Monolithic catalyst for catalyzing combustion of volatile organic compounds and preparation method of catalyst

A monolithic catalyst and volatile organic compound technology, applied in physical/chemical process catalysts, combustion methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of cumbersome preparation process, small loading capacity, and reduced catalyst activity and other problems, to achieve the effect of simplifying the preparation process, improving the preparation efficiency and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

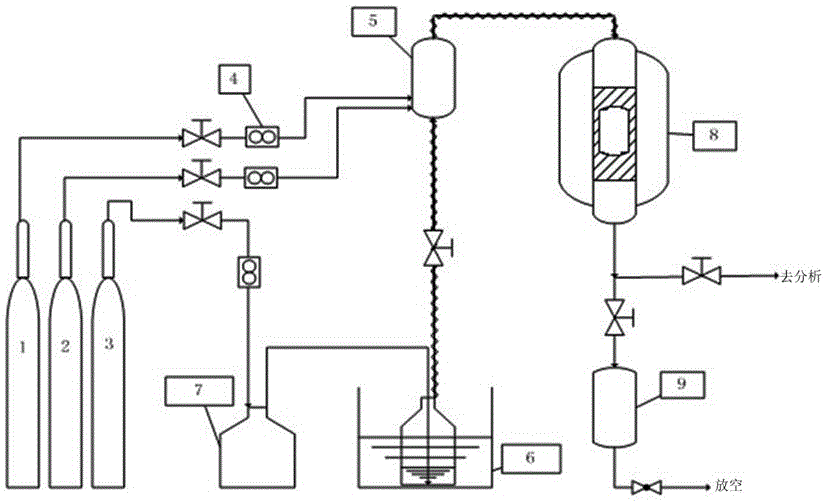

[0045] Catalyst performance evaluation is carried out using a laboratory small-scale reaction device. The schematic diagram of the experimental evaluation device is shown in figure 1 shown. The loading capacity of the catalyst is 18ml, and asbestos is fixed around the catalyst to prevent gas from passing through it. First, the catalyst was reduced with a hydrogen / nitrogen mixed gas, the volume of hydrogen accounted for 5% of the total mixed gas volume, the flow rate of the mixed gas was 200ml / min, the reduction temperature was 80°C, and the reduction time was 24 hours. Catalytic combustion tests were carried out using toluene as a representative of VOCs. The reaction gas is a mixture of toluene and air, the concentration of toluene in the toluene / air mixture is 1000ppm, and the space velocity of the reaction gas is 20000h -1 . The system pressure is normal pressure. During the evaluation of the catalyst, the activity of the catalyst to catalyze the combustion of volatile o...

Embodiment 2

[0054] Preparation of catalyst precursor

[0055] Weigh 2g of pseudo-boehmite, and measure 2ml of concentrated nitric acid, and add to 40ml of deionized water. Then 25g γ-Al 2 o 3 Add it to the above mixed slurry, put it into a 500ml ball mill tank, adjust the speed of the ball mill to 400r / min, and ball mill it for 0.5 hours to obtain the catalyst coating slurry. A cordierite honeycomb ceramic carrier with a cell mesh number of 200 holes / square inch was selected, and a conventional impregnation method was used for 2 minutes, and then compressed air was used to remove excess liquid slurry inside the channel of the cordierite honeycomb ceramic carrier. Then the catalyst was slowly dried at a temperature of 50°C, and weighed after drying. Repeat the above steps until the mass of the catalyst precursor accounts for 9% of the mass of the catalyst carrier and stop uploading. Then the catalyst was slowly dried at a temperature lower than 50°C, and after drying for 12 hours, it w...

Embodiment 3

[0060] Preparation of catalyst precursor

[0061] Weigh 10ml of H 2 Pd(NO 3 ) 4 The solution (Pd elemental content is 6mg / ml) was dissolved in 35ml of deionized water, and then 25g of γ-Al 2 o 3 Pour into the mixed solution for dipping, and mix well. Other preparation method steps are with embodiment 1. The number of the catalyst is Exa.3, and the experimental results of the evaluation are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com