Combined catalyst for simultaneously eliminating four kinds of pollutants from diesel exhaust and purification method

A combination of catalyst and diesel engine technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., to achieve mild reaction and operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

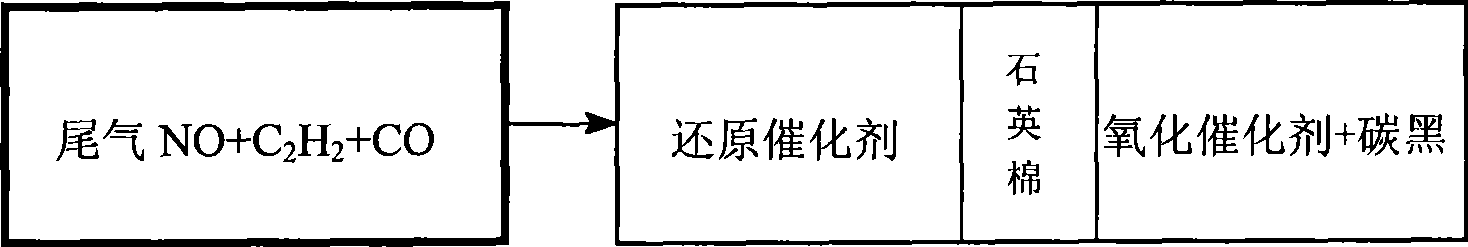

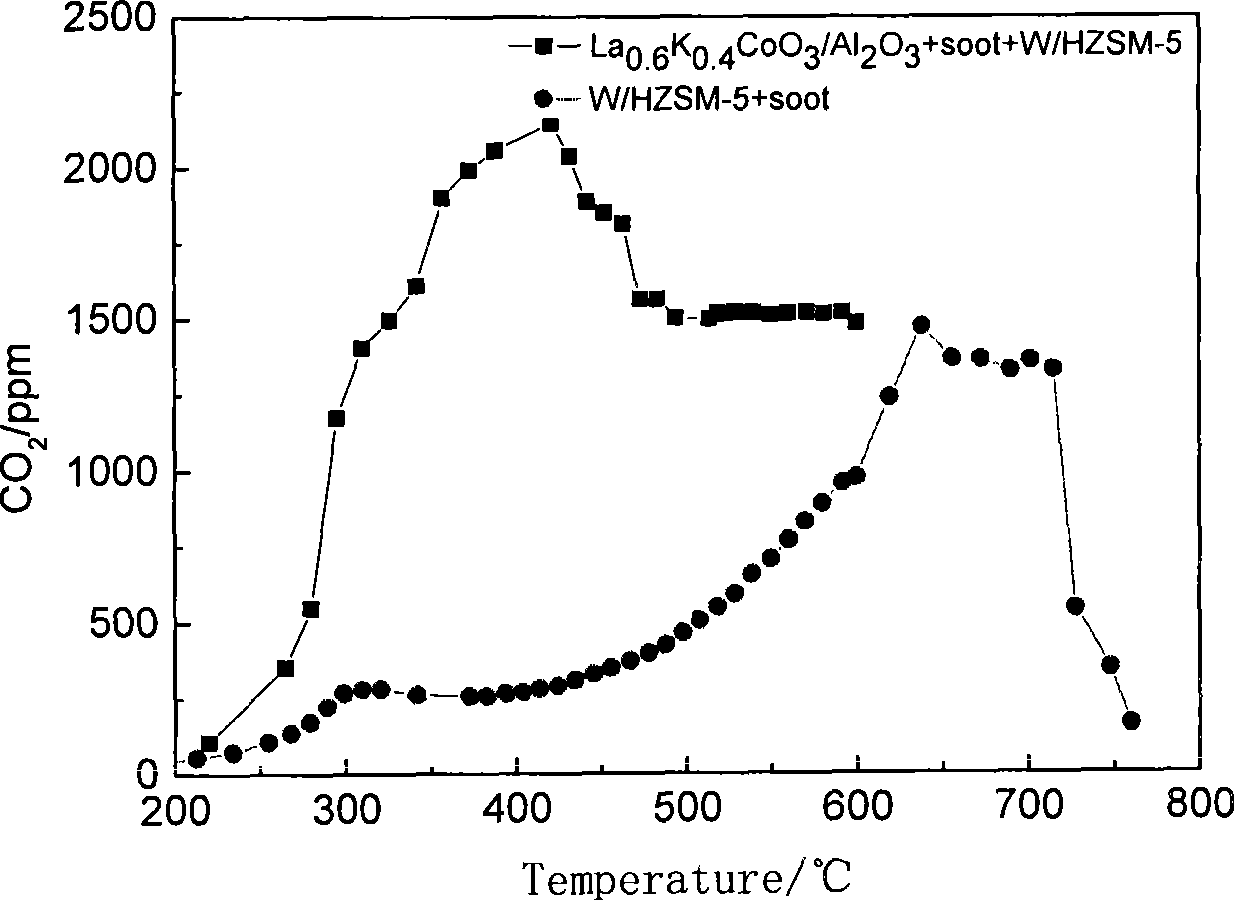

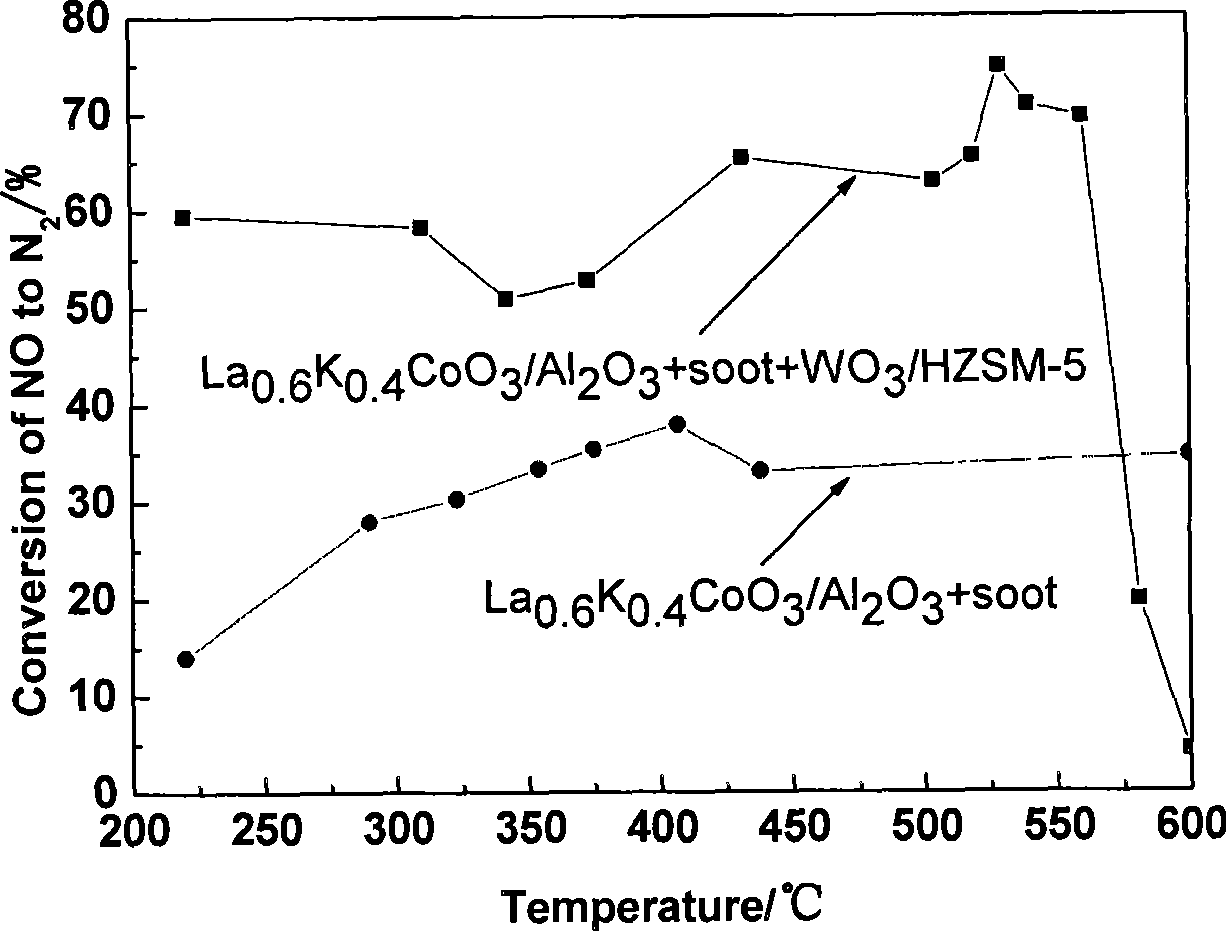

[0035] Combine 0.005 g of simulated carbon particles with 0.1 g of La 0.6 K 0.4 CoO 3 / Al 2 O 3 (50% loading, the specific surface area of the activated alumina carrier is 147.9m 2 / g, pore volume 0.2793ml / g) The catalyst was stirred evenly with a sample spoon to form loose contact, and then filled into the upper layer of the quartz tube reactor, separated by quartz wool (about 1 cm spacing), and then filled with 0.2g of W / HZSM-5 (1% tungsten oxide loading, and the silicon-alumina ratio of molecular sieve is 25).

[0036] Diesel engine exhaust gas simulated gas composition: 2000ppm NO, 1000ppm C 2 H 2 , 2000ppm CO, O 2 The initial concentration was 5%, and He was the diluent gas.

[0037] The above simulated diesel exhaust gas enters upward from the lower part of the reactor, see appendix figure 1 , first contact the lower molecular sieve supported catalyst (reduction catalyst), and then enter the activated alumina supported perovskite catalyst (oxidation catalyst)...

Embodiment 2

[0049] Simulated gas composition: 2000ppm NO, 500ppm C 2 H 2 , 2000ppm CO and 5% O 2 At the initial concentration, He gas was used as the diluent gas. Combine 0.005 g of simulated carbon particles with 0.1 g of La 0.6 K 0.4 CoO 3 / Al 2 O 3 The catalyst was stirred evenly with a sample spoon and contacted loosely, and then filled into the upper layer of the quartz tube reactor, separated by quartz wool, and then filled with 0.1 g of W / HZSM-5. The catalyst was the same as in Example 1. In the temperature-programmed reaction, the experimental simulated gas was introduced from the lower part of the reactor. After the reaction, the maximum conversion rate of NO could reach 39%, and the combustion temperature of carbon particles was reduced by 187 °C (compared to Comparative Example 1), and the acetylene was completely converted. At a temperature of 339°C, the maximum selectivity of carbon dioxide combustion to carbon dioxide can reach 99.7%.

Embodiment 3

[0051] Simulated gas composition: 2000ppm NO, 500ppm C 2 H 2 , 2000ppm CO and 5% O 2 At the initial concentration, He gas was used as the diluent gas. 0.1 g of W / HZSM-5 (tungsten oxide loading 1%, molecular sieve with a silicon-alumina ratio of 25) was filled into the upper layer of the quartz tube reactor, separated by quartz wool, and then filled with 0.1 g of La 0.6 K 0.4 CoO 3 / Al 2 O 3 (50% loading, the specific surface area of the activated alumina carrier is 147.9m 2 / g, pore volume 0.2793ml / g) catalyst, 0.005g simulated carbon particles were mixed with La 0.6 K 0.4 CoO 3 / Al 2 O 3 The catalyst is loosely contacted. In the temperature-programmed reaction, the experimental simulated gas is fed downward from the upper part of the reactor. After the reaction, the maximum conversion rate of NO can reach 15%, and the combustion temperature of carbon particles can be reduced by 214 °C (compared to Comparative Example 1). ), the temperature for complete conversio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com