Combined catalysis reactor

A catalytic reactor, reactor technology, applied in combinatorial chemistry, chemical/physical/physical chemistry stationary reactors, chemical instruments and methods, etc., can solve problems such as no indication of catalyst selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

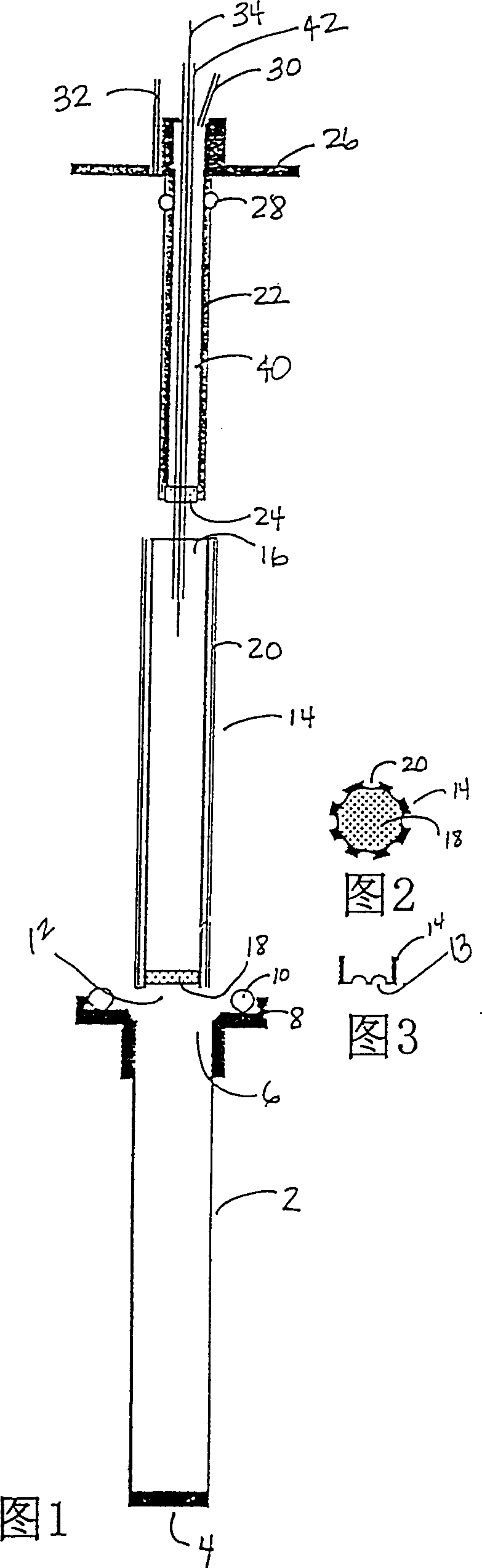

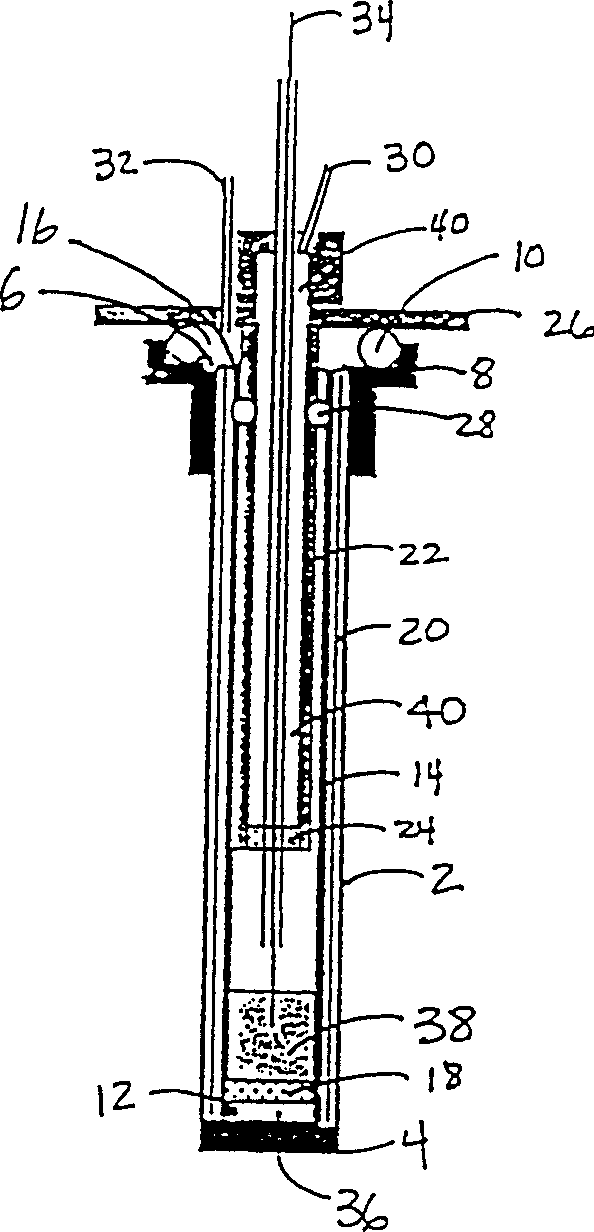

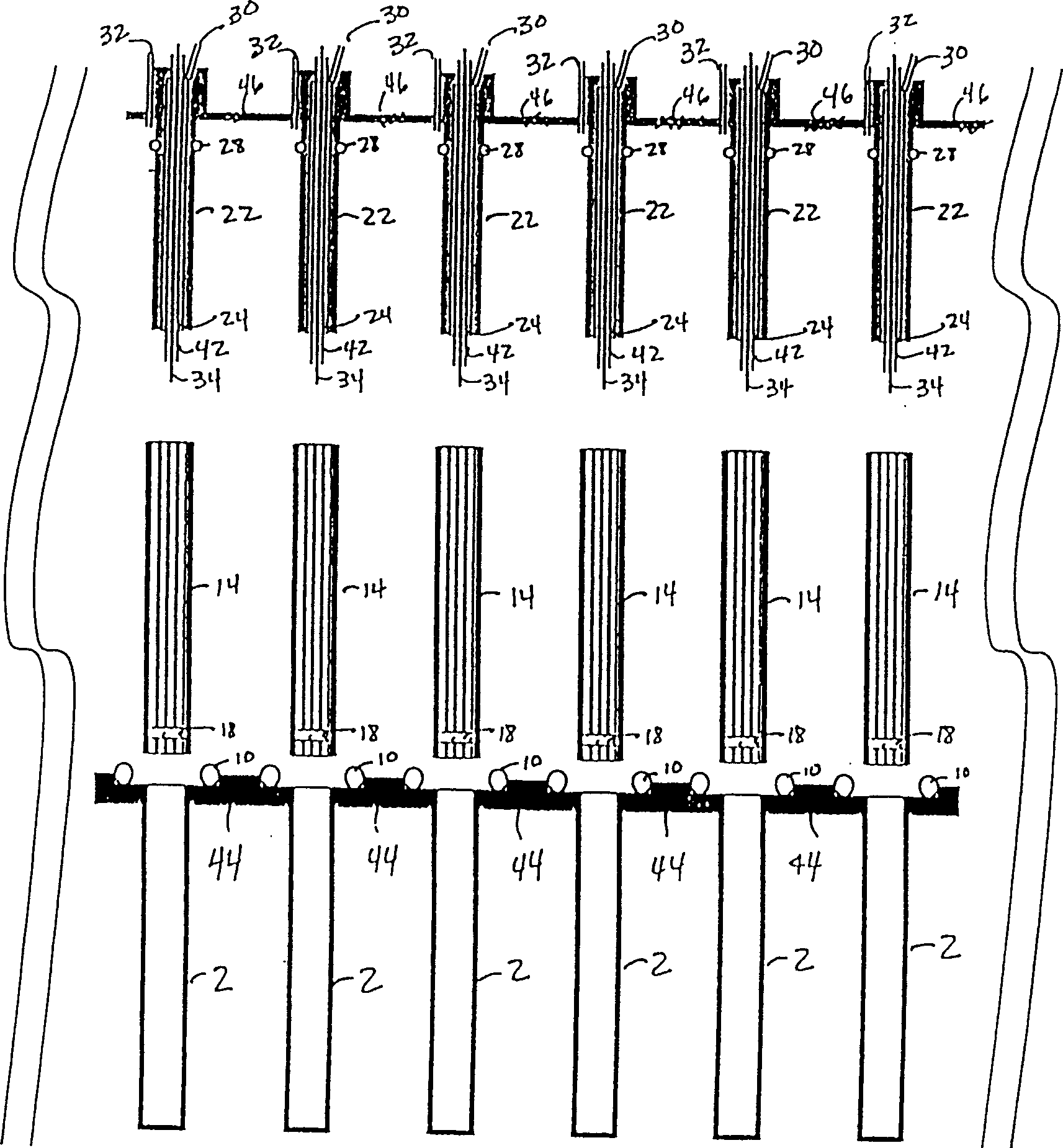

[0016] In general, the present invention is a reactor for combined applications and a method for performing combined catalytic reactions. In a combined application, such a reactor of the present invention is used as an array of multiple reactors operating in parallel at the same time. Preferred such reactors consist of three main components, (1) a top or reactor insert, (2) a vessel or sleeve, and (3) a bottom or shaft. Each of the major components can be fabricated from materials suitable for the application under the intended conditions. Materials are selected to withstand the temperature, pressure and chemical compounds of the specific application. Examples of applicable materials include metals and their alloys, low-grade steels and stainless steels, superalloys such as Incolloy, Inconel, Inconel ( hastalloy), engineering plastics and high temperature plastics, ceramics such as emery and silicon nitride, glass, and quartz, etc.

[0017] In a preferred assembly, the open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com