Hydroconversion composition and process for hydroconversion of Fischer-Tropsch synthetic wax

A Fischer-Tropsch synthetic wax and hydroconversion technology, which is applied in chemical instruments and methods, lubricating compositions, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems affecting process economy, light base oil group Solve problems such as large loss of viscosity index, low yield of light and heavy base oils, etc., to achieve the effect of improving product yield and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

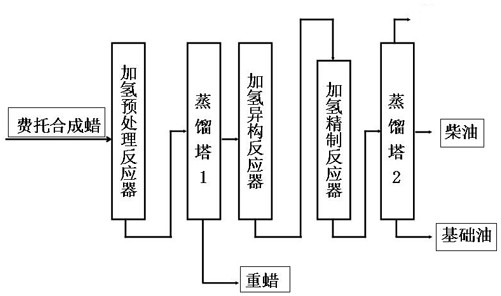

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The hydroconversion composition includes a hydrogenation pretreatment catalyst, a combined catalyst and a hydrofining catalyst; the combined catalyst is composed of catalyst A and catalyst B in a volume ratio of 1:10 to 10:1, and the catalyst A is composed of aluminum phosphate molecular sieves with AEL structure as a carrier, loaded with active metal platinum and / or palladium and / or iridium, and catalyst B is made of aluminum phosphate molecular sieves with ATO structure as a carrier, loaded with active metal platinum and / or Composed of palladium and / or iridium; the hydrogenation pretreatment catalyst is supported by heat-resistant inorganic oxides, one or more active metals of cobalt, nickel, molybdenum and tungsten loaded on the carrier, and selected from nitrogen, phosphorus , sulfur or boron in one or more additives; the hydrofinishing catalyst is supported by a heat-resistant inorganic oxide, and one or more active metals in platinum, palladium and iridi...

Embodiment 2

[0031] Embodiment 2: The hydroconversion composition includes a hydrogenation pretreatment catalyst, a combined catalyst and a hydrofinishing catalyst; the combined catalyst is composed of catalyst A and catalyst B in a volume ratio of 1:10 or 10:1, and the catalyst A is composed of aluminum phosphate molecular sieves with AEL structure as a carrier, loaded with active metal platinum and / or palladium and / or iridium, and catalyst B is made of aluminum phosphate molecular sieves with ATO structure as a carrier, loaded with active metal platinum and / or Composed of palladium and / or iridium; the hydrogenation pretreatment catalyst is supported by heat-resistant inorganic oxides, one or more active metals of cobalt, nickel, molybdenum and tungsten loaded on the carrier, and selected from nitrogen, phosphorus , sulfur or boron in one or more additives; the hydrofinishing catalyst is supported by a heat-resistant inorganic oxide, and one or more active metals in platinum, palladium and...

Embodiment 3

[0034] Embodiment 3: As the optimization of the above-mentioned embodiment, the aluminum phosphate molecular sieve with AEL structure is one or both of molecular sieve SAPO-11 and molecular sieve MeAPO-11 with AEL structure, and Me in molecular sieve MeAPO-11 is One or more of Zn, Mg, Mn, Co, Cr, Cu, Cd and Ni. The molecular sieve with ATO structure is one or two kinds of molecular sieve SAPO-31 and molecular sieve MeAPO-31, and Me in molecular sieve MeAPO-31 is one of Zn, Mg, Mn, Co, Cr, Cu, Cd and Ni or two or more. The acid amount of catalyst A is 2.1mmol(NH3) / g to 2.5mmol(NH3) / g, the acid amount of catalyst B is 1.9mmol(NH3) / g to 2.8mmol(NH3) / g, the active metal in catalyst A The mass loading of the active metal in catalyst B is 0.1wt% to 0.5wt%, and the mass loading of the active metal in catalyst B is 0.3wt% to 0.8wt%. In the hydrogenation pretreatment catalyst, the mass loading amount of the active metal is 20wt% to 55wt%, and the mass loading amount of the auxiliary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com