Combined catalyst and method for producing lubricating oil base oil from hydrocracking tail oil

A combination of catalysts and catalysts, applied in chemical instruments and methods, catalyst activation/preparation, molecular sieve catalysts, etc., can solve the problems of reducing interaction, mesopores without structure, etc., to achieve increased yield and good isomerism depreciation effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

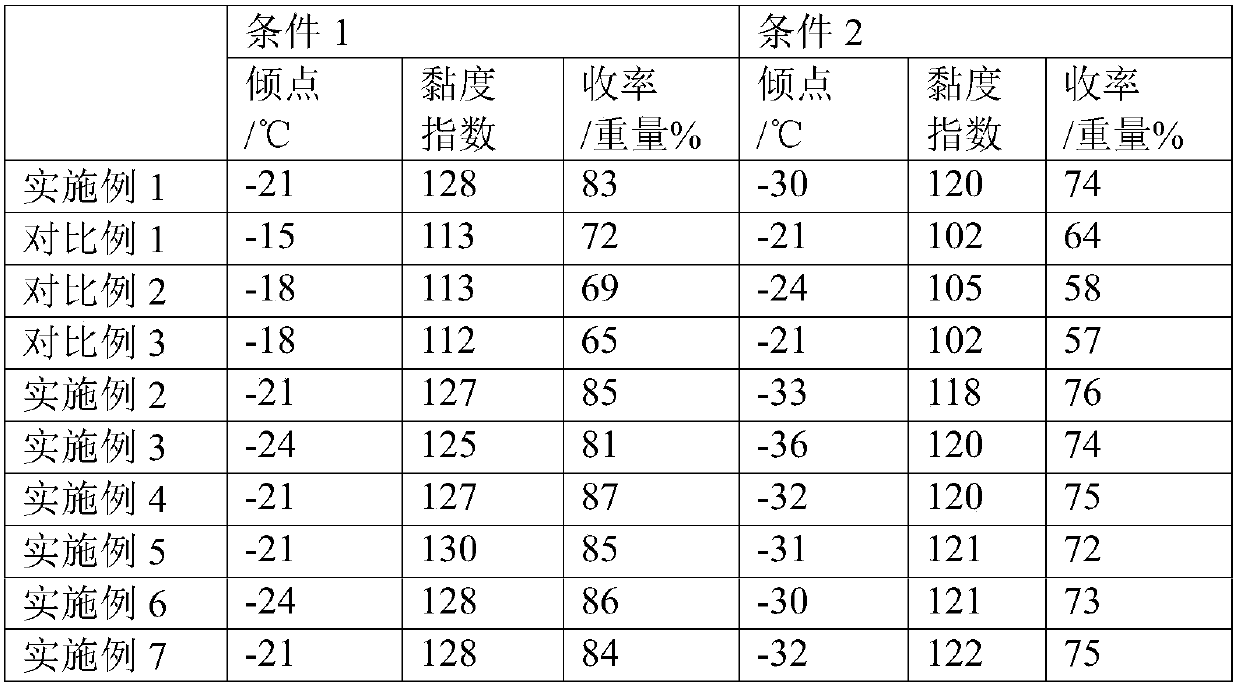

Examples

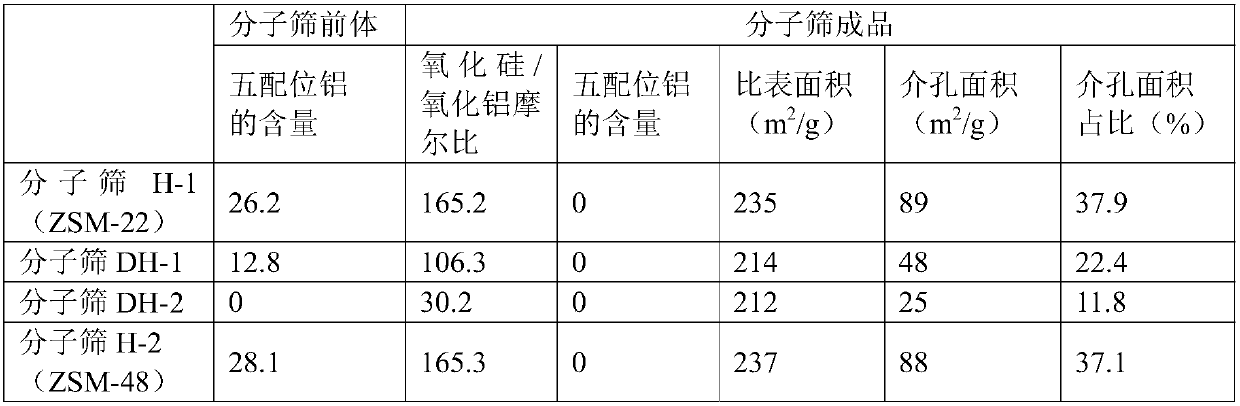

preparation example Construction

[0064]In the present invention, the mother liquor after crystallization can be prepared according to conventional methods in the art, for example, when the ten-membered ring molecular sieve is ZSM-22 molecular sieve, the preparation method of the mother liquor after crystallization can refer to document O. Muraza et al., Microporous and Mesoporous Materials 206(2015) 136–143. When the ten-membered ring silica-alumina molecular sieve is ZSM-48 molecular sieve, the preparation method of the mother liquor after crystallization can refer to the literature P.Me'riaudeau et al / Journal of Catalysis, 1999 (185), 435-444, or refer to United States patent application US5961951. In one embodiment, the preparation process of the crystallized mother liquor includes: preparing a silicon-containing solution, an aluminum-containing solution, and an alkaline liquid, mixing the above-mentioned liquids to form a gel, and then performing crystallization at a certain temperature.

[0065] In the ...

preparation example 1

[0084] (1) Preparation of mother liquor after crystallization

[0085] Take 36.3 grams of SiO containing 40% by weight 2 silica sol, 1.77 g of analytically pure Al 2 (SO 4 ) 3 18H 2 O, 3.94 grams of analytically pure KOH and 8.44 grams of hexamethylenediamine are ready for use. Hexamethylenediamine was mixed with silica sol, KOH and Al 2 (SO 4 ) 3 18H 2 O and 89.4 grams of deionized water were mixed, and then the two solutions were mixed, stirred for 1 hour, then transferred to a reaction kettle, and crystallized at 160° C. for 72 hours.

[0086] (2) Preparation of filter cake

[0087] Filter the mother liquor after crystallization prepared in the operation (1), and continue suction filtration for 5 minutes when there is no filtrate on the filter cake, and obtain the filter cake F-1, which has a dry basis content of 11.2 % by weight and a silica / alumina molar ratio of 60.

[0088] (3) Preparation of molecular sieve precursor

[0089] The filter cake F-1 was raised ...

preparation example 2

[0099] (1) Preparation of mother liquor after crystallization

[0100]Get 45 grams of white carbon black, 1.25 grams of analytically pure Al 2 (SO 4 ) 3 18H 2 O, 1.88 grams of analytically pure NaOH and 39.3 grams of hexamethylenediamine are ready for use. Mix hexamethylenediamine with silica and 200 g of deionized water, NaOH and Al 2 (SO 4 ) 3 18H 2 O and 272 grams of deionized water were mixed, and then the two solutions were mixed, stirred for 1 hour, then transferred to a reaction kettle, and crystallized at 160° C. for 72 hours.

[0101] (2) Preparation of filter cake

[0102] Filter the crystallized mother liquor prepared in step (1), count as there is no filtrate on the filter cake, continue suction filtration for 5 minutes, obtain filter cake F-2, and the dry basis content of the filter cake F-2 is 11.2 % by weight and a silica / alumina molar ratio of 60.

[0103] (3) Preparation of molecular sieve precursor

[0104] The filter cake F-2 was raised from room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com