Combined catalyst and method for producing biological aviation kerosene

A combination of catalysts and catalysts, applied in chemical instruments and methods, molecular sieve catalysts, physical/chemical process catalysts, etc., can solve the problems of mesopores without structure, reduce interaction, etc., to achieve increased yield, lower freezing point, better The effect of heterogeneous pour point depressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

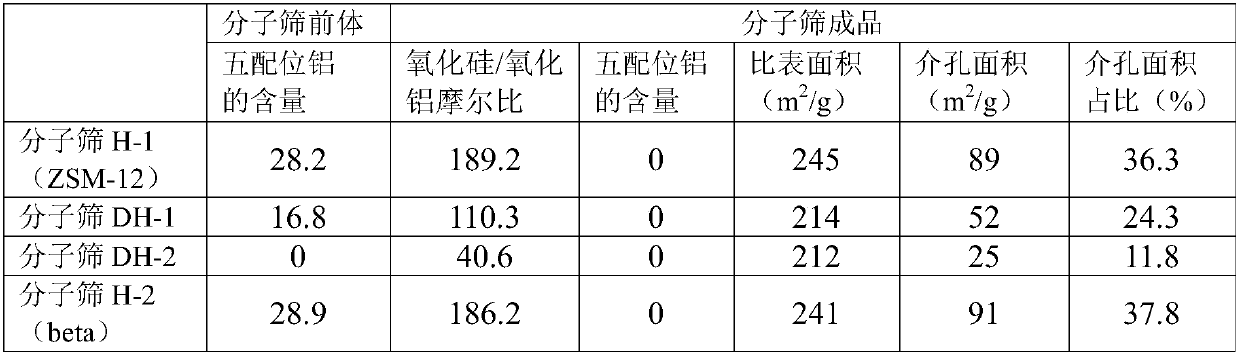

preparation example 1

[0083] (1) Preparation of mother liquor after crystallization

[0084] Take 38.5mL containing 40% by weight of SiO 2 Silica sol, 1.48 grams of analytically pure sodium aluminate, and 17.5 mL of tetraethylammonium hydroxide (40% by weight) solution are ready for use. Mix tetraethylammonium hydroxide, sodium aluminate and 37 grams of deionized water, then add silica sol, stir for 1 hour, then transfer to a reaction kettle, and crystallize at 160°C for 132 hours.

[0085] (2) Preparation of filter cake

[0086] Filter the mother liquor after crystallization prepared in the operation (1), and continue suction filtration for 5 minutes when there is no filtrate on the filter cake, and obtain the filter cake F-1, which has a dry basis content of 11.2 % by weight and a silica / alumina molar ratio of 40.6.

[0087] (3) Preparation of molecular sieve precursor

[0088] The filter cake F-1 was raised from room temperature to 450° C. at a heating rate of 25° C. / min, and kept at a const...

preparation example 2

[0098] (1) Preparation of mother liquor after crystallization

[0099] Take 6.05mL of white carbon black, 0.51g of analytically pure aluminum sec-butoxide, and 18.4mL of tetraethylammonium hydroxide (40% by weight) solution for use. Mix 15 grams of deionized water with tetraethylammonium hydroxide, aluminum sec-butoxide and 37 grams of deionized water, then add white carbon black, stir for 1 hour, then transfer to a reaction kettle, and crystallize at 140°C for 120 hours.

[0100] (2) Preparation of filter cake

[0101] Filter the crystallized mother liquor prepared in step (1), count as there is no filtrate on the filter cake, continue suction filtration for 5 minutes, obtain filter cake F-2, and the dry basis content of the filter cake F-2 is 11.2 % by weight and a silica / alumina molar ratio of 40.6.

[0102] (3) Preparation of molecular sieve precursor

[0103] The filter cake F-2 was raised from room temperature to 450° C. at a heating rate of 25° C. / minute, and kept at...

Embodiment 1

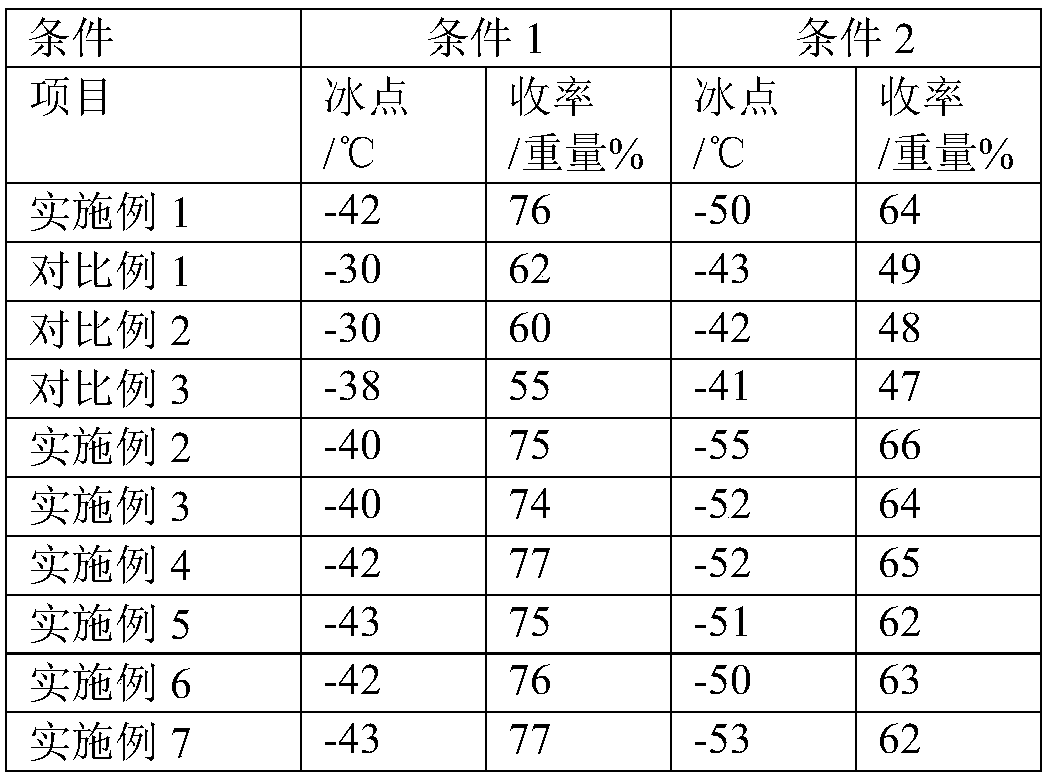

[0112] Such as figure 1 As shown, 50 g of catalyst Cat-1 and 150 g of catalyst Cat-2 were respectively installed in the first reactor 1 and the second reactor 2 of the high-pressure hydrogenation reaction device. The bio-jet fuel (parameters shown in Table 2) was injected into the reactor from top to bottom for reaction, and the reaction was carried out according to the two conditions shown in Table 3 below. After the reaction is finished, the product is distilled to remove light components less than 180°C and heavy components greater than 280°C. The freezing point analysis and yield calculation of the target product were performed, and the results are shown in Table 4. Yield is defined as: Yield=weight of 180-280°C components in product / weight of feed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com