A Catalytic Heating Coupling Methanol Hydrogen Production Process

A methanol hydrogen production and process technology, which is applied in the fields of hydrogen, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of the need to discharge combustible tail gas, large area, unsafe, etc., and achieves small area and equipment area. Small, emission-safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

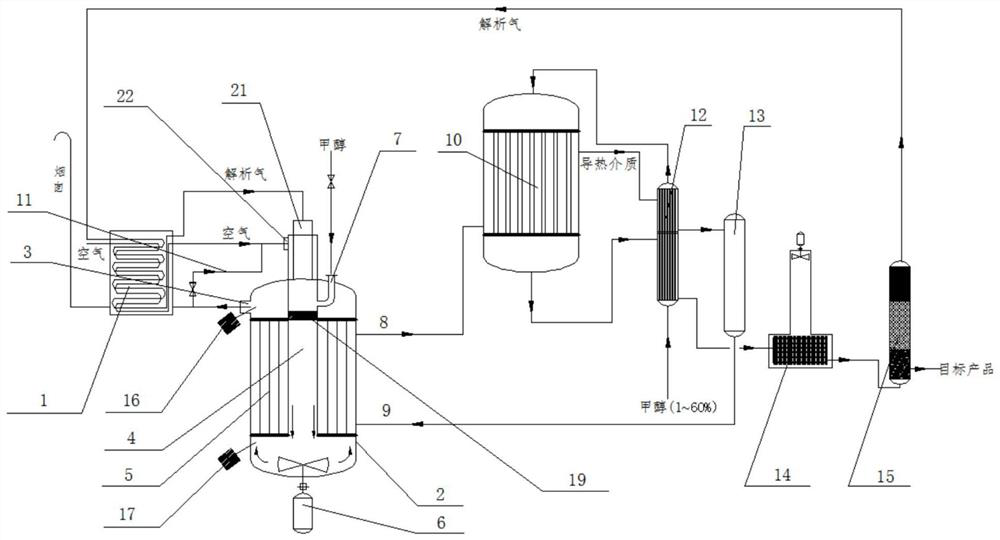

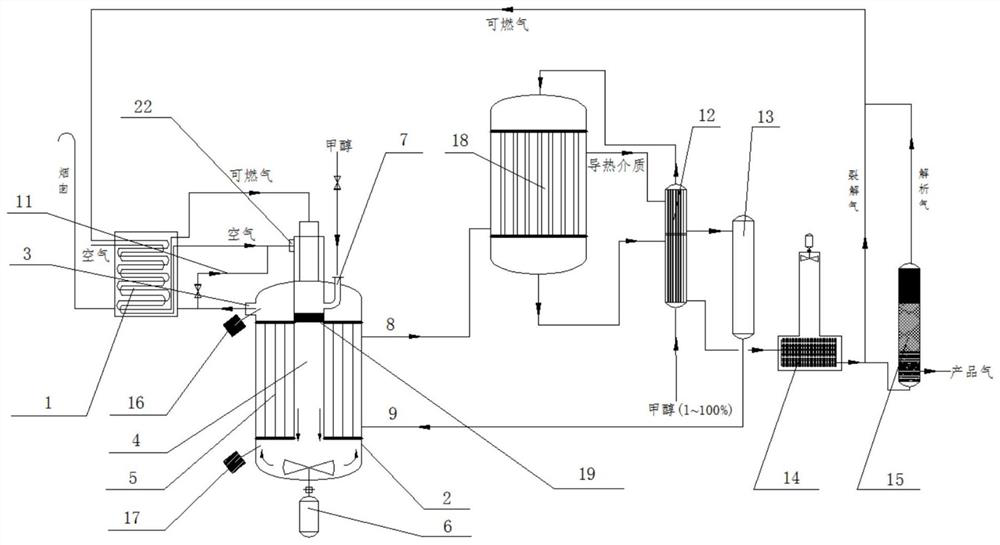

[0045] Such as Figure 1-2 , a catalytic heating coupled methanol hydrogen production process, including a catalytic oxidation reactor 2 and a methanol hydrogen production system, in the catalytic oxidation reactor 2, methanol and air in the raw material are oxidized at a constant temperature at a catalyst layer under the condition of above 10°C The catalytic oxidation reaction occurs, and the heat generated provides heat energy for the start-up of the methanol hydrogen production system.

Embodiment 2

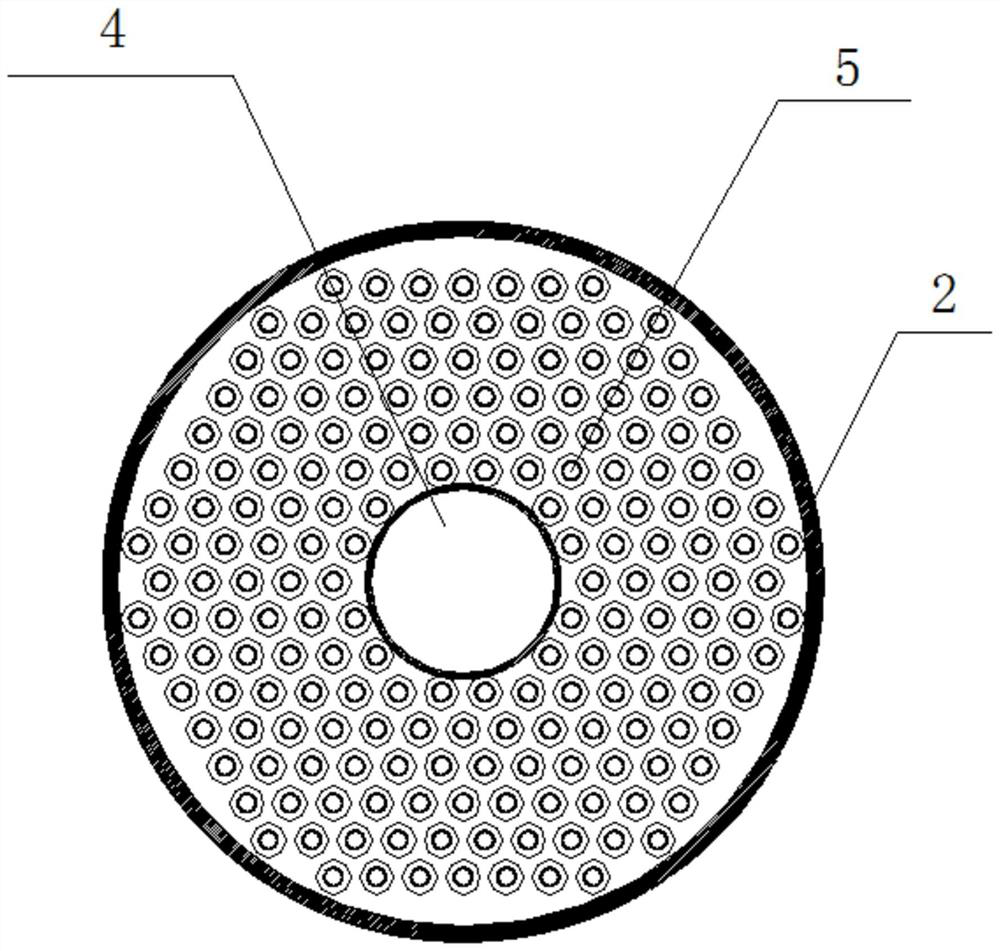

[0047] On the basis of Example 1, such as Figure 1-3 , the catalytic oxidation reactor 2 includes a reactor cylinder with both ends closed and connected with a plurality of inlet and outlet pipes, a central pipe 4 is arranged in the reactor cylinder, and the central pipe 4 extends to the reactor cylinder Outside the top of the body, a mixer 19 is arranged on the upper part of the center tube 4 in the reaction cylinder, and a plurality of reaction tubes 5 are evenly arranged around the center tube 4, and each reaction tube 5 is provided with a A combined catalyst layer, the combined catalyst layer includes the normal temperature oxidation catalyst layer at the lower part and the medium temperature oxidation catalyst layer located at the upper part of the normal temperature oxidation catalyst layer, both ends of the central tube 4 and the reaction tube 5 are open, A heat transfer medium outlet 8 and a heat transfer medium inlet 9 are provided on the wall of the reaction cylinde...

Embodiment 3

[0049] On the basis of Example 2, the normal temperature oxidation catalyst layer includes a first catalyst, the shape of the first catalyst is spherical and / or honeycomb cylinder, and the medium temperature oxidation catalyst layer includes a second catalyst, the second The shape of the catalyst is spherical and / or honeycomb cylindrical; the volume ratio of the first catalyst to the second catalyst is 1:1-1:5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com