HUNAN UNIV

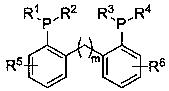

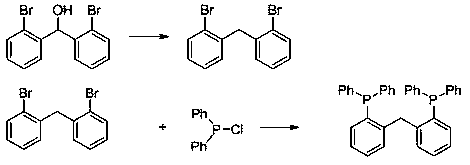

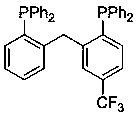

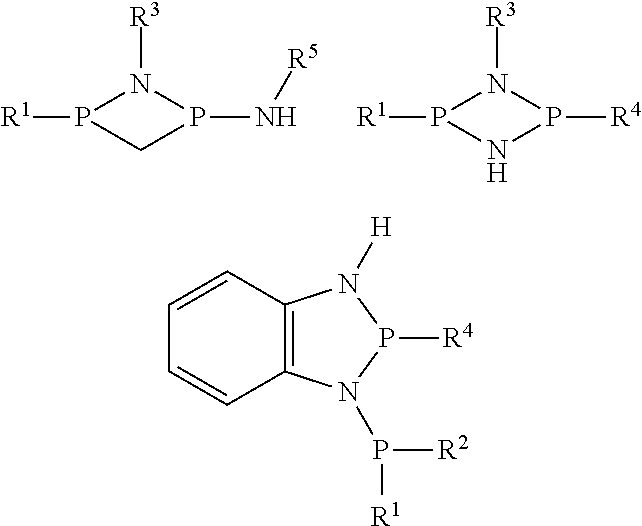

Method for preparing organic carboxylic ester through combined catalysis of aryl bidentate phosphine ligand

ActiveCN111087306ACoordination mode is stableStabilize the active structureCarboxylic acid nitrile preparationOrganic compound preparationArylPtru catalyst

Owner:NANJING CHENGZHI CLEAN ENERGY CO LTD +1

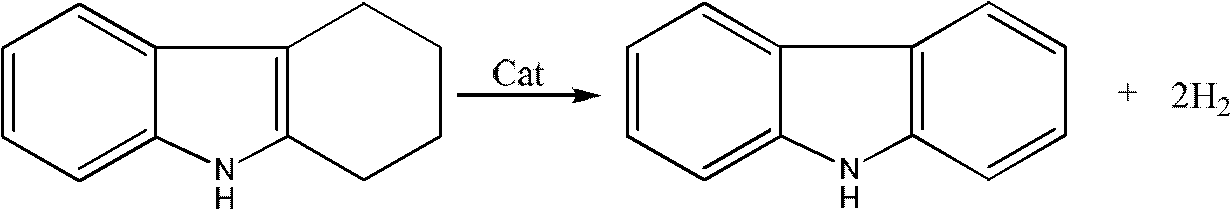

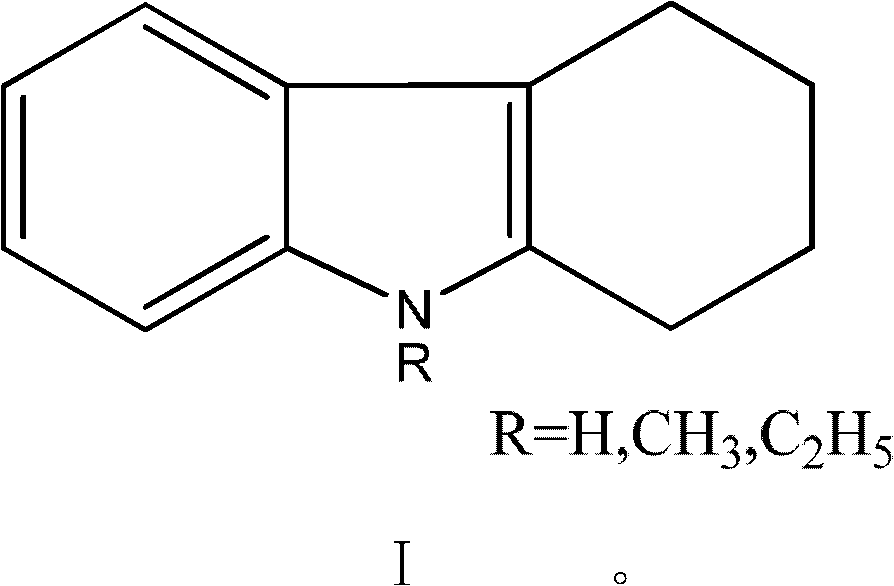

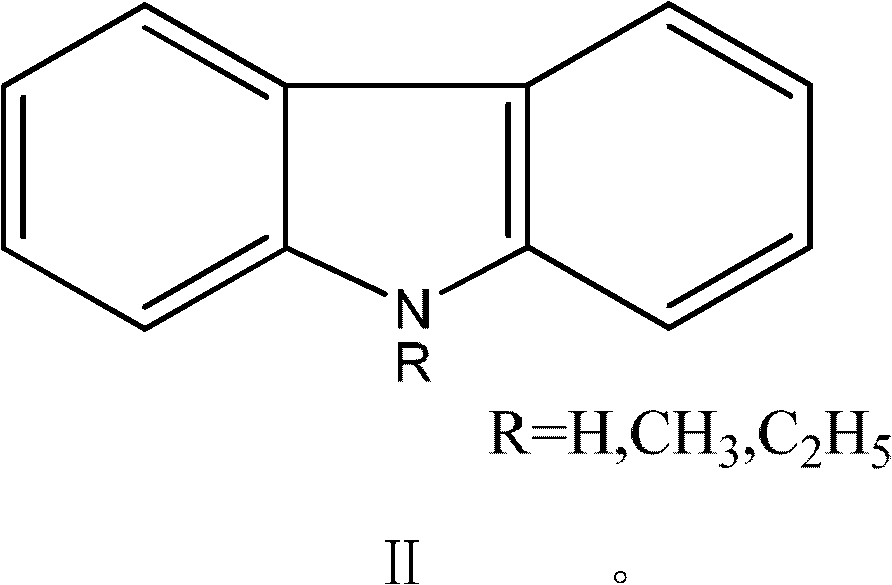

Method for synthesizing carbazole compounds

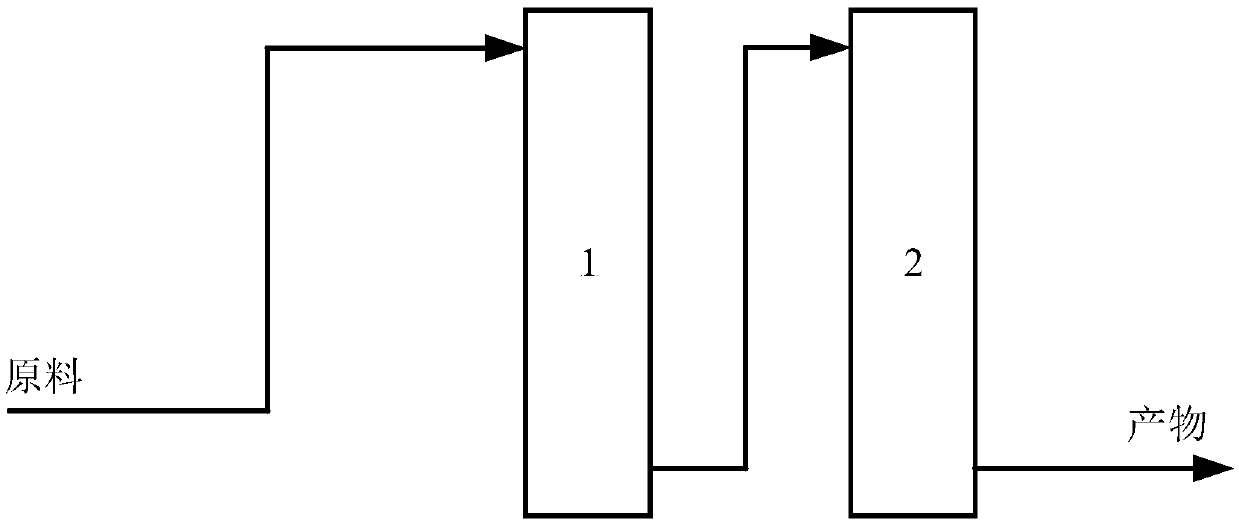

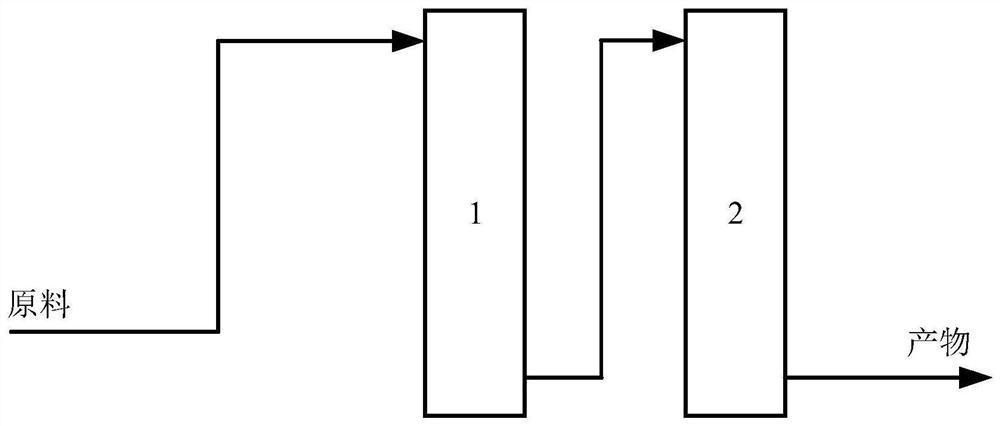

The invention relates to the technical field of preparation of carbazole compounds, in particular to a method for synthesizing carbazole compounds, which includes: obtaining a product by using 1, 2, 3, 4-tetrahydrocarbazole compound as raw materials by means of catalytic dehydrogenation, and leading cheap catalyst and high-activity catalyst to undergo combinatorial catalysis in the catalytic dehydrogenation process: the cheap and low-activity catalyst is used for catalysis at the first step, and then the high-activity catalyst is used for catalysis at the second step; or the high-activity catalyst is used for catalysis at the first step, and then the cheap and low-activity catalyst is used for catalysis at the second step. The method for synthesizing the carbazole compounds is small in catalyst use amount, low in cost and high in reacting conversion rate and selectivity, the content of carbazole is higher than 99%, solvent and the catalyst can be recovered and used indiscriminately, and the method is suitable for industrial production and has the advantages of simple process, high reacting yield, high product purity and environmental friendliness.

Owner:NANTONG HAIDI CHEM

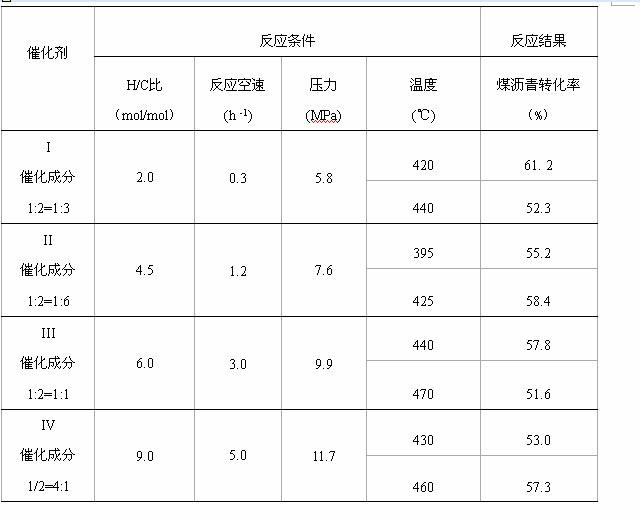

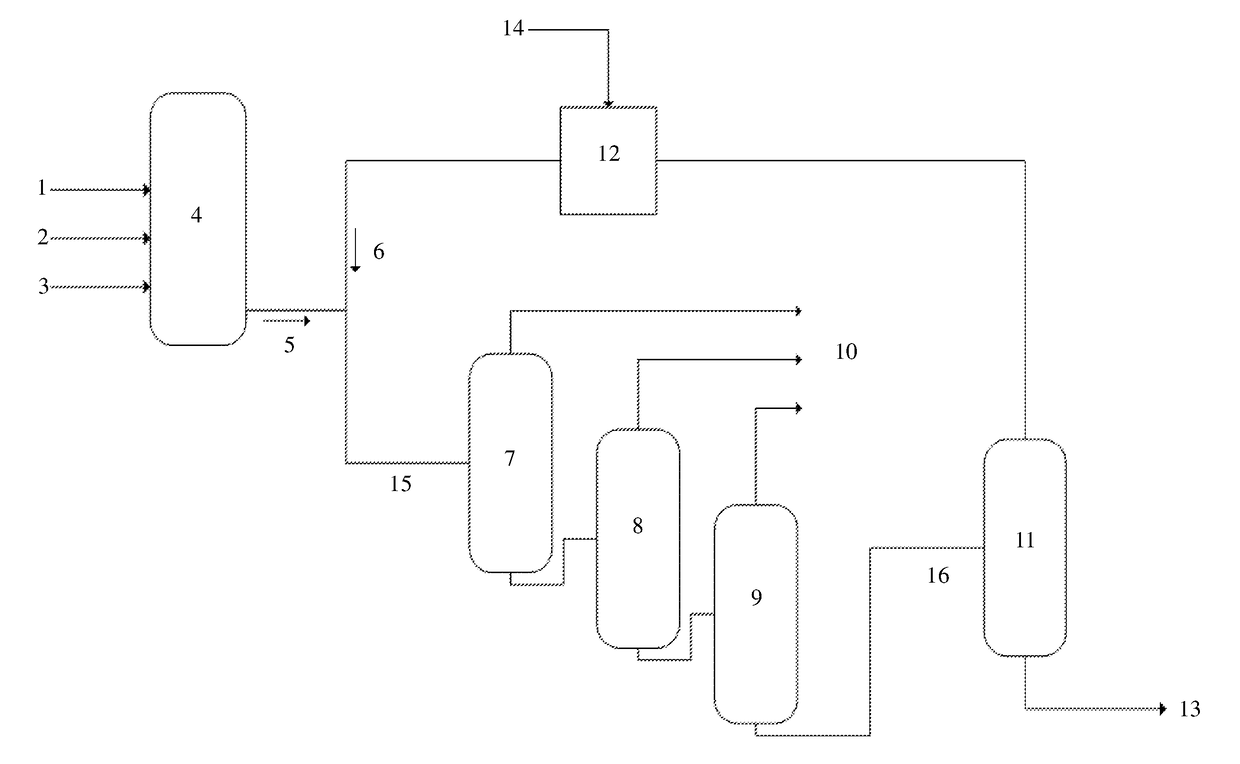

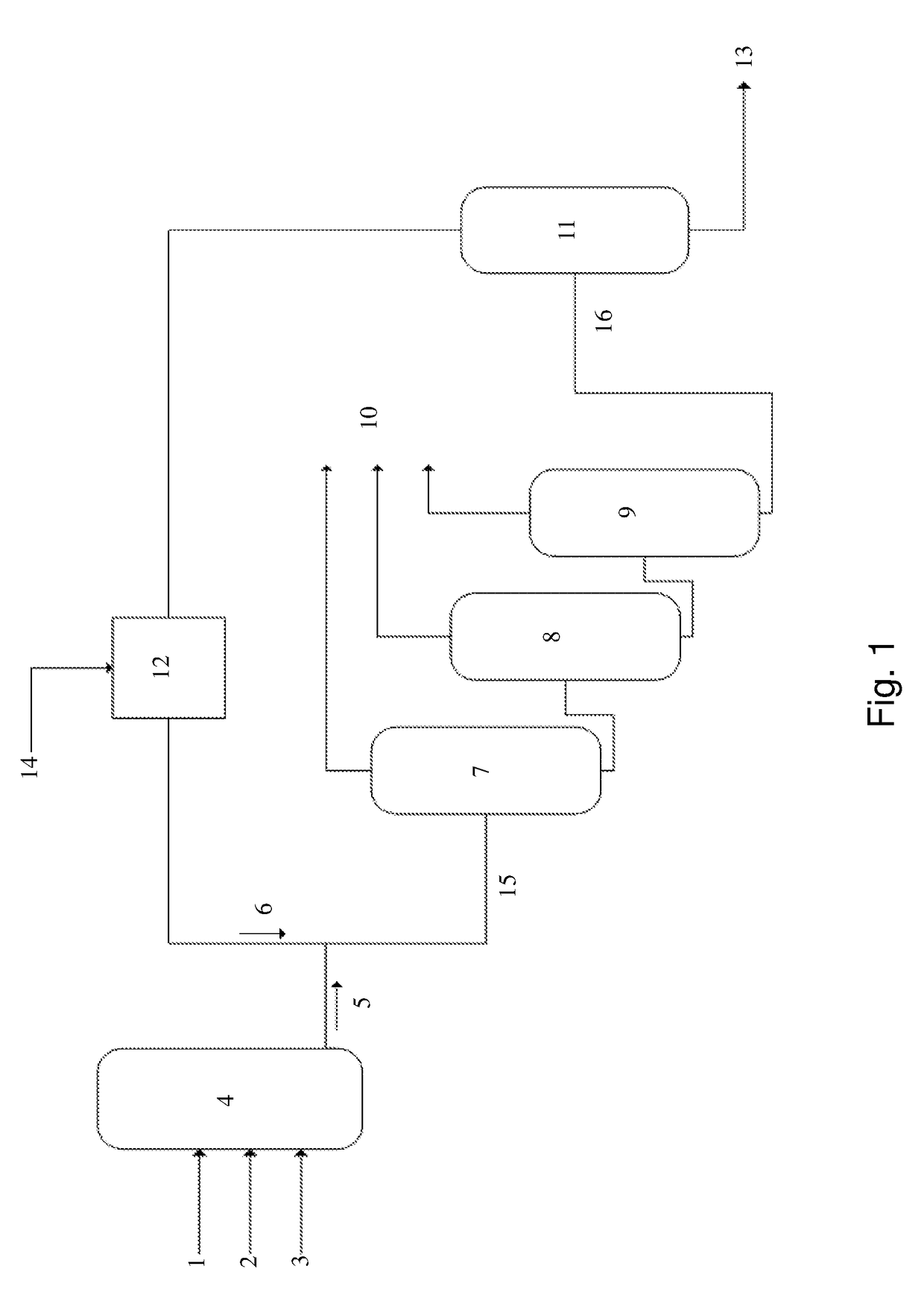

Preparation method and use method of two-stage bed reaction catalyst used in coal tar pitch lightening process

ActiveCN102008974AHigh yieldHigh activityMolecular sieve catalystsHydrocarbon oil crackingMaterial consumptionReaction temperature

The invention relates to a preparation method and use method of a two-stage bed reaction catalyst used in the coal tar pitch hydrocracking lightening process. The use method of the catalyst comprises the following specific steps: the mixture of coal tar pitch and toluene is used as the raw material and a fixed bed reactor is adopted to perform the efficient combinatorial catalysis through the two-stage bed reaction catalyst under the conditions that the reaction temperature is 380-500 DEG C, the reaction pressure is 5.0-12.0MPa and the reaction air speed is 0.2-5h<-1>, thus realizing the lightening process of the hydrocracking two-stage reaction of coal tar pitch. The two-stage bed combined catalyst in the invention consists of two catalytic components with different functions at a ratio of (1:10)-(10:2). By using the method in the invention in the coal tar pitch hydrocracking lightening reaction process, the reaction activity is higher, the stability is better, the production technology can be effectively simplified, and the production energy consumption, the material consumption and the cost can be reduced.

Owner:JIANGSU TIANNUO NEW MATERIAL TECH

Process for deactivation of an olefin oligomerization catalyst

ActiveUS20180258009A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAlpha-olefinSolvent

A process for deactivation of an olefin oligomerization catalyst is described, including contacting a catalyst composition with a catalyst quenching medium to form a deactivated catalyst composition, and recovering excess catalyst quenching medium. The catalyst quenching medium includes an alcohol having at least 6 carbon atoms, an organic amine, an amino alcohol, or a combination comprising at least one of the foregoing. The catalyst quenching medium is present in a molar ratio of catalyst quenching medium to catalyst of at least 3:1. A process for the oligomerization of an olefin is also described, including feeding the olefin, a solvent, and a catalyst composition into a reactor, oligomerizing the olefin in the reactor to form a reaction product stream including linear alpha olefins, solvent, and the catalyst composition, and contacting the reaction product stream with a catalyst quenching medium.

Owner:SABIC GLOBAL TECH BV

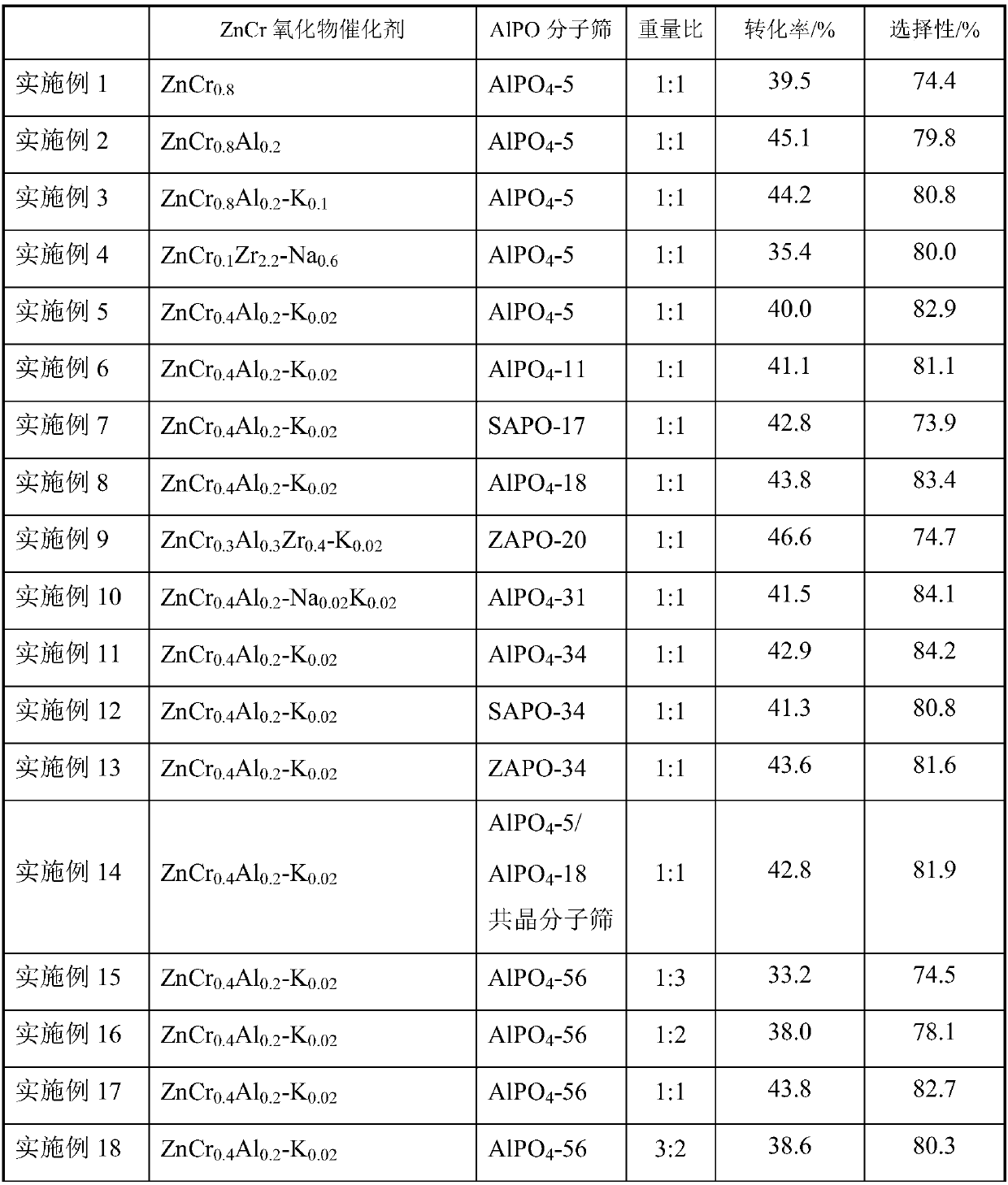

Combined catalyst used for preparing light olefins and use method thereof

ActiveCN109701629AHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sievePtru catalyst

The invention belongs to the technical field of chemistry and chemical engineering and particularly provides a combined catalyst used for preparing light olefins from synthetic gas and a use method thereof, and mainly solves the problem that a catalyst used for preparing light olefins from synthetic gas is low in selectivity in the prior art. In the catalyst, an ZnCr oxide catalyst is coupled witheight-membered ring, ten-membered ring and twelve-membered ring molecular sieve catalysts containing P and Al, wherein the ZnCr oxide catalyst has the molecular general formula of ZnCrXY<c>O<d>. The catalyst achieves direct production of olefins from the synthetic gas in one step, solves the problems well, can be used for preparing C2-C4 olefins high-effectively, continuously and stably, and can be used for industrial production of preparing light olefins from synthetic gas.

Owner:CHINA PETROLEUM & CHEM CORP +1

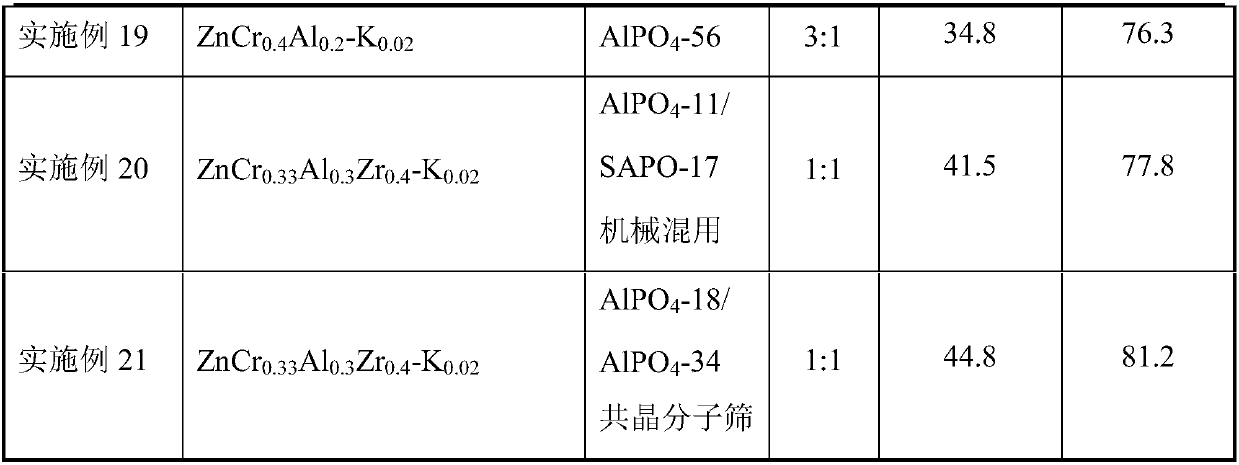

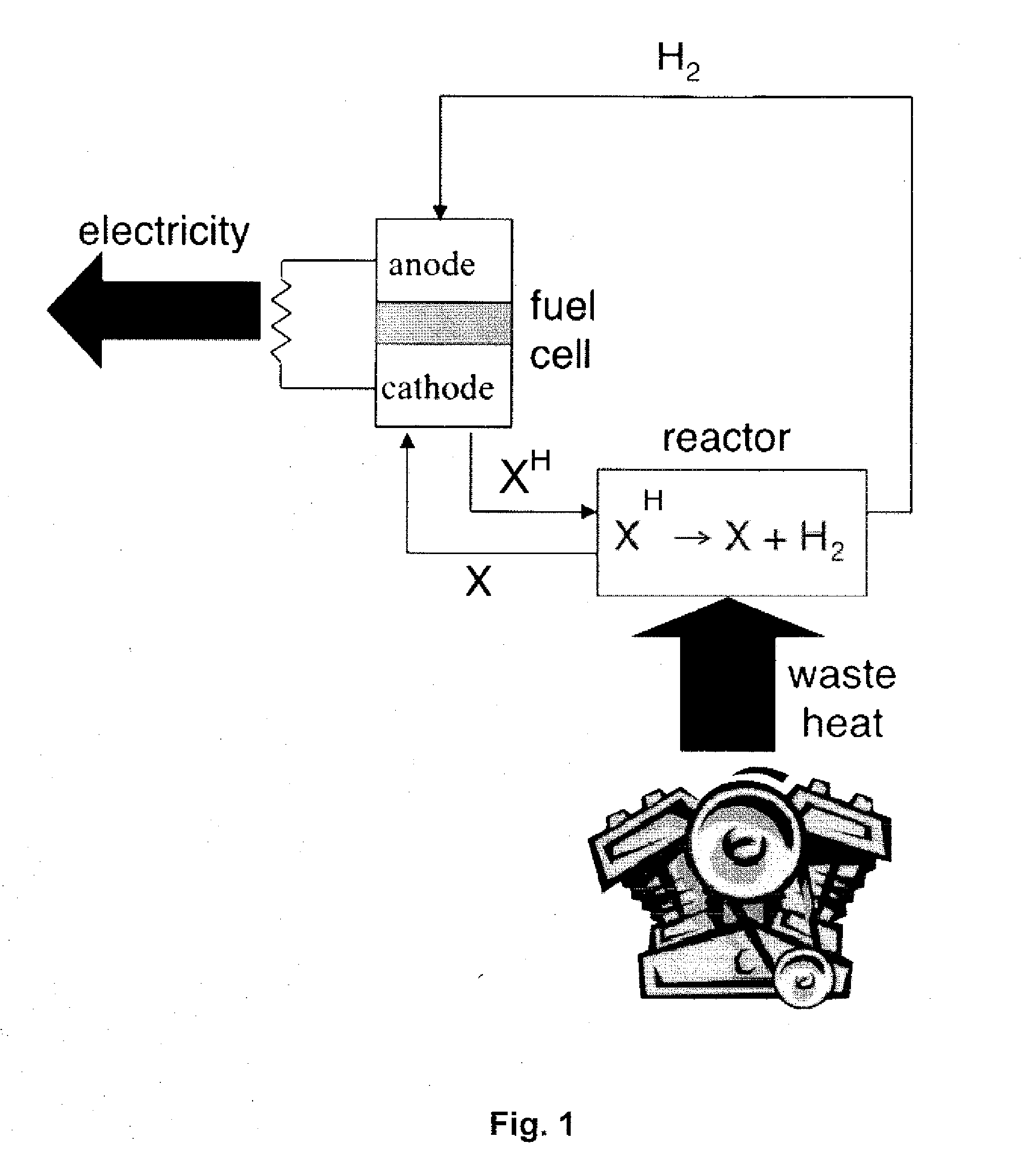

Catalyst and Liquid Combination for a Thermally Regenerative Fuel Cell

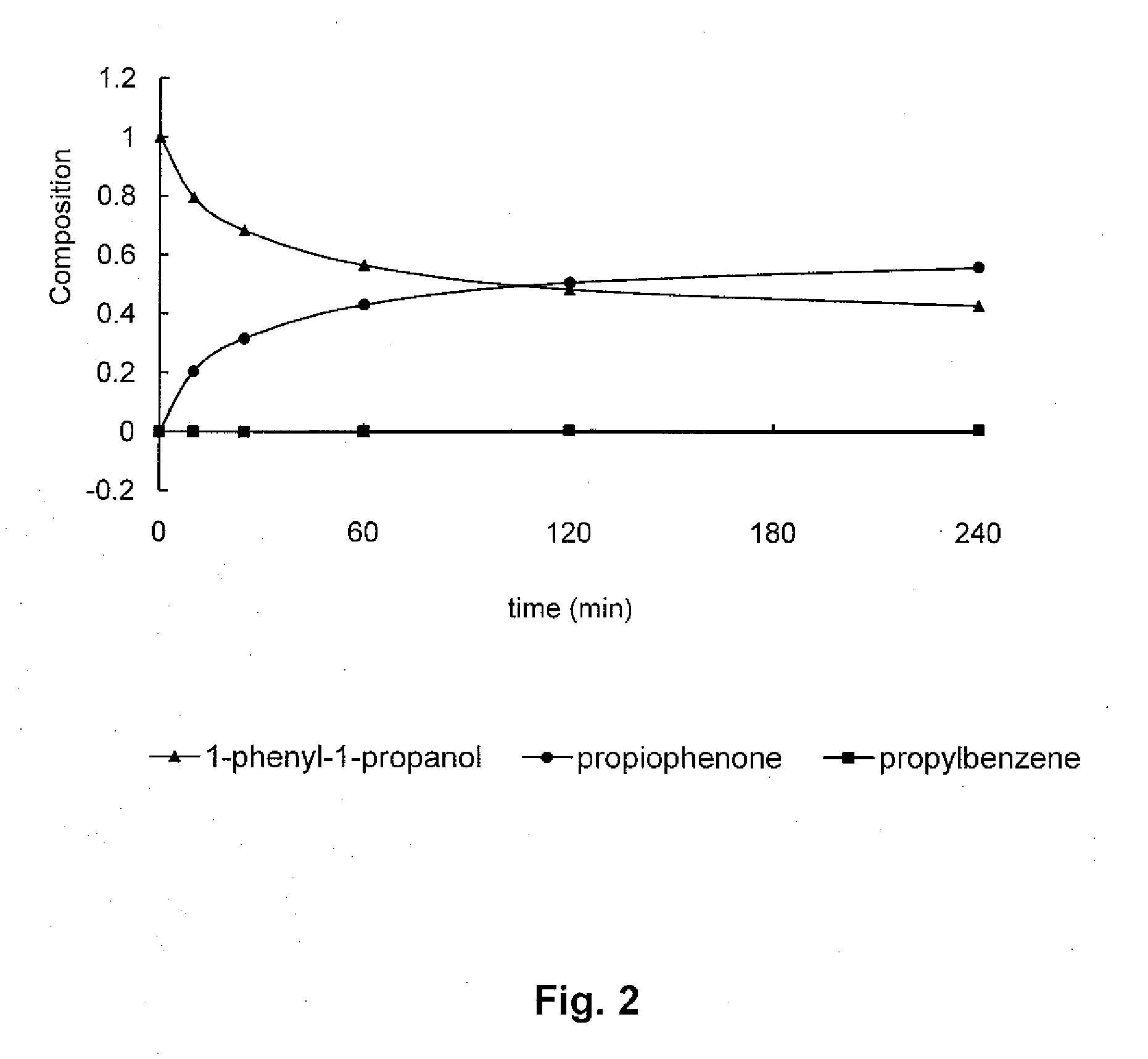

InactiveUS20110274994A1Inhibit dehydrogenation reactionImprove responseRegenerative fuel cellsEnergy inputFuel cellsPtru catalyst

Combinations of catalyst and compound are described that are suitable for use in a thermally regenerative fuel cell. Such combinations offer greater than 99% selectivity and accordingly they cycle through a reversible dehydrogenation process with substantially no loss due to byproduct formation. Combinations of secondary benzylic alcohols and Pd / SiO2 catalysts offer levels of by-products that are undetectable by NMR and GC analysis. With such TRFC, thermal energy can be converted into electric energy in a moving vehicle without the requirement of storage of H2, and its safety issues. Instead, a catalytic amount of H2 is cycled through the system and used to generate electric energy.

Owner:QUEENS UNIV OF KINGSTON

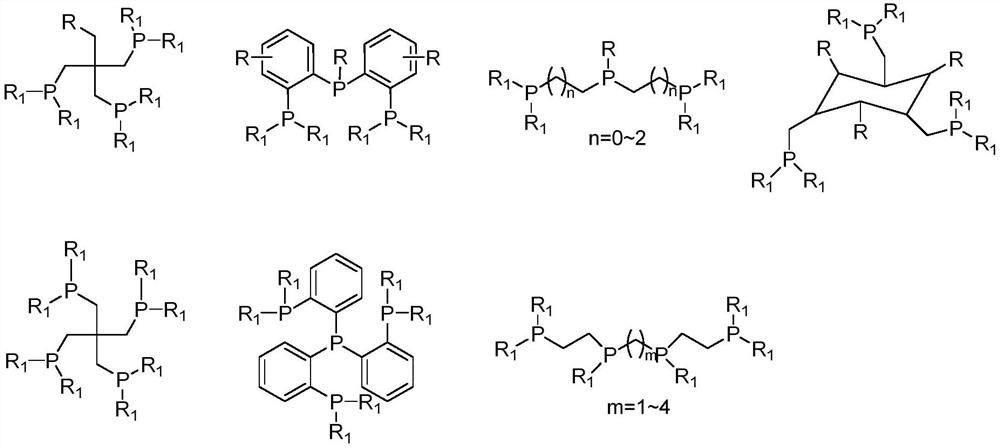

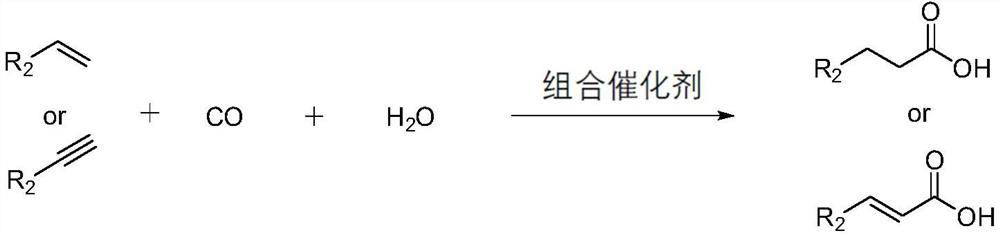

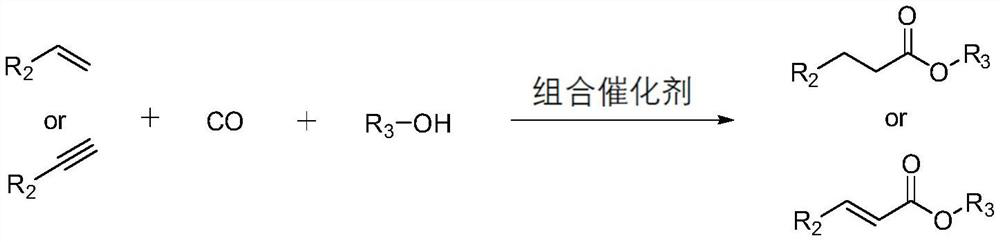

Method for preparing straight-chain carbonyl compound by catalyzing unsaturated hydrocarbon through polydentate phosphine ligand modified palladium combined catalyst

PendingCN113788748ANo emissionsAtom economyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhosphine

The invention discloses a method for preparing a straight-chain carbonyl compound by catalyzing unsaturated hydrocarbon through a polydentate phosphine ligand modified palladium combined catalyst. The straight-chain carbonyl compound comprises carboxylic acid, carboxylic ester and amide. The combined catalyst is composed of a divalent or zero-valent palladium compound, a polydentate phosphine ligand and an acidic auxiliary agent. Under the action of the combined catalyst, unsaturated hydrocarbon, carbon monoxide and a nucleophilic reagent are used as raw materials for carbonylation reaction to successfully prepare the straight-chain carbonyl compound. The nucleophilic reagent comprises water, alcohol, organic primary amine or inorganic ammonia. The catalyst provided by the invention has the advantages of high catalytic activity, good straight-chain carbonyl compound selectivity, good stability and recyclability. The method is a one-pot homogeneous synthesis process, the synthesis process is simple, reaction conditions are mild, a new technology is provided for synthesis of important chemical straight-chain carbonyl compounds, and the method has good application and popularization prospects.

Owner:EAST CHINA NORMAL UNIV

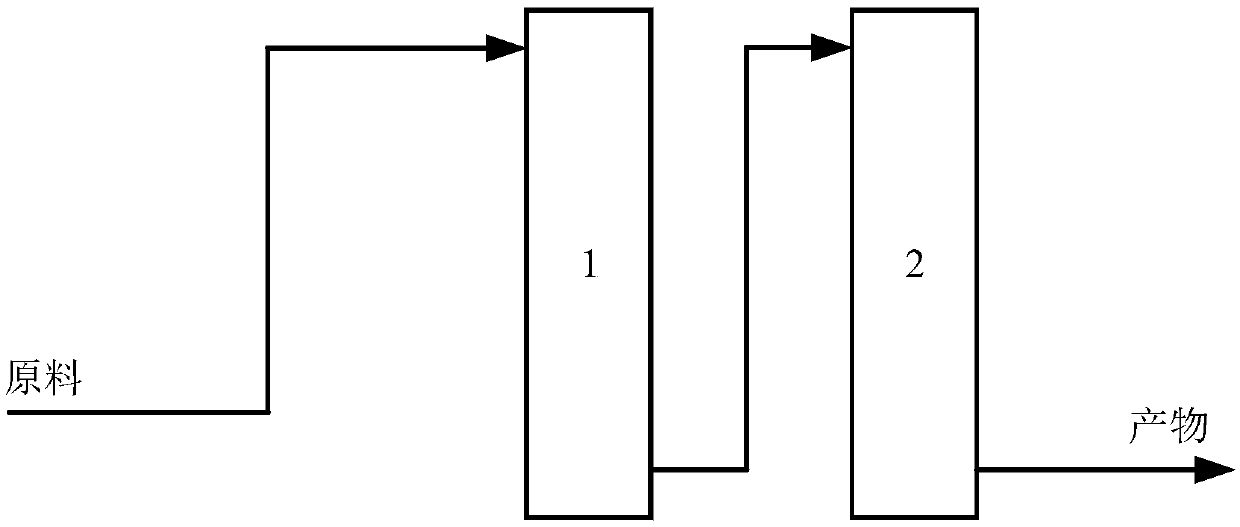

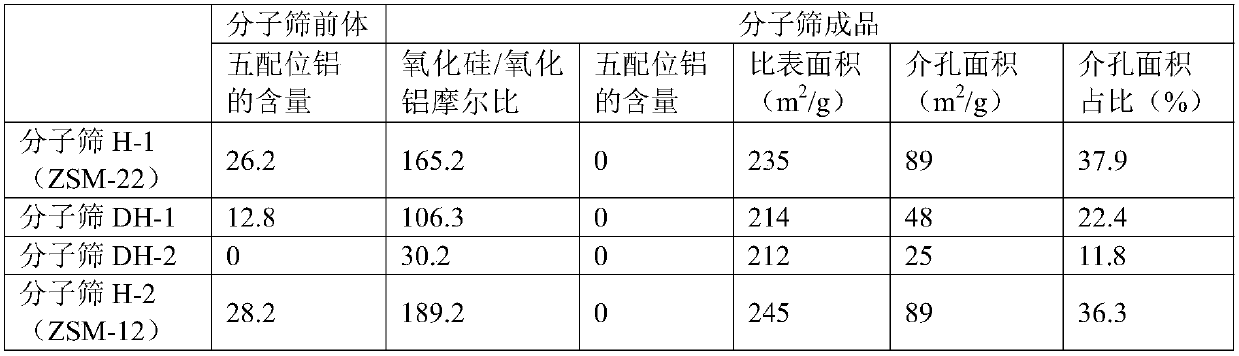

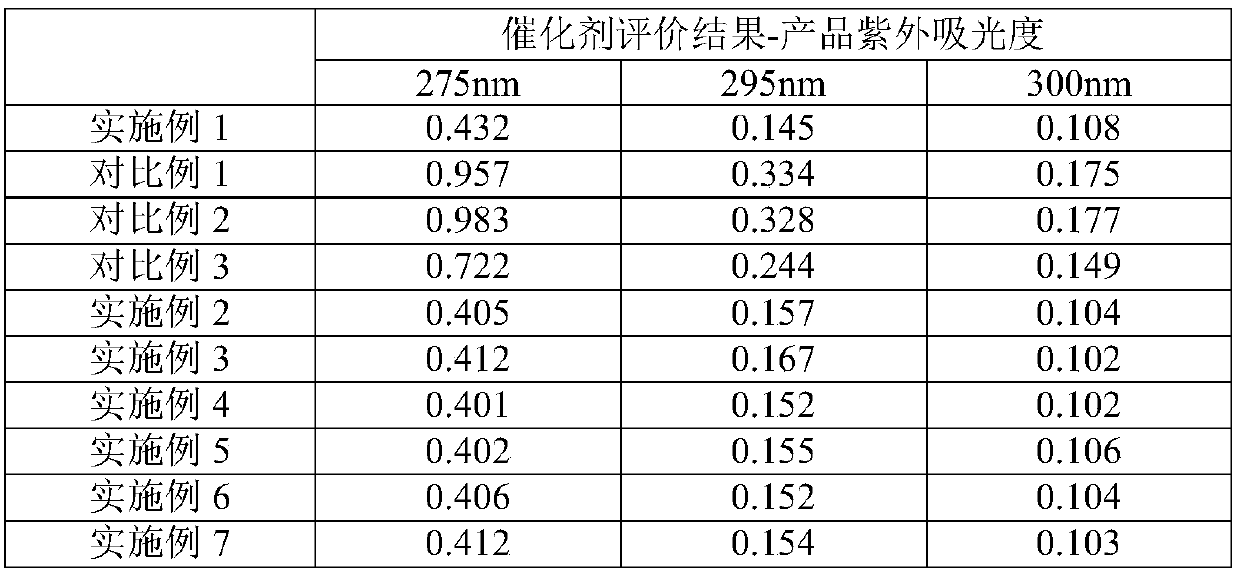

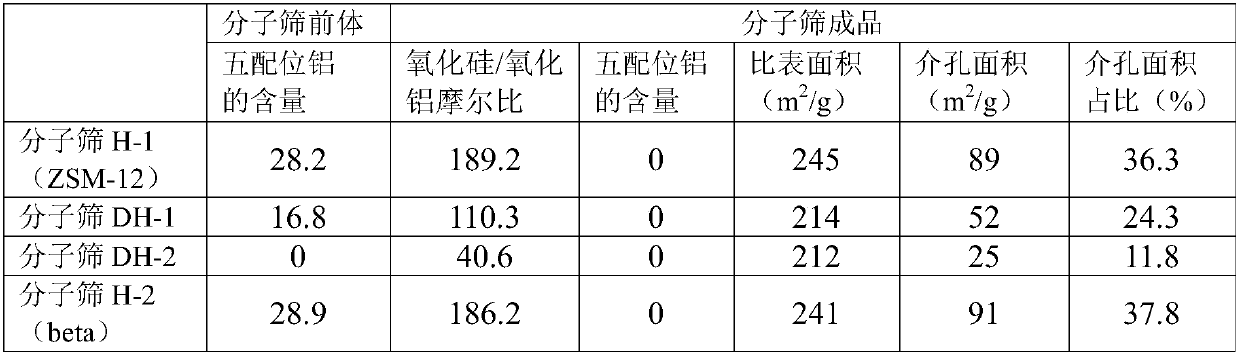

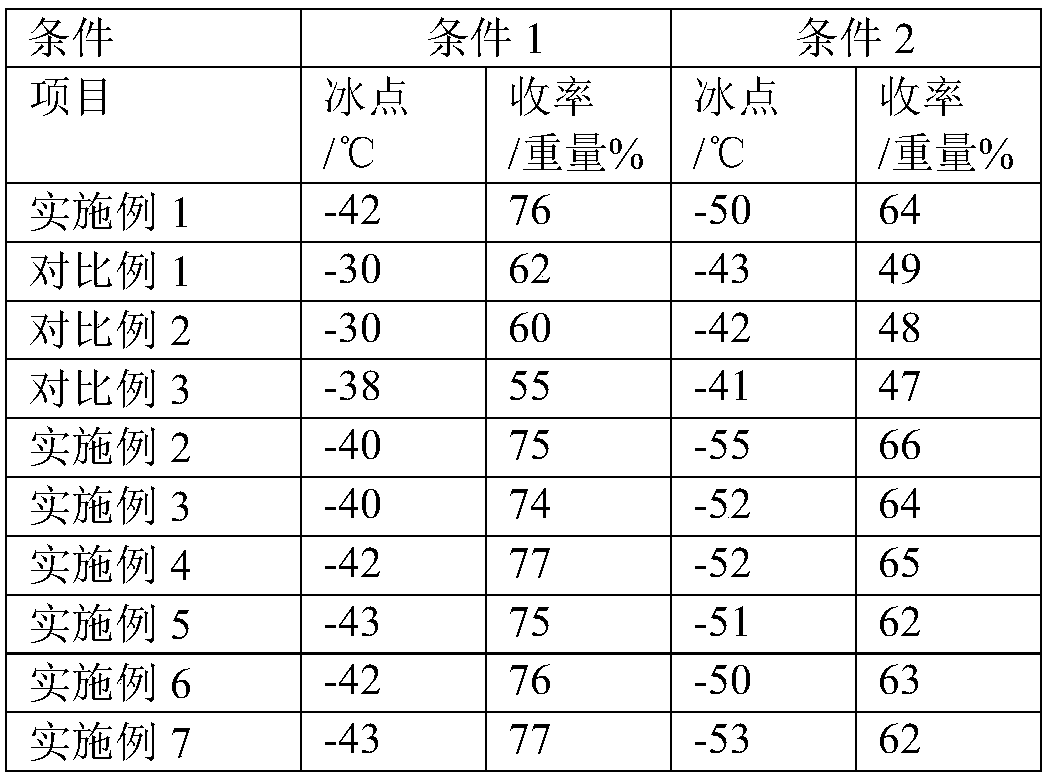

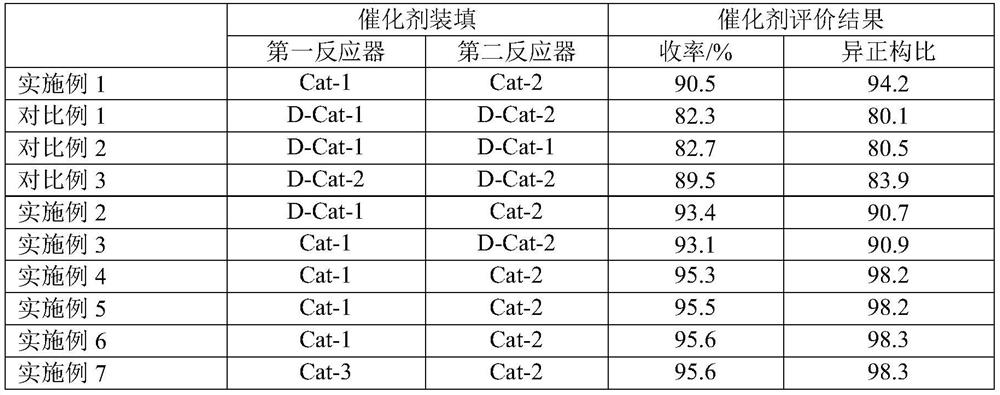

Combined catalyst and method for producing C5 and C6

ActiveCN110841707AMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

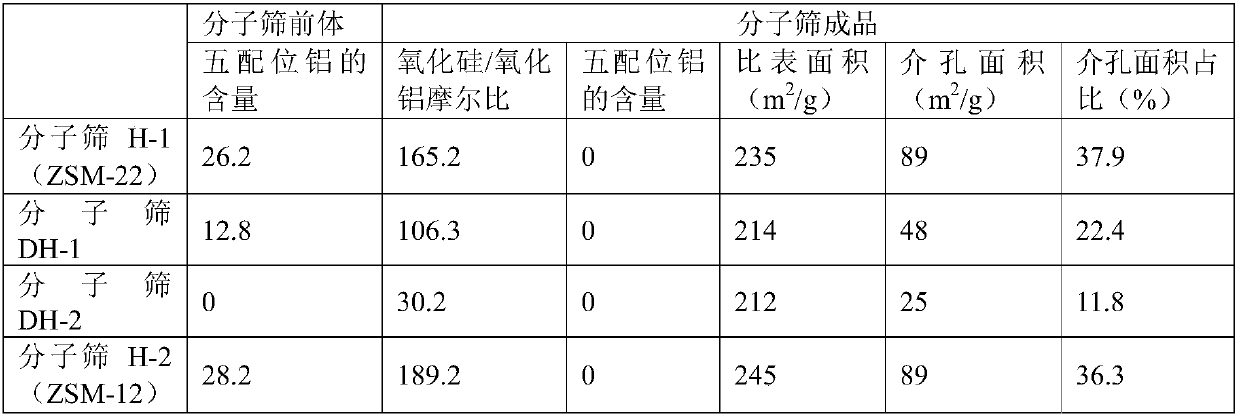

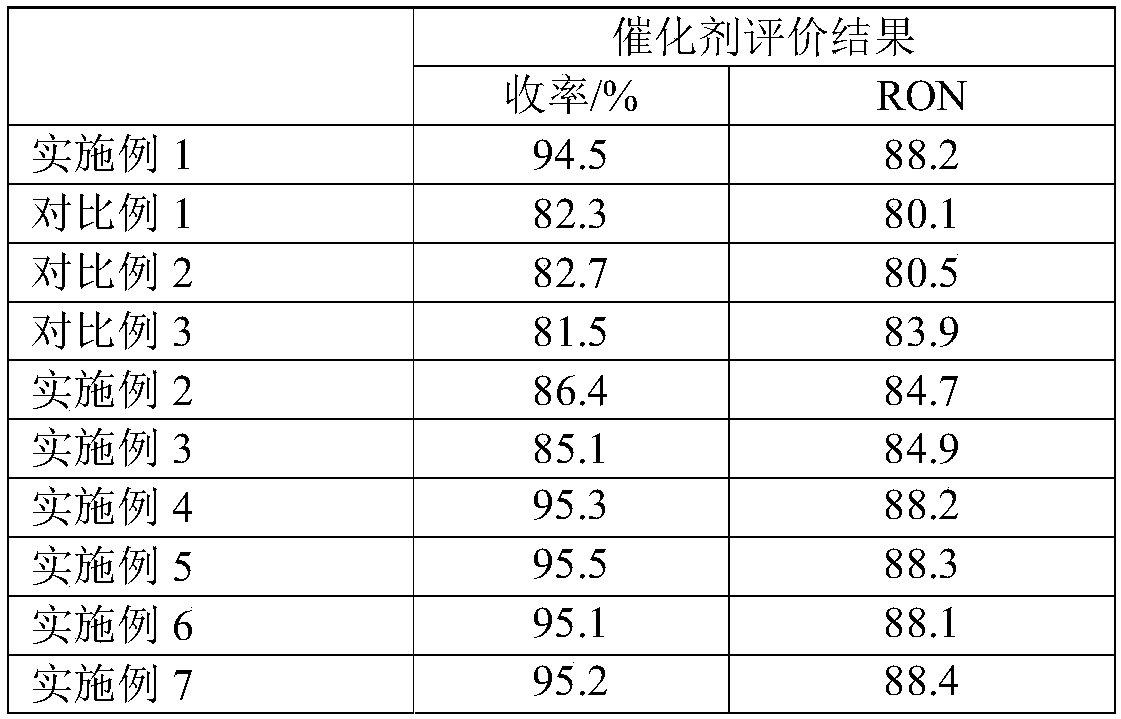

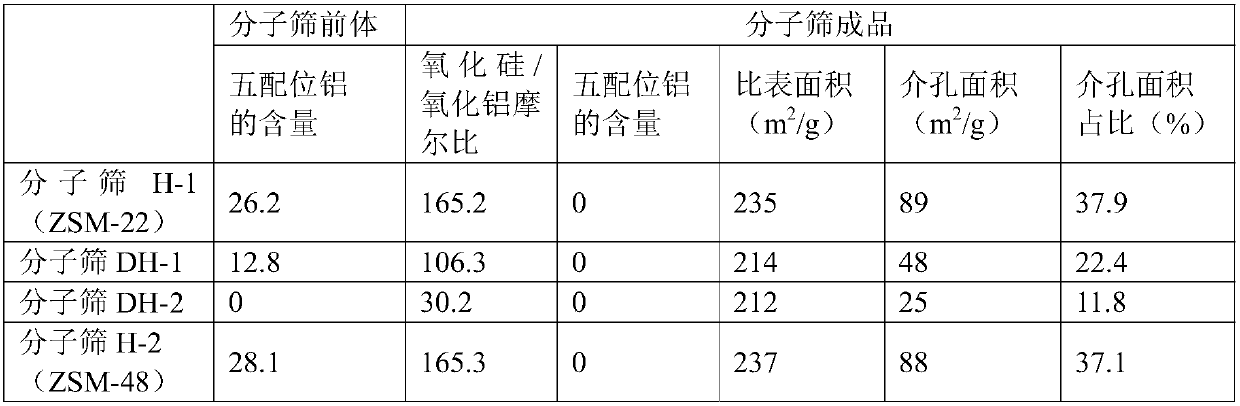

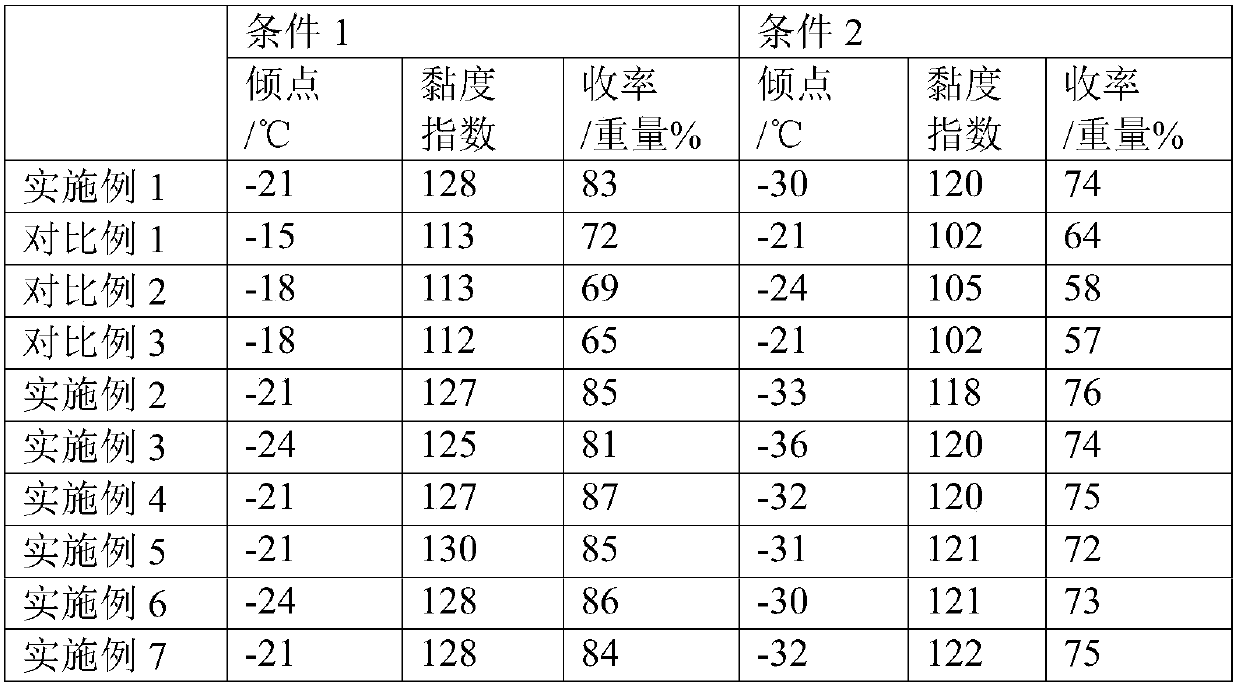

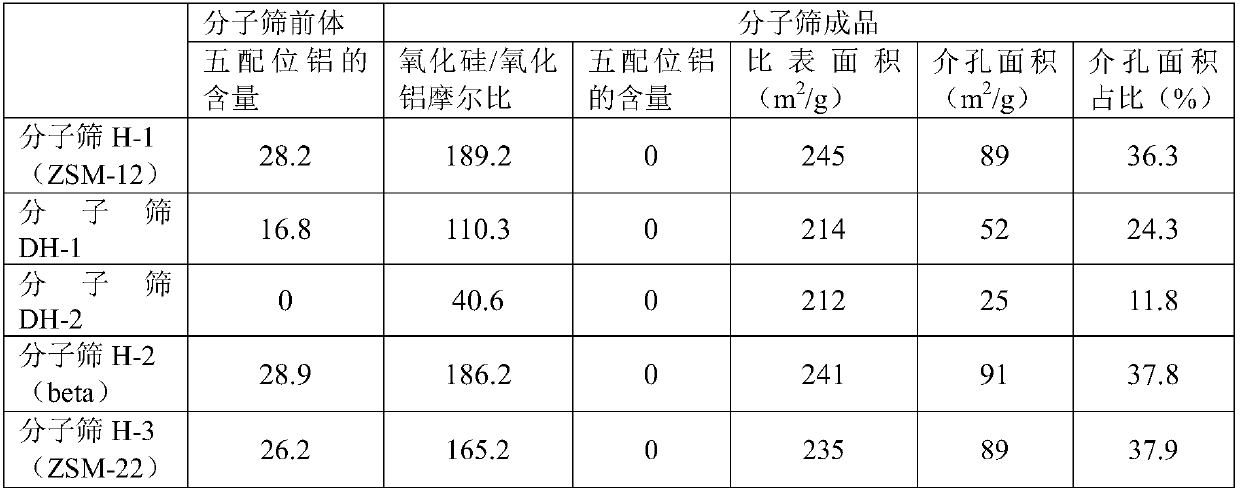

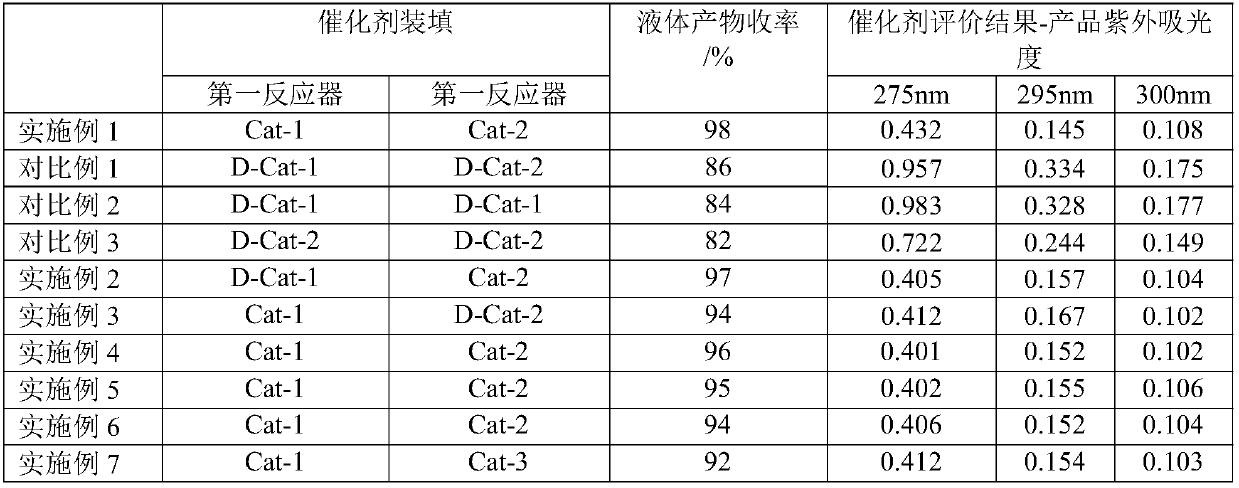

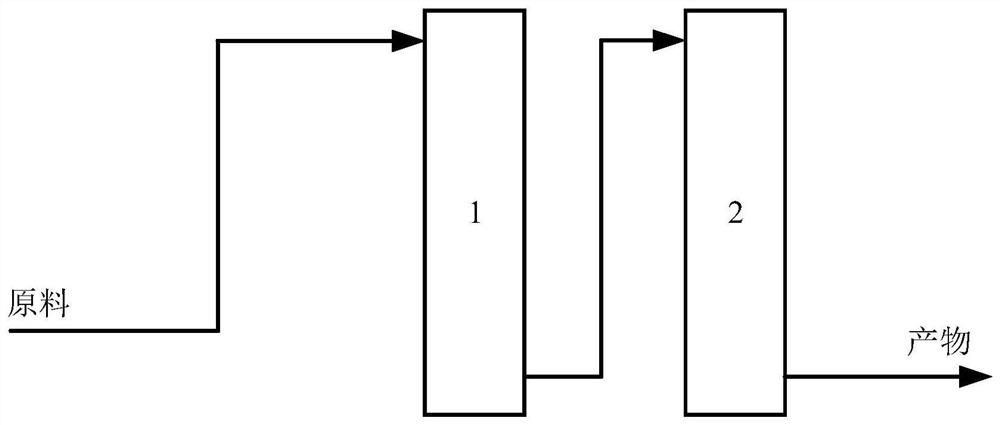

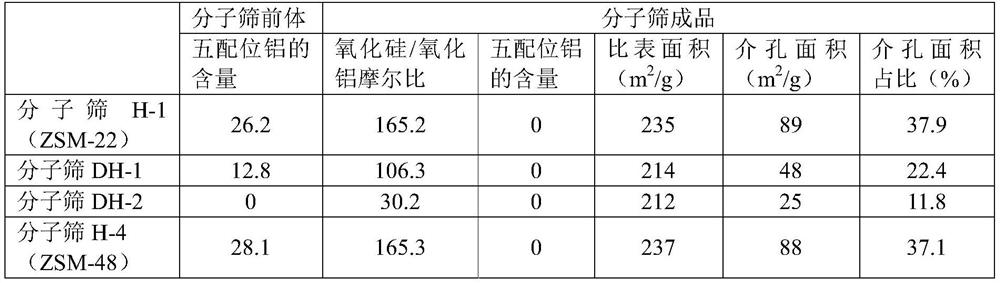

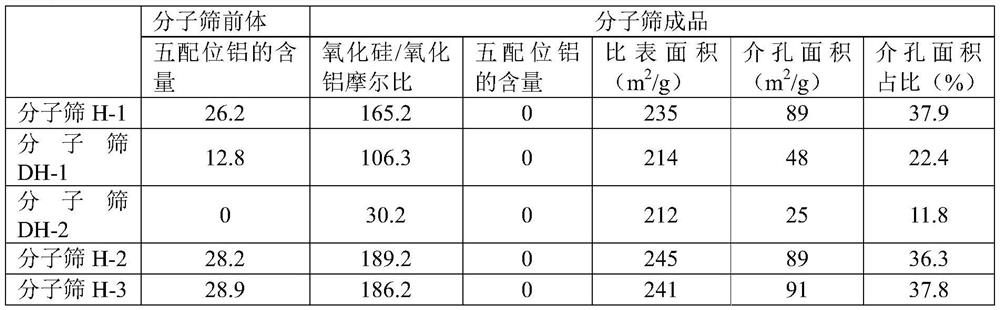

The invention relates to a combined catalyst and a method for producing C5 and C6, wherein the combined catalyst comprises a first catalyst and a second catalyst, the first catalyst contains a ten-membered ring molecular sieve M1, the second catalyst contains a twelve-membered ring molecular sieve M2, the first catalyst and the second catalyst respectively and independently contain active metal components Pt and Pd, the first catalyst and the second catalyst are respectively filled in different reactors, and the ten-membered ring molecular sieve M1 and / or the twelve-membered ring molecular sieve M2 has the following characteristics that a molar ratio of silicon oxide to aluminum oxide is 120-300, the catalyst contains a mesoporous structure, a closed hysteresis loop appears at a low-temperature nitrogen adsorption-desorption curve P / P0 of 0.4-0.99, and the initial position of the closed hysteresis loop is P / P0 of 0.4-0.7. According to the invention, with the application of the method to produce C5 and C6, the yield is high, and the octane numbers of the produced C5 and the produced C6 are high.

Owner:CHINA PETROLEUM & CHEM CORP +1

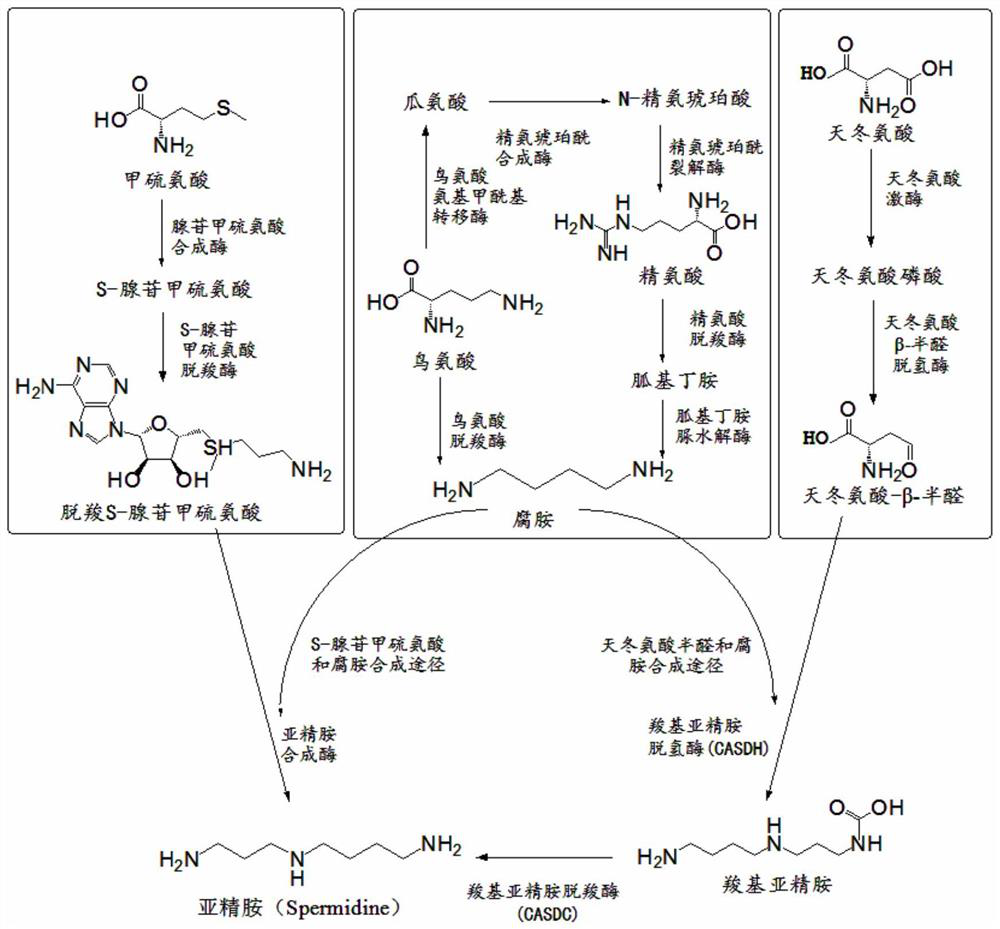

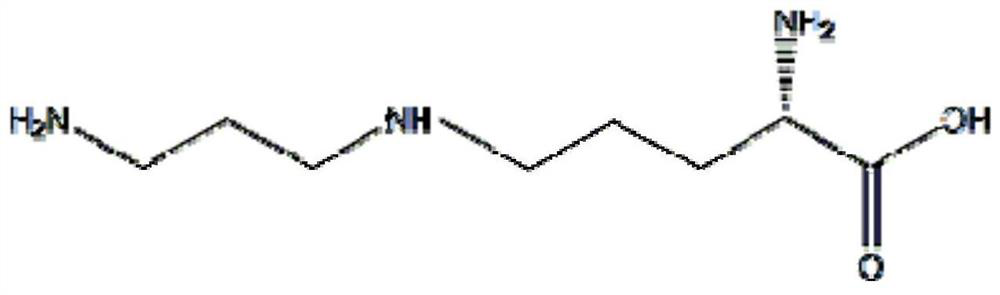

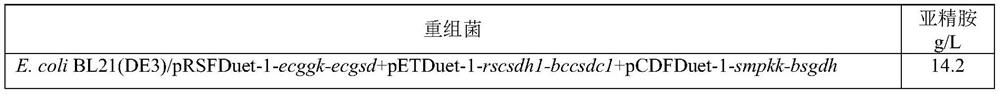

Method for producing spermidine by using cheap substrates and engineering bacterium

ActiveCN112442518ASimple methodRaw materials are easy to getBacteriaTransferasesCarboxyl radicalArginine

The invention discloses a method for producing spermidine by using cheap substrates and engineering bacteria, and belongs to the technical field of bioengineering. The method is characterized in thatrecombinant cells or a combination of recombinant cells expressing gamma-glutamyl kinase, glutamate-5-semialdehyde dehydrogenase, aspartokinase, aspartate-beta-semialdehyde dehydrogenase, amine dehydrogenase, L-2,4-diaminobutanoate decarboxylase, carboxyspermidine dehydrogenase, carboxyspermidine decarboxylase, glucose dehydrogenase, and polyphosphate kinase 2-I are constructed; and aspartic acidand arginine are catalyzed to synthesize the spermidine by utilizing the recombinant cells or the combination of the recombinant cells. According to the method, selected oxidoreductase can efficientlyuse NAD (NADH) as coenzyme, and the product feedback inhibition is avoided in a reaction process; and the method has a good industrial application prospect.

Owner:卓虹超源生物科技(郑州)有限公司

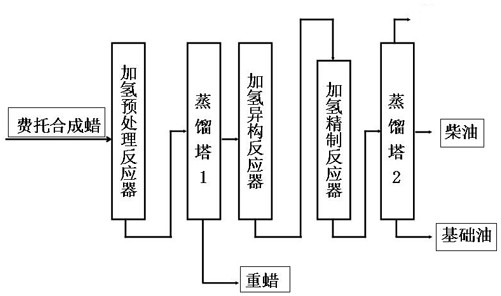

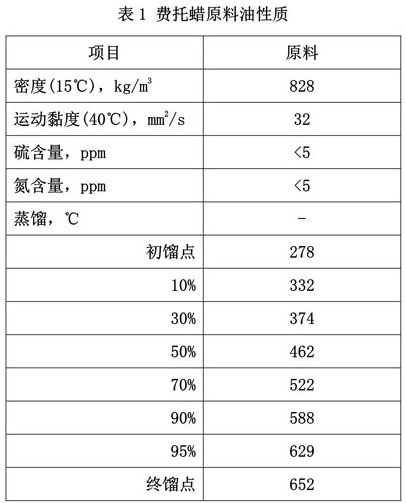

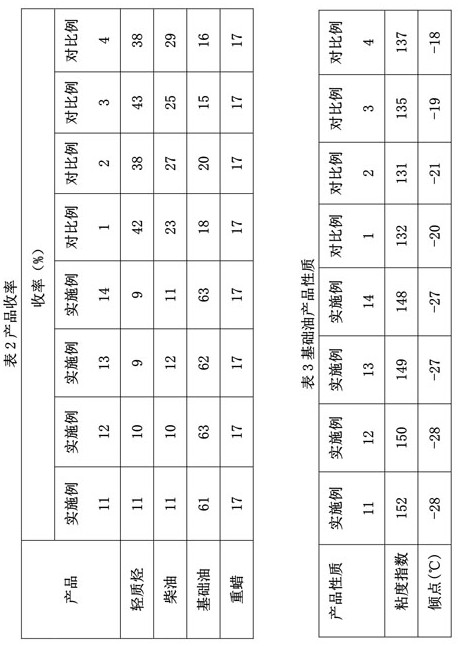

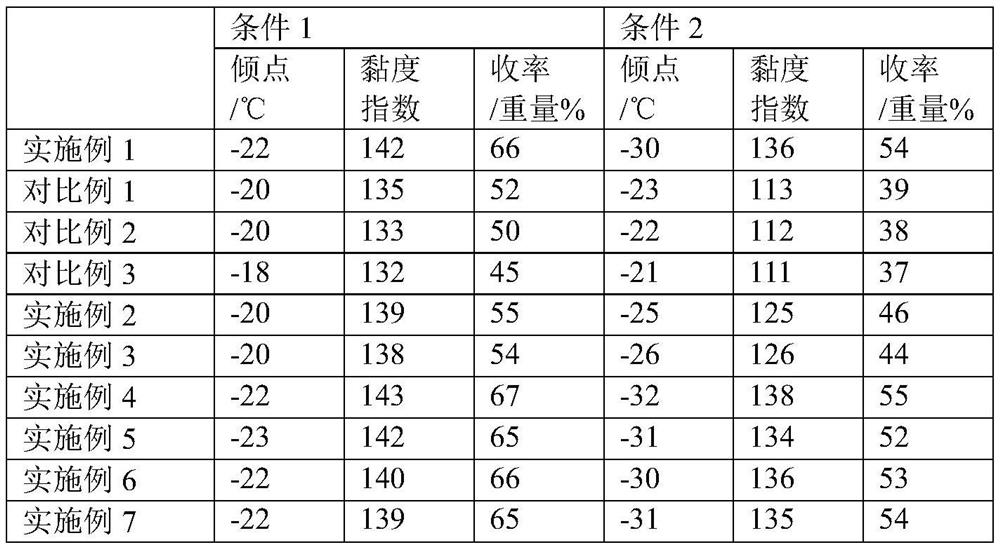

Hydroconversion composition and process for hydroconversion of Fischer-Tropsch synthetic wax

ActiveCN112143520AHigh yieldHigh viscosity indexMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sieveIsomerization

The invention relates to the technical field of Fischer-Tropsch synthesis product hydro-conversion, and relates to a hydroconversion composition and a Fischer-Tropsch synthesis wax hydroconversion method, and the hydroconversion composition comprises a hydrogenation pretreatment catalyst, a combined catalyst and a hydrofining catalyst. According to the invention, the Fischer-Tropsch synthetic waxfraction of a temperature of 280-660 DEG C is subjected to simple hydrogenation pretreatment, fractionation, hydroisomerization, hydrofining and fractionation processes, such that lubricating oil baseoil with a low pour point and a high viscosity index can be prepared with a high yield. The technical core of the method is a hydroisomerization process based on a combined AEL and ATO structure aluminophosphate molecular sieve catalyst, so that each component in a wide-distillation-range raw material can be highly selectively converted into an isomerization product, and the yield and the performance of the product are improved at the same time.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +2

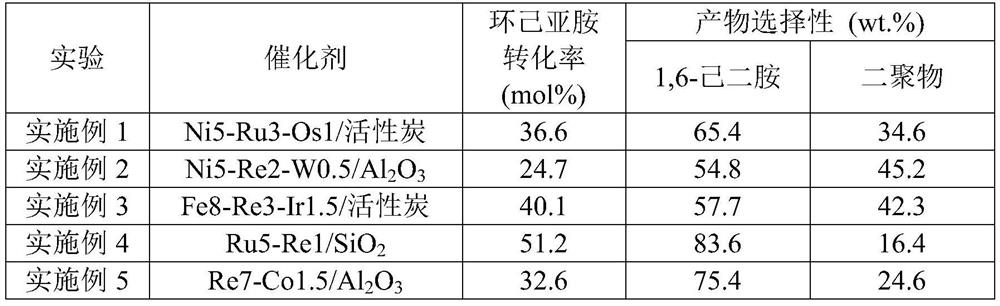

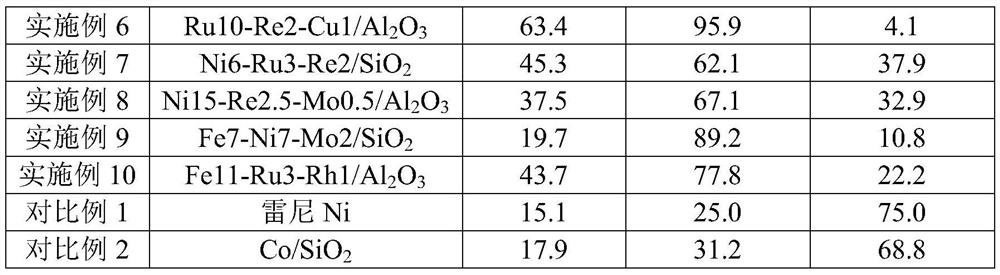

Method for preparing 1, 6-hexamethylenediamine by ammoniating hexamethyleneimine

ActiveCN112898163AOrganic compound preparationAmino compound preparationActivated carbonMolecular sieve

The invention relates to a method for preparing 1, 6-hexamethylenediamine by ammoniating hexamethyleneimine. The catalyst in the method comprises an active component, an auxiliary agent and a carrier, the active component is one or a combination of transition metals Ni, Fe, Ru and Re, the auxiliary agent is one or a combination of elements W, B, Ir, Pt, Os, Co, Cu, Rh and Mo, and the carrier is one or a combination of Al2O3, activated carbon, a molecular sieve, SiO2 and Al2O3-SiO2 which are subjected to ammoniation treatment. The weight of the active component in the catalyst accounts for 1-45% of the weight of the catalyst, and the weight of the auxiliary agent accounts for 0.05-15% of the weight of the catalyst. The catalyst is used for preparing 1, 6-hexamethylenediamine by ammoniating hexamethyleneimine in a hydrogen atmosphere, has the advantages of high activity, high target product yield, good stability, good economical efficiency and the like, and has a wide application prospect.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

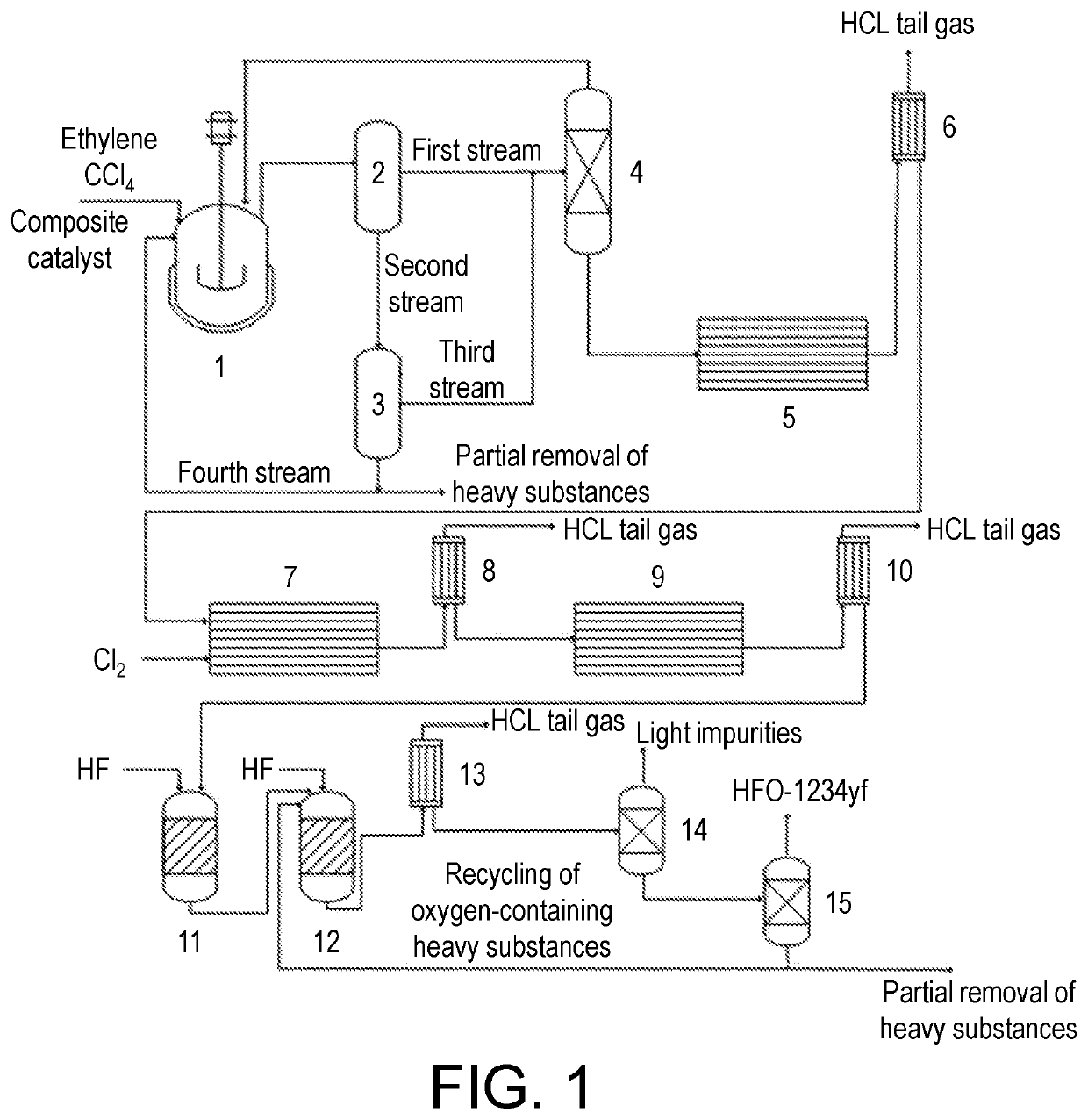

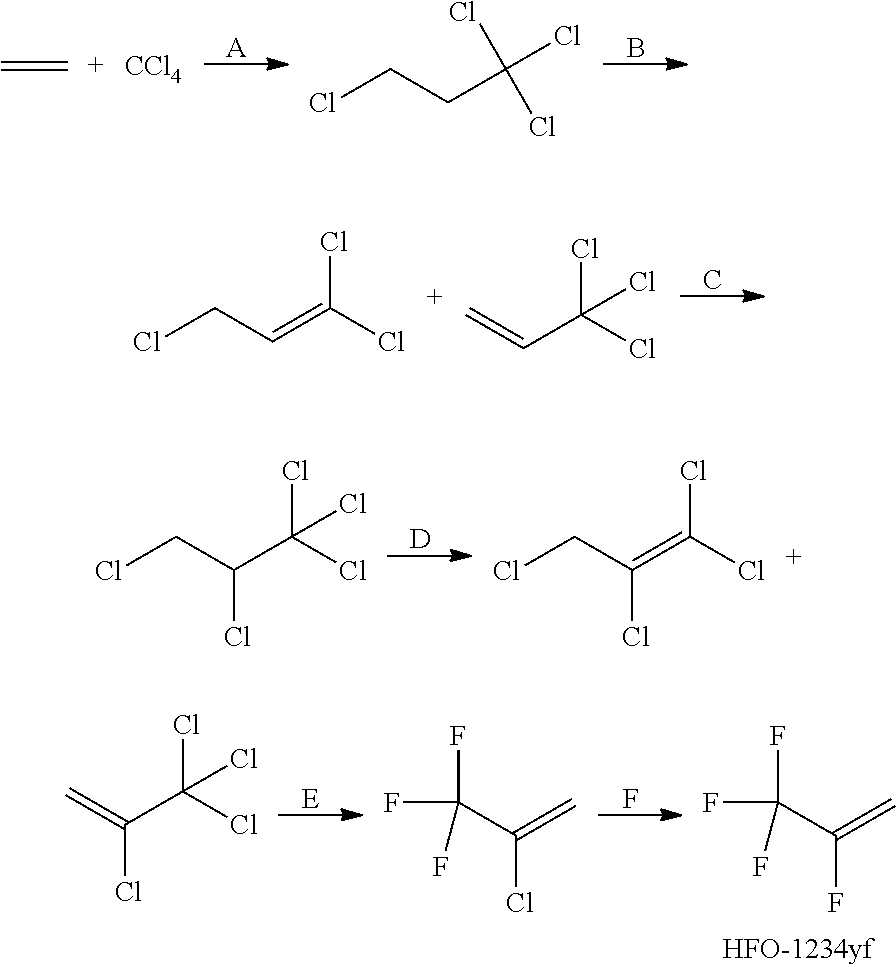

Method for continuous preparation of 2,3,3,3-tetrafluoropropene

PendingUS20220081379A1Simple processReduce usagePreparation by hydrogen halide split-offOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystFluid phase

The invention provides a continuous preparation method of 2,3,3,3-tetrafluoropropene, comprising the following steps: carrying out liquid-phase catalytic telomerization reaction on ethylene and carbon tetrachloride serving as initial raw materials in the presence of a composite catalyst to obtain a reaction product; performing two-stage membrane separation and purification on the reaction product, and then sequentially performing a primary high-temperature cracking reaction, a gas-phase chlorination reaction, a secondary high-temperature cracking reaction, a primary gas-phase catalytic fluorination reaction and a secondary gas-phase catalytic fluorination reaction to obtain a reaction product; condensing and rectifying the secondary gas-phase catalytic fluorination reaction product to obtain the 2,3,3,3-tetrafluoropropene product.

Owner:JUHUA GROUP TECH CENT

Combined catalyst and method for producing white oil

ActiveCN110841701AAromaticsGood effectMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sievePtru catalyst

The invention relates to a combined catalyst and a method for producing white oil, wherein the combined catalyst comprises a first catalyst and a second catalyst, the first catalyst contains a ten-membered ring molecular sieve M1, the second catalyst contains a twelve-membered ring molecular sieve M2, the first catalyst and the second catalyst are respectively filled in different reactors, and theten-membered ring molecular sieve M1 and / or the twelve-membered ring molecular sieve M2 has the following characteristics that a molar ratio of silicon oxide to aluminum oxide is 120-300, the catalyst contains a mesoporous structure, a closed hysteresis loop appears at a low-temperature nitrogen adsorption-desorption curve P / P0 of 0.4-0.99, and the initial position of the closed hysteresis loop is P / P0 of 0.4-0.7. According to the invention, with the application of the method to produce white oil, the good aromatic hydrocarbon saturation effect can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Combined catalyst and method for producing biological aviation kerosene

ActiveCN110846069AHeterogeneous pour point depressing effect is goodHigh yieldMolecular sieve catalystsHydrocarbon oils refiningMolecular sievePtru catalyst

The invention relates to a combined catalyst and a method for producing biological aviation kerosene, wherein the combined catalyst comprises a first catalyst and a second catalyst, the first catalystcontains a twelve-membered ring molecular sieve M1, the second catalyst contains a twelve-membered ring molecular sieve M2, the first catalyst and the second catalyst are respectively filled in different reactors, and the twelve-membered ring molecular sieve M1 and / or the twelve-membered ring molecular sieve M2 has the following characteristics that a molar ratio of silicon oxide to aluminum oxide is 120-300, the catalyst contains a mesoporous structure, a closed hysteresis loop appears at a low-temperature nitrogen adsorption-desorption curve P / P0 of 0.4-0.99, and the initial position of theclosed hysteresis loop is P / P0 of 0.4-0.7. According to the invention, with the application of the method to produce biological aviation kerosene, the good pour point depressing effect can be obtained, and the yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of trimethylaluminum

ActiveCN112552324AIncrease reaction rateEasy to handleGroup 3/13 element organic compoundsBulk chemical productionAluminium chlorideAlkaline earth metal

The invention provides a preparation method of trimethylaluminum, which comprises the following steps: in the presence of a catalyst and a solvent, reacting methyl aluminum dichloride or sesquimethylaluminum chloride or dimethylaluminum chloride with a system of metal M and chloromethane to generate trimethylaluminum and a chloride of metal M; wherein the catalyst is selected from metal or ions thereof which are arranged behind metal aluminum in an electrochemical sequence; the metal M is selected from alkali metals, alkaline earth metals, or combinations thereof. The catalyst can significantly increase the reaction rate, so that the reaction can be carried out under very simple experimental conditions such as near normal pressure, the reaction yield and the product purity are higher, no by-product metal aluminum or unreacted alkali metal or alkaline earth metal is contained in the product, and the product is more convenient to treat.

Owner:JIANGSU NATA OPTO ELECTRONICS MATERIAL

Combined catalyst and method for producing lubricating oil base oil from hydrocracking tail oil

ActiveCN110841724AHigh yieldHigh viscosity indexMolecular sieve catalystsCatalyst activation/preparationMolecular sievePtru catalyst

The invention relates to a combined catalyst and a method for producing lubricating oil base oil from hydrocracking tail oil, wherein the combined catalyst comprises a first catalyst and a second catalyst, the first catalyst contains a ten-membered ring molecular sieve M1, the second catalyst contains a ten-membered ring molecular sieve M2, the first catalyst and the second catalyst are respectively filled in different reactors, and the ten-membered ring molecular sieve M1 and / or the ten-membered ring molecular sieve M2 has the following characteristics that a molar ratio of silicon oxide to aluminum oxide is 120-300, the catalyst contains a mesoporous structure, a closed hysteresis loop appears at a low-temperature nitrogen adsorption-desorption curve P / P0 of 0.4-0.99, and the initial position of the closed hysteresis loop is P / P0 of 0.4-0.7. According to the invention, with the application of the combined catalyst to produce lubricating oil base oil from hydrocracking tail oil, the good pour point depressing effect can be obtained, and the lubricating oil base oil is high in yield and viscosity index.

Owner:CHINA PETROLEUM & CHEM CORP +1

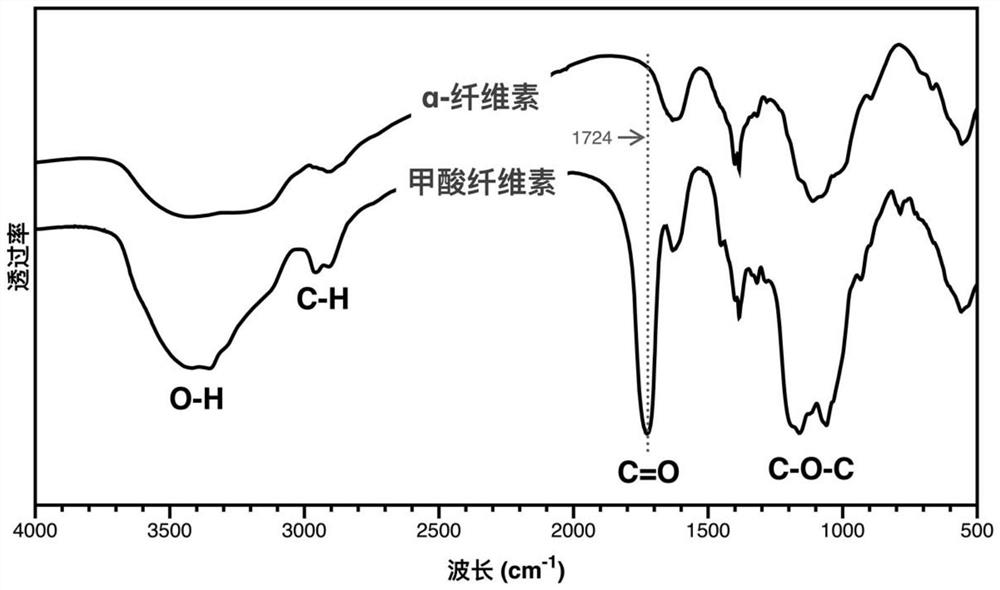

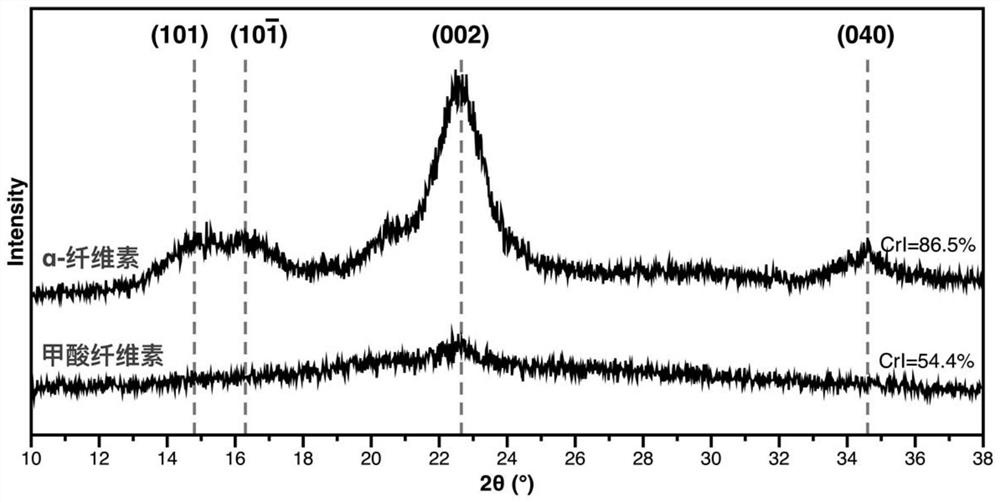

Method for preparing 5-hydroxymethylfurfural by catalyzing cellulose formate with dimethyl sulfoxide-water cosolvent system

The invention discloses a method for preparing 5-hydroxymethylfurfural by catalyzing cellulose formate with a dimethyl sulfoxide-water cosolvent system. The method comprises the following steps: firstly, adding alpha-cellulose into a formic acid solution for oil-bath heating, and carrying out centrifugal filtration to obtain a reaction filtrate; carrying out rotary evaporation and concentration onthe reaction filtrate, pouring the filtrate into an ethanol solution, and carrying out centrifugal filtration to obtain a white precipitate; pouring the white precipitate into an ethanol solution, carrying out centrifuging and filtering, repeating the operation for three times, and implementing freeze-drying to obtain cellulose formate; finally, performing microwave catalytic conversion in a dimethyl sulfoxide water cosolvent system by taking alpha-cellulose or cellulose formate as a substrate, and hydrochloric acid and aluminum chloride as catalysts to obtain the 5-hydroxymethylfurfural. Cellulose is treated with formic acid for acidolysis and formylation to obtain cellulose formate, and aluminum chloride hydrochloride is used as a combined catalyst to directly and efficiently catalyze cellulose formate in a dimethyl sulfoxide water cosolvent system to prepare 5-hydroxymethylfurfural.

Owner:ZHEJIANG UNIV

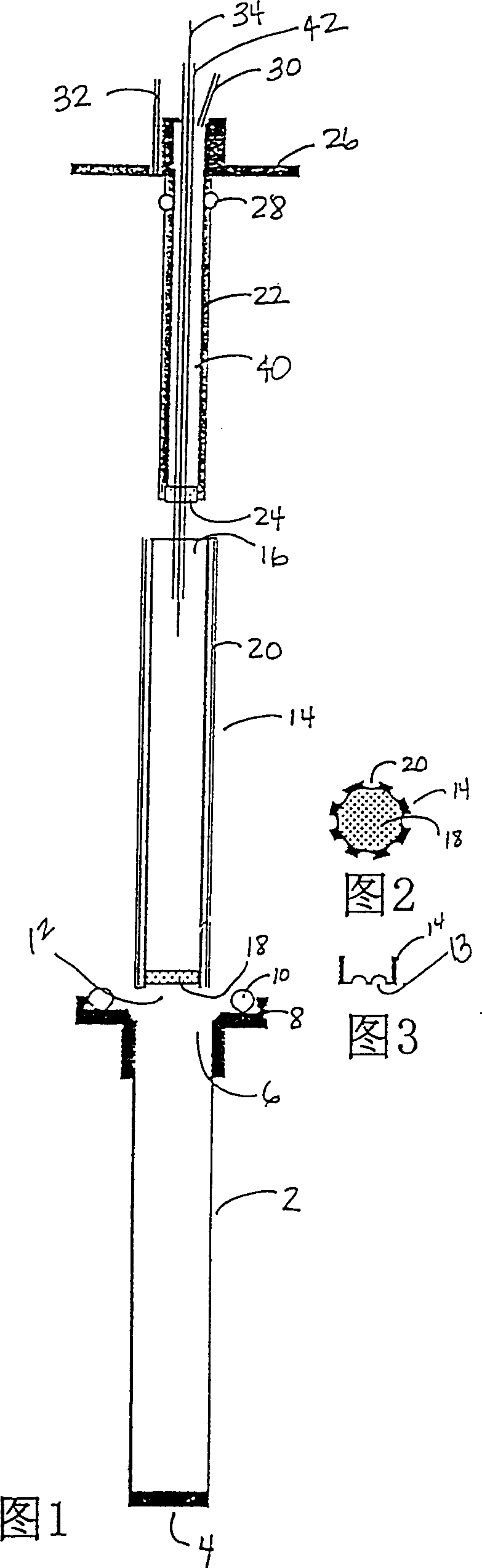

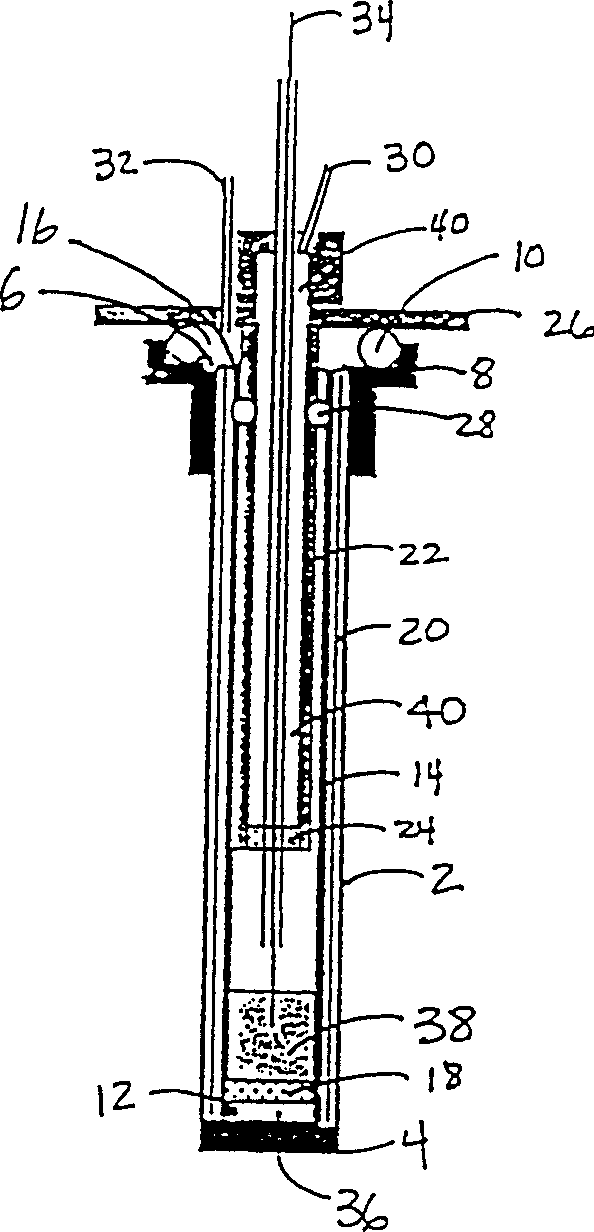

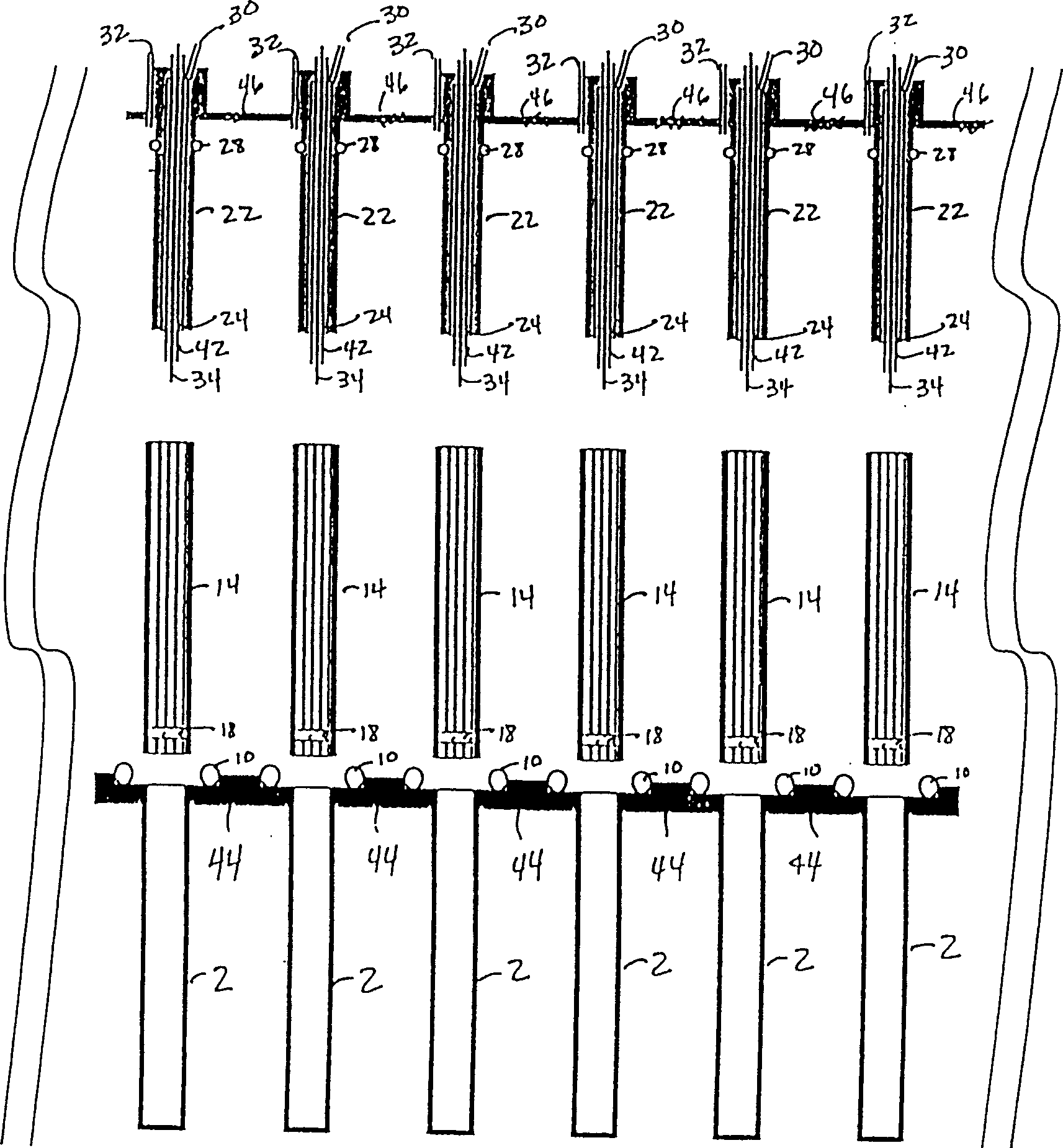

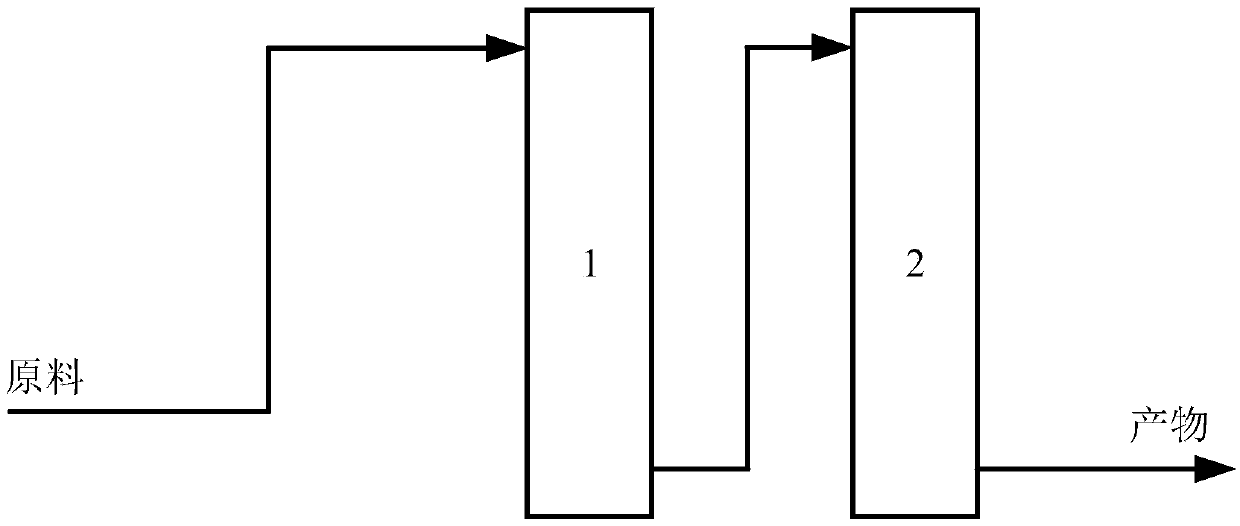

Combined catalysis reactor

InactiveCN1198681CChemical analysis using catalysisSequential/parallel process reactionsChemical reactionEngineering

Owner:UOP LLC

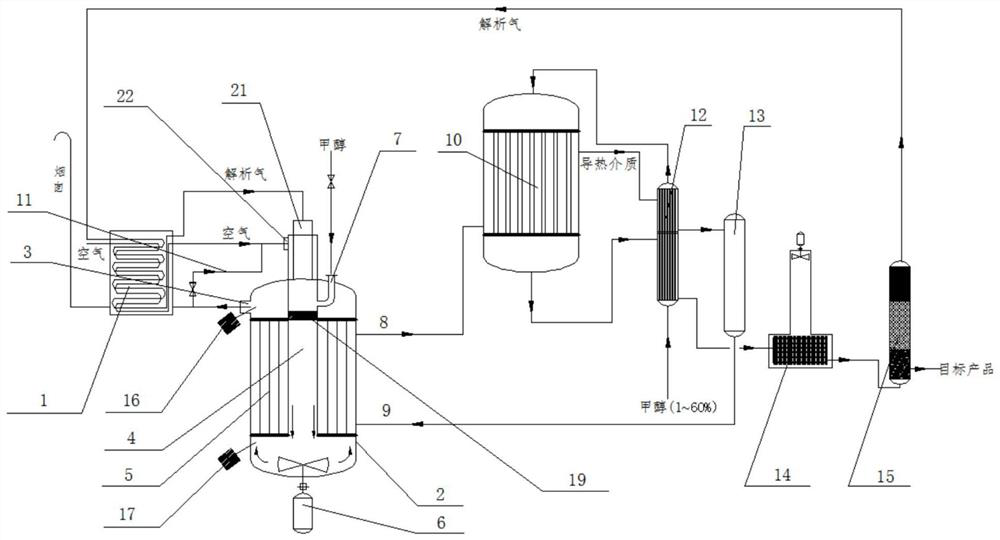

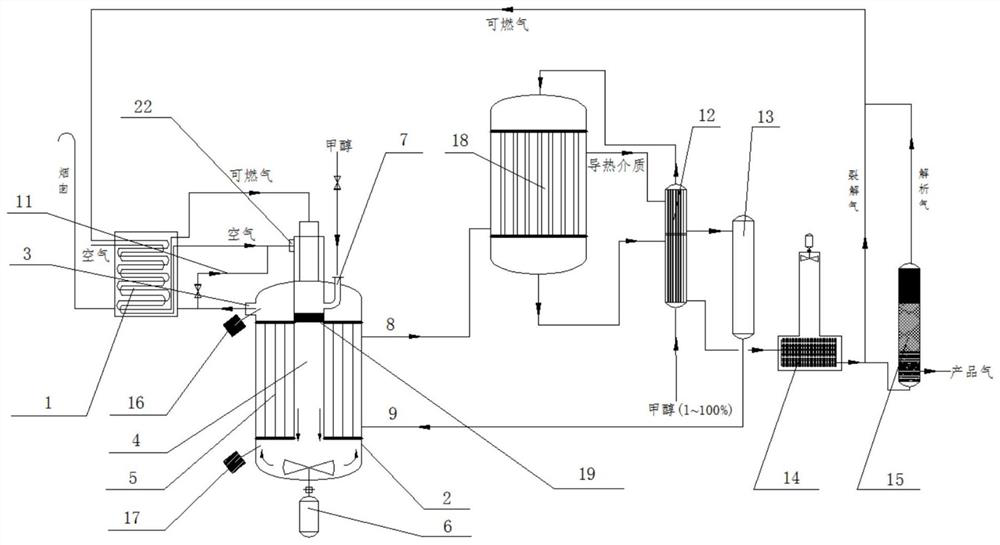

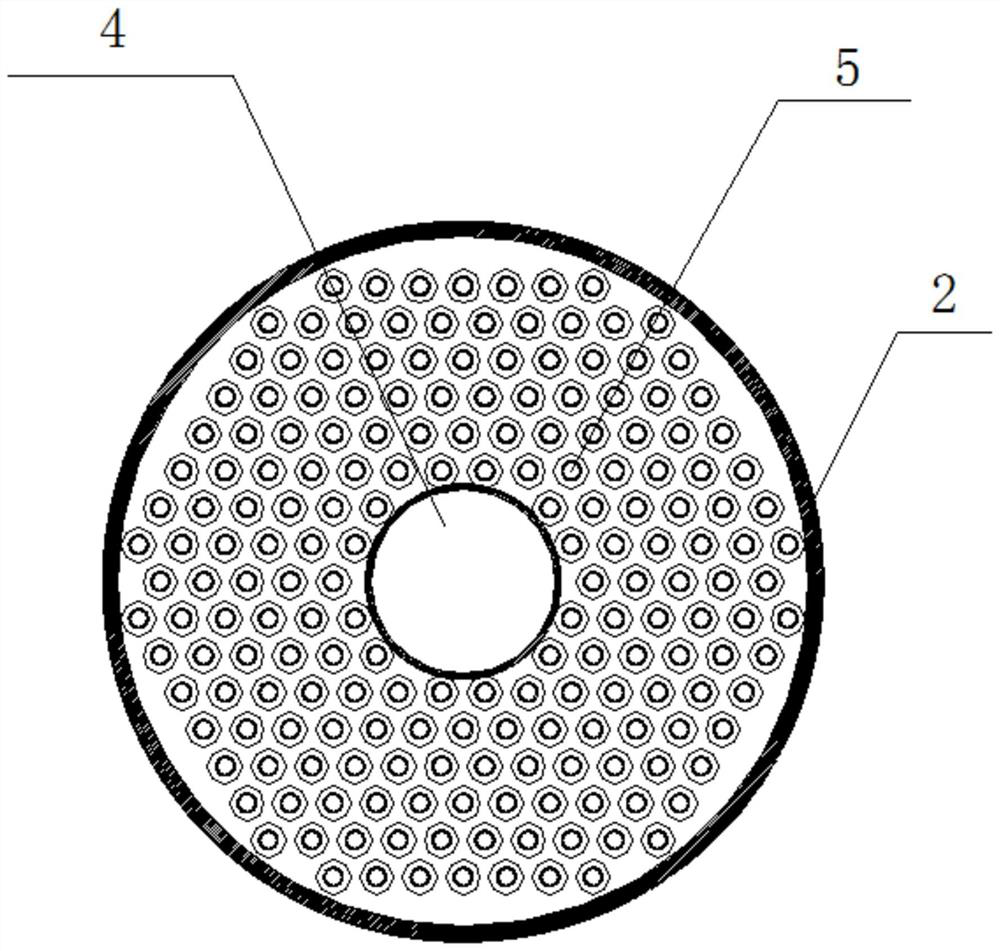

A Catalytic Heating Coupling Methanol Hydrogen Production Process

ActiveCN111977612BSmall footprintReduce energy consumptionHydrogenHydrogen/synthetic gas productionPtru catalystCatalytic oxidation

The invention discloses a catalytic heating coupled methanol hydrogen production process, which belongs to the field of hydrogen production, and specifically relates to the technical field of methanol hydrogen production, in order to solve the problem that the existing methanol hydrogen production process requires external heating to start, additional equipment is required, and energy consumption is high. It covers a large area, including a catalytic oxidation reactor and a methanol hydrogen production system. In the catalytic oxidation reactor, methanol and air in the raw material are oxidized at a temperature above 10°C, and the catalyst layer is oxidized at normal temperature, and the catalytic oxidation reaction occurs. The generated heat provides thermal energy for the start-up of the methanol hydrogen production system. Under the condition of no heat source, the raw material methanol and air undergo a catalytic oxidation reaction in the catalytic oxidation reactor under the action of the combined catalyst layer, and the heat generated provides heat energy for the start-up of the methanol hydrogen production system, making the entire methanol hydrogen production process run at room temperature It starts from the bottom, does not require external heating to start, and does not require additional external heat source equipment. The equipment occupies a small area and consumes low energy.

Owner:四川蜀泰化工科技有限公司

Method for preparing tetrahydrofurfuryl alcohol and pentanediol through furyl alcohol hydrogenation

PendingCN112657485AHigh selectivitySimple production processPreparation by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsPolymer sciencePtru catalyst

The invention discloses a method for preparing tetrahydrofurfuryl alcohol and pentanediol through furyl alcohol hydrogenation. According to the method, furfuryl alcohol is taken as a substrate, isopropanol is taken as a solvent, a metal supported carbon-based catalyst and calcium oxide are taken as a combined catalyst, hydrogenation reaction is carried out at 150-180 DEG C in a hydrogen environment of 1-4MPa under a stirring condition, and tetrahydrofurfuryl alcohol, 1, 2-pentanediol and 1, 5-pentanediol are prepared. The method disclosed by the invention realizes high-value conversion of furfuryl alcohol, is simple and convenient in production process and low in operation difficulty, and has a certain popularization and application prospect.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

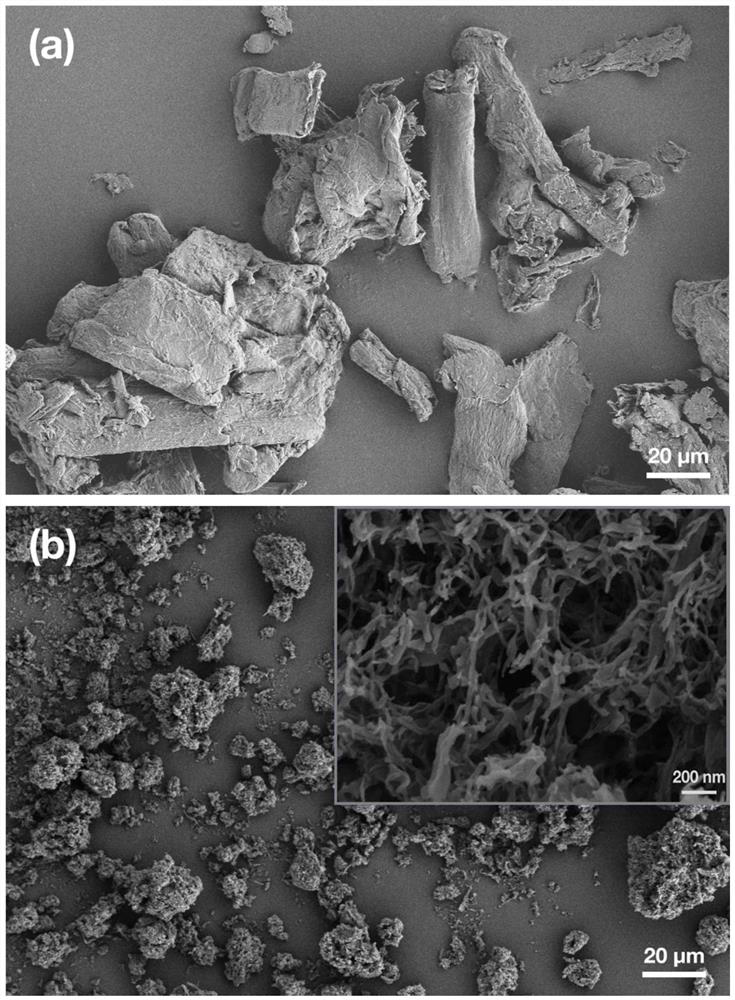

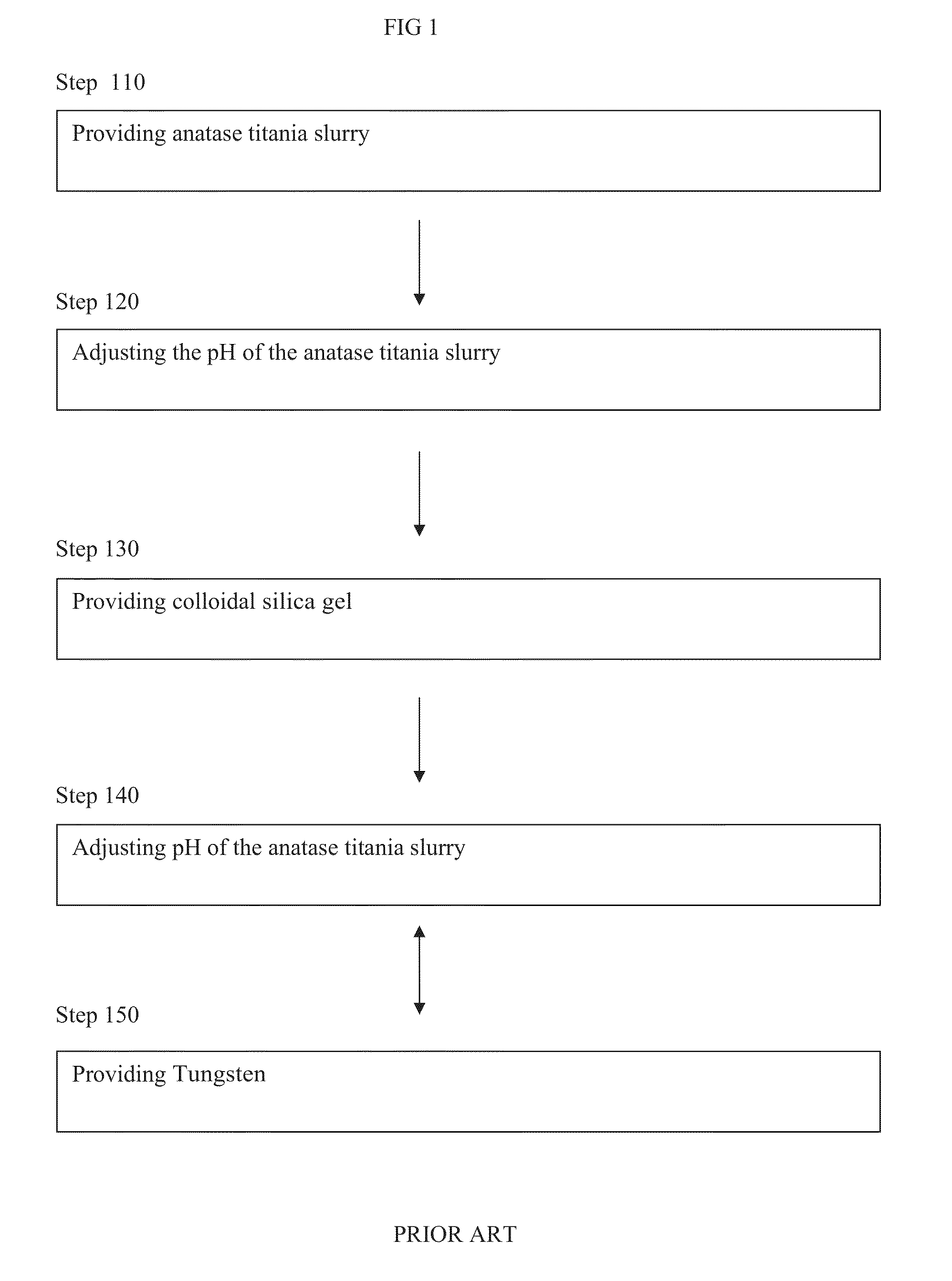

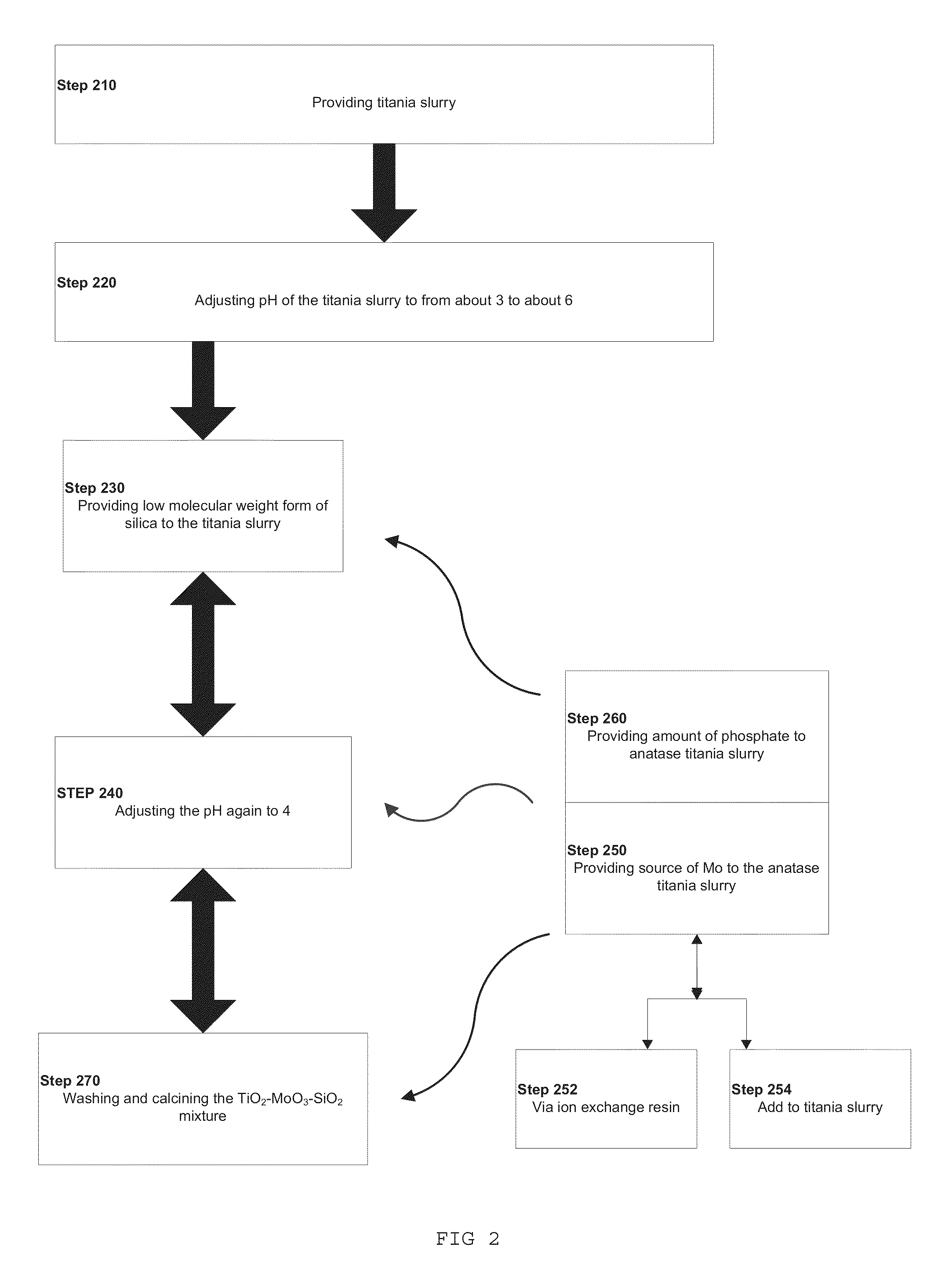

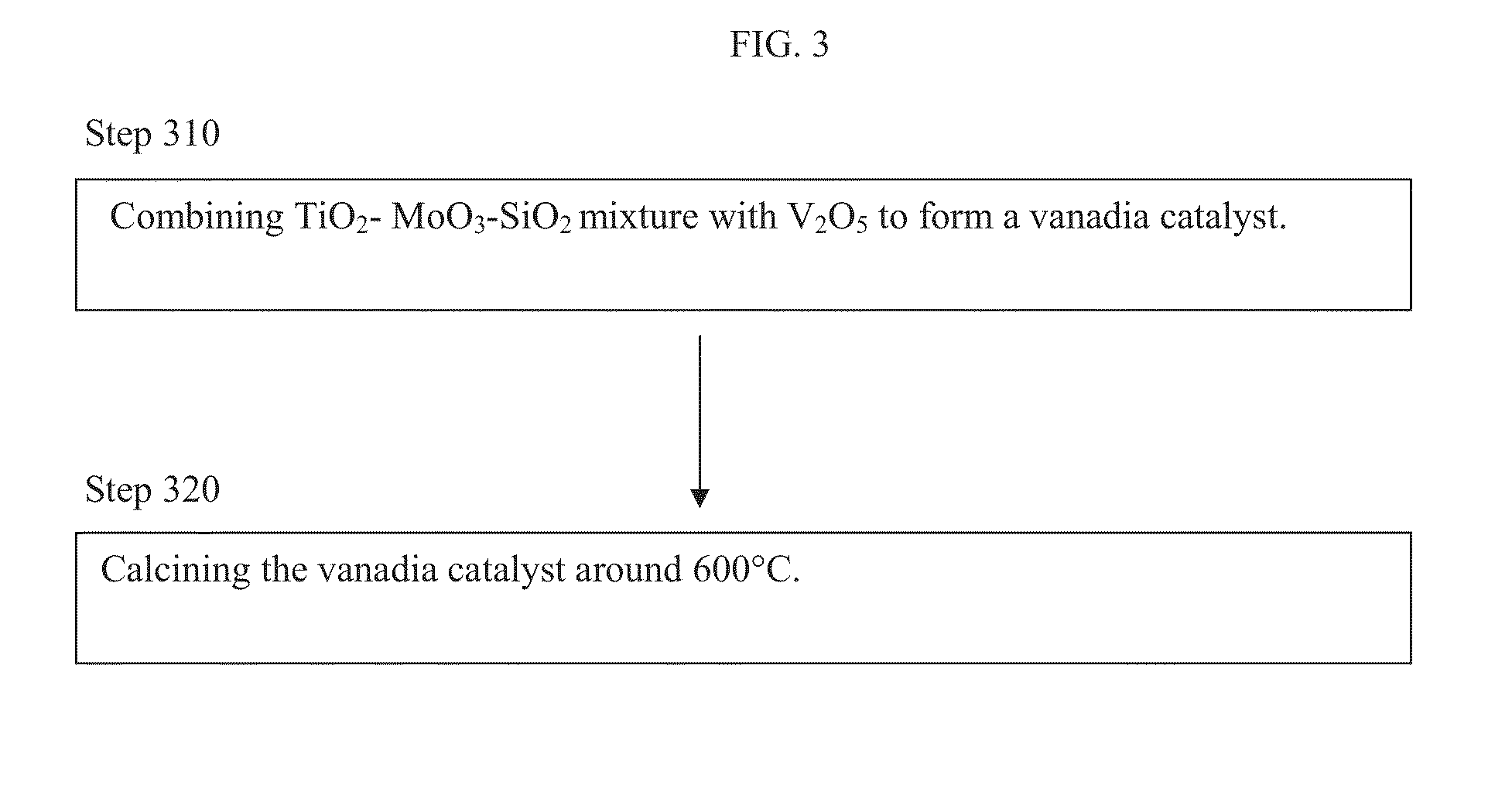

Catalyst support materials, catalysts, methods of making them and uses thereof

ActiveUS20140056793A1Nitrogen compoundsHeterogenous catalyst chemical elementsPtru catalystPhysical chemistry

Catalyst support materials, catalysts, methods of making such and uses thereof are described. Methods of making catalyst support material include combining anatase titania slurry with i) a low molecular weight form of silica; and ii) a source of Mo to form a TiO2—MoO3—SiO2 mixture. Catalyst support material include from about 86% to about 94% weight anatase titanium dioxide; from about 0.1% to about 10% weight MoO3; and from about 0.1% to about 10% weight SiO2. Low molecular weight forms of silica include forms of silica having a volume weighted median size of less than 4 nm and average molecular weight of less than 44,000, either individually or in a combination of two or more thereof. Catalyst include such catalyst support material with from about 0.1 to about 3% weight of V2O5 and optionally from about 0.01% to about 2.5% weight P.

Owner:TRONOX LLC

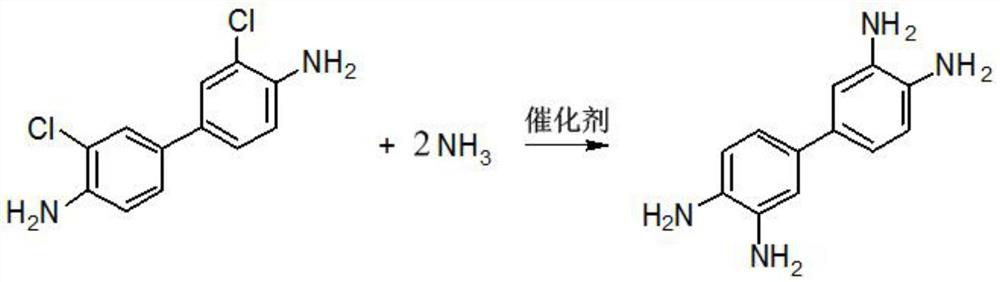

Preparation method of 3,3',4,4'-tetraaminobiphenyl

PendingCN112920054AProcess stabilityReduce dosageOrganic compound preparationAmino compound preparationPtru catalystReaction temperature

The invention discloses a preparation method of 3,3',4,4'-tetraaminobiphenyl The method comprises the following steps: in the presence of a first catalyst and a second catalyst, carrying out an amino substitution reaction on dichlorobiphenyl diamine and an ammoniation reagent to obtain a crude 3,3',4,4'-tetraaminobiphenyl product; and carrying out post-treatment on the crude 3,3',4,4'-tetraaminobiphenyl product to obtain a purified 3,3',4,4'-tetraaminobiphenyl product, wherein the first catalyst is a mixture of specified amino acid and cuprous salt, and the second catalyst is a phase transfer catalyst. Specific amino acid and the phase transfer catalyst are innovatively introduced to assist a small amount of cuprous salt in forming a new combined catalyst, so the smooth proceeding of the amino substitution reaction can be efficiently promoted, and reaction yield and product purity are improved. The usage of cuprous salt in the catalyst is obviously reduced, so the post-treatment pressure of high-concentration heavy metal salt wastewater is effectively reduced. Reaction temperature and reaction pressure are milder, so energy consumption is reduced, the safety of a process flow is improved, and the method is more suitable for industrial production.

Owner:INSIGHT FINECHEM +1

Combined catalyst and method for producing high-quality naphtha

ActiveCN110841689AHigh yieldLow aromatic contentMolecular sieve catalystsHydrocarbon oils treatmentMolecular sievePtru catalyst

The invention relates to a combined catalyst and a method for producing high-quality naphtha, wherein the combined catalyst comprises a first catalyst and a second catalyst, the first catalyst contains a twelve-membered ring molecular sieve M1, the second catalyst contains a twelve-membered ring molecular sieve M2, the first catalyst and the second catalyst respectively and independently contain active metal components Pt and Cu, the second catalyst further contains or does not contain a ten-membered ring molecular sieve M3, and at least one of the molecular sieves has the following characteristics that a molar ratio of silicon oxide to aluminum oxide is 120-300, the catalyst contains a mesoporous structure, a closed hysteresis loop appears at a low-temperature nitrogen adsorption-desorption curve P / P0 of 0.4-0.99, and the initial position of the closed hysteresis loop is P / P0 of 0.4-0.7. According to the invention, with the application of the method to produce high-quality naphtha, the yield is high, and the aromatic hydrocarbon content is low.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of method that Fischer-Tropsch wax produces lubricating oil base oil

ActiveCN110846071BHigh yieldHigh viscosity indexMolecular sieve catalystsHydrocarbon oils treatment productsMolecular sievePtru catalyst

The invention relates to a method for producing lubricating oil base oil from Fischer-Tropsch wax. The method comprises: injecting Fischer-Tropsch wax into a reaction device for hydrogenation, the catalyst loaded in the reaction device contains a combined catalyst, and the combined catalyst includes the first A catalyst and a second catalyst, the first catalyst contains ten-membered ring molecular sieve M1, and the second catalyst contains ten-membered ring molecular sieve M2; wherein, the ten-membered ring molecular sieve M1 and / or the ten-membered ring Molecular sieve M2 has the following characteristics: the silica / alumina molar ratio is 120-300; it contains a mesoporous structure and a closed hysteresis loop appears at the low-temperature nitrogen adsorption-desorption curve P / P0=0.4-0.99, and the closed hysteresis The starting position of the ring is at P / P0 = 0.4-0.7. By adopting the method of the invention to produce lubricating oil base oil with Fischer-Tropsch wax, better pour point depressing effect can be obtained, and the yield of lubricating oil base oil is high, and the viscosity index is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

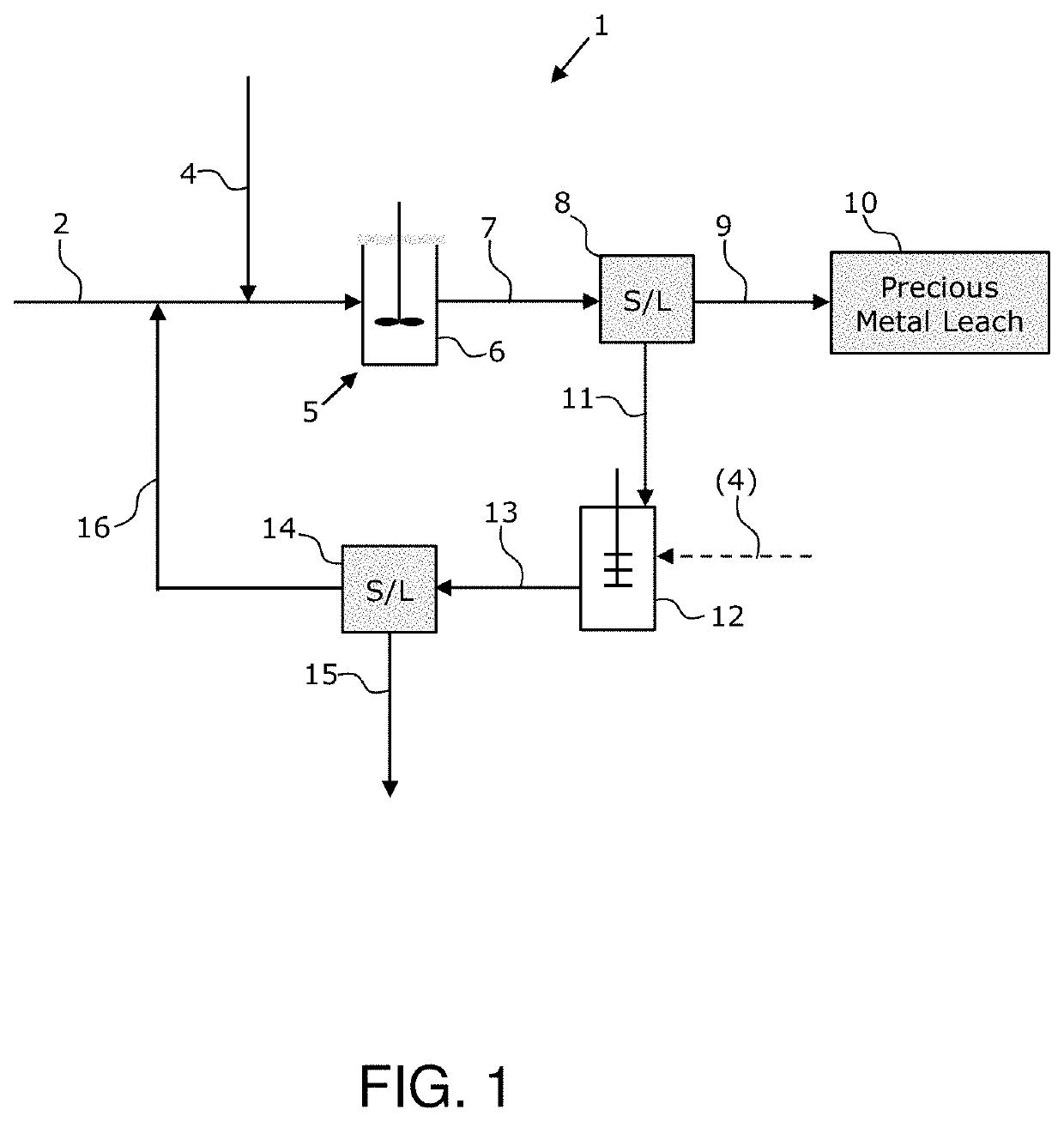

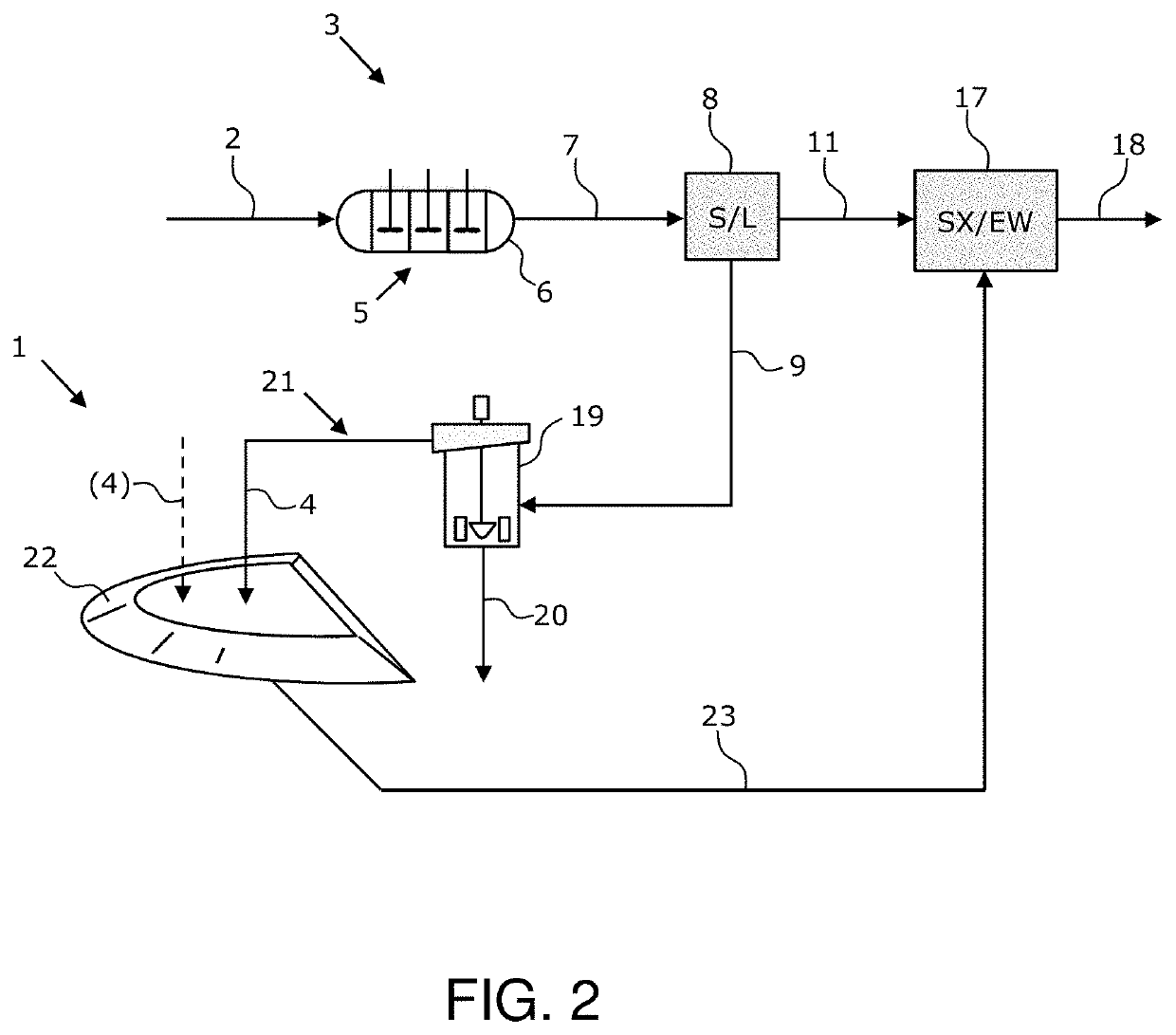

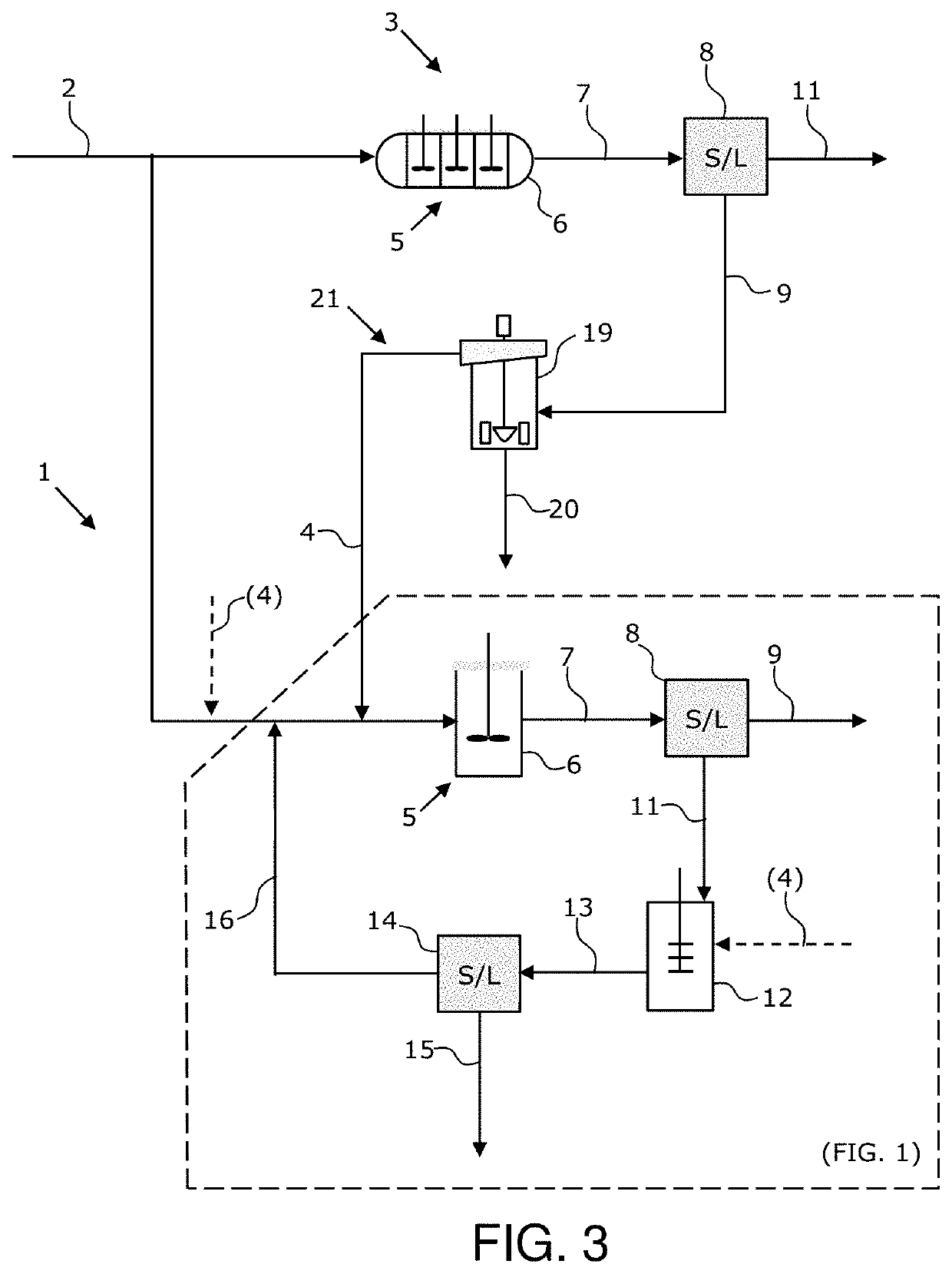

Solid-state catalysts for low or moderate temperature leach applications and methods thereof

ActiveUS20210246526A1Eliminating and significantly reducing conversionReducing and eliminating and preventing formationIron oxides/hydroxidesProcess efficiency improvementPtru catalystMetallic sulfide

A method for removing sulfate iron-containing compounds from a low- to moderate-temperature metal sulfide leach circuit (1) is disclosed. A reactor (6) within a chloride leach circuit (5) and which is preferably maintained at a temperature between 20 and 150 degrees Celsius may be provided with a catalyst (4) comprising a material selected from the group consisting of: colloidal hematite, colloidal goethite, particulate containing FeOOH, particulate containing α-FeOOH, particulate containing γ-FeOOH, particulate containing Fe2O3, particulate containing α-Fe2O3, particulate containing γ-Fe2O3, particulate containing Fe3O4, particulate containing Fe(OH)SO4, and a combination thereof. The catalyst (4) may also be used with heap leach and / or dump leach circuits (22), without limitation. Methods for using and generating the catalyst (4) are also disclosed. In some embodiments, the catalyst (4) may be used as an anti-frothing agent (e.g., for zinc leaching, without limitation).

Owner:F L SMIDTH & CO AS

A method for combining catalyst and solvent oil production

ActiveCN110841703BMolecular sieve catalystsTreatment with hydrotreatment processesMolecular sievePtru catalyst

The invention relates to a method for producing a combined catalyst and solvent oil, the combined catalyst includes a first catalyst and a second catalyst, the first catalyst contains a ten-membered ring molecular sieve M1, and the second catalyst contains a twelve-membered ring Molecular sieve M2, the first catalyst and the second catalyst each independently contain active metal components Pt and W; the first catalyst also contains or does not contain twelve-membered ring molecular sieve M3; wherein, the ten-membered ring molecular sieve M1 One or more of the 12-membered ring molecular sieve M2 and the 12-membered ring molecular sieve M3 has the following characteristics: the silicon oxide / alumina molar ratio is 120-300; it contains a mesoporous structure and has a low-temperature nitrogen adsorption-desorption curve P A closed hysteresis loop appears at / P0=0.4-0.99, and the initial position of the closed hysteresis loop is at P / P0=0.4-0.7. By adopting the method of the invention to produce solvent oil, better isomerization effect can be obtained, and the yield is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com