Preparation method and use method of two-stage bed reaction catalyst used in coal tar pitch lightening process

A technology of lightening and coal tar pitch, which is applied in the field of preparation of two-stage bed reaction catalysts, can solve the problems such as coal tar pitch hydrocracking that has not been used and has not been effectively realized, achieves considerable yield, and increases lightening and isomerization. The effect of improving yield and small loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

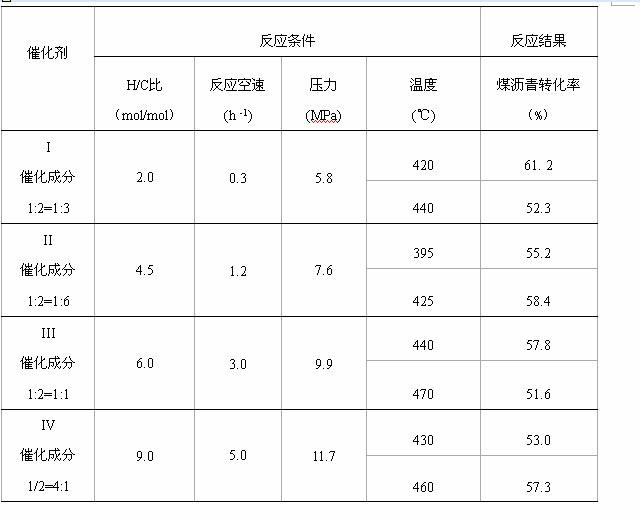

Examples

Embodiment 1

[0021] 1) SiO 2 / Al 2 o 3The ZSM-5 molecular sieve with a molar ratio of 25 was evenly mixed with the molecular sieve through an alumina binder, and then a certain amount of 3 wt% dilute nitric acid was added and kneaded evenly, then extruded and formed, and dried at 110°C for 2 hours and dried at 110°C for 2 hours. After calcination at 510°C for 2 hours, impregnated with 7.5wt% nickel nitrate solution, dried at 110°C for 2 hours, and then fired at 460°C for 2 hours, the metal nickel oxide loading modification was completed, and 4.4wt% Ni / ZSM was obtained. -5, recorded as catalytic component 1; 2) Dry 14-mesh silica gel at 120°C for 2 hours, weigh 10 g of the dried silica gel carrier and place it in a dry branch bottle, connect a separatory funnel and a vacuum pump, and check the seal properties, vacuumize, impregnate with 10wt% ammonium molybdate solution, dry at 110°C for 2 hours, and then bake at 420°C for 2 hours to complete the metal molybdenum oxide loading modificatio...

Embodiment 2

[0023] 1) SiO 2 / Al 2 o 3 The Y molecular sieve with a molar ratio of 60 was mixed evenly with the molecular sieve through the alumina binder, and then a certain amount of 3 wt% dilute nitric acid was added and kneaded evenly, and then extrusion molding was carried out. After molding, it was dried at 110°C for 2 hours and heated at 530°C After roasting at low temperature for 2 hours, impregnate with 7.0wt% ammonium molybdate solution, dry at 110°C for 2 hours, and then bake at 460°C for 2 hours to complete the metal molybdenum oxide loading modification and obtain catalytic components 1-4.3 wt%. Mo / Y; 2) Molecular sieve MCM-41 was dried at 100°C for about 2 hours, impregnated with 10.0wt% nickel nitrate solution, dried at 110°C for 2 hours, and then calcined at 500°C for 2 hours to complete the metal Nickel oxide was loaded and modified to obtain catalytic component 2—7.3wt% Ni / MCM-41; 3) The above two modified catalytic components 1 and 2 with different functions were colle...

Embodiment 3

[0025] 1) SiO 2 / Al 2 o 3 The Beta molecular sieve with a molar ratio of 23 is mixed evenly with the molecular sieve through the alumina binder, and then a certain amount of 3wt% dilute nitric acid is added and kneaded evenly, and then extruded, dried at 120°C for 2 hours and dried at 520°C After calcination for 2 hours, it was impregnated with 4.0wt% nickel nitrate solution, dried at 110°C for 2 hours, and then fired at 460°C for 2 hours to complete the metal nickel oxide loading modification and obtain 2.9wt% Ni / Beta. 2) Dry the macroporous alumina at 120°C, impregnate it with 7.0wt% ammonium molybdate solution, dry it at 110°C for 2 hours, and then bake it at 500°C for 2 hours to complete the metal molybdenum oxide loading modification and obtain 5.9wt% Mo / Al 2 o 3 . 3) The above two modified catalytic components 1 and 2 with different functions are collectively referred to as catalyst III.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com