Method for preparing 1, 6-hexamethylenediamine by ammoniating hexamethyleneimine

A technology of cyclohexamethyleneimine and hexamethylenediamine, which is applied in the field of ammoniation of cyclohexylimine to prepare 1,6-hexamethylenediamine, which can solve the problems of inability to realize continuous production, poor stability, and low catalyst activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

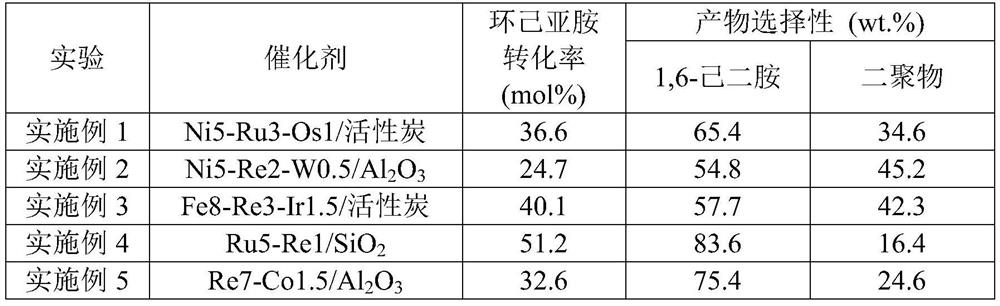

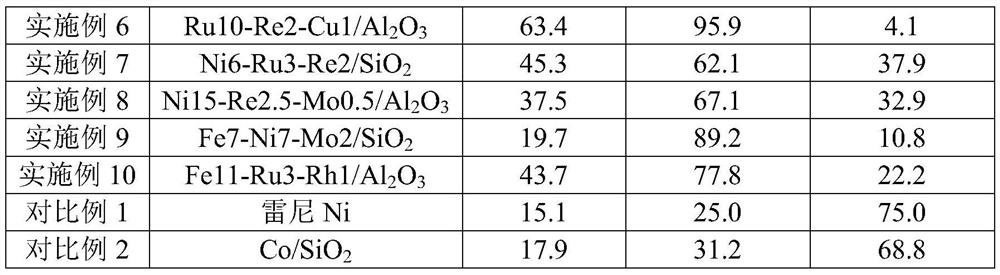

Examples

Embodiment 1

[0080] Preparation and Application of Ni5-Ru3-Os1 / Activated Carbon Catalyst

[0081] Take 9.1 grams of 20-40 mesh activated carbon and treat it at 150°C for 1 hour under an ammonia atmosphere. Configuration 20ml contains 2.477 grams of Ni (NO 3 ) 2 ·6H 2 O, 0.776 g RuCl 3 ·3H 2 O, 0.184 g OsCl 3 ·3H 2 O aqueous solution, impregnate the above-mentioned activated carbon carrier with this aqueous solution, dry it naturally, dry at 120°C for 4h, and roast at 500°C for 6h in an argon atmosphere. Before the reaction, the catalyst is reduced and activated in a fixed bed device. The activation conditions are: 0.1MPa, temperature 450°C, hydrogen volume space velocity 500h -1 , Time 4h. After the reduction process, the temperature of the reactor is adjusted to 160°C and the pressure is 8MPa. After the system is stable, the molar ratio of cycloheximide and ammonia is mixed at a ratio of 1:10. After preheating at 100°C, it is pumped into the fixed bed reactor. The catalytic react...

Embodiment 2

[0083] Ni5-Re2-W0.5 / Al 2 o 3 Catalyst preparation and application

[0084] Take 9.25 grams of 20-40 mesh Al 2 o 3 , treated at 200°C for 2h under an ammonia atmosphere. Configuration 20ml contains 2.477 grams of Ni (NO 3 ) 2 ·6H 2 O, 0.288 g NH 4 ReO 4 , 0.077 g (NH 4 ) 2 WO 4 Aqueous solution, impregnating the above Al with this aqueous solution 2 o 3 The carrier was air-dried, dried at 120°C for 4h, and calcined in a muffle furnace at 450°C for 6h. Before the reaction, the catalyst is subjected to reduction and activation treatment in a fixed bed device, the activation conditions are: 0.1MPa, temperature 390°C, hydrogen volume space velocity 500h -1, time 5h. After the reduction process, the temperature of the reactor is adjusted to 150°C and the pressure is 8MPa. After the system is stable, the molar ratio of cyclohexylimine and ammonia is 1:5, and it is pumped into the fixed bed reactor after preheating at 100°C. The catalytic reaction is carried out in, wh...

Embodiment 3

[0086] Preparation and Application of Fe8-Re3-Ir1.5 / Activated Carbon Catalyst

[0087] Take 8.75 g of 60-80 mesh activated carbon and treat it at 150°C for 2 hours under an ammonia atmosphere. Disperse activated carbon in water to form a suspension, and stir at a medium speed at a constant temperature of 50°C. Configuration contains 3.465 g Fe(NO 3 ) 3 , 0.432 g NH 4 ReO 4 , 0.275 g IrCl 3 ·3H 2 Precursor fluid of O. The precipitating agent used is 4mol / L KOH solution. Add the precursor liquid and the precipitating agent dropwise to the above suspension at a rate of 1ml / min at the same time, keep the pH value at 9 until the precipitation is complete, wash the precipitate with deionized water until neutral, filter, dry in the air, and dry at 120°C 4h, and baked at 500°C for 4h in an argon atmosphere. Before the reaction, the catalyst is subjected to reduction and activation treatment in a fixed bed device, the activation conditions are: 0.1MPa, temperature 400°C, hydro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com